DHR 230RCN 230 Technical manual

Navigation Lights

Signalling Lights

Searchlights

Whistles

TECHNICAL DOCUMENT

DHR 230RCN 230

Remote Controlled Searchlight

Den Haan Rotterdam

S

i

n

c

e

1

9

2

2

2Version 1.0 October 2018

Den Haan Rotterdam

(Intentionally blank page)

3Version 1.0 October 2018

Den Haan Rotterdam

Safety notes:

• Turn power off before inspection, installation or removal

• Keep combustible materials away from lamp

• Do not exceed 105% of rated voltage

• Allow lamp/fixture to cool before handling

• Do not use the searchlight if outer glass is scratched or broken

Damage due to inappropriate handling is

not covered by the warranty.

© Copyright, Den Haan Rotterdam B.V.

Version 1.0 October 2018

This document contains proprietary information that is protected by copyright.

All rights reserved.

!

4Version 1.0 October 2018

Den Haan Rotterdam

Den Haan Rotterdam is a family-owned company established in 1922. Started as a small tinsmith, it has

evolved into a globally respected producer of navigation lights, searchlights, air horns and a wide range of

nautical lamps made from copper and brass. By introducing products with advanced LED-technology, DHR

has safeguarded a visibly safe future for marine vessels in all weather conditions.

Den Haan Rotterdam manufactures halogen searchlights for over 30 years and are known for their robust-

ness, quality and reliability: key values for marine equipment. The RCN-series is the second generation of

DHR remote controlled type of searchlights introduced in 2011. This product range is very popular, because

of its compact size and its simplicity in installation and operation. The RCN-series includes various types of

light sources, such as: halogen bulbs, sealed beams and metal halide bulbs. Also the optical performance

is top-notch, thanks to the use of silverplated mirror reflectors in the 260 & 350 models.

The application of the 260- and 350-series searchlights is limitless. Mostly they are benificial for work boats,

tugs, fishing vessels, dredgers and even watch towers for land based solutions.

DEN HAAN ROTTERDAM B.V.

D.M. Den Haan

Managing Director

FOREWORD

QUALITY STANDARDS

Excellent Optics

Maintenance Friendly

Light Weight Construction

IP66 Water Ingress Protection

Remote control

LED technology

5Version 1.0 October 2018

Den Haan Rotterdam

TABLE OF CONTENTS

1. Mounting instructions 6

2. Specifications 8

3. Dimensions 11

4. Photos 13

5. Wiring diagrams 14

6. Maintenance and correct use 19

7. Replacing of motor frame 20

8. Recommended spare parts 21

6Version 1.0 October 2018

Den Haan Rotterdam

1. MOUNTING INSTRUCTIONS

Mounting the panel

Place the control panel inside the wheelhouse, where it is protected against weather influences. The housing

is especially constructed to be flush mounted in an instrument cabinet according the illustration on the right.

The minimum space needed behind the panel is 110 mm. (depth)

97 ± 1 mm

97 ± 1 mm

Cut-out panel

Searchlight installation

Install the searchlight in a horizontal upright position with sufficient space around the head of the searchlight

to ensure it can move freely. The dimensions can be found on page 9.

Bolt M10x (60 + M)

Insulation sleeve

Lantern base

Insulation sleeve

Washer M10

Mounting plate Min. 5 mm

Nut M10

M

All dimensions in mm

Fasteners

• The permissible torque should be 8 Nm

• Use only A4-grade stainless steel

Caution!

Even though the housing is made of corrosion resistant materials, galvanic corrosion may still occur. To

prevent galvanic corrosion use the supplied insulation sleeves to isolate the aluminium housing from

other metal parts.

4 x Ø10

162,5

162,5

Warning!

Den Haan Rotterdam does not accept responsibility for any damage if the searchlight is in-

stalled incorrectly and/or used improperly. When in doubt consult a qualified electrical techni-

cian.

!

7Version 1.0 October 2018

Den Haan Rotterdam

Electrical installation

Install the electrical wiring according to the wiring diagrams showed on pages 11 - 14. Keep the distance

between the power supply and halogen lamp as short as possible. Long wires will increase a voltage drop

near the halogen lamp, which affects the light output.

Cable glands

ØD

Cable

• Prefered diameter D is 7 - 12 mm

• Material: Neoprene H07RN-F

Cable too tight!

This gives unwanted stress at the sealing of the

cable gland and water ingress will occur.

Include cable slack at the entering

point of the cable gland

Replacing cable gland

• Use gasket between housing

and cable gland

• Tighten firmly (6Nm) with

wrench

Remove the plug before placing the cable.

If no cable is connected, leave the plug in place!

Note

The cable glands on the searchlight prevent water ingress. Do not use (electrical) tape to cover the

cable where it enters the cable gland as this will cause water ingress. Do not use a rubber or shrink-

able cover on the cable gland to improve water tightness.

8Version 1.0 October 2018

Den Haan Rotterdam

2. SPECIFICATIONS

Control panel

Model PAN2011

Dimensions

Depth 110 mm

Width 110 mm

Weight 0,6 kg

Electrical

Voltage 24 VDC±20%

Maximum wattage 20 W

Fuse T2A

Electrical insulation class III

Housing

Front Stainless steel 316

Back Aluminium, painted black

Operating temperature 0° / + 45° C

Switches

1. BEAM ON/OFF, switches the searchlight on or off.

2. Joystick, controls the direction of the movement.

3. ON/OFF, switches the panel on or off.

Potentiometers

4. SPEED U/D, speed of the movement up and down.

5. SPEED L/R, speed of the movement left and right.

ON/OFF

BEAM ON/OFF

SPEED U/D SPEED L/R

1

3

2

4 5

9Version 1.0 October 2018

Den Haan Rotterdam

Searchlight

Model 230RCN230

Dimensions

Height 617 mm

Width 331 mm

Weight

Electrical

LED-driver 230 VAC / 75W

Motor voltage 6-13 VDC

Preferred cable type H07RN-F

Cable diameter Ø 6-12 mm

Optics

Mirror Parabolic mirror reflector Ø 230 mm

Range 775m

Adjustable Focus No

Beam angle at 50% -

Luminous intensity 600.000 cd

LED

Model CLU731

Luminous flux 8767 lm

Rated LED voltage -

Rated LED wattage -

Average life-time 30.000 h

Color temperature 5000 K

Base -

Heater

Type PTC-heater

Voltage 24VDC

Maximum wattage 70 W

Motor Unit

Tilt + 30° / - 60°

PAN 340°

Max. speed left / right approx. 34°/ sec

Max. speed up / down approx. 3,2° / sec

Housing

Material Chromated seawater resistant aluminium

Finish UV resistant powder coating - White RAL9016

Front glass Hardened front glass

Seals Silicone / Neoprene, black

Cable gland M25x1.5

Operating temperature - 25° / + 40° C

Ingress protection class IP66 c/w Membrane vent

10 Version 1.0 October 2018

Den Haan Rotterdam

11 Version 1.0 October 2018

Den Haan Rotterdam

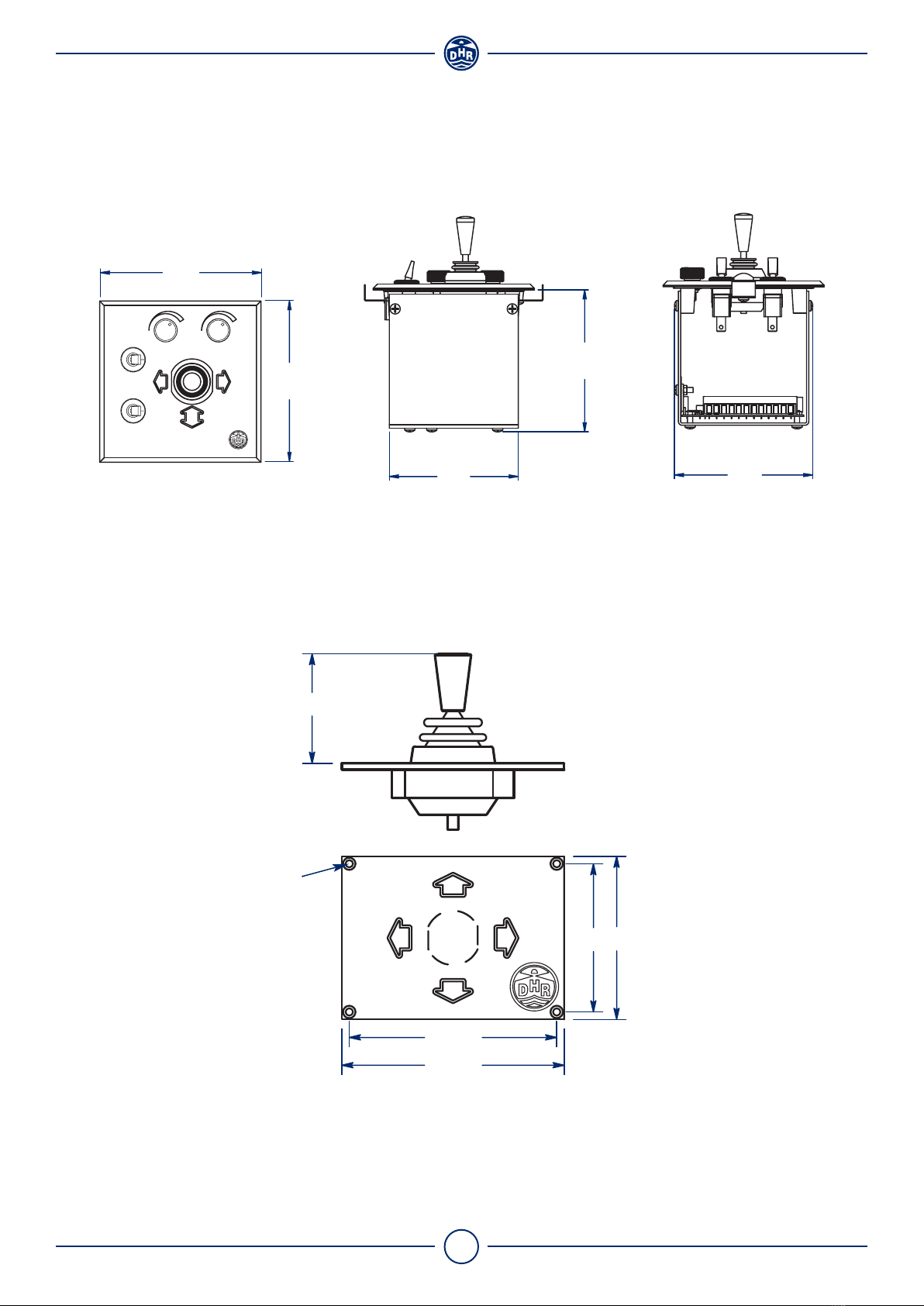

3. DIMENSIONS

All sizes are in mm.

Control Panel

Joystick

112

SPEED U/D SPEED L/R

BEAM ON/OFF

ON/OFF

94

88

98

110

110

6660

84

90

Ø3

45

12 Version 1.0 October 2018

Den Haan Rotterdam

All sizes are in mm.

Base RCN

162,5

162,5

4 x Ø10

Searchlight

617

277

13 Version 1.0 October 2018

Den Haan Rotterdam

4. PHOTOS

14 Version 1.0 October 2018

Den Haan Rotterdam

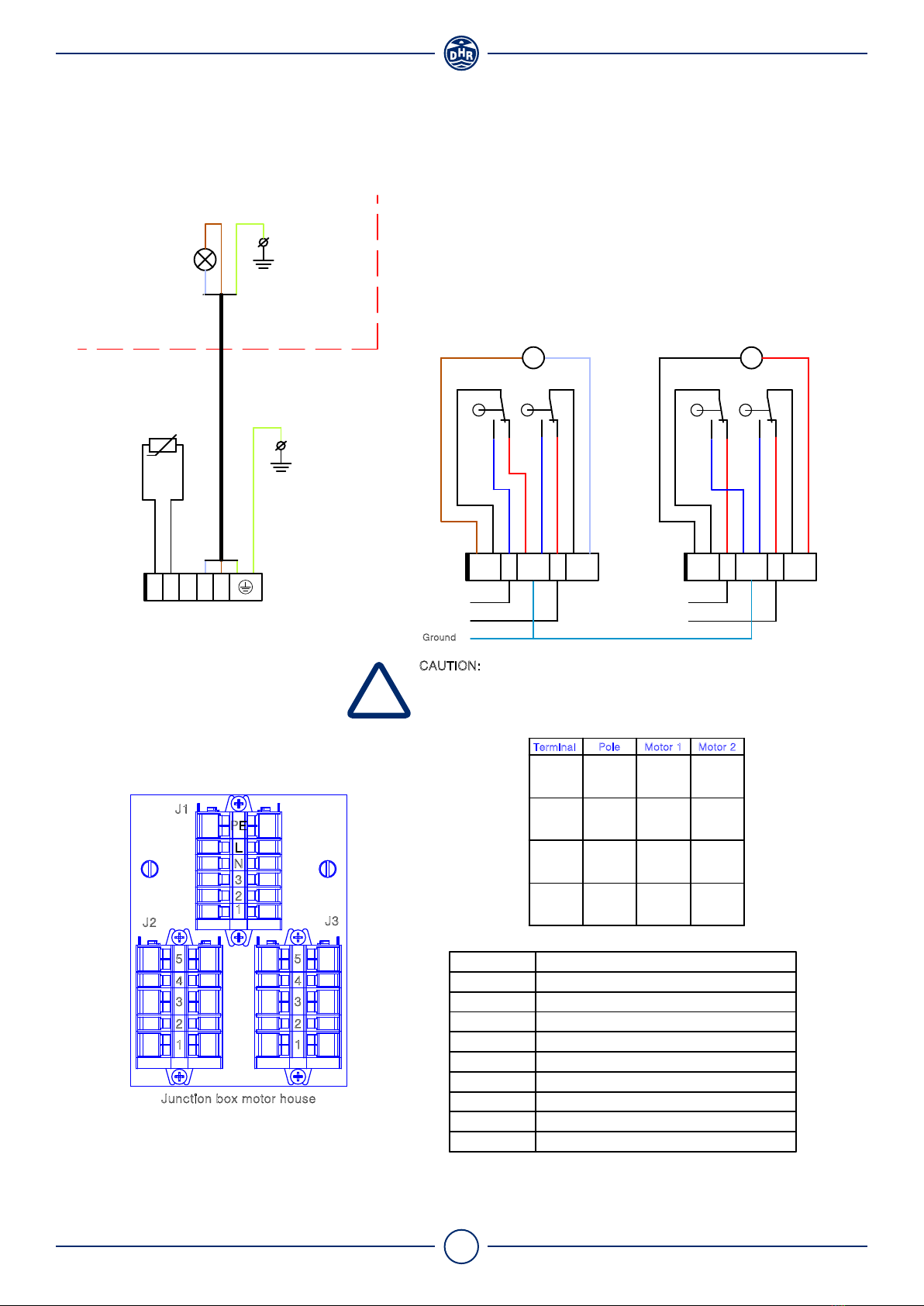

5. WIRING DIAGRAMS

M

M

PTC Heater 12- 24V 30W,

Motor house

Power for LEDdriver

L1

S1, S2, S3, S4

PTC

J2, J3

J1

M1

X6

M2

X3, X4, X5

Component

J2 J3

1

Junction box motor house

1

2

3

4

5

1

2

4

3

5

N

J1

2

3

L

PE

-

Ground

+

J3-2

J3-3

J3-4

Motor 12VDC/6W, gearhead 1:100 (right / left)

Head resisting cable 3 x1,5 - 1,25 m

Special spindle Motor 25W (up / down)

Mounting wire 1,5 mm², green/yellow (earth)

Description

Terminal block 5 way - Motors

Terminal block 6 way - Mains

PTC heater 12-24V 30W (self-regulating)

Halogen lamp

Microswitch V3 with roller lever, IP67 sealed

Motor 1

-

Down

Up

-

+

Ground

-

J2-2

J2-3

J2-4

-

Ground

+

J2-2

J2-3

J2-4

+

Ground

-

J3-2

J3-3

J3-4

Pole

Terminal

-

Left

Right

-

Motor 2

Motor Up / down

6 - 13VDC

S1

1

L = 100mm

J1

X3

X6

N123L

PTC

(Mounting plate motor house)

Ground

CAUTION:

Ground is used as return pad when on the end-position switch.

Always use the ground from the control panel to avoid unwanted

potential differences.

(Drum)

Head searchlight

L1

Motor left / right

6 - 13VDC

J2

3542 54123 J3

S2

M1

S4S3

M2

A. Internal Connections

!

15 Version 1.0 October 2018

Den Haan Rotterdam

B. External Connections

Motor up / down

3

F2A

Voltage 24VDC

F3A

1 2

6-13VDC

Beam On/Off

LEDdriver

23LN

PTC Heater

230VAC

1J1 532

6-13VDC

- +

J2 J3

- +

1 454

Motor left / right

F0.5AF1A

Joystick

(Four directions

and neutral)

Voltage 230VAC

16 Version 1.0 October 2018

Den Haan Rotterdam

L N PE

230VAC

5 x 1 mm²

4

587691012 11

24VDC

321

F2A

K1 2414

2313

Motor housing

PTC Heater

1

Motor up / down

F3A

Powerfor LEDdriver

J2

2

5

4

3

2

3

1

PE

N

L

J1

Motor left / right

3 x 1,5 mm²

1

J3

5

4

3

2

C. Control panel

17 Version 1.0 October 2018

Den Haan Rotterdam

3 x 1,5 mm²

L N PE

230VAC

1

4

7

1112 10 9 678 5

24VDC

13 K3**56

123

F2A

8

14

K1 14

24

13 13

23

Motor housing

PTC Heater

11

1

5 x 1 mm²

Motor up / down

F3A

1 09

14

Powerfor LEDdriver

5

3

4

2

J2

3

2

1

J1

L

N

PE

** K3 not standard in delivery

Coil operating range 70-110%

Motor left / right

12

4

3

2

J3

5

2

3

4

1

24

23

9

1112 10

K2

568 7 3214

D. Dual control panel

18 Version 1.0 October 2018

Den Haan Rotterdam

LN PE

230VAC

5 x 1 mm²

24VDC

See table 1

K1

Motor housing

PTC Heater

1

Motor up / down

F3A

Powerfor LEDdriver

J2

2

5

4

3

2

3

1

PE

N

L

J1

Motor left / right

3 x 1,5 mm²

1

J3

5

4

3

2

21 364 5

T1AS2

12/24VDC

E. Joystick

19 Version 1.0 October 2018

Den Haan Rotterdam

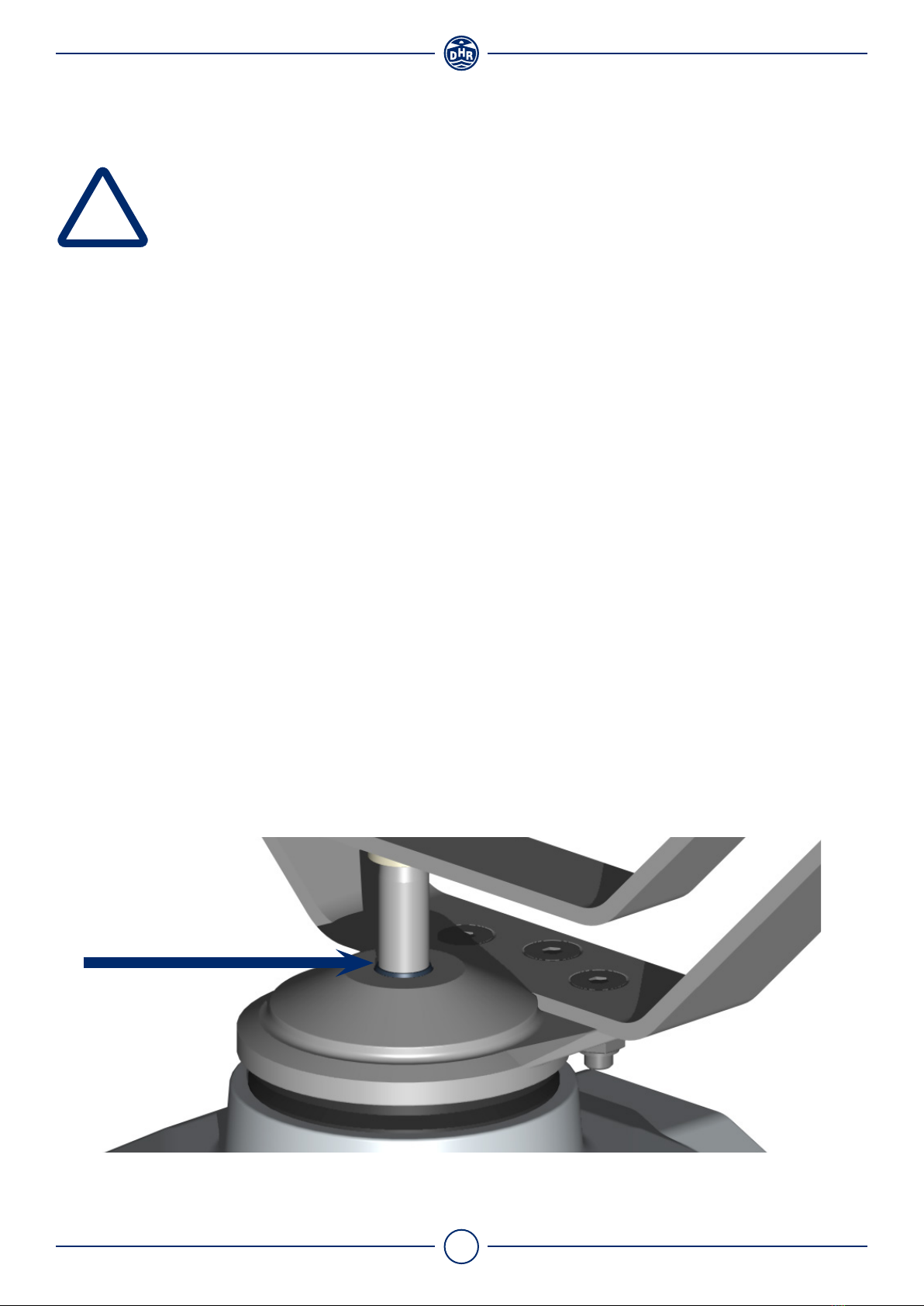

6. MAINTENANCE AND CORRECT USE

Tips for correct use

• Do not overheat the searchlight - max. burning time 20 min.

• Switch off the searchlight immediately after use, this increases the life

expectancy of the bulb

• Do not light-up objects closer than 2 metres

• Clean the searchlight regularly with water

• Do not point the light beam at the eyes of humans or animals

Preventive maintenance

Clean the searchlight with clean water regularly. Do not use any aggressive cleaning agents. At least twice

a year rub the dirt wiper, on top of the motor housing (see drawing below), in with silicone grease.

Safety notes

• Handle with care

•Turn off main power

• Warning, lamp is hot

!

20 Version 1.0 October 2018

Den Haan Rotterdam

7. REPLACING OF MOTOR FRAME

Motor frame replacement

1. Switch off the main power

2. Open the backplate of the motor housing

3. Disconnect the power cables connected to the motor frame

4. Unscrew the four (4) bolts to dismount the searchlight from the base structure

5. Unscrew the spindle nut

6. Tilt the searchlight vertically

7. Disassemble the bottom plate

8. Unscrew the (4) bolts and carefully remove the defective motor frame

9. Slowly insert the new motor frame in the motor housing. Be careful not to damage the dirt wiper

located on top of the motor housing

10. Before fixing the (4) bolts of motor frame, the following steps should be taken:

A. Reconnect the power cables

B. Turn the motors left/right and up/down using the controls. This is necessary to settle the motor

frame inside the motor housing

11. Close the motor housing by mounting the bottom plate

12. Reposition the searchlight and mount it on the base structure

13. Fasten the spindle nut. Do not overtighten it!

14. Test the searchlight both in vertical and horizontal directions to ensure that the searchlight is function-

ing properly

15. Searchlight is ready for use

Spindle nut

Bottom plate

Four bolts

Dirt wiper

1

1

2

2

4

3

3

5

Motor frame

5

4

!

!

Table of contents

Other DHR Floodlight manuals