diagenode BioAcc-cool User manual

Cat. No. BioAcc-cool

Water Cooler

Version 1.1

diagenode headquarters

Diagenode s.a. BELGIUM | EUROPE

Avenue de l’hôpital,1

Tour GIGA, 3rd Floor

4000 Liège - Belgium

Tel: +32 4 364 20 50

Fax: +32 4 364 20 51

orders@diagenode.com

info@diagenode.com

Diagenode Inc. USA | NORTH AMERICA

400 Morris Avenue, Suite #101

Denville, NJ 07834

Tel: +1 862 209-4680

Fax: +1 862 209-4681

orders.na@diagenode.com

info.na@diagenode.com

For a complete listing of Diagenode’s international distributors visit:

http://www.diagenode.com/pages/distributors.html

For rest of the world, please contact Diagenode sa.

OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

3

Water Cooler

This opera ion manual is a ransla ion of he original opera ion manual

OPERATION MANUAL

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

4

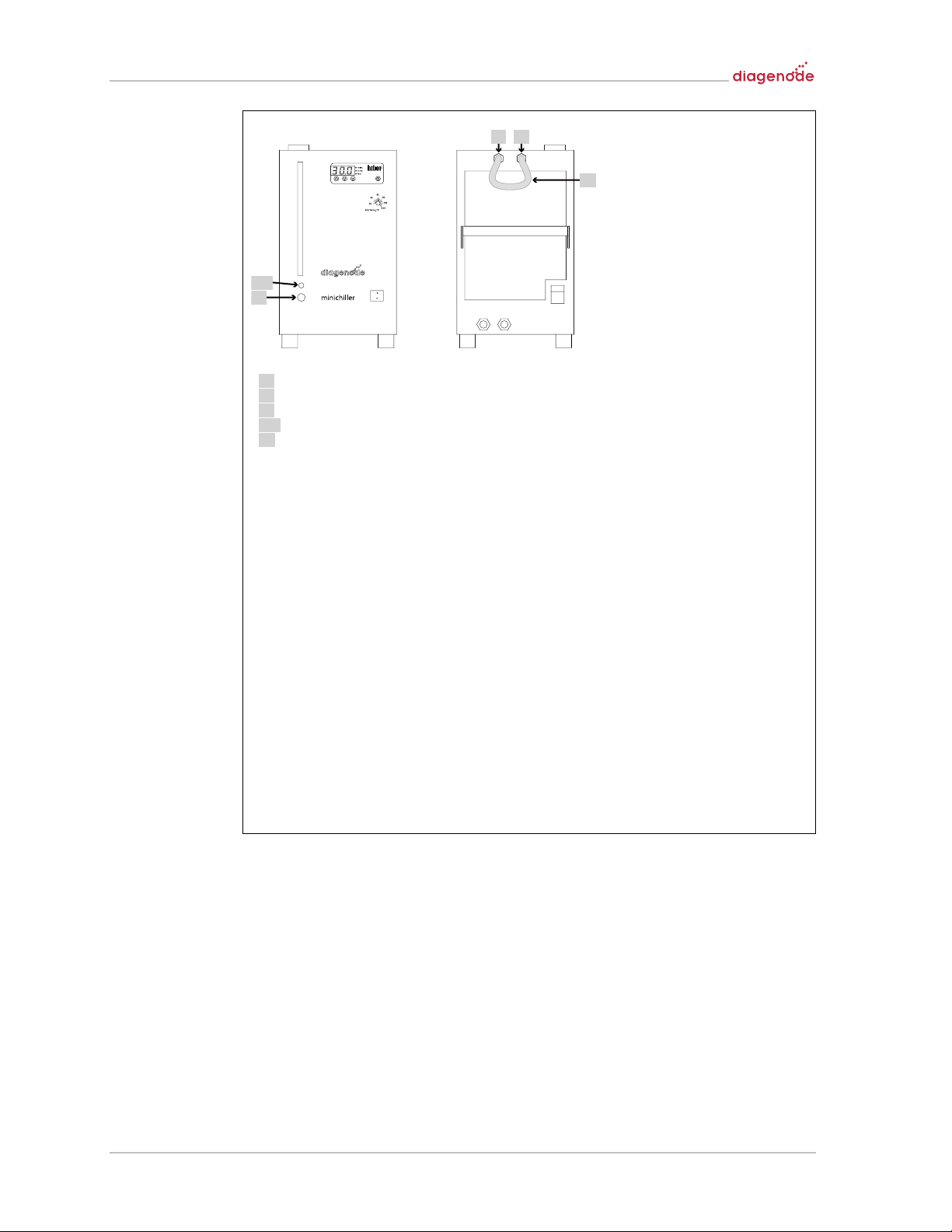

[1]

[2]

[8]

[12]

[13]

[23]

[17]

[14]

[26]

[37]

[45]

[A]

Blue

Red

Drain

Over ow

Cooling water inlet (only w)

Cooling water outlet (only w)

Filling port

Sight glass

Overtemperature protec"on (only -H)

Mains switch

Controller

Connector kit for Water Cooler

[12]

[8]

[45]

[26]

[37]

[23]

[14] [13]

[A]

[2]

[17]

[1]

Figure

1

:

Connec ing/filling

ex ernally copen

applica ion

OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

5

[1]

[2]

[8]

[12]

[A]

Circula on flow

Circula on return

Drain

Overflow

Temperature control hose

[12]

[8]

[A]

[2] [1]

Figure

2

:

Thermal fluid

change/check and

in ernal clean

OPERATION MANUAL

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

6

OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

7

Table of contents

V1.1.0en/13.12.12

1Introduction .............................................................................11

1.1 Safety ............................................................................................................ 12

1.1.1 Depic ion of safe y ins ruc ions ...................................................................... 12

1.1.2 Proper opera ion............................................................................................. 12

1.1.3 Reasonably foreseeable misuse...................................................................... 13

1.2 User and operators Obligations and requirements ..................................... 14

1.2.1 Obliga ions of he user.................................................................................... 14

1.2.1.1 Temperature control unit with natural refrigerants (NR) ........................... 14

1.2.1.2 Temperature control units with 3 to 30 kg fluorinated greenhouse

gases natural refrigerant ........................................................................... 15

1.2.2 Requiremen s for opera ors ........................................................................... 16

1.2.3 Obliga ions of he opera ors........................................................................... 16

1.3 General information ...................................................................................... 16

1.3.1 Descrip ion of he works a ions...................................................................... 16

1.3.2 Safe y devices o DIN 12876 ........................................................................... 16

1.3.3 Addi ional safe y devices ................................................................................ 17

1.3.3.1 Auto-Start function ..................................................................................... 17

1.3.3.2 Alarm functions .......................................................................................... 17

1.4 Schematic illustration of the cooling variants ................................................ 18

1.4.1 Air cooling ....................................................................................................... 18

1.4.2 Wa er cooling.................................................................................................. 19

1.4.3 Consequence of inadequa e energy dissipa ion ............................................. 20

2Commissioning.........................................................................21

2.1 In-plant transport .......................................................................................... 22

2.2 Unpacking...................................................................................................... 22

2.3 Ambient conditions ....................................................................................... 22

2.4 Installation conditions ................................................................................... 24

2.5 Recommended temperature control and cooling water hoses....................... 25

2.6 Wrench sizes and torques .............................................................................. 25

2.7 Connecting an externally open application (bath).......................................... 26

2.8 Connecting to the power supply .................................................................... 27

2.8.1 Connec ion using socke wi h pro ec ive ear h (PE)....................................... 27

2.8.2 Connec ion via direc wiring ........................................................................... 27

3Function description.................................................................29

3.1 Function description of the temperature control unit.................................... 30

3.1.1 General func ions............................................................................................ 30

3.1.2 O her func ions ............................................................................................... 30

3.2 Information on the thermal fluids.................................................................. 30

3.3 Testing planning ............................................................................................ 31

3.4 Display and control instruments .................................................................... 32

3.4.1 Display............................................................................................................. 32

3.4.2 LED display s a us............................................................................................ 32

3.4.3 Arrow keys ...................................................................................................... 32

3.4.4 SET key ............................................................................................................ 32

3.4.5 S ar /S op key ................................................................................................. 32

3.5 Menu navigation............................................................................................ 33

3.6 Function examples......................................................................................... 33

3.6.1 Display of he Se poin .................................................................................... 33

3.6.2 Se ing/change he se poin ........................................................................... 33

3.6.3 Se ing he Au o-S ar func ion (au oma ic mains failure) ............................. 34

OPERATION MANUAL

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

8

4Setup mode..............................................................................35

4.1 Setup mode ................................................................................................... 36

4.1.1 Turning on he empera ure con rol uni ....................................................... 36

4.1.2 Se ing he se poin ......................................................................................... 36

4.2 Filling, venting, off-gassing and draining........................................................ 36

4.2.1 Ex ernally open applica ion............................................................................. 36

4.2.1.1 Filling and venting externally open application.......................................... 36

4.2.1.2 Draining externally open applications ........................................................ 38

5Normal operation.....................................................................39

5.1 Automatic operation...................................................................................... 40

5.1.1 Tempera ure con rol....................................................................................... 40

5.1.1.1 Starting the temperature control process .................................................. 40

5.1.1.2 Ending the temperature control process .................................................... 40

6Interfaces.................................................................................41

6.1 Interface at the temperature control unit (optional) ..................................... 42

6.1.1 Jack RS232....................................................................................................... 42

7Service/maintenance................................................................43

7.1 Display error messages .................................................................................. 44

7.2 Maintenance.................................................................................................. 45

7.2.1 Func ion check and visual inspec ion.............................................................. 45

7.2.2 Clean condenser fins (air-cooled empera ure con rol uni ) .......................... 46

7.3 Thermal fluid inspection, replacement and circuit cleaning ........................... 47

7.3.1 Thermal fluid inspec ion ................................................................................. 47

7.3.1.1 Externally open application ........................................................................ 47

7.3.2 Cleaning he hermal fluid circui .................................................................... 47

7.4 Cleaning the surfaces ..................................................................................... 48

7.5 Inspect the mechanical seal ........................................................................... 48

7.6 Plug contacts ................................................................................................. 48

7.7 Decontamination/repairs .............................................................................. 49

8Shutting down..........................................................................51

8.1 Safety instructions and basic principles ......................................................... 52

8.2 Switch-off ...................................................................................................... 53

8.3 Packing .......................................................................................................... 53

8.4 Shipping......................................................................................................... 53

8.5 Disposal ......................................................................................................... 53

8.6 Telephone numbers and company address.................................................... 54

8.6.1 Telephone number: Cus omer Suppor .......................................................... 54

8.6.2 Telephone number: Sales ............................................................................... 54

8.6.3 Email adress: Cus omer Suppor ..................................................................... 54

8.6.4 Email adress: Technical Suppor ..................................................................... 54

8.7 Certificate of Compliance............................................................................... 54

9Annex ......................................................................................55

Technical data sheet, replacement parts list, connection diagram

OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

9

Foreword

Dear cus omer,

You have op ed for a empera ure con rol uni from Diagenode. You have made a good choice.

Thank you for your confidence in our produc s.

Read hrough his opera ion manual carefully prior o s ar -up. S ric ly follow all no es and safe y in-

s ruc ions.

Proceed wi h ranspor , s ar -up, opera ion, main enance, repairs, s orage and disposal in accor-

dance wi h his opera ion manual.

Subjec o proper opera ion, we offer a full warran y for your empera ure con rol uni .

OPERATION MANUAL

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

10

Introduction

Chap er 1 OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

11

1 Introduction

This chap er con ains he following sec ions:

1.1 Safety ............................................................................................................ 12

1.1.1 Depic ion of safe y ins ruc ions ...................................................................... 12

1.1.2 Proper opera ion............................................................................................. 12

1.1.3 Reasonably foreseeable misuse...................................................................... 13

1.2 User and operators Obligations and requirements ..................................... 14

1.2.1 Obliga ions of he user.................................................................................... 14

1.2.1.1 Temperature control unit with natural refrigerants (NR) ........................... 14

1.2.1.2 Temperature control units with 3 to 30 kg fluorinated greenhouse

gases natural refrigerant ........................................................................... 15

1.2.2 Requiremen s for opera ors ........................................................................... 16

1.2.3 Obliga ions of he opera ors........................................................................... 16

1.3 General information ...................................................................................... 16

1.3.1 Descrip ion of he works a ions...................................................................... 16

1.3.2 Safe y devices o DIN 12876 ........................................................................... 16

1.3.3 Addi ional safe y devices ................................................................................ 17

1.3.3.1 Auto-Start function ..................................................................................... 17

1.3.3.2 Alarm functions .......................................................................................... 17

1.4 Schematic illustration of the cooling variants ................................................ 18

1.4.1 Air cooling ....................................................................................................... 18

1.4.2 Wa er cooling.................................................................................................. 19

1.4.3 Consequence of inadequa e energy dissipa ion ............................................. 20

Introduction

OPERATION MANUAL Chap er 1

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

12

1.1 Safety

1.1.1 Depic ion of safe y ins ruc ions

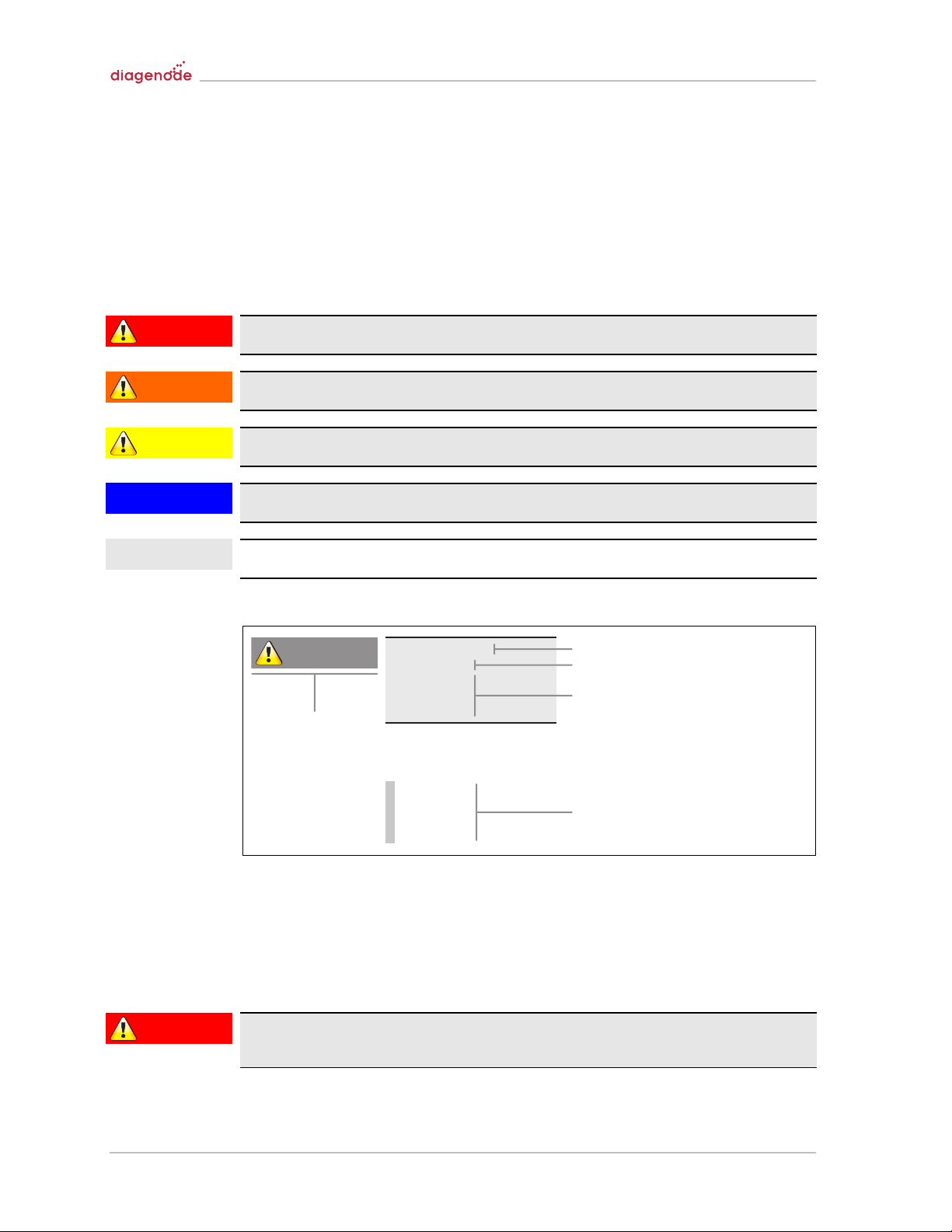

Safe y ins ruc ions are depic ed by he following pic ogram/signal words combina ions. The signal

word describes he classifica ion of he residual risk if he opera ion manual is no observed.

Denotes an imminent hazardous situation that will result in death or serious injury.

G

Denotes a generally hazardous situation that can result in death or serious injury.

W

Denotes a hazardous situation that can result in injury.

V

Denotes a situation that can result in property material damage.

H

Deno es impor an no es and usable hin s.

I

Errac behaviour

EFFECT

ØPrevenon

ØResolve

ØKnowledge

Severity of the

residual risk

Possible hazard source

Possible effects

Prevenon of errors

Resolving problems

Knowledge transfer

ØStep 1

Step 2

Step 3

Ø

Ø

Ø

Step 4

PROCEDURE

The procedure is explained

here step by step.

The safe y ins ruc ions in his opera ion are in ended o pro ec you as he user, opera or and he

plan from damage. Safe y ins ruc ions mus always appear BEFORE he handling ins ruc ion and a

he s ar of each chap er. You should be informed abou he residual risks caused by misuse before

s ar ing he ac ion concerned.

1.1.2 Proper opera ion

Operating the temperature control unit in a potentially explosive area

DEATH THROUGH EXPLOSION

Do NOT ins all or opera e he empera ure con rol uni wi hin an ATEX zone. G01

HAZARD

WARNING

CAUTION

NOTE

.

INFORMATION

.

Explana ion

Safe y ins ruc ions

and procedure

HAZARD

Introduction

Chap er 1 OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

13

Improper use

SERIOUS INJURY AND PROPERTY DAMAGE

S ore he opera ion manual where i is easy o access in close proximi y o he empera ure con-

rol uni .

Only adequa ely qualified opera ors may work wi h he empera ure con rol uni .

Opera ors mus be rained before handling he empera ure con rol uni .

Check ha he opera ors have read and unders ood he opera ion manual.

Define precise responsibili ies of he opera ors.

Personal pro ec ive equipmen mus be provided o he opera ors.

S ric ly heed he safe y ins ruc ions of he opera or in order o pro ec life and limb and limi

proper y damage. W01

Modifications to the temperature control unit by third-parties

DAMAGE TO THE TEMPERATURE CONTROL UNIT

Do no allow hird par ies o make echnical modifica ions o he empera ure con rol uni .

Every modifica ion no agreed wi h he manufac urer invalida es every CE Declara ion of Con-

formi y for he empera ure con rol uni .

Only specialis s rained by he manufac urer may carry ou modifica ions, repairs or main enance

work.

The following must be observed without fail:

Only use he empera ure con rol uni in a faul -free condi ion!

Have s ar -up and repairs carried ou only by specialis s!

Never omi , bypass, remove or deac iva e safe y devices! H01

The empera ure con rol uni mus no be used for any purposes o her han empera ure con rol in

accordance wi h he opera ion manual.

The empera ure con rol uni is manufac ured for indus rial use. The empera ure con rol uni main-

ains he empera ure of cer ain applica ions, including glass or me al reac ors or o her expedien

i ems in labora ories and indus ry. Flow- hrough coolers and calibra ion ba hs mus be used only in

combina ion wi h Huber empera ure con rol uni s. Thermal fluids sui able for he overall sys em

are used. The chilling and hea ing capaci y is provisioned a he pump connec ions or - where pre-

sen - in he empering ba h. The echnical specifica ion of he empera ure con rol uni is given in

he da a shee (from page 55 in sec ion »Annex«). The empera ure con rol uni mus be ins alled,

configured and opera ed according o he handling ins ruc ions in his opera ing manual. Failure o

comply wi h he opera ion manual is deemed improper use. The empera ure con rol uni conforms

o s a e-of- he-ar echnology and he recognized safe y regula ions. Safe y devices are buil in o

your empera ure con rol uni .

1.1.3 Reasonably foreseeable misuse

Use wi h medical devices (e.g. in Vi ro diagnos ic procedure) or for direc foods uff empera ure

con rol is NOT permissible.

The empera ure con rol uni mus NOT be used for any purposes o her han empera ure con rol in

accordance wi h he opera ion manual.

The manufac urer accep s NO liabili y for damage caused by technical modifications o he em-

pera ure con rol uni , improper handling or use of he empera ure con rol uni if the operation

manual is not observed.

WARNING

NOTE

.

Introduction

OPERATION MANUAL Chap er 1

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

14

1.2 User and operators Obligations and requirements

1.2.1 Obliga ions of he user

The opera ion manual is o be s ored where i is easy o access in close proximi y o he empera ure

con rol uni . Only adequa ely qualified opera ors (e.g. chemis s, CTA, physicis s e c.) are permi ed

o work wi h he empera ure con rol uni . Opera ors mus be rained before handling he empera-

ure con rol uni . Check ha he opera ors have read and unders ood he opera ion manual. Define

precise responsibili ies of he opera ors. Personal pro ec ive equipmen mus be provided o he

opera ors.

1.2.1.1 Temperature control unit with natural refrigerants (NR)

Over 8 g refrigerant per m³ room air

DEATH OR SERIOUS INJURY DUE TO EXPLOSION

Observe he ra ing pla e (amoun of na ural refrigeran con ained) and he room size (maximum

room concen ra ion of na ural refrigeran in case of leakage) when ins alling he empera ure

con rol uni .

For empera ure con rol uni s wi h more han 150 g na ural refrigeran : A gas warning sensor

mus be fi ed and func ioning.

The gas warning sensor mus be calibra ed and main ained a regular in ervals (be ween 6 and

12 mon hs).

The empera ure con rol uni is not approved for operation in ATEX areas. W07

Huber produc s wi h na ural refrigeran s work wi h numerous proven, safe and highly-sus ainable

echnologies. The relevan s andards and regula ions for empera ure con rol uni s wi h na ural re-

frigeran s con ain a number of s ipula ions, he impor ance of complying wi h which is se ou be-

low. Also observe on page 12 he sec ion »Proper operation«.

Huber empera ure con rol uni s are cons ruc ed o be permanen ly sealed and are carefully

checked for leak igh ness. Tempera ure con rol uni s wi h more han 150 g na ural refrigeran are

equipped wi h an addi ional gas warning sensor.

The fill quan i y of your empera ure con rol uni is s a ed on he da a shee (from page 55 in sec-

ion »Annex«)or on he ra ing pla e on he rear of he empera ure con rol uni . Observe page 22,

sec ion »Ambient conditions« and page 24, sec ion »Installation conditions«.

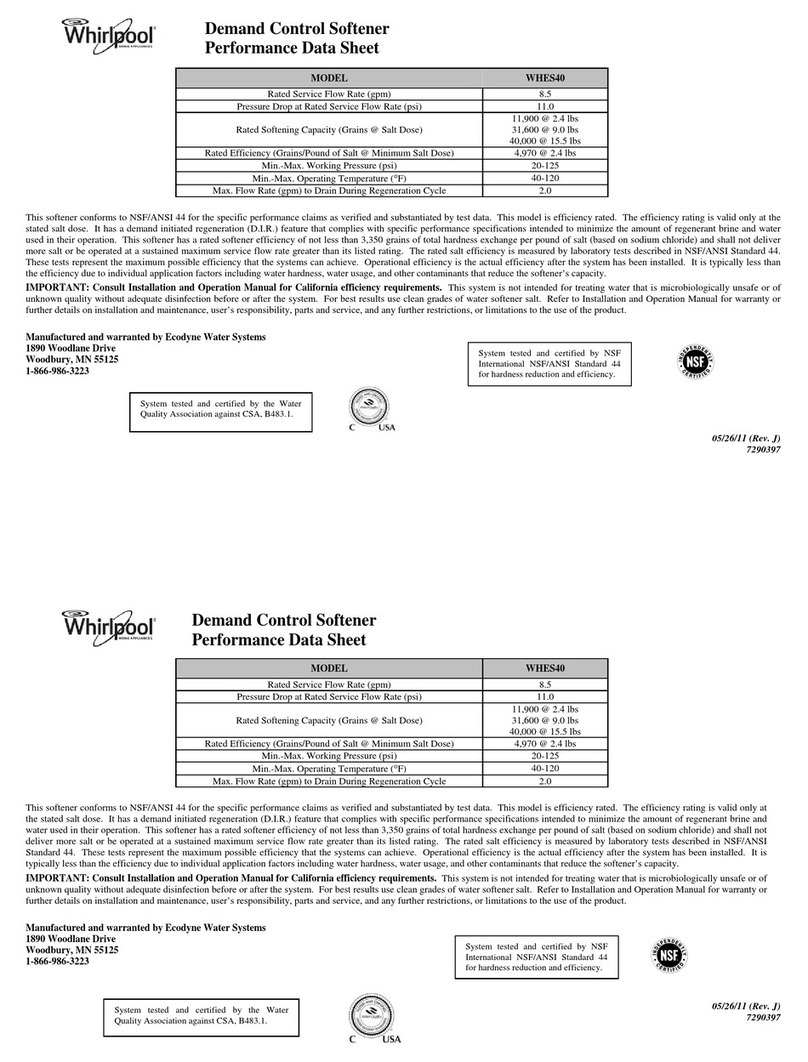

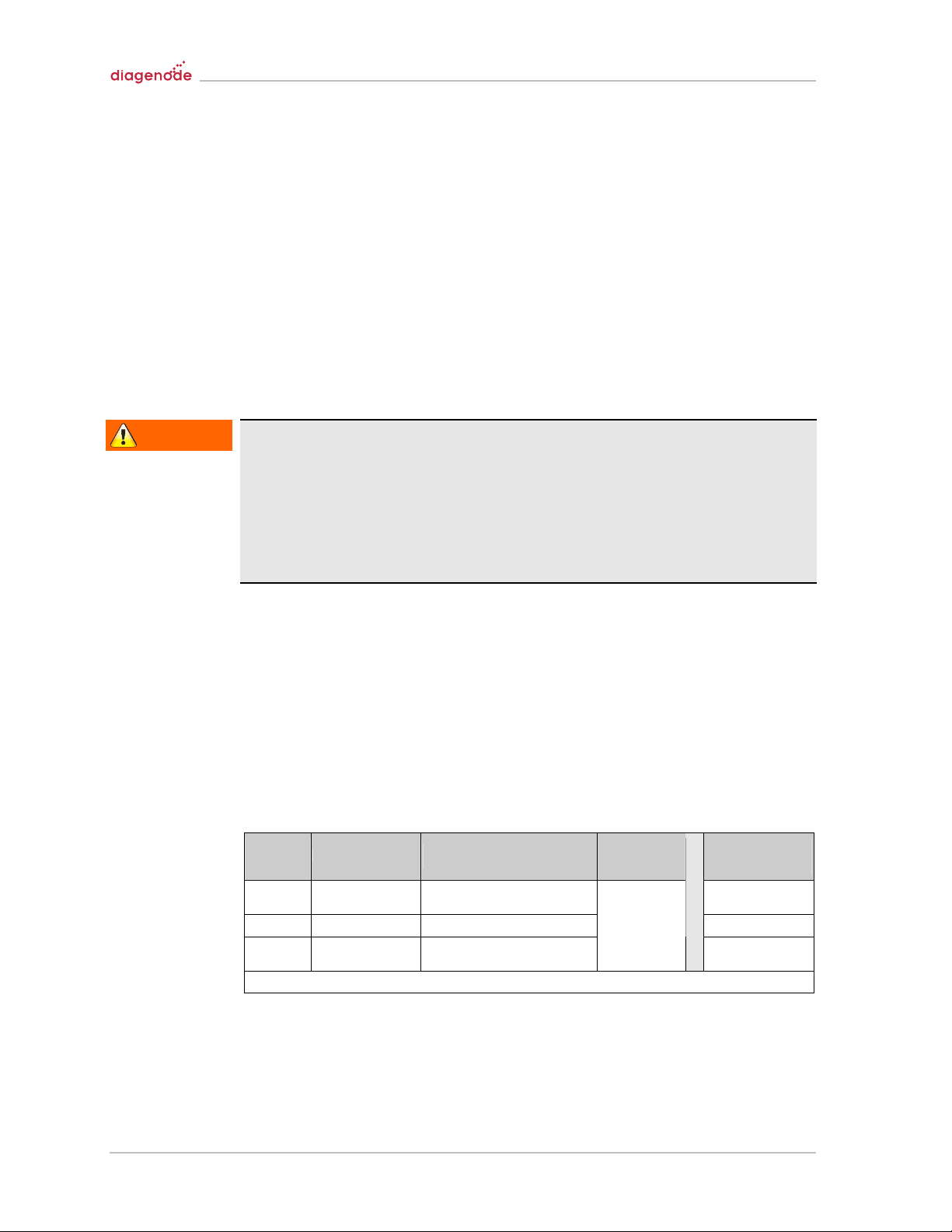

Class of the

application

field

Application field Example of the installation

location

Max.

refrigerant

quantity

Max. permissible

quantity above

ground level (GL)

AGeneral Publicly accessible area in a

public building 1.5 kg

BMoni ored Labora ories 2.5 kg

CAccess only for

au horized persons Produc ion equipmen

8g/m³ room air

OR

10.0 kg

Tempera ure con rol uni s wi h more than 1 kg refrigeran mus not be installed below ground level (GL).

Temperature control units with up to 150 g natural refrigerant

The empera ure con rol uni has been cons ruc ed o he requiremen s of EU and EFTA coun-

ries.

Use he able as guidance for classifying he applica ion field. Respec he max. refrigeran quan-

i y s a ed herein.

WARNING

Classifying he

applica ion field

Introduction

Chap er 1 OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

15

Temperature control units with more than 150 g natural refrigerant

The empera ure con rol uni has been cons ruc ed o he requiremen s of EU and EFTA coun-

ries.

Use he able as guidance for classifying he applica ion field. Respec he max. refrigeran quan-

i y or he permissible highes quan i y above ground level (GL) s a ed herein.

Fur her no es on he pre-ins alled gas sensor:

a) The in egra ed gas warning sensor permi s a safety cut-out at 20 % of the lower explosion

threshold via an isolation relay to be installed locally by the user.The empera ure con rol

uni is herefore shu down safely and a an early s age in case of malfunc ion.

b) For he pre-ins alled gas warning sensor, you mus hold ready an external power supply of

24 V DC.The gas warning sensor alarm is ou pu using a 4 - 20 mA signal. For fur her echnical

de ails, please see he da a shee for he gas warning sensor.

Upon reques , aseparate evaluation unit is available as an accessory for con rolling he

isola ion relay. The evalua ion uni provides a floa ing swi ch con ac , while also supplying he

vol age and evalua ing he gas warning sensor.

Dimensioning and ins alla ion by he user are required for bo h varian s. The echnical de ails

required for ins alla ion can be found on he da a shee of he gas warning sensor. The gas

warning sys em alarm can also be rou ed o a user's alarm con rol uni . The user is responsible

for his and for any fur her measures.

c) The user is responsible for calibrating the gas warning sensor prior o ini ial s ar -up and for

main aining he calibra ion and main enance in ervals in accordance wi h he manufac urer's

opera ing ins ruc ions. If no o her informa ion is available, we recommend calibra ion and

main enance in ervals of be ween 6 and 12 mon hs. Shor er in ervals can also be specified o

mee ougher safe y requiremen s. Upon reques , we would be happy o propose a specialis

company o carry ou he calibra ion and main enance work.

1.2.1.2 Temperature control units with 3 to 30 kg fluorinated greenhouse gases/natural refrigerant

F-Gas Directive (EC) No. 842/2006 of he European Parliamen and of he Council of 17 May 2006 on

specific fluorina ed greenhouse gases.

This direc ive concerns all sys ems ha con ain fluorina ed refrigeran s. The subs ances se ou in

Direc ive (EC) No. 1005/ 2009 of he European Parliamen and of he Council of 16 Sep ember 2009

ha deple e he ozone layer are excep ed (CFC/HCFC).

The Direc ive regula es he reduc ion of emissions, he use, he recovery and he des ruc ion of spe-

cific fluorina ed greenhouse gases, as well as he iden ifica ion and disposal of produc s and equip-

men con aining hese gases. Since 4 July 2007, users mus check heir s a ionary refrigera ion sys-

ems for leaks on a regular basis and rec ify any leaks wi hin he shor es possible ime.

Direc ive (EC) No. 303/2008 con ains s ipula ions on he raining and cer ifica ion of companies and

personnel ha are permi ed o execu e he specified ac ivi ies.

Obligations of the user:

Annual inspec ion, for ins ance, for leaks from s a ionary refrigera ion sys ems by cer ified per-

sonnel (e.g. service echnicians of Pe er Huber Kael emaschinenbau GmbH) for a fill quan i y of

fluorina ed greenhouses from 3kg to 30 kg.

Obliga ion o keep records (main enance and inspec ion) in he opera ion manual of he refrig-

era ion sys em, specifying he ype and quan i y of used or recovered refrigeran s, which he user

mus re ain for a leas 5 years af er hey are produced and presen o he compe en au hori y

on demand.

Responsibili y of plan users o recover F-gases using cer ified personnel.

Tempera ure con rol uni s wi h na ural refrigeran s (NR) are exemp from his Direc ive.

The refrigeran quan i y is s a ed on he da a shee or ra ing pla e of your empera ure con rol

uni .

Introduction

OPERATION MANUAL Chap er 1

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

16

1.2.2 Requiremen s for opera ors

Work on he empera ure con rol uni is reserved for appropria ely qualified specialis s, who have

been assigned and rained by he user o do so. Opera ors mus be a leas 18 years old. Under 18-

year olds may opera e he empera ure con rol uni only under he supervision of a qualified spe-

cialis . The user is responsible vis-a-vis hird-par ies in he work area.

1.2.3 Obliga ions of he opera ors

Carefully read he opera ion manual before handling he empera ure con rol uni . S ric ly observe

he safe y ins ruc ions. Wear personnel pro ec ive equipmen when handling he empera ure con-

rol uni (e.g. safe y goggles, pro ec ive gloves, an i-slip foo wear).

1.3 General information

1.3.1 Descrip ion of he works a ions

The works a ion is loca ed a he con rol panel in fron of he empera ure con rol uni . The work-

s a ion is de ermined by he cus omer's connec ed peripheries. Accordingly, i mus be designed

safe by he user. The works a ion design also depends on he applicable requiremen s of he Ger-

man occupa ional heal h and safe y regula ions [Be rSichV] and he risk analysis for he works a ion.

1.3.2 Safe y devices o DIN 12876

Adjus able over- empera ure pro ec ion (applicable for empera ure con rol uni s wi h hea ing

func ion).

Low level pro ec ion.

The ra ing of your empera ure con rol uni is s a ed on he da a shee in he appendix.

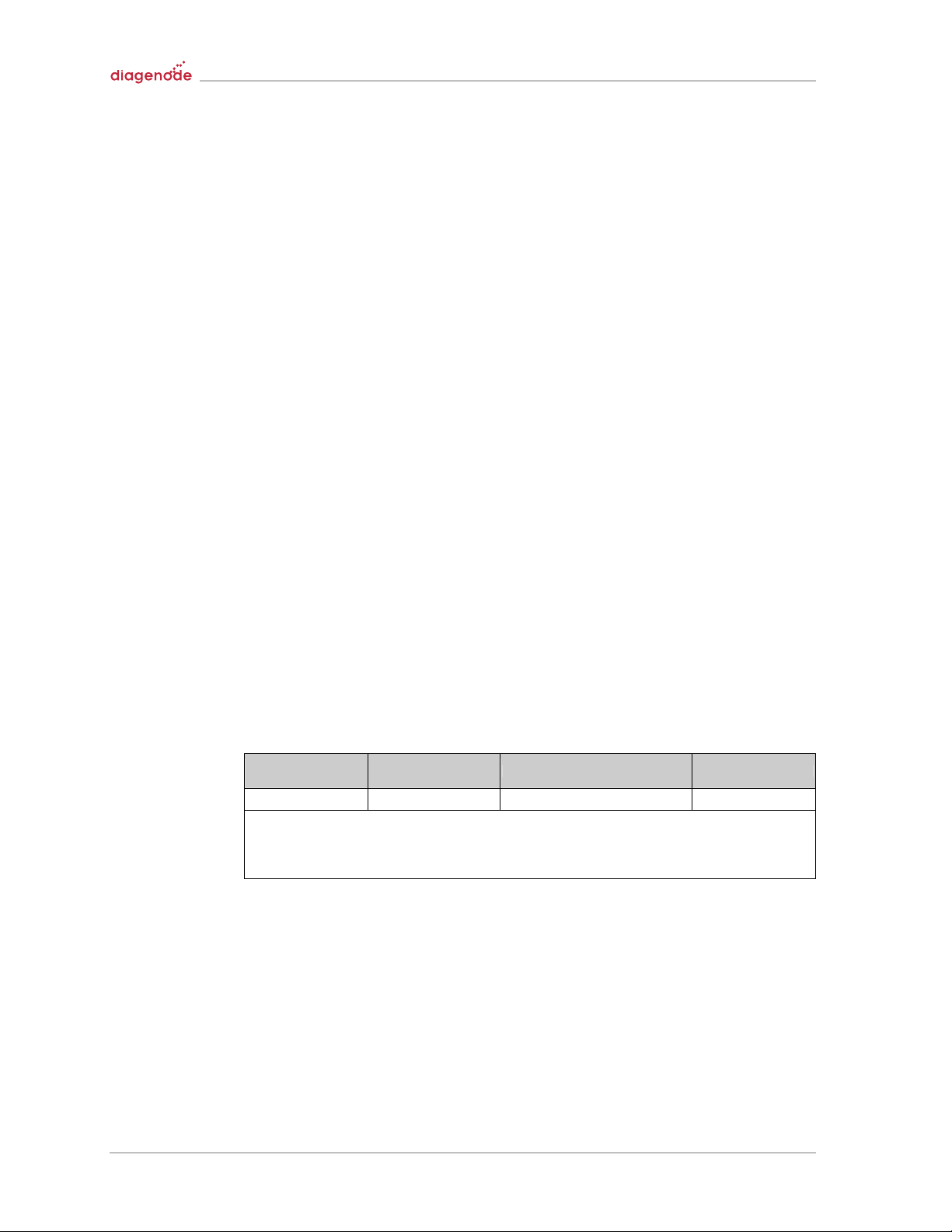

Rating Temperature control

fluid Technical requirements Code c)

IDis illed Wa er a) Overhea pro ec ion b) NFL

a) Usually wa er; o her fluids only if non-combus ible even wi hin he empera ure range of an individual faul .

b) The overhea pro ec ion can, for ins ance, be realized using a sui able fill level sensor or a sui able empera-

ure limi er.

c) Op ional a he choice of he manufac urer.

Tempera ure con rol uni s wi h hea ing (marked by an “-H” in he name) are designa ed as class

III FL.

Tempera ure con rol uni s wi hou hea ing are designa ed as class I NFL.

Ra ing of labora ory

hermos a s and labo-

ra ory ba hs

Introduction

Chap er 1 OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

17

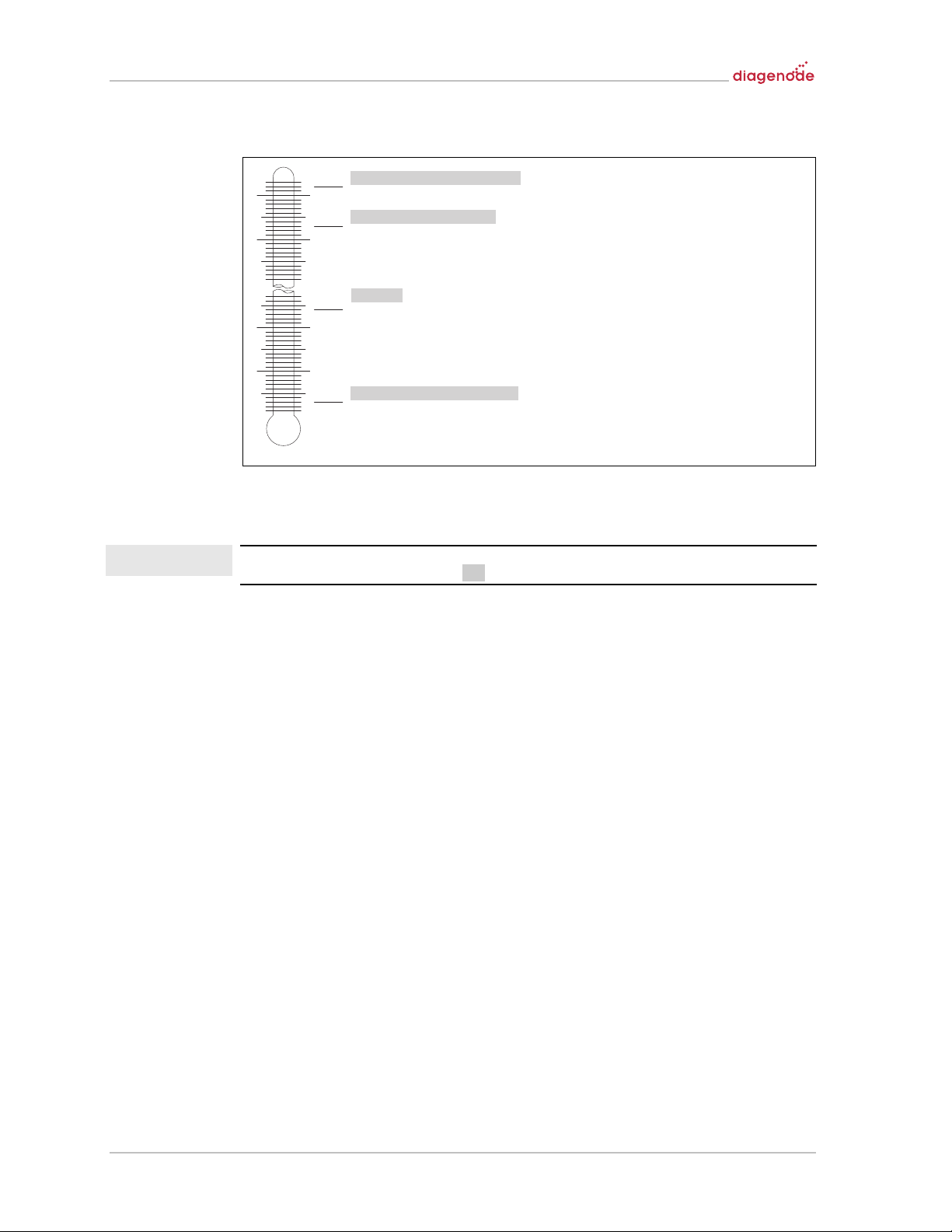

°C

Can only be set in defined range

(between maximum/minimum setpoint).

25 K below combuson point of the thermal fluid.

[Over-temperaturetreshold]

Highest possible temperatureof the temperature control unit.

[Maximum working temperature]

Lowest possible temperatureof the temperature control unit.

[Minimum working temperature]

[Setpoint]

1.3.3 Addi ional safe y devices

Emergency s ra egy – isola e he power supply!

Do his by urning he >Mains switch< [37] o he “0” posi ion!

1.3.3.1 Auto-Start function

Following a power ou age (or when swi ching on he empera ure con rol uni ), his func ion can be

used o de ermine how he empera ure con rol uni is supposed o respond.

Standard setting (OFF):

OFF Once he empera ure con rol uni is swi ched on, he empera ure con rol process is

s ar ed only af er manual inpu .

ON The empera ure con rol uni is res ored o he same s a us as i was before he power

failure. For example, before he mains failure: empera ure is off, according o his se ing,

af er he power is res ored empera ure con rol is off.

Automatic power outage mechanism:

If empera ure con rol is ac ive during a power ou age, he process will au oma ically con inue af er

he power ou age.

Fur her informa ion can be found on page 34 in sec ion »Setting the Auto-Start function (automatic

mains failure)«.

1.3.3.2 Alarm functions

An alarm is a sys em s a e ha signals unfavorable process condi ions. The empera ure con rol uni

can be programmed so ha he plan opera or is warned when defined limi values are exceeded.

The response of he empera ure con rol uni o an alarm can be de ermined. Possible responses

are: Swi ch off empera ure con rol or con rol empera ure o a safe se poin (2nd se poin ).

Overview of he

empera ure

hresholds

INFORMATION

.

Introduction

OPERATION MANUAL Chap er 1

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

18

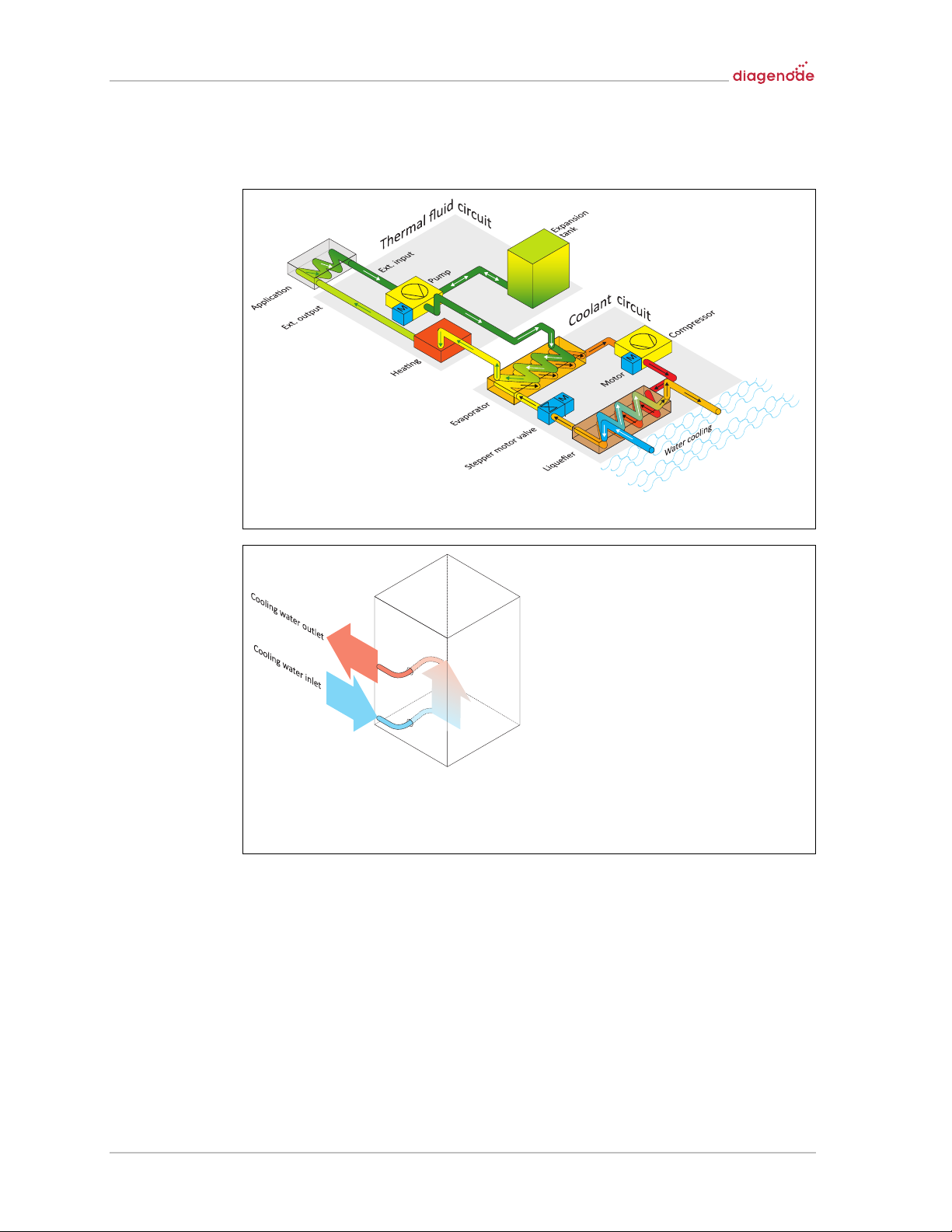

1.4 Schematic illustration of the cooling variants

1.4.1 Air cooling

Fresh air supply

from the front

Fresh air supply

from below

Fresh air supply

from below or or

Diagram:

Air cooling

Air inle

Introduction

Chap er 1 OPERATION MANUAL

V1.1.0en/13.12.12 Errors and omissions excep ed. Wa er Cooler

19

1.4.2 Wa er cooling

Diagram:

Wa er cooling

Wa er connec ion

Introduction

OPERATION MANUAL Chap er 1

Wa er Cooler Errors and omissions excep ed. V1.1.0en/13.12.12

20

1.4.3 Consequence of inadequa e energy dissipa ion

Room air/cooling water

Consequences of, for ins ance, con amina ion of he condenser fins, inadequa e clearance be ween

empera ure con rol uni o wall/ba h wall, room air/cooling wa er oo warm, cooling wa er differ-

en ial pressure oo low, suc ion s rainer con amina ion: The refrigeran in he refrigeran circui can

no longer fully discharge he admi ed energy o he room air/cooling wa er. Thus here is no suffi-

cien liquefied refrigeran available, he condensa ion empera ure and he energy consump ion o

rise.

Refrigerant circuit

Consequences of inadequa e refrigeran quan i y/rising condensa ion empera ure: No all he cool-

ing capaci y from he refrigeran circui is available a he evapora or. This means reduced energy

ransmission from he hermal fluid circui .

Thermal fluid circuit

Consequence of inadequa e energy dissipa ion from he hermal fluid: The hermal fluid can only

dissipa e he energy from your applica ion o a limi ed ex en .

Application

Consequences of inadequa e energy dissipa ion from he applica ion: The energy crea ed (exo her-

mic) in he applica ion can no longer be fully dissipa ed.

Temperature control unit

For op imal empera ure con rol performance and maximum cooling power he uni should be used

wi hin he specified ambien empera ure range. The empera ure con rol uni swi ches off when

he upper range is reached (maximum permissible ambien empera ure).

Table of contents

Popular Water Dispenser manuals by other brands

Runlucky

Runlucky RL-R50/MYA-1 user manual

Modena

Modena Salutare Series User manual book

Elkay

Elkay LZ Series Installation, care & use manual

Whirlpool

Whirlpool WHES48 Installation and operation manual

GE

GE SmartWater GXSF27B specification

WaterLogic

WaterLogic WL400 Series Operating, installation and service manual

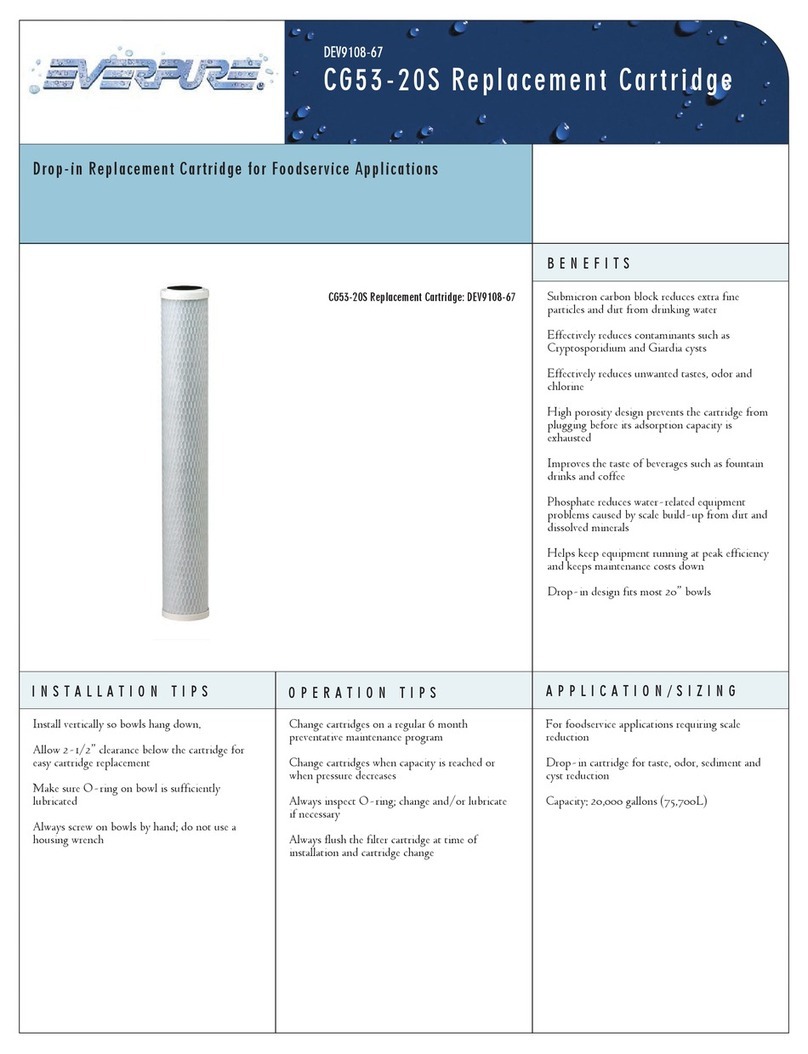

Everpure

Everpure DEV9108-67 Specifications

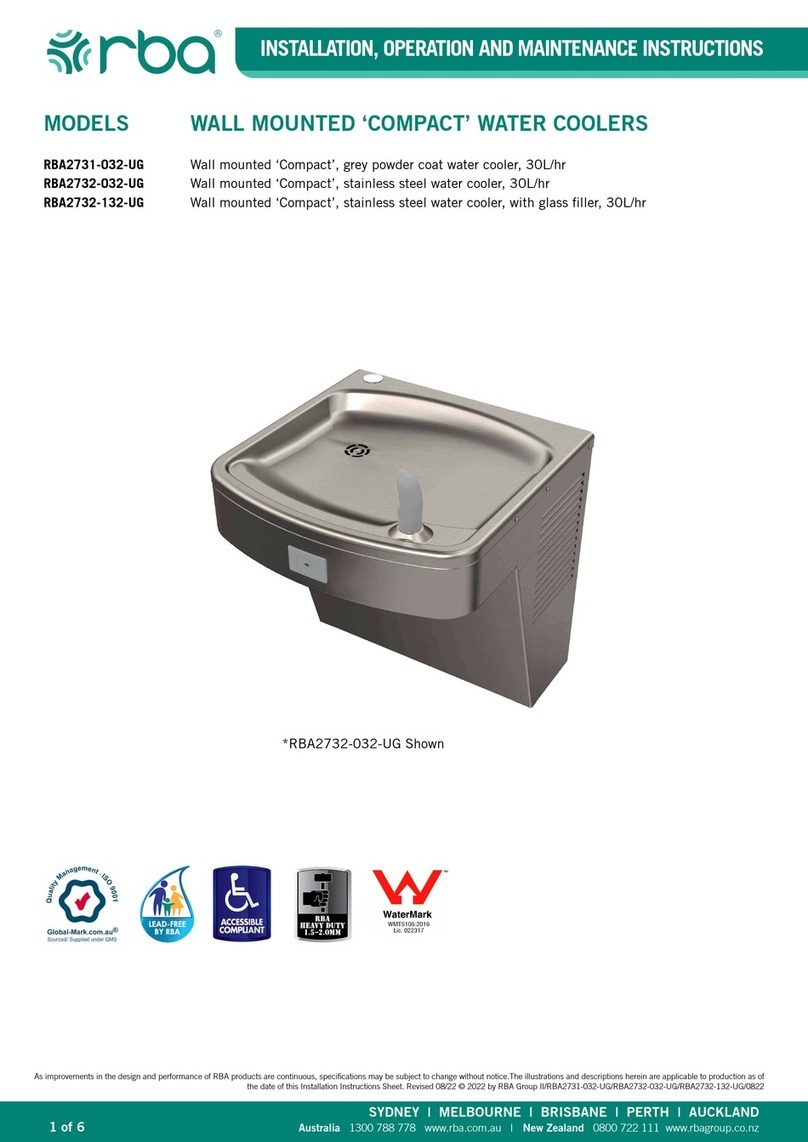

rba

rba RBA2731-032-UG Installation, operation and maintenance instructions

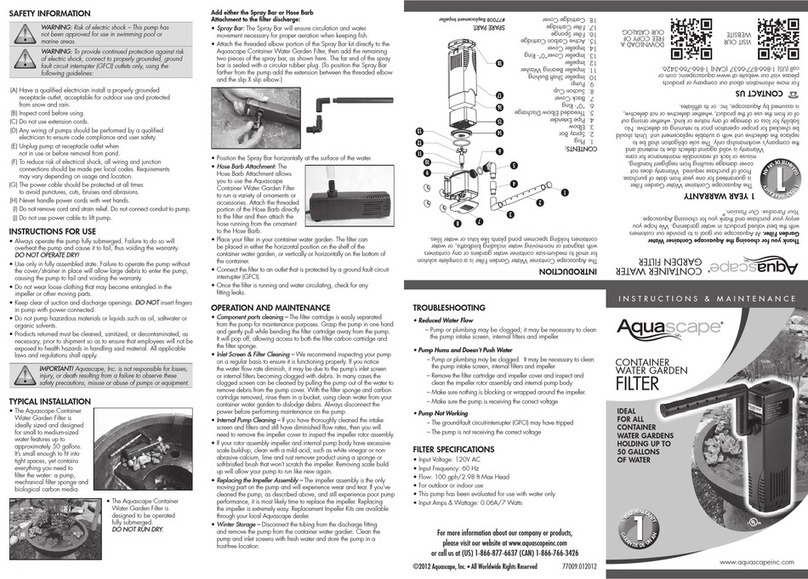

AquaScape

AquaScape 77005 Instructions & maintenance

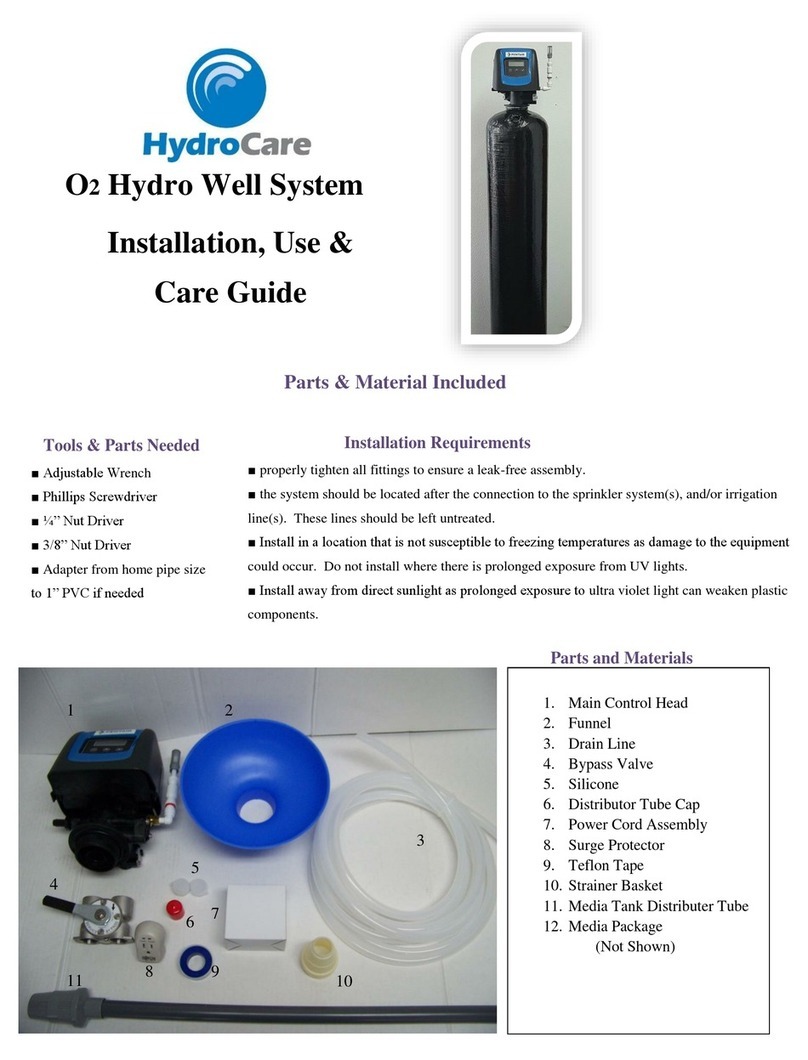

HydroCare

HydroCare O2 Hydro Well System Installation, use & care guide

Everpure

Everpure MD-HE Water Filters 255349 Specification sheet

Aquion

Aquion Micro Chrono Installation & operating instructions