DIAMON IN/RCX08-PVV User manual

Mod: IN/RCX08-PVV

Production code: 19058507

02/2019

DROP IN

REFRIGERATED VENTILATED WELL/ CUBA REFRIGERADA VENTILADA/

CUVE RÉFRIGÉRÉE FROID VENTILÉ

Ref:

A070200008

Vers. 1

[2]

Please check your equivalent model in the equivalent table

Consulte su modelo equivalente en la tabla de equivalencias

Consultez votre modèle équivalent dans le tableau d’équivalences

Refrigerated ventilated well/ Cuba refrigerada ventilada/ Cuve réfrigérée froid ventilé

[1]

12

Instruction manual

Installation and Operation

Anex/ Anexo/ Annexe

[2]

MACHINES DRAWING ELECTRICAL & DRAIN SITUATIONS / PLANOS TÉCNICOS EN SITUACIONES ELÉCTRICAS O,

DRENAJE / PLAN TECHNIQUE EN SITUATION DU ÉLECTRICITÉ OU VIDANGE

Fig 1.

Anex/ Anexo/ Annexe

[3]

Remote/ remota/ froid à distance

Fig. 2

Anex/ Anexo/ Annexe

[4]

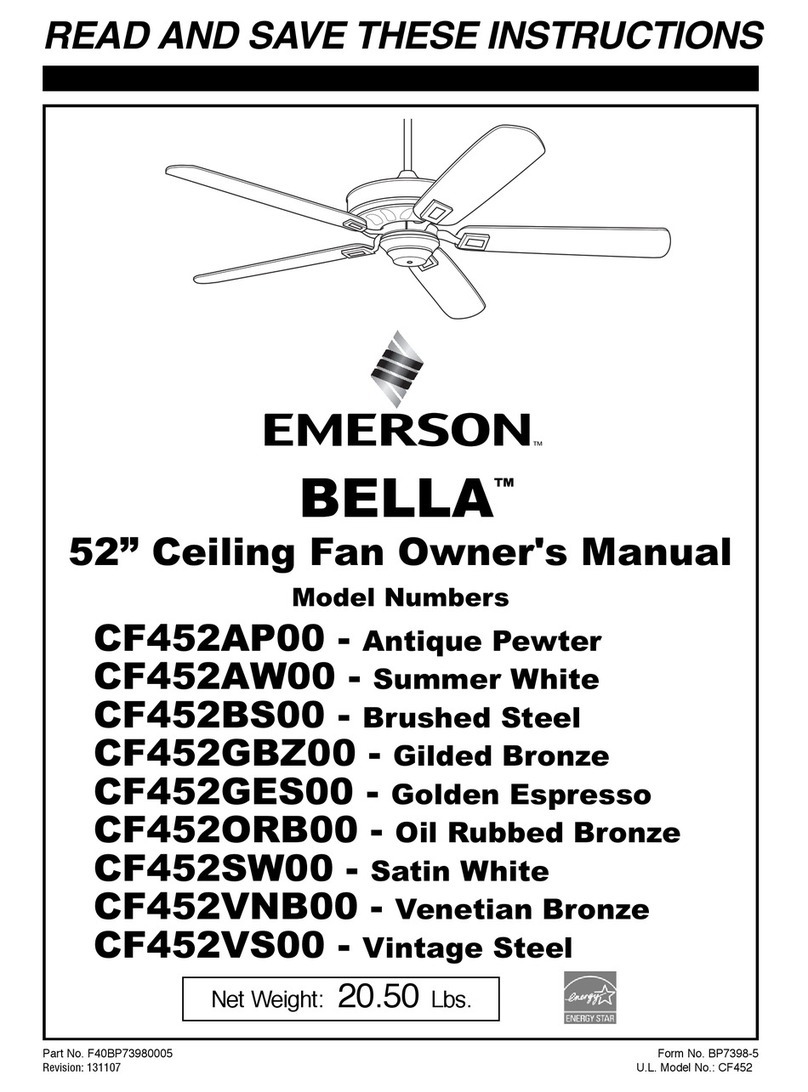

TECHNICAL CHARACTERISTICS / CARACTERÍSTICAS TÉCNICAS / CARACTÉRISTIQUES TECHNIQUES

Model/

Modelo

Capacity

(GN)/

Capacidad

(GN)/

Capacité

(GN)

Dimensions

(mm)/ Medidas

(mm)/ Mesures

(mm)

Cut

-

Out

Dimensions

(mm)/

Medidas

Encastre

(mm)/

Mesures

Encastrées

(mm)

Voltage/

Voltaje/ Voltage

Electrica

l Power

(W)/

Potenci

a

Eléctrica

(W)/

Puissanc

e

Électriq

ue (W)

Cooling Power

(W) -10ºC Tª

evap./

Potencia

Frigorífica (W)

-10ºC Tª

evap./

Puissance de

refroidisseme

nt (W)

-10ºC Tª evap.

Gas

Type/

Gas

Tipo/

Gaz

Type

Climatic

Class/ Clase

Climática/

Classe

Climatique

Work

Temperatur

e (ºC)/

Temperatur

a de Trabajo

(ºC)/

Températur

e de travail

(ºC)

DV7

-

C2

2

790x720x

677

R: 790x720x348

765x690

230/ I / 50 HZ

2

8

0

R: 20

430

R452a

IV

0ºC /

4ºC

DV7

-

C3

3

1115x720x

677

R: 1115x720x348

1090x690

395

R: 20

590

DV7

-

C4

4

1440x720x

677

R: 1440x720x348

1415x690

535

R: 20

770

DV7

-

C5

5

1765x720x

677

R: 1765x720x348

1740x690

710

R: 20

940

DV7

-

C6

6

2090x720x

677

R: 2090x720x348

2065x690

760

R: 20

1110

Tab 1.

Anex/ Anexo/ Annexe

[5]

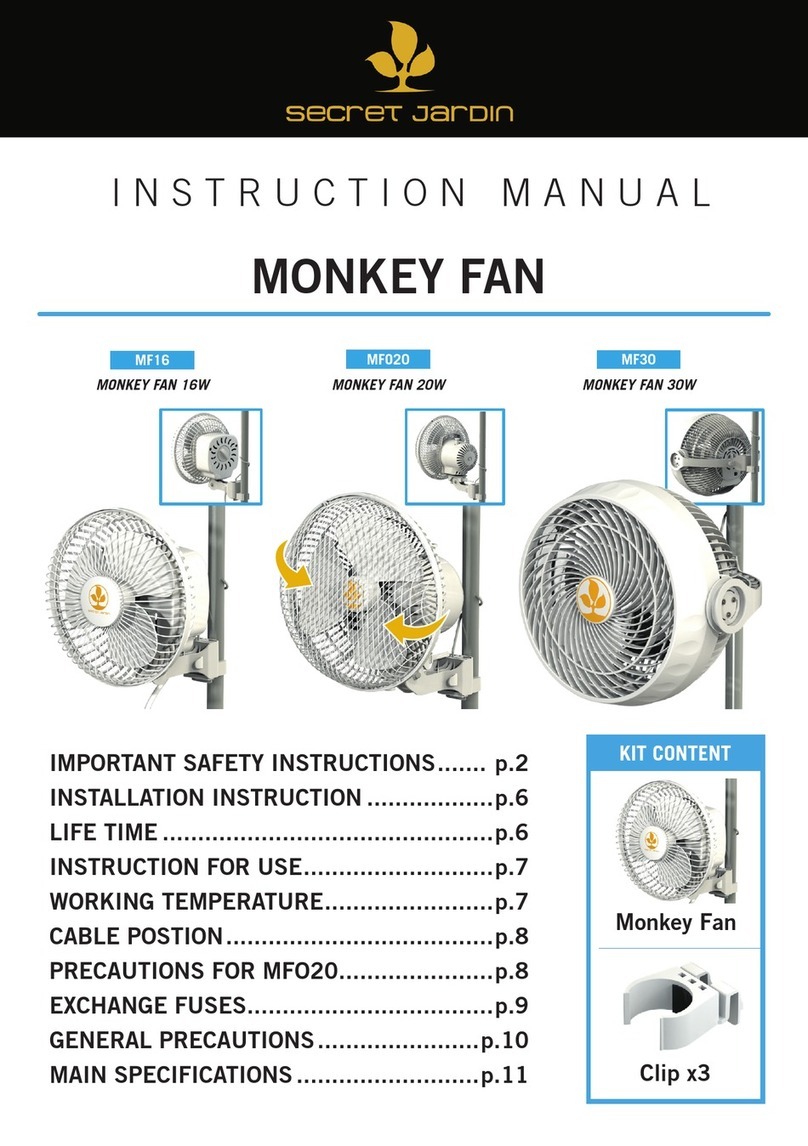

DROP IN ASSEMBLY / MONTAJE DEL DROP IN / ASSEMBLAGE D’ENCASTREMENT

Fig 3.

Anex/ Anexo/ Annexe

[6]

DROP IN DISASSEMBLY / DESMONTAJE DEL DROP IN / DÉMONTAGE D’ENCASTREMENT

Fig 4.

Anex/ Anexo/ Annexe

[7]

CONTROL PANEL SCROLLING/ DESPLAZAMIENTO PANEL DE CONTROL/ PANNEAU DE

COMMANDE DÉFILEMENT

Fig. 5

Anex/ Anexo/ Annexe

[8]

DROP IN MAINTENANCE / MANTENIMIENTO DEL DROP IN / ENTRETIEN D’ENCASTREMENT

Fig. 6

Anex/ Anexo/ Annexe

[9]

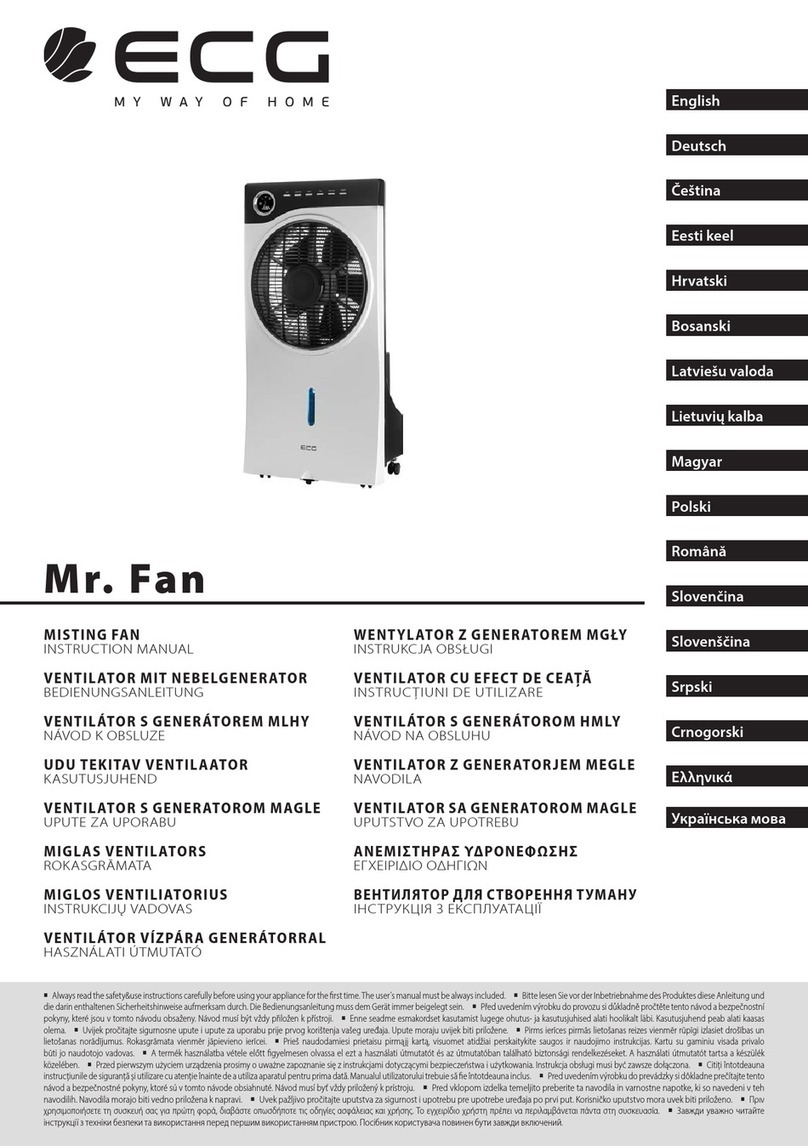

COLD UNIT VENTILATION/ VENTILACION DE LA UNIDAD DE FRIO/ VENTILATION DE L'UNITÉ FROIDE

Fig. 7

Anex/ Anexo/ Annexe

[10]

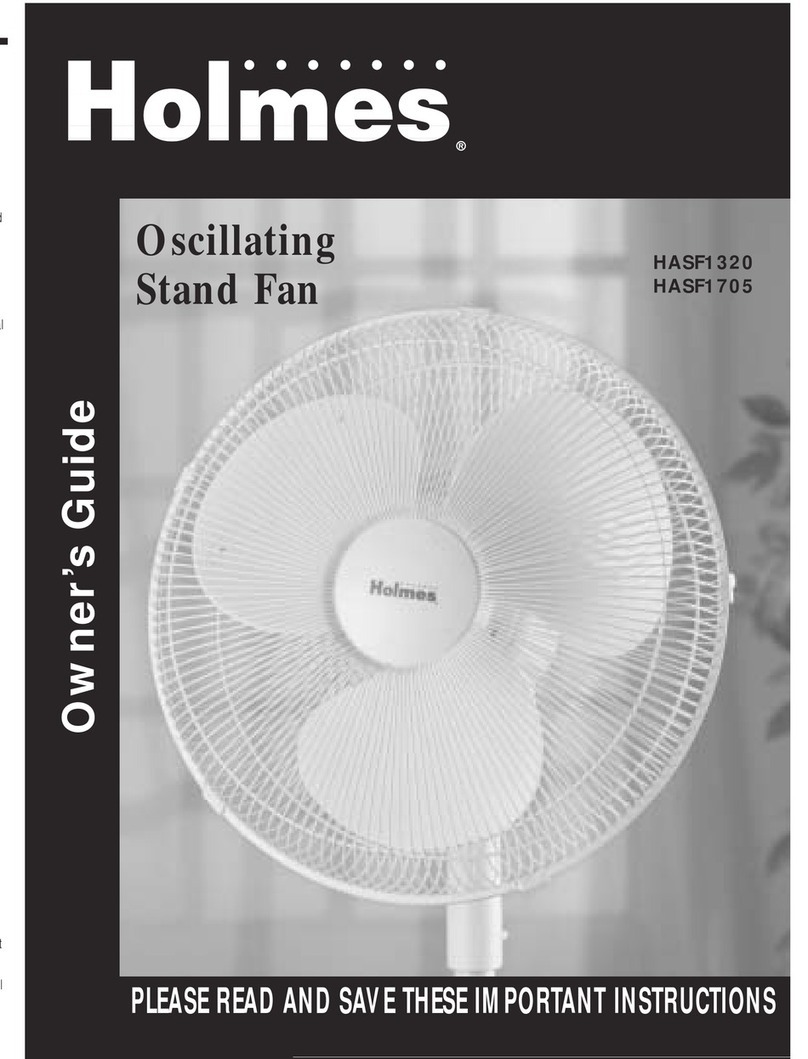

CONTROL PANEL / PANEL DE MANDOS / PANNEAU DE COMMANDE

Fig. 8

(1)

(

4

)

(

5

)

(

7

)

(3)

(

2

)

(

6

)

(

8

)

Anex/ Anexo/ Annexe

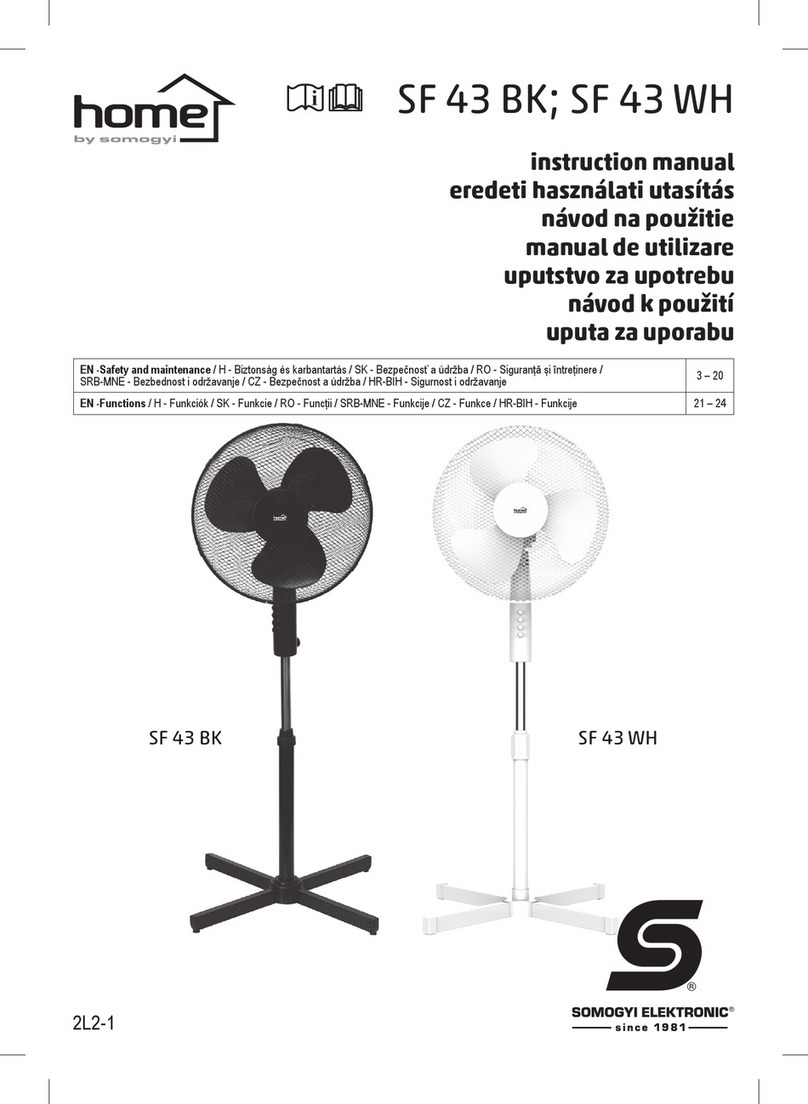

[11]

HOLE TO ASSEMBLY THE CONTROL PANEL / AGUJERO PARA INSTALAR EL PANEL DE MANDOS /

LE TROU POUR ASSEMBLER LE PANNEAU DE COMMANDE

Fig. 9

EN Instruction Manual

[12]

INDEX

INDEX ................................................................................................................................... 12

MACHINE INTRODUCTION .................................................................................................. 13

2.1 INTRODUCTION TO MACHINE & MODELS .................................................................. 13

2.2 IMPORTANT SAFETY INFORMATION ........................................................................... 13

2.3 SPECIFICATION CHART ................................................................................................ 13

INSTALLATION ..................................................................................................................... 14

3.1 GENERAL INFORMATION ............................................................................................. 14

3.2 TRANSPORT, HANDLING, UNPACKING, LOCATION ..................................................... 14

3.3 INTENDED USE AND RESTRICTIONS. ........................................................................... 14

3.4 MANUFACTURER’S IDENTIFICATION LABEL DESCRIPTION. ........................................ 14

3.5 INSTALLATION AND ASSEMBLY ................................................................................... 15

3.6 CONNECTIONS ............................................................................................................. 15

OPERATION ......................................................................................................................... 16

4.1 GENERAL INFORMATION ............................................................................................. 16

4.2 CONTROL PANEL DESCRIPTION ................................................................................... 16

4.3 MACHINE SETTINGS AND PROGRAMS ........................................................................ 17

MAINTENANCE .................................................................................................................... 18

5.1 GENERAL SAFETY RULES .............................................................................................. 18

5.2 MACHINE CLEANING AND MAINTENANCE ROUTINE .................................................. 18

5.3 MACHINE DISPOSAL .................................................................................................... 18

TROUBLESHOOTING CHART ................................................................................................ 19

6.1 TROUBLESHOOTING CHART ........................................................................................ 19

EN Instruction Manual

[13]

MACHINE INTRODUCTION

2.1 INTRODUCTION TO MACHINE & MODELS

The purpose for which this equipment has been designed is to be built into a self-service buffet

and is specially conceived for the display and service of cold food, maintaining the food in the

best temperature condition during the period of time of the serving. Said conditions will depend

on the initial temperature of the products when displayed and the environmental conditions of

the premises. In no case can this technical appliance be used to freeze food.

The trays can house food pans of up to 100 mm in depth of 2 to 6 GN 1/1. If these pans are not

used the food can be displayed on the inside shelves of the tray, which is adjustable in height.

The technical cabinet located on the lower part includes the electricity panel, the regulating

thermostat and the condensing unit.

2.2 IMPORTANT SAFETY INFORMATION

The in-situ installation and start-up of this appliance must be carried out by qualified technical

personnel.

The technical parametres inside this manual are subject to change without notification.

The appliance must be only repaired by qualified personnel. Please contact your distributor and

do not attempt to open this appliance.

If the appliance is not going to be used for long periods of time, make sure it is empty, cleaned

and disconnected from the mains electricity supply.

The working temperature of the appliance may be affected by the ambient temperature and its

location.

Make sure that external sources do not influence the appliance that may prejudice its

performance (heating or direct sources of heat, air currents or similar).

The suitable ambient temperature is from +16ºC to +30ºC. If the premises exceed 32ºC the

necessary performance for a correct cooling is not guaranteed.

This appliance is made of stainless sheet steel and there are risks of cutting inherent in its design

and to being made of thin sheet steel. Please take extra special care when handling it and

cleaning the same.

The inside of the technical cabinet where the condensing unit located has intrinsic risks such as

electricity, cutting, trapping, burns and moving rotor (fan)..

The inside of the technical cabinet has intrinsic risks such as electricity, cutting, and burns.

Never place hot food or recipients in the appliance.

Keep the technical cabinet closed at all times.

Do not allow children to handle the appliance under any circumstances.

Keep to the recommendations made by the food manufacturers.

Do not pour liquids into the tray.

2.3 SPECIFICATION CHART

Please check Table 1 for detailed information of the product.

EN Instruction Manual

[14]

INSTALLATION

3.1 GENERAL INFORMATION

The use instructions of the digital thermostat are attached to this manual. However, WE DO NOT

RECOMMEND THE ADJUSTMENT OF THE THERMOSTAT BY UNQUALIFIED PERSONNEL. Please,

CONTACT YOUR DISTRIBUTOR IN ORDER TO HAVE THE NECESSARY ADJUSTMENTS CARRIED

OUT.

3.2 TRANSPORT, HANDLING, UNPACKING, LOCATION

The application with its packaging in wood makes a heavy item.

Be careful in transport, handling and location operations.

On receiving the device, make sure that it has not suffered any damage in transport. Otherwise,

make all pertinent claims to your supplier or to our company.

When the device has been accepted, it is preferable to keep it unpacked until it is put into service

in order to protect it from any possible mechanical knocks, dust, dirt, etc....

The packaging consists of a wooden palette, a plastic surround and wooden/cardboard corner

pieces, all recyclable materials

The warranty will only cover manufacturing defects, excluding any incorrect handling or use of

the material by the clients or users. Labour costs and travelling expenses are always on the

account of the client. Any responsibility for defects attributable to transport will not be

accepted, unless the relevant claim is placed within a maximum period of time of 24 hours after

receiving the goods.

For correct and safe lifting and handling operations:

Arrange a suitable area with flat floor for machine unloading and handling operations.

Use the type of equipment most suitable for characteristics and capacity

Make sure the load is stable;

Handle the machine, keeping it at minimum height from the ground.

3.3 INTENDED USE AND RESTRICTIONS.

Check that the voltage and frequency of the electricity supply network coincide with those

described in the characteristics plaque. It is essential that the electricity installation where the

appliance is to be installed has an earth connection, as well as the necessary protection of a

thermal magnetic switch and a circuit breaker. Do not connect other appliances in the same

electric socket.

The manufacturer declines any liability for improper use of the product.

3.4 MANUFACTURER’S IDENTIFICATION LABEL DESCRIPTION.

EN Instruction Manual

[15]

Data in the identification label:

1. Brand

2. Serial number (code+ year+ serial

number)

3. Code:

4. Model:

5. CE symbol

6. Waste disposal symbol

7. Manufacturing site

8. Gas Type

9. Gas quantity (gr)

10. Climatic class

11. Working range temperature:

12. Voltage:

13. Power consumption

3.5 INSTALLATION AND ASSEMBLY

Avoid having direct sources of heat, cold, humidity, sunlight and ultraviolet rays in the final

location of this appliance. Heaters, radiators, air conditioning, air currents etc. can have a

negative influence on the correct operation of the same.

Make sure the floor is level, in this way preventing any vibration or noise.

Make sure that the appliance has adequate ventilation. Do not block the ventilation grid of the

condensing unit.

Follow the instructions in Figure 1-2 to assembly the product in the selected location and make

the appropriate connections.

3.6 CONNECTIONS

Once the device has been fitted into the hole of the furniture destined for this purpose, the

anchoring is carried out by means of the anchoring system supplied as shown in the figure 3.

The condensing unit should be well ventilated for an optimum performance of

the cooling system. Please follow figure 7 for designing the furniture’s ventilation

grill.

The control box located on the lower part of the appliance can easily be moved to the side of

the technical cabinet if required (for example in the case of having the front access of the

appliance closed due construction reasons).

At the same time, it can be removed from the device and installed in any other panel (for

example, in the front of buffet to operate and regulate the appliance without need to open the

door). The control panel can be moved a maximum of 1.6m from the original position. This is

explained in figure 5. At the same time, the control panel can be assembled in other furniture,

for this purpose the hole described in figure 9 must be done in the panel.

In figures 4 it is explained how to move out the device from the furniture if maintenance or

repairement is required.

The drainage from the cold tray collects the liquid that may have been accidentally spilled, and

the evaporator defrosting water which on occasions and depending on the climate can be

EN Instruction Manual

[16]

considerable. Therefore, it is essential to connect said outlet to the drainage network. The

present appliance does not have a collection tray and automatic evaporation of said liquid.

REMOTE UNIT OPTIONAL

All refrigerated inlet is supplied in copper pipes, both for connecting the high pressure (liquid)

and low pressure (gas) lines of the refrigeration unit are sized 3/8”. It is not included the

thermostatic expansion valve, capillary tube, solenoid valve nor the cutoff valve.

The electrical connection socket for solenoid valve or refrigeration unit is provided by

connection terminals, located in the junction box for a maximum compressor power of 1 1/2 ".

For higher powers it is necessary to implement a relay or contactor, this element will not be

supplied.

OPERATION

4.1 GENERAL INFORMATION

This appliance carries out defrosting to get rid of the ice generated by the evaporator. It may be

necessary to sometimes slightly vary the default programme of said defrosting process due to

climate reasons and/or conditions in the premises.

If there is an excessive accumulation of ice on the evaporator or in the event of a lack of cooling

performance of the appliance, please contact your distributor for a diagnosis to be made and

assess if an adjustment in the defrosting programme is necessary.

See figure 8 for the thermostat information.

4.2 CONTROL PANEL DESCRIPTION

1- Display

2- Main On-Off buttom (except light)

3- Set

4- ECO function

5- Light On-Off

6- Programing and disconnect sound/ alarm

7- Up ▲

8- Down ▼, manual defrosting (only in refrigeration)

The machine is switched on by pushing the on-off bottom of the thermostat for 5 seconds. For

maintenance operations, disconnect the machine from the mains, because the machine is in

stand-by situation when it is switch off. In the refrigerated equipment, there is delay of 3 minutes

till the starting up, this delay is the protection programmed by default, it should not be modified by

the user.

The regulation is made by electronic thermostat with a digital display, allowing to adjust the

different working temperatures of the machine:

Pressing the SET (3) command for 1 second activates the set point to reach the desired

temperature value displayed on the Display (1). To do this, press the cursors (8 or 9) ▲ ▼ until

the desired temperature is reached. Once reached, press and hold the SET (3) command for 1

second to set the acquired value.

It is possible to activate the ECO mode (5) energy saving by pressing for 3 seconds this key.

When activated, ECO will appear in the display (1). To return to the normal state, perform the

same operation. This will display the word NOR in the display (1).

EN Instruction Manual

[17]

It is possible to activate or deactivate the light output by pressing the LIGHT (6) command for 1

second.

To access the sounds and alarms program (7), press and hold for more than 5 seconds. The

parameter setting menu (F) will appear in the display (1) or in case of alarms, the alarm will be

silenced and the alarm relay will be deactivated.

Pressing this command (7) and command ▲ (8) simultaneously for more than 5 seconds, all

alarms are reset.

Pressing this command (7) and the SET (3) command for more than 5 seconds simultaneously

accesses the parameter setting menu (C)

To change the parameters C or F once within the selected menu, move through the parameters

with the cursors ▲ (8) and ▼ (9) until you reach the parameter to be modified or the sound and

alarms key (7) to display the menu complete to reach the category more quickly. Pressing SET

(3) selects the category or parameter to modify and is modified by ▲ (8) and ▼ (9). Once all the

desired parameters are modified, they are memorized by pressing the sounds and alarms

command (7) for more than 5 seconds. If nothing is pressed in 60 s you lose the Co F menu by

losing data that has not been saved.

Pressing this command ▲ (8) and the SET (3) command simultaneously for more than 5 seconds

activates the printout of the report.

BASIC PARAMETERS MODIFIED BY THE USER.

"Pro"

Pw (Password): Default value 22.

/ 5 (Selection ºC or ºF): Default value ºC.

"CtL"

St (Setpoint): Default value per model. Modify if applicable.

"ALM"

AL (Low temperature alarm activation): Default value 0 (disabled).

AH (High temperature alarm activation): Default value 0 (disabled).

"CnF"

H2 (Keyboard Disable): Default value 1.

4.3 MACHINE SETTINGS AND PROGRAMS

COOLING SYSTEM:

The tray is equipped with a ventilated evaporator, which can be accessed for cleaning purposes

and repairs by opening the hinged lids which cover the same.

Table of contents