diamond mowers ALL AMERICAN DISC User manual

DIAMONDMOWERS.COM

3-POINT HITCH

ALL AMERICAN DISC

OPERATOR’S MANUAL

PRODUCT INFORMATION

Record the model and serial number of your unit here. When calling for

warranty, service or parts, you may be asked to provide this information,

in order to ensure fast, accurate service.

MODEL:All American Disc

SERIAL NUMBER:___________________________________________________

© Diamond Mowers, LLC

All rights reserved.

Any failure to read, understand and follow the instructions found in this operator’s

manual could lead to serious injury. Operators who choose to operate this equipment

without following instructions, or who choose to operate this equipment in a manner

inconsistent with the recommendations set forth in this manual, do so at their own

risk and assume the risk of injury. Diamond Mowers will not be liable for an owner

or operator’s loss, damage, or injury due to the misuse of the equipment, failure to

understand the inherent risks, or inability to properly operate the equipment.

2

WELCOME!

Thank you for choosing Diamond Mowers, and welcome to your All American

Disc. Before you begin operating, we encourage you to look through this

manual to review the proper maintenance and operating techniques that will

keep you, and your equipment, safe — while ensuring you the most productive

road grader in the market.

We have nothing but respect and admiration for you. Our job at Diamond is

to provide you with the toughest, most reliable and safest equipment that

will allow you to do your job better. That also means being there when you

need us.

CONTACT US:

Parts: 888.960.0361 | parts@diamondmowers.com

Main Office:800.658.5561 | 605.977.3300

Website: www.diamondmowers.com |Email: inf[email protected]

Your time is important to us.

We guarantee that Genuine Diamond Parts will ship within 72-hours of the

order being placed or the parts and shipping are free.

Your satisfaction is guaranteed.

If you are not completely satisfied with your new Diamond in the first

30-days, we will buy it back. No questions asked.

Thanks again for choosing Diamond.

If at any time your needs are not being met by our team, please feel free

to call me direct.

Tim Kubista

VP Sales & Marketing

651.955.6665

OWNER REGISTRATION

In your welcome packet you should have received a warranty registration

form. Complete and return this form to our main office. It’s a self-mailer,

so no postage is required.

If you’d rather complete this info online, go to:

http://info.diamondmowers.com/register-my-product

Returning your registration information to Diamond will help us process any

warranty claims quickly and efficiently – so you can get back to work, fast.

TRANSFERRED OWNERSHIP

If you have acquired this All American Disc from a previous owner, we

encourage you to register your equipment online. By registering your

Diamond Mowers unit, you’ll stay informed on product advancements,

offers and service alerts.

Register by going to: http://info.diamondmowers.com/register-my-product

We honor our equipment’s warranty from the date it was put into service,

no matter who’s in charge of running it.

For any questions, contact our Warranty / Service team at:

888.960.0364 or 605.977.3300

PRODUCT REGISTRATION

4

INTENDED USE 6

TAKE A LOOK AROUND 7

GETTING STARTED 8

OPERATING THE ALL AMERICAN DISC 10

MAINTENANCE 14

TROUBLESHOOTING 17

PARTS BOOK 19

INDEX 27

TABLE OF CONTENTS

INTENDED USE

Do not operate this unit without first reading the safety precautions

and operating instructions in this manual.

This attachment is designed to be used for the grading of gravel

road shoulder applications.

This includes:

•Removing berms along the roadside edge.

•Reclaim gravel lost during grading.

•Removing clumps of rooted material along the transition of road to ditch.

•Contouring asphalt shoulders.

This attachment should only be used in an area free of obstructions and

bystanders. Any use on non-vegetative material, or in an area that is not

clear of persons and property, is strictly prohibited. Any use outside of the

aforementioned application is considered contrary to its intended use. Any

damage that may occur as a result of misuse will void warranty as stated in

Diamond Mowers’ warranty policy.

Do not operate this unit without first reading the safety precautions

and operating instructions in this manual.

6

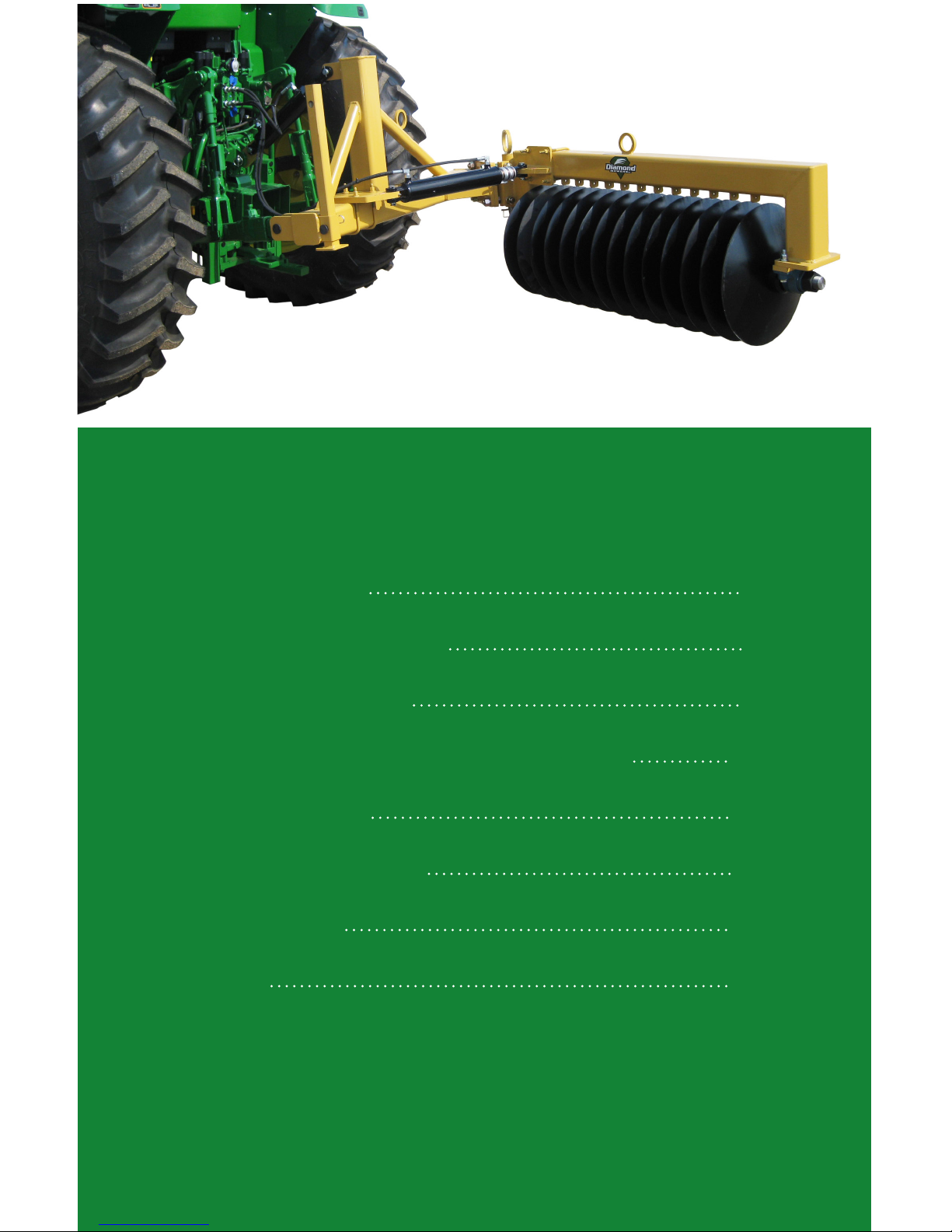

TAKE A LOOK AROUND

DISC HOUSING

The disc housing contains (14) 22”

(559mm) hardened steel convex

discs, for long life with

superior performance.

HITCH FRAME

The unit includes an easy to mount

hitch frame, compatible with all

category II 3-Point hitches.

SWING CYLINDER (OPTIONAL)

An optional swing cylinder is

available; allowing the operator

to swing the disc housing in for

storage and transport, or out for

cutting operations.

PITCH CYLINDER

Standard equipment is a hydraulic

cylinder that controls the pitch

of the disc housing, allowing the

operator to control the angle and

depth of the cutting discs for

optimum performance.

7

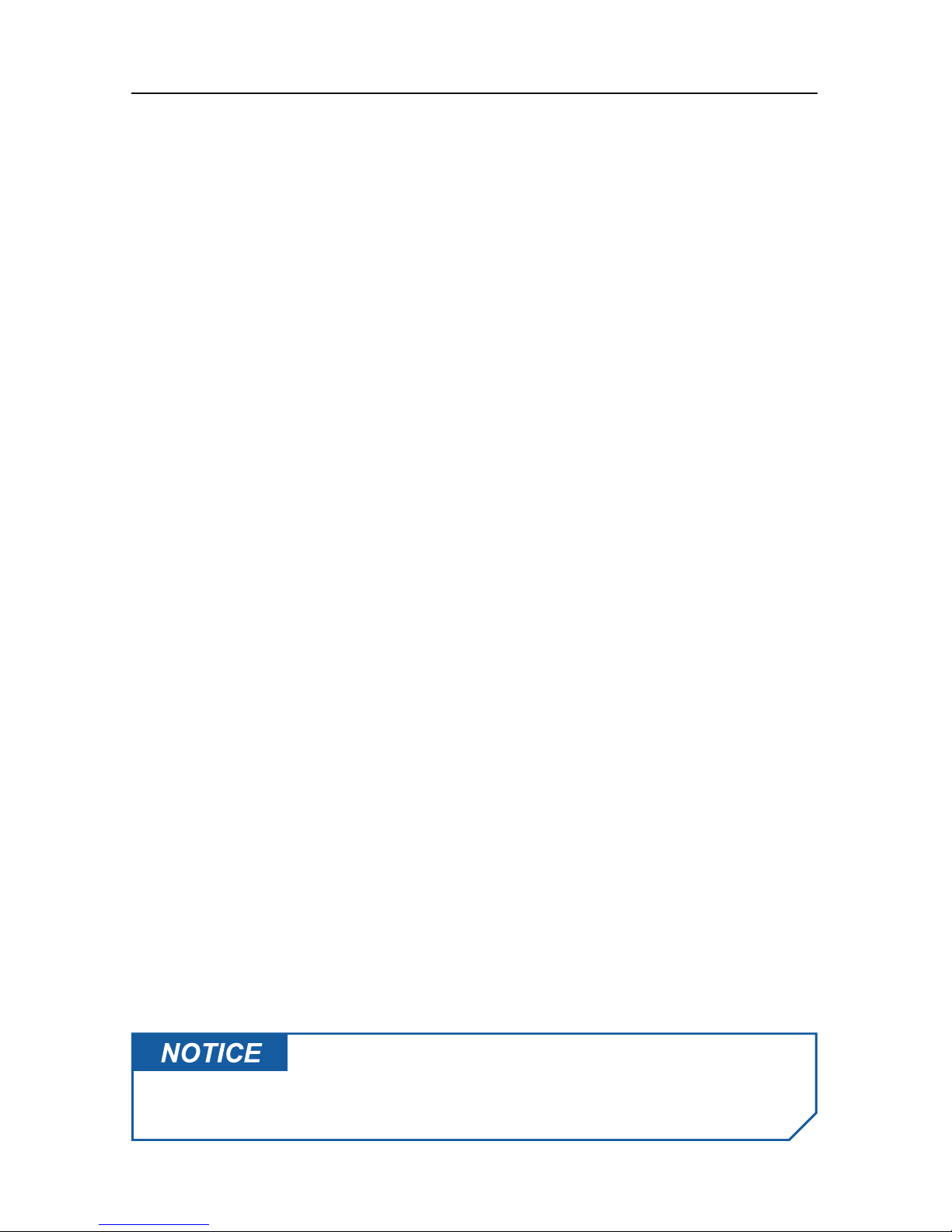

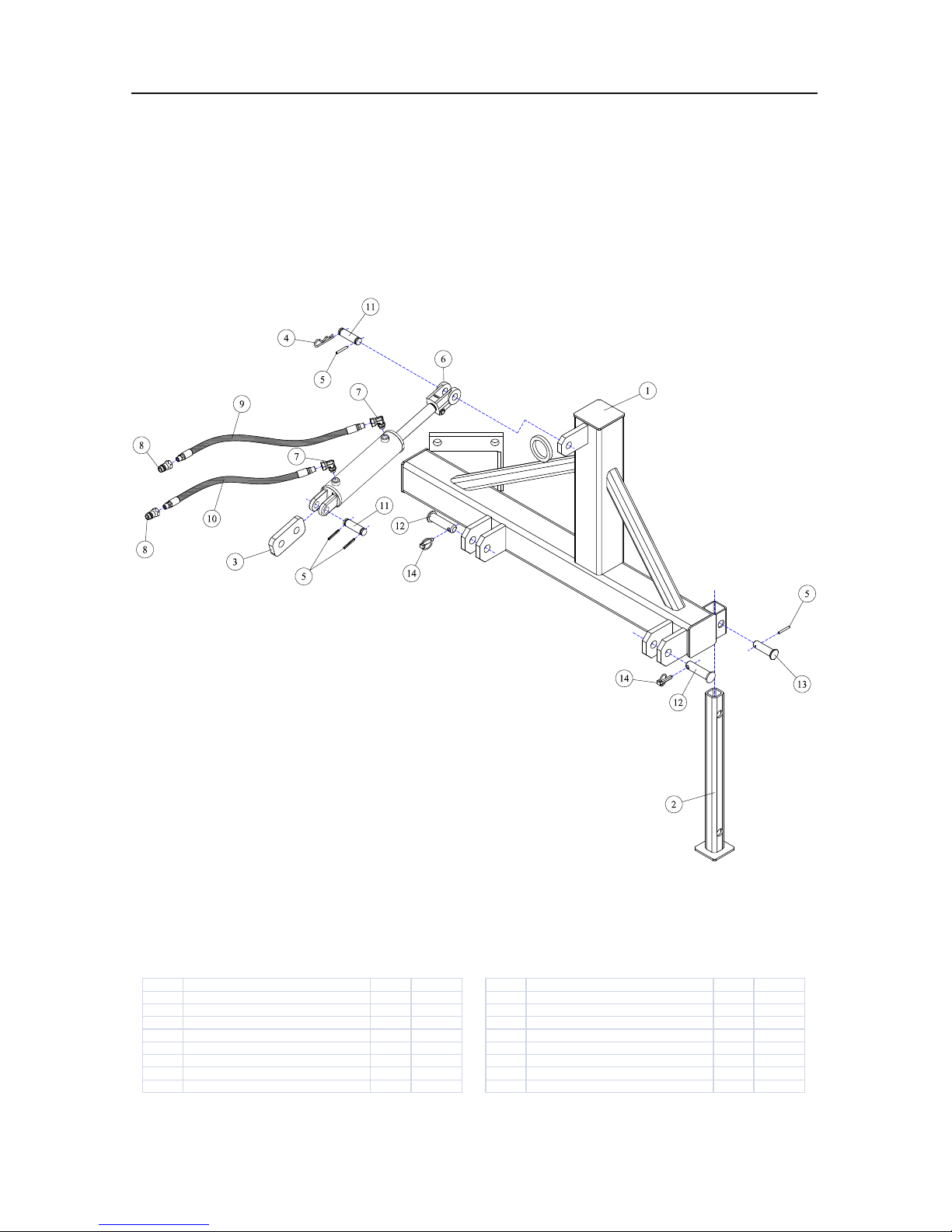

GETTING STARTED

MOUNTING THE DISCS

Reference the tractor’s operator manual

for information on adjusting the draft

links(1) and anti-sway bars/spacers(2)(3) (if

present) on the tractor’s 3-Point hitch.

This unit requires a Catagory II hitch.

•Adjust the 3-Point hitch draft links(1)

to the fixed (non-floating) position.

◦NOTE: Draft links vary in

appearance for various

tractor models (if present).

•Replace the factory 3-Point upper

hitch link with the cylinder link(4).

•Mount the pitch cylinder(5) to the

cylinder link(4) with its hardware.

◦NOTE: Reference the parts pages

for additional clarification.

•Connect draft beams “A”(6) and “B”(7)

and the pitch cylinder(5) to the hitch

frame(8) with the QD pins and lynch

pins.

•Raise the stand(9) and secure it in

place with its pin and lynch pin.

◦NOTE: lower the stand when

removing the All American Disc

from the tractor.

•Connect the hydraulic hoses(10) to

the tractor’s auxiliary remotes.

•Adjust the 3-Point hitch anti-sway

bars/spacers(11)(12) to minimize

horizontal sway of the discs.

◦NOTE: Anti-sway bars/spacers

vary in appearance for various

tractor models (if present).

(1)

(11) (12)

(5)

(10)

(4)

(6)

(7)

(5) (9)

(8)

8

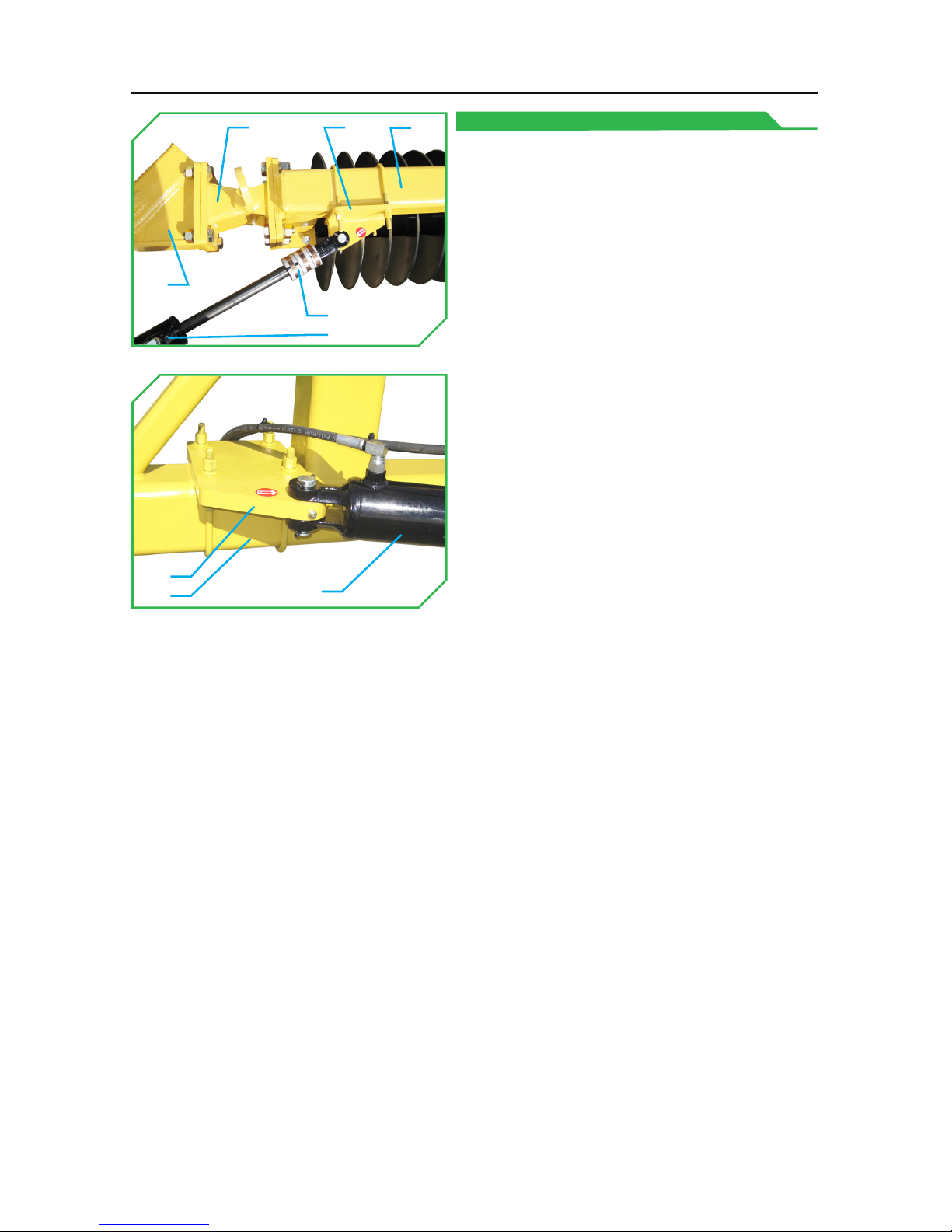

MOUNTING THE SWING CYLINDER

The swing cylinder is OPTIONAL, and

may not be present. Reference the parts

pages in this manual for additional

clarification.

•Unbolt the disc housing(13) from the

hitch frame(14).

•Mount the swivel assembly(15)

between the disc housing(13) and

hitch frame(14).

•Mount the base anchor(18) to the

hitch frame(14).

•Mount the base end of the swing

cylinder(19) to the base anchor(18).

•Swing the disc housing(13) until the

swivel assembly(15) is straight.

•Mount the rod anchor(16) to the

disc housing(13).

◦DO NOT tighten the hardware

securing the rod anchor(16) to the

disc housing(13) at this time.

•Connect the rod end of the swing

cylinder(19) to the rod anchor(16).

•Extend the swing cylinder(19) rod to

full extension.

◦Keep the disc housing(13) in its

straight orientation, and allow

the rod anchor(16) to slide down

the length of the disc housing(13)

as needed for the swing

cylinder(19) rod to be at

full extension.

•Secure the rod anchor(16) to the

disc housing(13). Place the spacers(17)

onto the swing cylinder(19) shaft.

(14)

(13)

(17)

(16)

(15)

(14)

(18)

(19)

(19)

9

OPERATING THE ALL AMERICAN DISC

CONTINUED ON NEXT PAGE

Before you operate, note that the primary responsibility for safety on this

equipment falls to the operator. Only trained individuals who have read and

understood this manual should operate this unit.

If any portion of this manual is not understood, contact:

Diamond Mowers’ Service/Warranty at 888.960.0364 or 605.977.3300.

Be sure to read all warnings carefully. They are included for your safety,

and for the safety of others working with you.

SAFETY TIPS

Indicates where SERIOUS injury or death WILL result if instructions

are not followed.

Indicates where SERIOUS injury or death COULD result if instructions

are not followed.

Indicates where MINOR injury COULD result if instructions are

not followed.

Indicates a property damage hazard ONLY, no PERSONAL injury.

•Always wear personal protective equipment (safety glasses, goggles,

etc.), when operating.

•Operate only from the operator’s station.

•Clear the work area of obstructions and safety hazards.

•Bystanders must keep a distance of 300ft/100m from the unit

when operating.

•Discs are always sharp and can cause injury, even when not

in motion.

•DO NOT use extremities to dislodge debris from the cutting discs.

10

•Hydraulic fluid is hot and will heat any exposed steel, hoses, motor, or

spindle in its proximity.

•Make certain hoses are out of the way and will not snag on vegetation

and debris.

•Be certain to come to a complete stop and all motion is ceased before

exiting the cab.

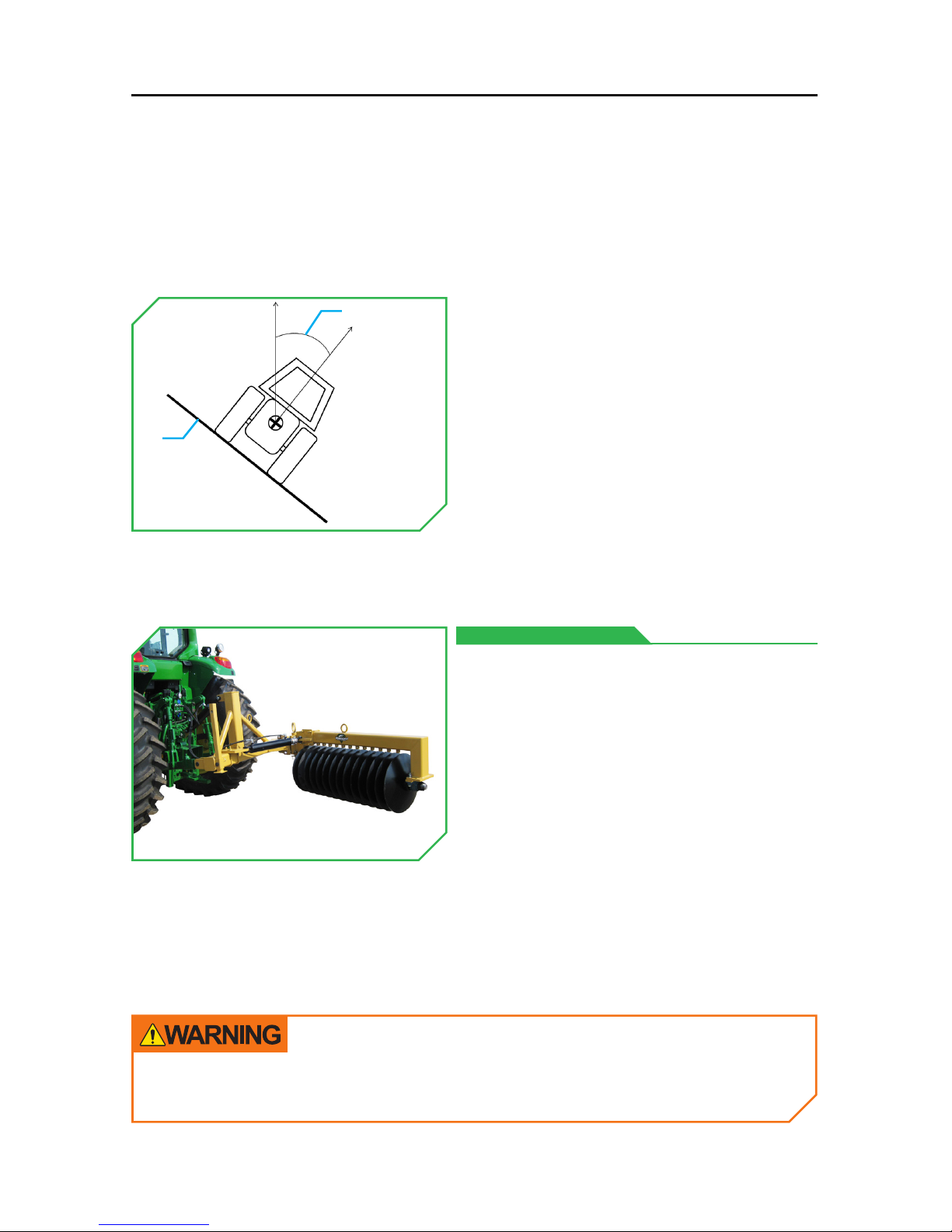

When transporting Diamond’s All

American Disc between operations,

make sure to protect it from collisions

and accidental damages by placing it in

the stowed position.

Failure to place the head in its stowed

position could result in

structural damage.

STOWED POSITION

•EXTREME CAUTION should be used

when operating on slopes(1) greater

than 25°(2). It is the operator’s

responsibility to properly counter-

balance the vehicle and machine to

prevent rollover.

Contact with the cutting discs while the All American Disc is in

operation can result in serious injury or death.

(2)

(1)

11

OPERATING THE ALL AMERICAN DISC

DISCING

CONTINUED ON NEXT PAGE

Use to reclaim road shoulder material.

•Start the tractor and raise the engine RPM’s to operating speed.

•Extend the optional swing cylinder (if present) until the disc housing(1) is

at full extension(2).

•Use the pitch cylinder to adjust the pitch(3) of the cutting discs.

◦The pitch of the cutting discs should allow the rearmost disc to enter

the soil before the lead disc when the discs are lowered into the soil.

◦DO NOT exceed a maximum of 15° difference in height between the

rearmost and lead cutting disc.

•Lower the cutting discs into the ground, but do not exceed 1” (25mm)

cut depth.

◦DO NOT cut sod with the lead blade! This indicates either there is

not enough pitch or the cutting depth is too deep, and will result

in peeling large clumps of sod; this is undesireable. Cutting is

accomplished with the other blades.

-Adjust your pitch as needed to prevent cutting with the lead disc.

(2)

(1)

(3)

12

•Begin discing the road shoulder at a steady pace (10MPH/16KMH)

maximum for gravel roads, less for hard surfaced roads.

◦Keeping the speed even and constant will allow the cutting discs to

feather the material evenly.

-It is recommended to allow the material to dry for a minimum of

two to three days, longer if there is precipitation, before discing.

Dry material grades easier than wet material.

-A roller will help on hard surfaced road shoulders. It is suggested

to disc, roll, grade, and then do a final roll for best results on hard

surfaced road shoulders.

-Always grade after the first pass of the discs.

DO NOT make multiple passes of the cutting discs and then

attempt to grade; there will be too much material to grade

effectively.

For more tips, visit us online at www.DiamondMowers.com

Lowering the cutting discs too deep into the soil can damage the road

shoulder, and can cause damage to the cutting discs, housing, and

hitch frame.

13

MAINTENANCE

Regular maintenance will make certain your unit stays productive and retains

a long operating life. The following chart represents the minimum intervals

recommended for inspection and maintenance.

MAINTENANCE INTERVALS

PROCEDURE 10 HOURS/DAILY

BEARINGS Inspect/Grease

HITCH FRAME Inspect

SWING CYLINDER (OPTIONAL) Grease

SWIVEL Grease

When replacing parts, use Genuine Diamond Parts. Guaranteed to ship within

72-hours of your order being placed, or the parts and shipping are free.

Call: 888-960-0361 or 605.977.3300 | Email: [email protected]

Order online: www.diamondmowers.com

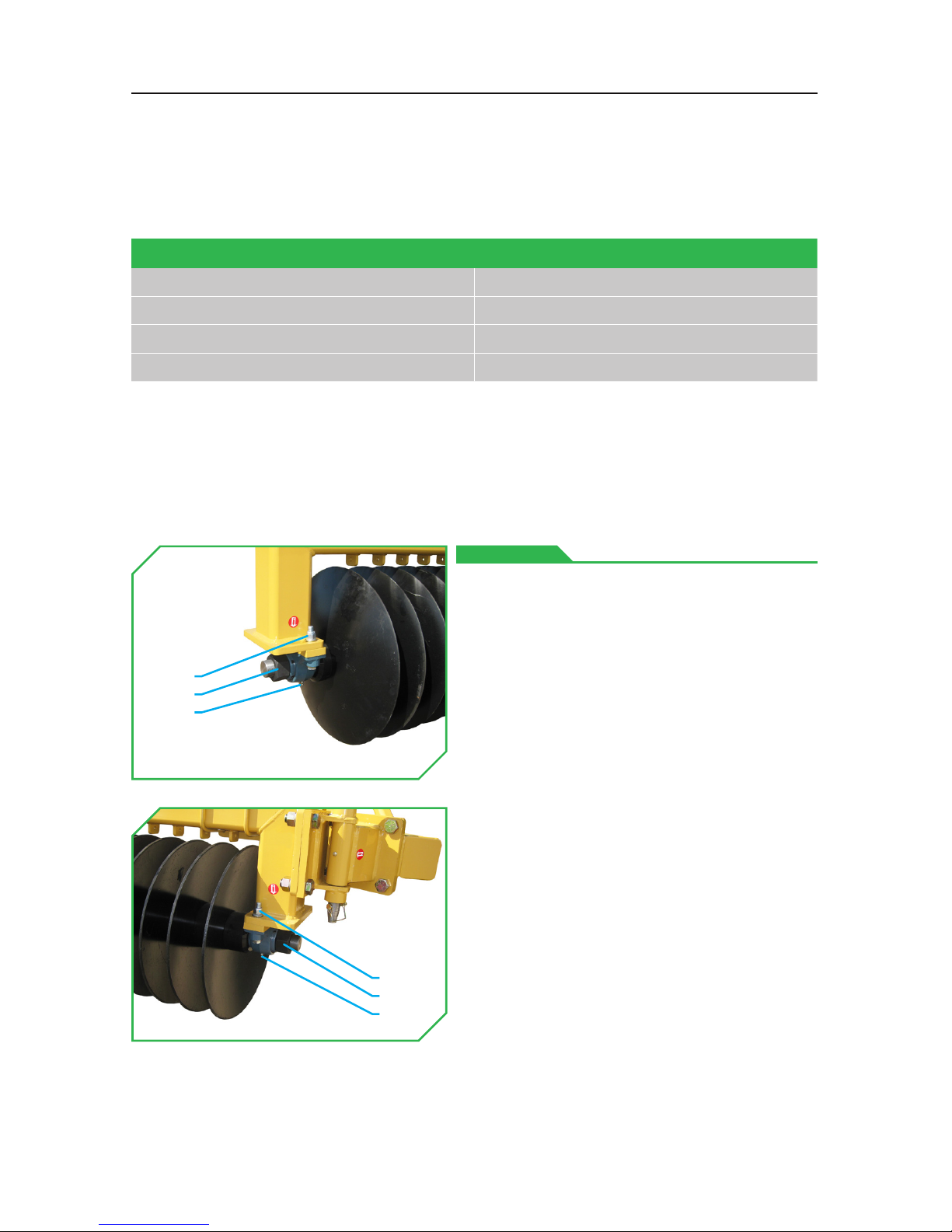

BEARINGS

•Inspect the hex nuts(1) on the disc

axle for loosening every 10 hours or

daily.

◦If hex nuts(1) are loose, torque

them with an impact wrench to

1500ft-lbs (2034Nm), or until

the discs are “ringing” from the

impact wrench.

•Inspect the mounting hardware(2)

for the axle bearings for loosening

every 10 hours or daily.

◦If mounting hardware(2) are loose,

torque them to

240ft-lbs (325Nm).

•Grease the zerks(3) on the axle

bearings until grease comes out

around the bearing axle bosses

every 10 hours or daily.

◦Use #2 lithium based grease.

(3)

(3)

(1)

(2)

(1)

(2)

14

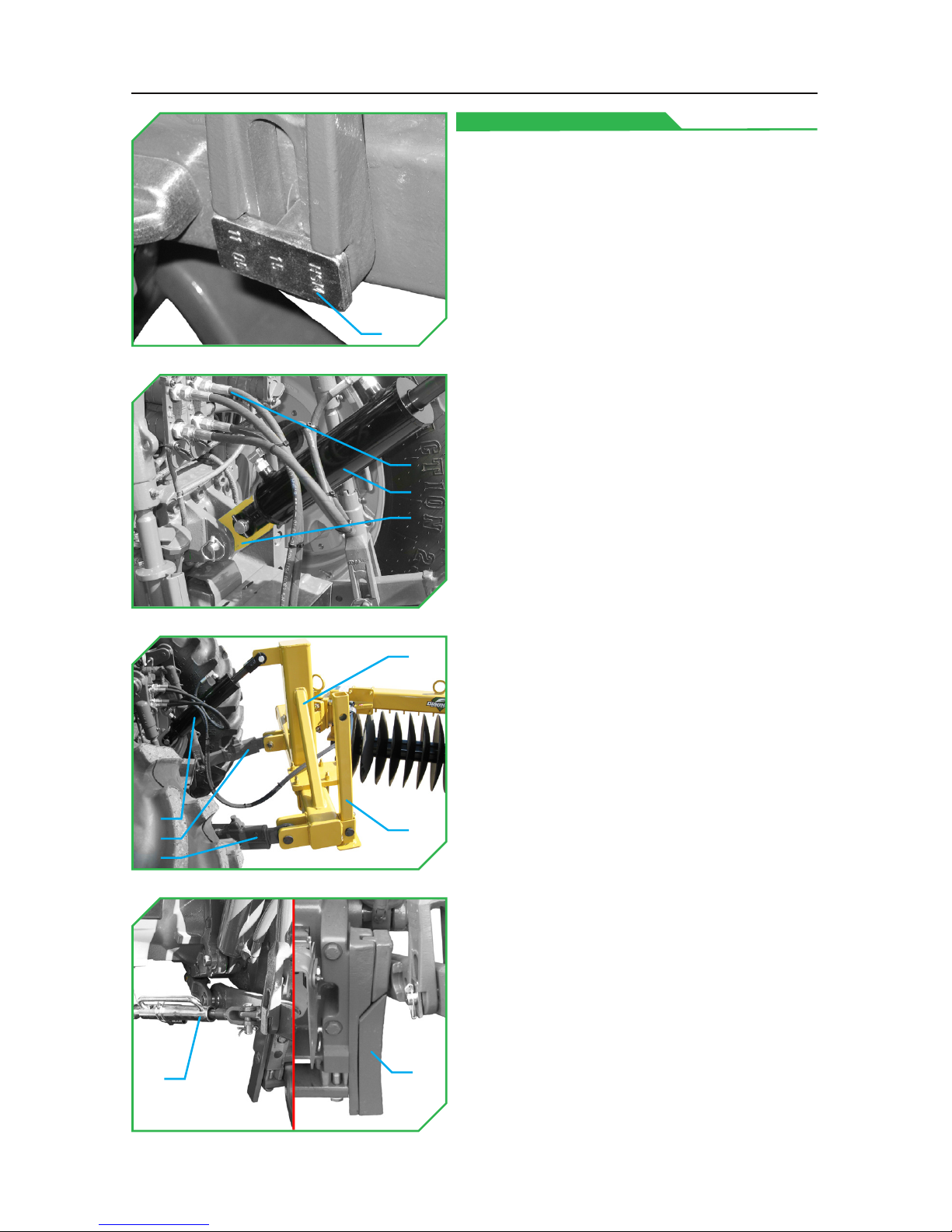

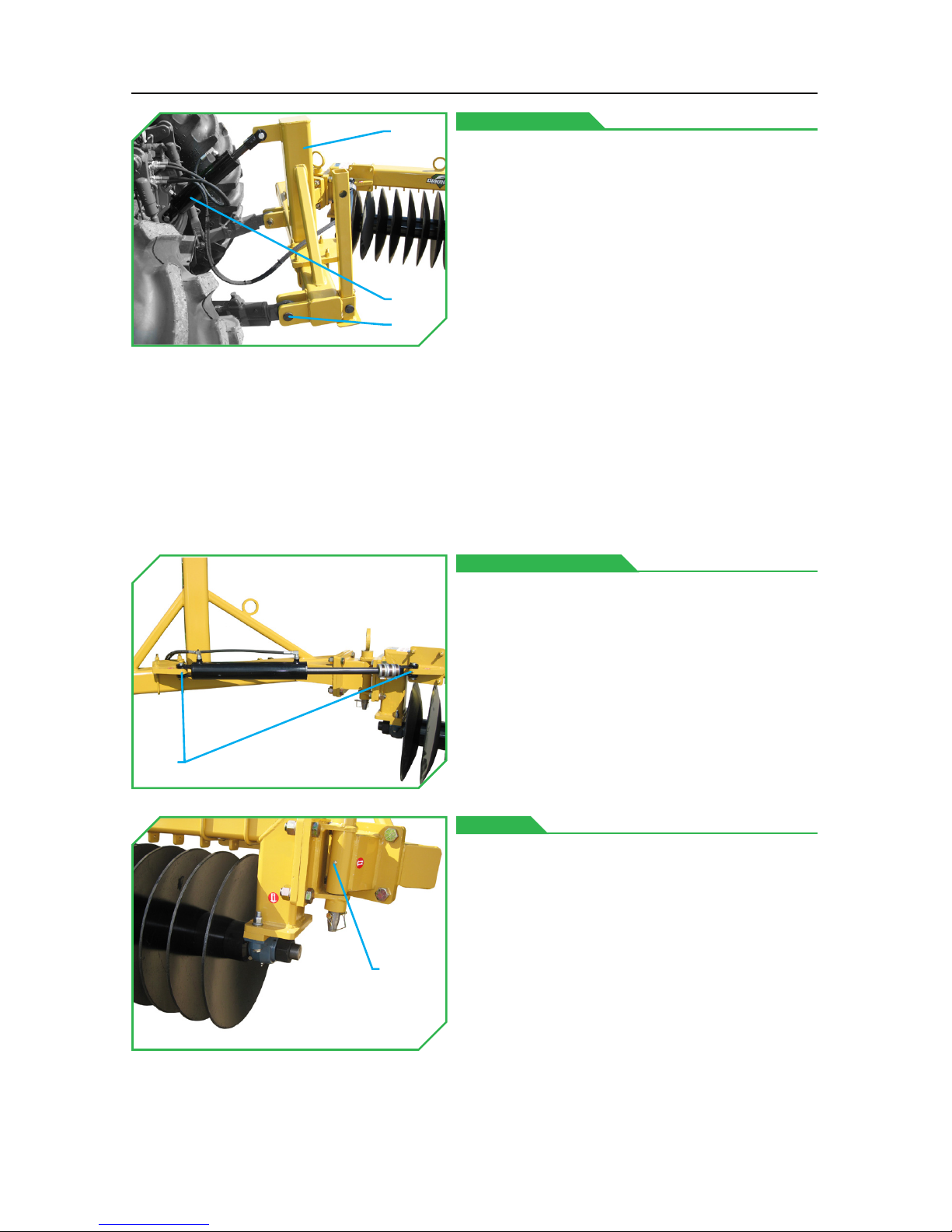

SWING CYLINDER

HITCH FRAME

SWIVEL

•Inspect the hitch frame(6) every 10

hours or daily before using

the implement.

Check the following:

◦Quick disconnect pins(4) and their

lynch pins.

◦Pitch cylinder(5), hardware, and

connections are in good repair.

◦Hitch frame(6) is in good repair.

-No stress cracks.

-No bent frame or components.

-No loosened hardware.

•OPTIONAL feature.

•Grease the zerks(7) every 10 hours or

daily on the swing cylinder anchors

until grease comes out around the

swing cylinder/anchor connections.

◦Use #2 lithium based grease.

•Grease the zerk(8) every 10 hours

or daily on the swivel until grease

comes out around the

swivel bosses.

◦Use #2 lithium based grease.

(4)

(7)

(8)

(6)

(5)

15

MAINTENANCE

(This Page Is Intentionally Left Blank)

16

TROUBLESHOOTING

For any questions, contact our Warranty / Service team at

888.960.0364 or 605.977.3300

PROBLEM POTENTIAL CAUSE SOLUTION

Disc Will Not Lift

Hydraulic cylinder

lift lines are not

connected

Connect the hydraulic cylinder lift

lines as instructed in this

operator’s manual.

Hydraulic cylinder or

hose leaks

Tighten hose connections.

Repair leaky cylinders and hoses.

Hydraulic cylinder

faulty

Repair or replace faulty cylinder.

Tractor 3-Point hitch

not working

Reference tractor operator manual for

troubleshooting the 3-Point

hitch system.

PROBLEM POTENTIAL CAUSE SOLUTION

Excessive

Vibration

Tractor 3-Point hitch

lower draft beam

float links set to

float (if equipped)

Place the tractor’s 3-Point hitch lower

draft beam float links to their

fixed position.

Loose hardware

Torque all hardware to the

recommended torque specifications

for that hardware.

Cutting blades are

employed too deep,

or at the wrong pitch

Verify the cutting blades are being

employed as recommended in the

operator’s manual.

Cutting assembly

is damaged or

unbalanced

Replace damaged blades.

Remove any debris (wire, etc.)

entangling the cutting

assembly.

17

(This Page Is Intentionally Left Blank)

TROUBLESHOOTING

18

PARTS BOOK

19

REF# PARTS DESCRIPTION REQ PART #

1 3-POINT FRA M E 1 1014

2 3-POINT STAND 1 1020

3 CENT ER LINK BRA CKET 1 1028

4 3/16 R-CLIP 1 11-2001

5 ROLLPIN 4 11-2005

6 3 X 10 W ELDED CYLINDER 1 14-0001

7 1/2ADJ-OR X 1/2FPX-90DEG 2 21-1119

REF# PARTS DESCRIPTION REQ PART #

8 1/2 MALE QUICK COUPLER 2 21-2119

9 HOSE 1/2 X 36 (1/2MP X 1/2MP) 1 21-2702

10 HOSE 1/2 X 24 (1/2MP X 1/2MP) 1 21-2706

11 CLEVIS PIN 2 27-0004

12 3-POINT PIN 2 27-0016

13 STAND PIN 1 27-0019

14 LYNCH PIN 2 27-1005

PARTS BOOK

HITCH FRAME, CATEGORY II 3-POINT

All American Disc

20

Table of contents