DIAQUIP QHS-400 User manual

QHS-400 ELECTRIC HANDSAW

OPERATORS MANUAL

21

20

22

OPTION

North America: 20 A,

/02 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /03

TECHNICAL DATA

Power Input

Voltage

Rated speed/ min-1

Blade Diameter

Arbor

North America: 115V~60Hz, Other Regions: See Machine Nameplate

n=3900 min-1

400mm (16”)

25.4 (1”)

Max. Cutting Depth

Weight

Dimensions

Vibrations (excl. blade)

Sound Power Level

No Load Speeds

150mm (6”)

9.1kg, 10kg with guide rollers

735mm x 259mm x 364mm

3.0 m/s2- rear handle 3.9 m/s2- front handle

116.0dB (A) - (LWA) 105.0dB (A) - (LPA)

3900min-1

GENERAL SAFETY INSTRUCTIONS

WARNING! Read all safety warnings and all instructions. Failure to follow the

warningsandinstructionsmayresultinelectricshock,reand/orseriousinjury.

ORIGINAL INSTRUCTIONS: For your personal safety, read and understand before using.

Save these instructions for future reference

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains operated (corded) power tool or

battery-operated (cordless) power tool.

General Power Tool Safety Warnings - Work Area Safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence

ofammableliquids,gasesordust.Power tools create sparks which may ignite

the dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

General Power Tool Safety Warnings - Electrical Safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodied

plugs and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is unavoidable, use a PRCD or

ground fault circuit interrupter (GFCI) protected supply.

Use of a GFCI reduces the risk of electric shock.

Other Regions

110-120V:2300W certicate (3000W actual)

220-240V: 2700W certicate (3200W actual)

12

1. Water Feed Nozzle

2. Blade Guard Locking Lever

3. Load Warning Lamp

4. Release Button

5. Main Handle

6. Trigger Switch

7. Brush Cover

8. Guide Roller Assembly

9. Buttery Bolt

10. Side Handle

11. Arbor Lock Button

12. Water Feed Valve

13. Toggle Latches

14. Blade Guard

15. Arbor Bolt

16. Outer Flange

17. 400mmØ Diamond Blade

18. Blade Guard Brush

19. Vacuum Port

20. Splash Guard

21. Male Clip

22. Female Clip

1

2

3

45

6

7

8

9

10

11

13

14

15

16

17

18

19

TECHNICAL DATA

/04 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /05

GENERAL SAFETY INSTRUCTIONS

General Power Tool Safety Warnings - Personal Safety

a. Stay alert, watch what you are doing and use common sense when operating a

powertool.Donotuseapowertoolwhileyouaretiredorundertheinuence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b.Usepersonalprotectiveequipment.Alwaysweareyeprotection.Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before

connectingtopowersourceand/orbatterypack,pickinguporcarryingthe

tool. Carrying power tools with your nger on the switch or energising power tools

that have the switch on invites accidents.

d.Removeanyadjustingkeyorwrenchbeforeturningthepowertoolon.A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f. Dressproperly.Donotwearlooseclothingorjewellery.Keepyourhair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

GENERAL SAFETY INSTRUCTIONS

General Power Tool Safety Warnings -

Power Tool Use And Care

a. Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c.Disconnecttheplugfromthepowersourceand/orthebatterypackfromthe

powertoolbeforemakinganyadjustments,changingaccessories,orstoring

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc., in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

/06 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /07

GENERAL SAFETY INSTRUCTIONS

General Power Tool Safety Warnings - Service

a.Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidentical

replacement parts. This will ensure that the safety of the power tool is maintained.

Symbols used in this manual

V…….......Volts

A…….......Amperes

Hz…….....Hertz

W……......Watt

~………....Alternating current

no……….. Rated speed

min-1….....Revolutions or reciprocation per minute

.....Warning of general danger

.....Read these instructions

.....Always wear eye protection

.....Always wear a dust mask.

.....Always wear hearing protection

.....Wear safety-approved hard hat

.....DANGER! Keep hands away from cutting area and the blade.

Do not dispose of electric tools, accessories and

packaging together with household waste material

SAFETY INSTRUCTIONS FOR

CUTTING-OFF OPERATIONS

Cut-off machine safety warnings

a. The guard provided with the tool must be securely attached to the power tool

and positioned for maximum safety, so the least amount of wheel is exposed

towards the operator. Position yourself and bystanders away from the plane

of the rotating wheel. The guard helps to protect the operator from broken wheel

fragments and accidental contact with wheel.

b. Use only diamond cut off wheels for your power tool. Just because an

accessory can be attached to your power tool, it does not assure safe

operation.

c.Theratedspeedoftheaccessorymustbeatleastequaltothemaximum

speed marked on the power tool. Accessories running faster than their rated

speed can break and y apart.

d. Wheels must be used only for recommended applications. For example: do

not grind with the side of a cut-off wheel. Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to these wheels may cause them to shatter.

e.Alwaysuseundamagedwheelangesthatareofcorrectdiameterforyour

selected wheel. Proper wheel anges support the wheel thus reducing the

possibility of wheel breakage.

f. The outside diameter and the thickness of your accessory must be within

the capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

g.Thearborsizeofwheelsandangesmustproperlytthespindleofthepower

tool. Wheels and anges with arbor holes that do not match the mounting hardware

of the power tool will run out of balance, vibrate excessively and may cause loss of

control.

h. Do not use damaged wheels. Before each use, inspect the wheels for chips

and cracks. If power tool or wheel is dropped, inspect for damage or install an

undamaged wheel. After inspecting and installing the wheel, position yourself

and bystanders away from the plane of the rotating wheel and run the power

tool at maximum no load speed for one minute. Damaged wheels will

normally break apart during this test time.

/08 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /09

SAFETY INSTRUCTIONS FOR

CUTTING-OFF OPERATIONS

Cut-off machine safety warnings (continued)

i. Wearpersonalprotectiveequipment.Dependingonapplication,useface

shield, safety goggles or safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and shop apron capable of stopping small

abrasive or workpiece fragments. The eye protection must be capable of

stopping ying debris generated by various operations. The dust mask or respirator

must be capable of ltrating particles generated by your operation. Prolonged

exposure to high intensity noise may cause hearing loss.

j. Keepbystandersasafedistanceawayfromworkarea.Anyoneenteringthe

workareamustwearpersonalprotectiveequipment.Fragments of workpiece

or of a broken wheel may y away and cause injury beyond immediate area of

operation.

k. Hold the power tool by insulated gripping surfaces only, when performing an

operation where the cutting accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a “live” wire may make exposed metal parts of

the power tool “live” and could give the operator an electric shock.

l. Position the cord clear of the spinning accessory. If you lose control, the cord

may be cut or snagged and your hand or arm may be pulled into the spinning

wheel.

m. Never lay the power tool down until the accessory has come to a complete

stop. The spinning wheel may grab the surface and pull the power tool out of your

control.

n. Do not run the power tool while carrying it at your side. Accidental contact with

the spinning accessory could snag your clothing, pulling the accessory into

your body.

o. Regularly clean the power tool’s air vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause

electrical hazards.

p. Donotoperatethepowertoolnearammablematerials.Sparks could ignite

these materials.

SAFETY INSTRUCTIONS FOR

CUTTING-OFF OPERATIONS

Cut-Off Machine Safety Warnings -

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel. Pinching or

snagging causes rapid stalling of the rotating wheel which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the wheel’s rotation at

the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge

of the wheel that is entering into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

a.Maintainarmgriponthepowertoolandpositionyourbodyandarmtoallow

you to resist kickback forces. Always use auxiliary handle, if provided, for

maximumcontroloverkickbackortorquereactionduringstart-up.The

operator can control torque reactions or kickback forces, if proper precautions

are taken.

b. Never place your hand near the rotating accessory. Accessory may kickback

over your hand.

c. Do not position your body in line with the rotating wheel. Kickback will propel

the tool in a direction opposite to the wheel’s movement at the point of snagging.

d. Use special care when working corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or kickback.

e. Do not attach a saw chain, woodcarving blade, segmented diamond wheel

with a peripheral gap greater than 10 mm or toothed saw blade. Such blades

create frequent kickback and loss of control.

f. Donot“jam”thewheelorapplyexcessivepressure.Donotattempttomake

an excessive depth of cut. Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut and the possibility of

kickback or wheel breakage.

/10 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /11

SAFETY INSTRUCTIONS FOR

CUTTING-OFF OPERATIONS

Cut-Off Machine Safety Warnings -

Kickback and Related Warnings (continued)

g. When wheel is binding or when interrupting a cut for any reason, switch off

the power tool and hold the power tool motionless until the wheel comes to

a complete stop. Never attempt to remove the wheel from the cut while the

wheel is in motion otherwise kickback may occur. Investigate and take corrective

action to eliminate the cause of wheel binding.

h. Do not restart the cutting operation in the workpiece. Let the wheel reach full

speed and carefully re-enter the cut. The wheel may bind, walk up or kickback if

the power tool is restarted in the workpiece.

i. Support panels or any oversized workpiece to minimize the risk of wheel

pinching and kickback. Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

j. Useextracautionwhenmakinga“pocketcut”intoexistingwallsorother

blind areas. The protruding wheel may cut gas or water pipes, electrical wiring or

objects that can cause kickback.

SAFETY INSTRUCTIONS FOR

CUTTING-OFF OPERATIONS

Cut-Off Machine Safety Warnings - Additional Safety Rules

WARNING: Avoid cutting in the upper

quadrantoftheblade,especiallywhen

beginning the cut. This area is highly

likely to lead to kickback.

WARNING: When cutting plastics, do

not allow the plastic to melt. If the plastic

melts, it can stick to the blade, leading

to kickback.

TABLE A – REQUIRED GAUGES FOR EXTENSION CORDS

Ampere Rating

More Than

12

Not More Than

16

Volts

110-120

220-240

Total length of cord in feet

25(8m)

50(15m)

14(2.5mm2)

50(15m)

100(30m)

12(4.0mm2)

100(30m)

150(50m)

150(50m)

300(100m)

Minimum gauge for cord (AWG)

Not Recommended

/12 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /13

GROUNDING INSTRUCTIONS

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This tool is equipped with an

electric cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not t the outlet, have the proper outlet installed

by a qualied electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualied electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3 pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cord immediately.

GROUNDING INSTRUCTIONS

2. Grounded, cord-connected tools intended for use on a supply circuit

having a nominal rating less than 150 V:

This tool is intended for use on a circuit that has an outlet that looks like those

illustrated below.

Should an alternative connection type need to be used, please consult local advice and

guidance to the country of use, to ensure appropriate and effective electrical compliance is

maintained for maximum safety and protection to the user, and the immediate work area

and its occupants.

Note: In Canada, the use of a temporary adapter is not permitted by the

Canadian Electrical Code.

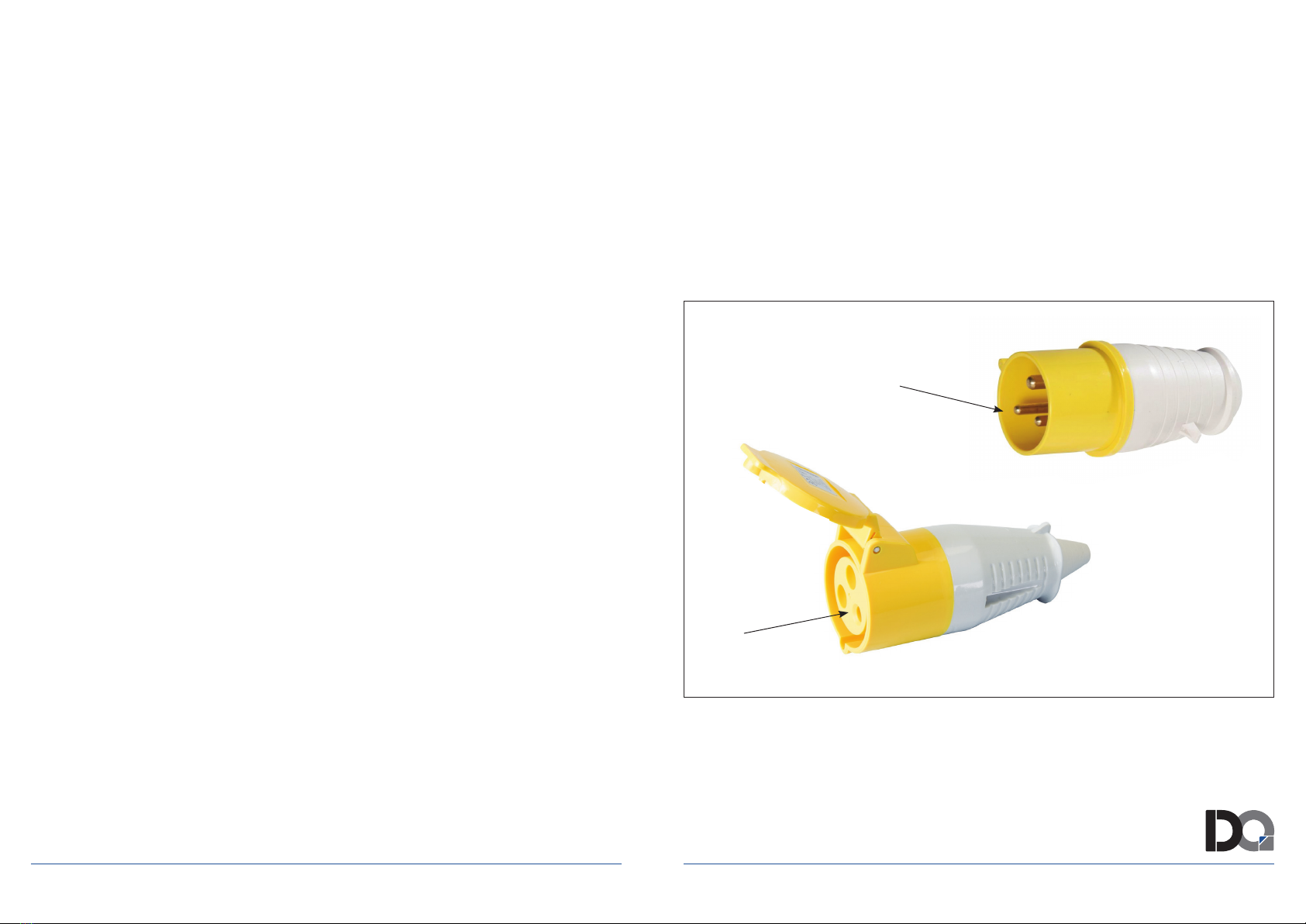

Grounding Pin

Pin Socket

Diaquip Standard 110V Plug and extension socket with integrated grounding pin

/14 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /15

ELECTRICAL CONNECTION

The network voltage must conform to the voltage indicated on the tool name plate. Under no

circumstances should the tool be used when the power supply cable is damaged. A damaged

cable must be replaced immediately by an authorized Customer Service Center. Do not try to

repair the damaged cable yourself. The use of damaged power cables can lead to an electric

shock.

WARNING: Never operate a damaged machine.

Always tag a damaged machine and take it out

of service until repairs can be made.

WARNING:ThismachinerequiresaPortable

Residual Current Device (PRCD) also known as

a Ground Fault Circuit Interrupter (GFCI). The

110 Volt version of this machine relies on the

110 Volt transformer providing this PRCD.

Always ensure that the transformer being

used is showing no signs of damage to the

casing and that there is a reset button present.

The230Voltversionofthismachineisequipped

with its own in-line PRCD. Always use this device

whenever using the machine to reduce the risk of shock hazards.

Always position the PRCD as close as possible to the power source. Test and reset the

PRCDdevicebeforeeachuse.Pressthe“Test”buttontotest.Pressthe“Reset”button

to energize the circuit to the machine.

WARNING: Always connect the plug into the wall socket with a drip loop. If the cable

leads downward directly into the wall socket, any water on the cable could run into the

socket, causing a hazard.

Note: PRCD (GFCI) appearances

vary according to the requirements of

various regions. Photos for reference

only

INTRODUCTION

This machine is equipped with two handles and a blade guard. The motor has overload and

overheat protection. It has an integrated water feed system as required for diamond cutting. It

must only be used with a diamond blade. It is intended for cutting masonry, stone, concrete,

reinforced concrete and similar materials. All other uses are prohibited.

LIST OF CONTENTS

Concrete Saw

Guide Roller Assembly

M17 Combination Wrench

Splash Guard

Allen Key

ASSEMBLY

Mount the blade. ( See below “Mounting the Blade”)

Mount the Guide Roller Assembly if desired ( See below “Guide Roller Assembly”)

Mount the blade guard brush (See below “Blade Guard Brush” for assembly instructions)

Mount the splash guard (See below “Splash Guard” for assembly instructions)

Cover

Test Button Reset Button On Lamp

LIST OF OPTIONAL CONTENTS

Flush Cut Flange with tools & xings

Dust Ski (Coming 2019)

400mmØ Blade

/16 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /17

DIAMOND BLADES

Allowed Types Of Blades

This machine may use diamond blades only.

NOTE: Abrasive wheels may not be used on this machine.

Only use either segmented or continuous rim diamond blades.

If the diamond blades are segmented, the maximum allowable peripheral gap between

segments is 10mm and must be with a negative rake angle.

Only diamond blades of 405mm (16”) or less may be used.

Blade thickness must be at least 2.0mm and no greater than 6.35mm

Blade Storage And Transport

Do not store or transport the machine with the blade mounted. Remove the blade and store in

such a way that it is protected from being bent or damaged when the machine is not in use-this

will help prevent damage to the blade.

A damaged blade can cause irregular conditions, this can cause imbalance and result in a

hazard. Always inspect new blades for storage or transport damage.

DIAMOND BLADES

About Diamond Blades

Diamond blades consist of a steel core with diamond segments added to its periphery.

Diamond blades are available for different hardnesses of masonry materials, stone, concrete,

reinforced concrete, etc.

Some diamond blades are designed to be used wet only, while others are designed to be

allowed to be used dry. Refer to the blade manufacturer’s instructions.

Generally speaking, even if the blade is specied as a dry type blade, diamond tools always

work better when wet, and dry cutting should be limited to situations in which water cannot or

should not be used. Water will prevent the blade from overheating, greatly reduce the amount of

harmful dust created by cutting, remove the slurry from the cut, and extend the life of the blade.

Diamond is the hardest substance known, but even diamond is unable to withstand extreme

overheating combined with the cutting forces involved. Dry cutting of very hard materials such

as porcelain or reinforced concrete will lead to rapid tool wear and possible failure.

The diamond impregnated segments in a sintered diamond blade operate on a principle of

controlled erosion. The blade does not cut the material, rather it grinds it away. The bond matrix

holding the diamonds is continually worn away by abrasion with the workpiece, exposing the

harder diamonds to stand proud from the bond matrix. A blade with good diamond exposure is

a sharp blade. Blades made for cutting harder materials will have a softer bond, allowing the

diamonds project more aggressively (but will not last as long).

Blades made for cutting softer, abrasive materials will have a harder bond, allowing them to

resist the abrasiveness of the material and to last longer. The other factor is the grit size of the

diamonds themselves: very hard materials tend to require a ner grit size, while coarser grits

will cut faster.

This erosion process causes heat and particles, which require water to cool and rinse free.

Without adequate water, the blade would overheat and be destroyed.

With too much water and not enough feed pressure, there would not be adequate erosion of the

bond matrix (the diamonds not exposed) and the blade becomes dull (diamond segments polish

smooth). This is called glazing and luckily the blade can be de-glazed (sharpened). If the blade

seems to refuse to cut anymore, you know that it is glazed.

/18 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /19

DIAMOND BLADES

About Diamond Blades (continued)

See below: “SHARPENINGAGLAZEDBLADE”

Never use a sharp motion or the blade will be damaged. Conversely, don’t feed too gently

or the diamond segments will become glazed. Keep the blade steadily working, but don’t be

abusive or give the blade shock impacts into the work surface.

Take great care to keep the blade perpendicularly aligned to the kerf. If the blade is crooked,

it will easily bind. When cutting reinforced concrete, if embedded steel such as rebar is

encountered, take special care. When the steel is encountered, the water will generally go

clear and vibration will begin. Reduce the feed pressure by about 1/3 and let the blade go at its

own pace, if there is too much vibration the blade may be destroyed. Once the steel is passed,

continue normally. A properly sharp blade with good diamond exposure should be able to

cut through rebar if handled well.

NOTE: Never use a wet-type diamond blade without water. It will overheat and be

destroyed.

NOTE: When using dry blades, do not allow them to overheat. It is best to cut no longer

than about 60 seconds at a time, with 10 second running in air cool down times in

between.

Always mount the blade with the arrow matching the direction of rotation of the machine (A

direction arrow is marked on the blade guard).

WARNING: Never use blades for cutting a material other than the material they were

intended for.

SHARPENING A GLAZED BLADE

Diamond blades may become glazed (dull) for various reasons, such as cutting reinforced

concrete with an excess of embedded steel, or from cutting with too little downforce which can

lead to the segments becoming polished or “glazed”. Once the diamond segments are glazed,

the blade’s cutting performance will degrade and the segments will overheat. To resharpen the

blade, turn down the water feed and make a few cuts in a very soft, abrasive material such as

brick.

MOUNTING THE BLADE

First make sure that the machine is unplugged.

Then, using the 17mm combination wrench, engage the arbor bolt and turn the arbor while

pressing on the arbor lock (See page 2). When the arbor reaches the right position, the arbor

lock will be allowed to engage. Then the arbor bolt may be loosened and the plain outer ange

may be removed. (It is a standard, right hand thread, so turn anticlockwise to loosen.)

The inner anges are specic to the blade arbor bore diameter. There are three possible blade

arbor bore sizes depending on the market where the machine is sold: 20mm, 22.2mm (7/8”),

and 25.4mm (1”) Check the inner ange to ensure that the size matches the bore of the blade

which you intend to use.

The 7/8” and 1” sizes each have a specic inner ange which must be used. For the 20mm

size, the bore directly engages the arbor and thus uses a plain ange on both the inside and

outside.

Inspect the blade before use. It must not be cracked, warped or damaged in any way that would

cause a hazard in operation. Loose diamond segments can be ejected at high speed, causing

possible injury. Always check that the diamond segments are not under cut. If the diamond

segments are thinner or nearly thinner than the blade core, the kerf will be too tight tting and

could easily lead to kickback.

Ensure that the anges and blade bore are clean and undamaged and that everything ts

properly. The anges may not be used if they are warped, the surface is uneven, burred or if

they are dirty. The arbor bolt and arbor threads must be undamaged. Inspect the blades for

segment damage, arbor hole damage or any other damage which could cause hazardous

operation.

The protruding edge of the inner ange should be facing the blade. Then mount the blade to the

inner ange and add the outer ange. Add the arbor bolt and tighten to 15-25 Nm.

WARNING: Do not attempt to mount a blade which does not match the mounting

hardware. It will lead to eccentric running and vibration which will be uncontrollable.

/20 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /21

ADJUSTING THE BLADE GUARD

The blade rotates clockwise when viewed from the arbor end. Therefore, most of the cutting

debris, sparks and slurry is thrown to the rear. So the blade guard should be adjusted so that

the rear edge is ush with the workpiece.

TO ADJUST

First pull out the locking lever against the spring

tension, then rotate the blade guard to the desired

position. Allow the locking lever to engage the

nearest slot in the guard to lock it into position.

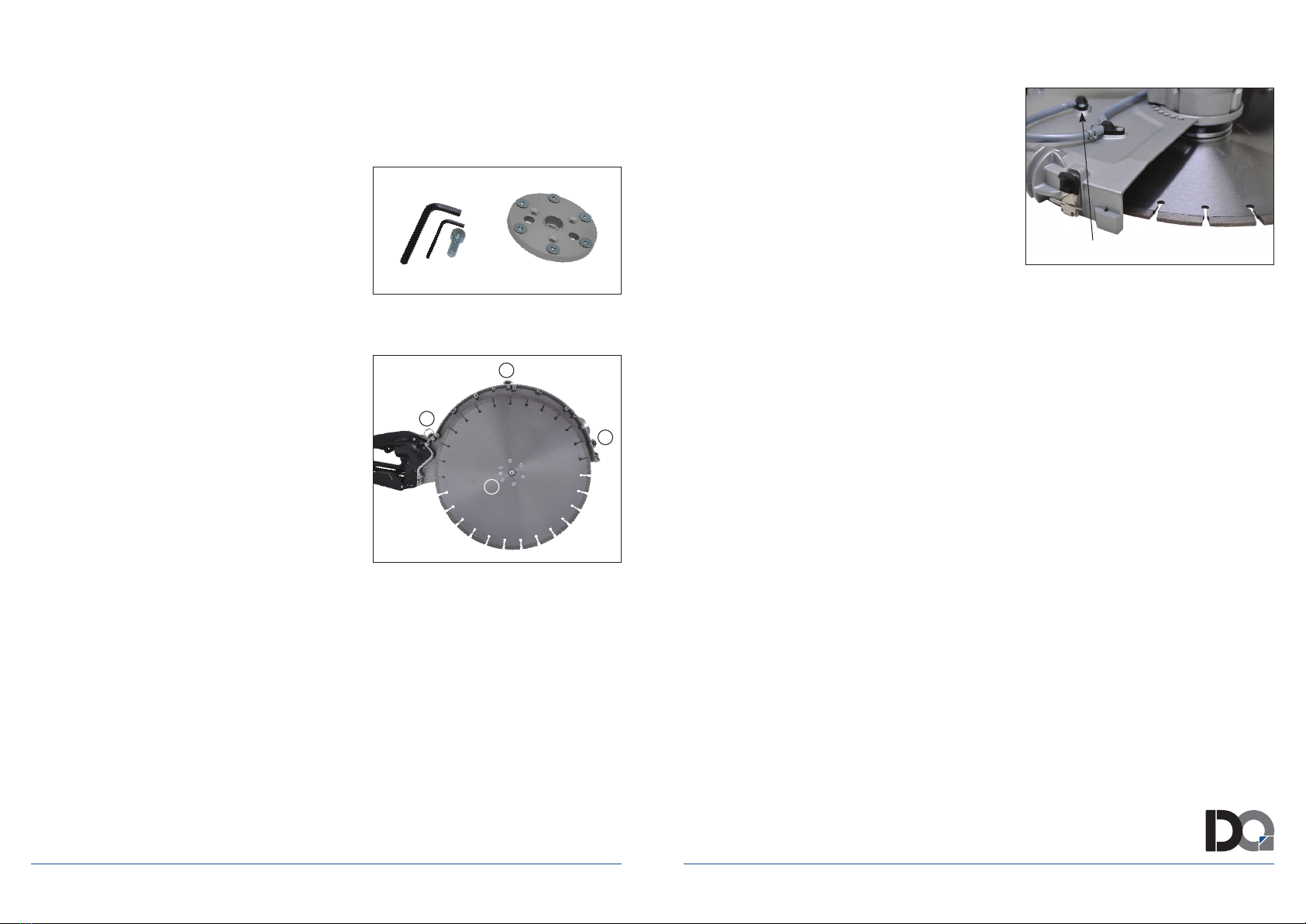

Blade Guard Locking Lever

BLADE GUARD BRUSH

There is a removable brush at the rear of the guard to help contain sparks, dust, debris and

slurry. To install, simply push the brush into the slot in the bottom of the dust port bracket until it

clicks in place. This brush may be pulled straight out to replace when worn.

SPLASH GUARD

The spring-loaded splash guard is useful to help to contain slurry which splashes toward the

back. To install, simply clip into place on the back of the dust port bracket. To remove, tilt

upward to pop free. If the splash guard is not needed, such as when cutting dry, it may be

clipped up out of the way. Simply engage the male clip on the ap with the female clip on the

mount. Unclip to release.

WATER CONNECTION

Water is a basic requirement for diamond sawing with

wet-type diamond blades. The water serves as a coolant to

avoid the working surface of the diamond segments from

overheating. When the diamond bit becomes overheated,

both the bond matrix and even the diamonds break down,

thus destroying the blade. Besides cooling, water also

keeps down dust and ushes away abrasive particles.

WARNING: Always ensure a PRCD (GFCI) is used

when operating with water

WARNING: Never allow water to enter the motor. It could lead to an electric shock.

WARNING: Check all connections of the water feed system to ensure there are no leaks.

Inspect hoses and other critical parts which could deteriorate.

WARNING: The maximum water pressure should not exceed 70 psi (4bar).

Use a water collector with a wet vacuum to collect cooling water if nearby objects could be

damaged by water. The water feed system is built into the machine. To connect with the water

supply, rst pull the quick-release collar to remove the female side of the water coupling. Then

unscrew the nut and engage the coupling to the water hose. Now reconnect the water coupling

to the male water feed valve. Press it until it clicks. The water ow is controlled by the water

feed valve. The water to the blade may be nely adjusted to the required amount and no more.

NOTE:Contaminantsinthewatersupplycaneasilyplugupthenewaternozzlesinthe

bladeguard.Ensurethatthesupplywaterisclean.Ifyoundthatthereisnowaterow

to the blade, then clean out the water feed system on the machine.

GUIDE ROLLER ASSEMBLY

The guide rollers make it easier to keep the blade plane

perpendicular to the workpiece. To install, slacken the buttery

bolt slightly and engage the four claws with the four eyelets

on the bottom of the motor housing, then tighten the buttery

bolt. Note that roller assembly is offset to one side to avoid

contacting the blade, so it may only be installed in one

orientation. If it is not needed, the guide roller assembly may

be removed and set aside.

Buttery Bolt

Open

Closed Water Feed Valve

/22 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /23

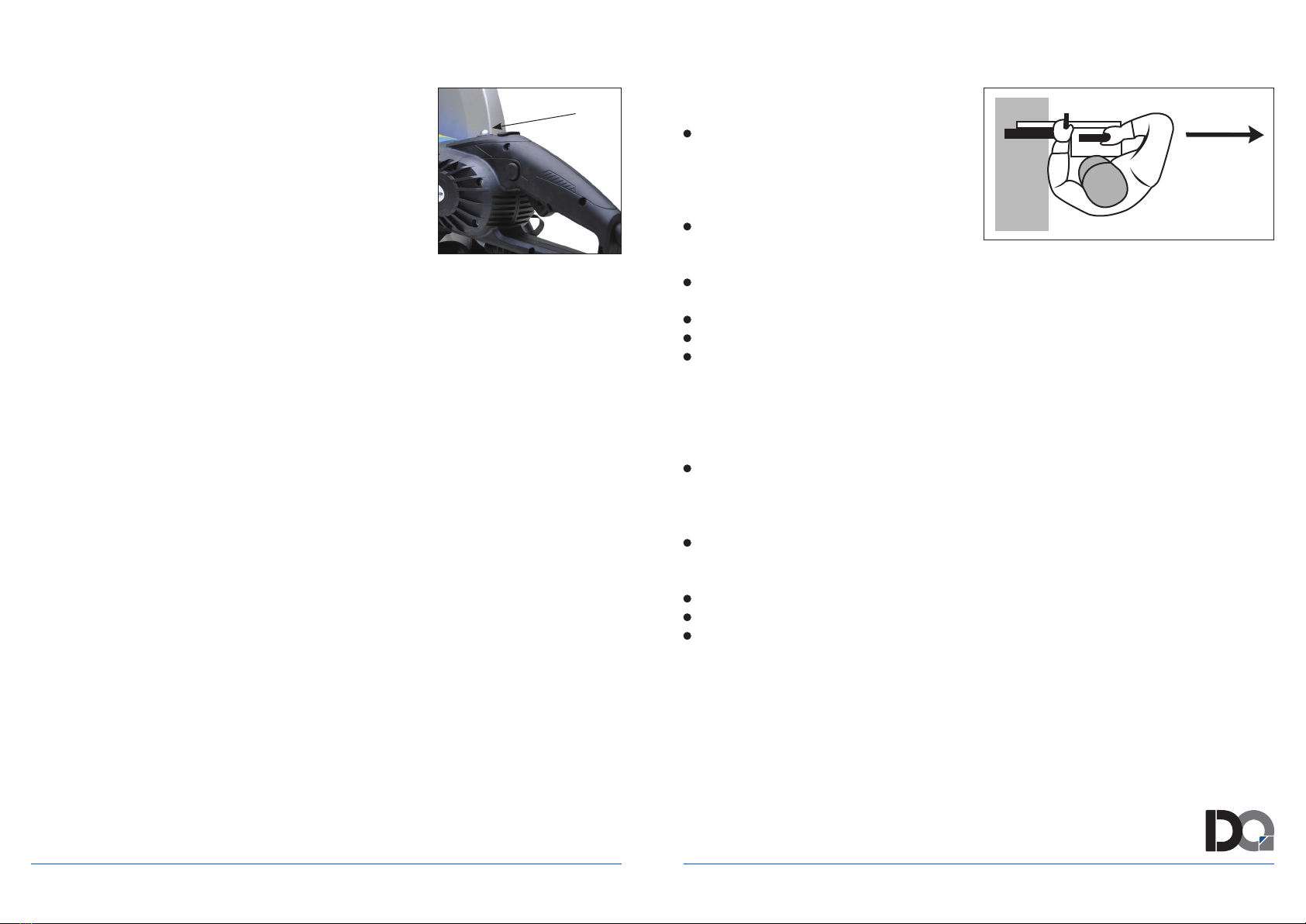

OVERLOAD & OVERHEAT PROTECTION

Overload & Load Warning Lamp

When full load is reached, the load warning lamp will ash red.

If full load is exceeded and sustained for too long, the motor

will shut down and the load warning lamp will glow solid red.

In this case, the motor must be rst shut off and then restarted.

When this happens, the motor will very likely be near

overheating, so it is also a good idea to run the motor at no

load for a few minutes to cool it before continuing.

Overheat Thermal Protection

If the temperature of the motor gets too high, the thermal protection will shut the motor down.

The switch must be rst shut off and then restarted. When this happens, do not immediately

start cutting after restarting the motor. Always run the machine at no load for a few minutes to

return to a normal operating temperature

before continuing.

CAUTION: The motor will be damaged if it is repeatedly overloaded or overheated.

Always cool the motor by running at no load for a few minutes whenever it stops from

either overheat or overload.

Load Warning

Lamp

OPERATION

How to hold the machine

Always hold the machine with both hands,

with the right hand on the main handle

and with the left hand on the side handle.

(This applies even if the operator is

left-handed)

Do not stand directly in line with the blade.

Rather, stand in such a way that, if it kicks

back, you will not be in the path of the blade.

Never lean over the blade path. That would put your body in line with the blade if it

kicks back.

Do not cut above shoulder height.

Never cut while standing on a ladder or other unstable platform.

While cutting on a vertical surface like a wall, hold the machine in a “tail down” position in

such a way that the upper quadrant of the blade does not contact the workpiece.

Before cutting

Check the area where the cut is to be

made to ensure that it is clear of objects

which could cause the operator to

stumble.

Before cutting, it is sometimes useful to

mark the line of cut with chalk or the like. For straight cutting, a wood plank is also useful in

guiding the machine to make a straight cut.

Ensure that all bystanders are at a safe distance.

Ensure that the equipment is grounded.

Ensure that all safety equipment is in place.

/24 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /25

OPERATION

Proper Support for the Workpiece

Support the workpiece on in such a way

that the kerf will not pinch down on

the blade.

Secure the workpiece so that it will not

roll, slip away or move due to vibration

while cutting

The cutting sequence is important when

making cutouts. Always make the last cut

in a way that avoids the blade being pinched. Thus, make the bottom horizontal cut rst,

then the sides and nally make the top horizontal cut last.

Make note of the weight of the workpiece and the direction which it will fall when it is cut

through.

Whenever there is a situation where severing the workpiece will cause a hazardous

situation, leave a tab of material intact and nish off the operation with a chisel or the like.

CuttingTechnique

Holding the machine with both hands to resist the start up torque, press the release button

and then squeeze the trigger switch.

Allow the machine to reach full speed before contacting the workpiece.

Adjust the water ow as needed by turning the water feed valve.

Then gently begin the cut with the rear portion of the blade until the kerf is established.

Make the rst cut in the forward direction (so that you can see the line of cut). Then make

following cuts in the backward direction.

Do not try to cut too much depth in one pass. Never exceed about 50mm (2”) per pass. It

is better to cut in multiple passes to minimize the cutting contact area of the blade and

keep the blade spinning fast.

OPERATION

CuttingTechnique(continued)

It’s a good idea to rst cut a shallow guiding groove in the forward direction before

proceeding to make the main cut in the backward direction. If any correction is needed.

Lift the blade and cut slightly ahead and then back into the existing kerf. Take care to avoid

the blade being pinched.

In round workpieces, the best technique is to use a slow, uniform back and forth motion

while cutting with the bottom quadrant of the blade.

Do not allow the machine to bog down. Limit your feed pressure to keep the blade spinning

at high speed.

Never side load the blade in the kerf.

If the workpiece is very heavy and may cause a hazard when it is cut through, do not cut

all the way through the material. Leave some tabs of material intact and then nish the cut

with a chisel or similar tool.

Concrete cutting is very stressful for the motor: After the cut is nished, it is a good practice

to run the machine at no load for a short time to lower the motor temperature before

stopping.

Stopping

Release the trigger to stop the machine. After the trigger is released, the blade will continue

spinning for a time.

WARNING: Do not set the machine down until the blade has stopped turning.

Release Button

Trigger Switch

12

1. Forwards

2. Backwards

/26 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /27

FLUSH CUTTING FLANGE (IF APPLICABLE)

FITTING & OPERATING

CONTENTS WITH THE FLANGE

OPERATION

1. Remove the water hose from the water nozzle

on the outer blade guard and connect it to

the alternate water nozzle on the inner blade

guard.

2. Remove the 6 screws securing the outer

blade guard.

3. Unclip the 3 toggle latches and pop the loose

clasps in the plastic clips to prevent rattling.

4. Lift away the outer blade guard and keep in a safe place.

5. Once the ush cutting operation is completed, immediately replace the outer blade guard

and water hose.

NOTE: There is roughly a 1mm or less effective offset (Depending on the width of the

diamondsegments).Sincethebladeguardhassomedegreeofexibility,pushingdown

slightlybringsitallthewaytofullyush.Inactualcutting,itcomesout100%ush.

There has to be a small degree of offset so the blade won’t make marks in the base

material, in cases where it matters. So to avoid the marks, don’t use any downforce.

Buttoget100%ush,usesomedownforce.

WARNING: Always operate with the outer blade guard in place while performing standard

cutting.Neveroperatethesawwiththeouterbladeguardremovedexceptforush

cutting operations.

WARNING: Check the tightness of the mounting screws and arbor screw periodically.

WARNING:Ifanyunusualvibrationisfeltinoperation,stopimmediatelyandndthe

cause before continuing.

Alternate Water Nozzle

INTRODUCTION

The ush cutting kit enables a ush cut 400mmØ

blade (not included) to be mounted to the machine in

order for ush cuts to be made while the outer blade

guard is temporarily removed. The ush cut blade

may be left in place and the operator may return to

standard cutting simply by replacing the outer blade

guard and securing it with the 3 toggle latches. This

way, it is quick and convenient to switch between

the standard mode and ush cutting mode. If more

appropriate for the operator & circumstances, the

ush cutting blade and ange may be removed

and the machine is then returned to the standard

conguration.

1. Flush Cutting Flange

2. Socket Cap Arbor Bolt & Washer

3. Flat-Head Socket Cap Screws x 6

4. M5 L-Hex Wrench

5. M8 L-Hex Wrench

ASSEMBLY

To mount the ush cutting kit, rst remove the standard arbor bolt, anges and blade according

to the instructions below;

1. Mount the ush cutting ange on the spindle and secure with the washer and socket cap

arbor bolt. Engage the arbor lock tighten the arbor bolt securely using the M8 L-hex

wrench.

2. Mount the ush cut blade on the ange, align the holes and thread in the at-head socket

cap screws. Using the M5 L-hex wrench, tighten the screws evenly and diagonally.

1. Toggle Latches

2. Flat-head Socket Cap Screws

1

1

1

2

/28 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /29

MAINTENANCE AND CLEANING

This machine operates in a very harsh environment. The slurry created by wet cutting and the

dust created by dry cutting gets sucked into the motor’s cooling slots and enters the motor. The

slurry of brick and concrete contains salts and other corrosive substances which will severely

shorten the life of the motor or cause electrical shorts if allowed to accumulate.

Therefore, it’s essential for the long life of the tool that it be thoroughly cleaned after each use.

Compressed air should be blown through the machine’s cooling slots at the back of the

machine while the motor is running.

Daily Maintenance

Keep the machine clean

Check to ensure that the power supply cable is in good condition.

Ensure all screws are tight.

Check the condition of all safety equipment such as the blade guard

Check the blade for damage.

MAINTENANCE AND CLEANING

Carbon Brushes

The carbon brushes are a normal wearing part and must be replaced when they reach their

wear limit. This machine is equipped with auto-stop carbon brushes. If the machine comes to

a stop unexpectedly, the brushes should be checked. The auto-stop brush design protects the

motor by stopping the machine before the carbon brushes are completely worn out.

Caution: Always replace the brushes as a pair.

To replace:

1. Remove the screw and remove the brush cover.

2. Using pliers rotate the brush spring out of the way

and slide the old carbon brush out of the brush holder.

3. Unscrew the screw to remove the brush lead.

The old carbon brush may now be lifted away.

4. Install a new brush. Installation is the reverse of

removal.

5. Replace the brush cover.

If the replacement of the power supply cord is necessary, this has to be done by the

manufacturer or their agent in order to avoid a safety hazard.

WARNING: All repairs must be entrusted to an authorized service center. Incorrectly

performedrepairscouldleadtoinjuryordeath.

Do not throw electric power tools into the household waste!

In accordance with the European Directive 2002/96/EG on Waste Electrical and Electronic

Equipment and transposition into national law, used electric power tools must be

collected separately and recycled in an environmentally friendly manner.

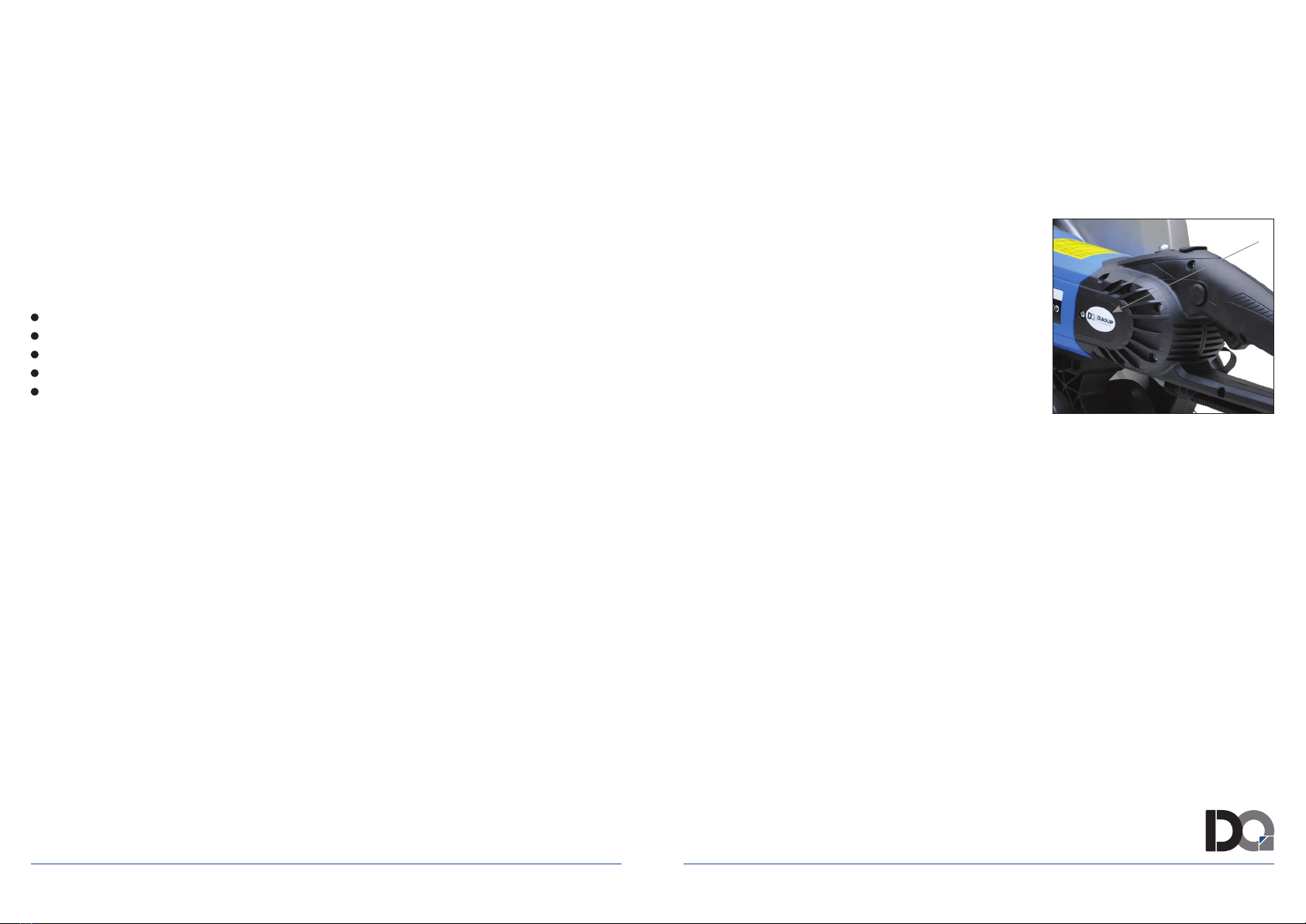

Brush Cover

/30 WWW.DIAQUIP.CO.UK WWW.DIAQUIP.CO.UK /31

WIRING

CARBON

BRUSH

CARBON

BRUSH

MOTOR

AC SWITCH

1

2

1

2

ELECTRONICS

UNIT

Te mperature Sensor

Diaquip hereby declare that the said products conform with the requirements

demanded to be met for CE and EMC Certication and regulations.

ATTESTATION OF CONFORMITY | EXTRACT

Product: QHS-400 Concrete Saw (Cut-off Machine)

Trade Name: DQ Machinery

Type/Model: QHS-400 in 110 & 230V

Requirements: EN ISO 12100:2010 – Safety of machinery. General

principles for design. Risk Assessment & Risk Reduction.

EN 60745-1:2009 +A11:2010

EN 60745-2-22:2011+A11:2013

This attestation is granted on account of an examination by a certied regulatory body,

the results of which are laid down in a condential le.

This attestation implies that the examined types are in accordance with the standards

designated under the Machinery Directive 2006/42/EC.

09 March 2018

APPROVED SERVICE CENTRE;

WWW.DIAQUIP.CO.UK

0161 406 0609

SALES@DIAQUIP.CO.UK

DIAQUIP HEAD OFFICE | MANCHESTER, UK

Table of contents

Other DIAQUIP Saw manuals