Dick SM-200 TE User manual

Friedr. Dick GmbH & Co. KG · PO Box 1173 · 73777 Deizisau · GERMANY

Tel.: +49 (0)7153-817-0 · Fax: +49 (0)7153-817-218/-219 · Web: www.dick.de · E-mail: [email protected] ·

No. 9 8320 4252 Vers.2 / 11-2017

Operating Instructions (Translation)

SM-200 TE

3~400 V - 50-60 Hz

Grinding and Honing Machine

Art. No. 98320005 with a universal grinding arm

Art. No. 98320000 with a radial grinding arm

GB

Manufacturer and customer service address

Friedr. Dick GmbH & Co. KG

PO Box 1173

73777 Deizisau

GERMANY

Copyright

© 2016 Friedr. Dick GmbH & Co. KG.

These operating instructions are protected by copyright; all rights are reserved.

These operating instructions may not be reproduced or copied, either in full or

in part, without the prior consent of Friedr. Dick GmbH & Co. KG. Infringements

are subject to compensation claims and can result in criminal prosecution.

Also visit the Friedr. Dick YouTube channel.

https://www.youtube.com/user/FriedrDick/videos

Videos show the operation of the Friedr. Dick machines.

SM-200 TE Grinding and Honing Machine 3

1

1. User Information.............................................................................5

1.1 General................................................................................................. 5

1.2 Symbols and conventions .................................................................... 5

1.3 Symbols................................................................................................ 6

2. Delivery, Transport and Storage...................................................7

2.1 Delivery ................................................................................................ 7

2.2 Package contents................................................................................. 7

2.3 Unpacking ............................................................................................ 7

2.4 Transportation ...................................................................................... 8

2.5 Storage location ................................................................................... 9

3. Product Liability ...........................................................................10

4. Environmental Protection............................................................10

5. Safety.............................................................................................11

5.1 Meaning of the warnings .................................................................... 11

5.2 Intended use....................................................................................... 11

5.3 General safety instructions................................................................. 12

5.5 Signage .............................................................................................. 17

5.6 Covers................................................................................................ 18

6. Design and Function....................................................................19

6.1 Technical data.................................................................................... 19

6.2 Overview ............................................................................................ 21

6.3 Design and Function .......................................................................... 22

6.4 Covers................................................................................................ 26

7. Putting the Machine into Operation............................................27

7.1 Installing the machine......................................................................... 27

7.2 Mounting the grinding arm.................................................................. 28

7.3 Removing the dressing tool................................................................ 29

7.4 Setting up the cooling water unit ........................................................ 29

7.5 Filling the cooling water unit ............................................................... 29

7.6 Electrical connection .......................................................................... 30

7.7 Performing test runs ........................................................................... 30

8. Setting up the Machine ................................................................33

8.1 Switching on the grinding and honing machine.................................. 33

8.2 Switching off the grinding and honing machine.................................. 34

8.3 Adjusting the wet grinding belt ........................................................... 34

8.4 Setting the cooling water supply......................................................... 36

8.5 Setting the guard ring ......................................................................... 37

8.6 Setting the universal grinding arm...................................................... 37

8.7 Setting the grinding radius on the universal grinding arm .................. 39

8.8 Setting the radial grinding arm ........................................................... 40

8.9 Setting the grinding radius on the radial grinding arm........................ 41

8.10 Clamping the grinding plate................................................................ 43

8.11 Setting up special solutions for circular blades .................................. 45

SM-200 TE Grinding and Honing Machine

4

1

9. Machining Workpieces ................................................................ 48

9.1 Sharpening machine knives ............................................................... 48

9.2 Clamping and unclamping knives in grinding plates........................... 48

9.3 Sharpening knives .............................................................................. 49

9.4 Machine knives with a bevelled contoured cutting edge .................... 50

9.5 Deburring and polishing machine knives............................................ 52

9.6 Sharpening circular blades ................................................................. 54

9.7 Grinding hand knives and cleavers .................................................... 55

9.8 Polishing workpieces .......................................................................... 58

10. Servicing and Maintenance......................................................... 59

10.1 Cleaning the SM-200 TE grinding and honing machine ..................... 59

10.2 Dressing the grinding wheel ............................................................... 60

10.3 Changing the grinding wheel .............................................................. 61

10.4 Changing the wet grinding belt ........................................................... 62

10.6 Readjusting the ribbed belt................................................................. 65

10.7 Readjusting the V-belt ........................................................................ 66

10.8 Adjusting the wedge on the lift rod ..................................................... 67

10.9 Troubleshooting.................................................................................. 69

11. Accessories and Spare Parts...................................................... 72

11.1 Accessories ........................................................................................ 72

11.2 Spare parts ......................................................................................... 73

11.3 Circuit diagram ................................................................................... 73

11.4 Ordering accessories and spare parts................................................ 73

12. EC Declaration of Conformity ..................................................... 75

SM-200 TE Grinding and Honing Machine 5

User Information

1

1. User Information

1.1 General

These operating instructions are an integral part of the SM-200 TE

grinding and honing machine with the serial number indicated on

the type plate (the type plate is located on the back of the SM-200

TE grinding and honing machine).

The operating instructions must be kept close at hand at all times.

They contain important information and instructions for safe,

proper and economic use of the SM-200 TE grinding and honing

machine. They must have been read and understood by each per-

son before this person can be entrusted with the following work

using the SM-200 TE grinding and honing machine:

• Putting the machine into operation,

•Operating,

• Servicing.

The operating instructions must be followed during all work on and

with the SM-200 TE grinding and honing machine. Following the

information and instructions helps to prevent hazards, to reduce

repair costs and to increase the reliability and life of the SM-200 TE

grinding and honing machine.

The technical information and instructions for use in these operat-

ing instructions are up-to-date and correct on delivery of the SM-

200 TE grinding and honing machine. Friedr. Dick GmbH & Co. KG

reserves the right to further develop the design and to make

changes without notice.

All directional information is given from the view of the user.

1.2 Symbols and conventions

Instructions

Sequences of actions, which must be carried out in the given order

are specified as a numbered list. Example:

1Instruction step 1.

2Instruction step 2.

SM-200 TE Grinding and Honing Machine

6

User Information

1

Lists

Lists without a particular order that have to be followed are shown

as a list with bullet points or indent markings. Example:

• Property A

- Detail 1

- Detail 2

• Property B

1.3 Symbols

Important or particularly useful information is highlighted by way of

symbols so that it is readily recognised.

WARNING

This symbol denotes a warning, which must always be noted and

followed.

• For more information on the meaning of the warnings,

refer to the Safety chapter.

MANDATORY

This symbol indicates instructions, which must be complied with

for safety reasons.

NOTE, TIP

This symbol denotes general information, which contains user tips

and useful information.

SM-200 TE Grinding and Honing Machine 7

Delivery, Transport and Storage

2

2. Delivery, Transport and Storage

2.1 Delivery

The SM-200 TE grinding and honing machine is delivered in a

cardboard box on a Euro pallet.

Use a suitable means of transport to move the delivered grinding

and honing machine in its packaging, e.g. a forklift or hydraulic pal-

let truck.

Do not stack the machine. Do not place any objects on the packed

machine.

2.2 Package contents

• a) SM-200 TE grinding and honing machine with a stand

b) SM-200 TE Grinding and honing machine

• Radial or linear grinding arm - not mounted

• Double grinding lever

• Cooling water unit

• Connecting hose

• Return hose (b)

• Foot pedal

• Dressing device

•Tool

• Polishing compound

• Operating instructions

2.3 Unpacking

Unpack the SM-200 TE grinding and honing machine immediately

after receipt and check whether there is damage or defects on the

SM-200 TE grinding and honing machine caused by the transpor-

tation. Also check the package contents to ensure that the delivery

is complete.

Report any defects immediately. Complaints made at a later date

can no longer be recognized.

Keep the invoice for the entire warranty period as proof of pur-

chase.

SM-200 TE Grinding and Honing Machine

8

Delivery, Transport and Storage

2

In case of complaints, write to Friedr. Dick GmbH & Co. KG,

enclose the original invoice and a precise description of the

defects.

Before returning the product, wait for the manufacturer's reply in

order to initiate the necessary steps.

Friedr. Dick GmbH & Co. KG does not pay any transport costs for

returns that have not been explicitly approved.

Keep the original box for any necessary returns in order to prevent

transport damage.

2.4 Transportation

Please note the following when transporting the SM-200 TE grind-

ing and honing machine after unpacking or starting it up:

• Use a suitable means of transport to move the machine,

e.g. a forklift or hydraulic pallet truck.

• The machine is fixed to the machine base with retaining

hooks on a Euro pallet for transportation purposes. Remove

the retaining hooks when unpacking the machine.

WARNING

Risk of injury when carrying and moving the grinding and

honing machine

• Do not carry the SM-200 TE grinding and honing machine.

This will risk damage to health.

• If the SM-200 TE grinding and honing machine starts to move

uncontrollably during transportation, this will risk damage to

the health of people in its vicinity.

CAUTION

Risk of damage to the SM-200 TE grinding and honing

machine during transportation.

• Disassemble the grinding arm before transportation.

SM-200 TE Grinding and Honing Machine 9

Delivery, Transport and Storage

2

• Use a crane and sling for lifting the machine. Use suitable

slings or lifting straps. The weight of the machine without the

stand is 98 kg. Place the slings outside the machine base on

the machine frame.

• A forklift may fit under the lower struts of the table in

a machine with a stand.

Make sure when lifting the machine with a stand with a suita-

ble sling that the sling does not get pulled over the tray in the

middle of the machine. The tray will then be damaged.

2.5 Storage location

Store the machine in a dry place. The storage location must be free

of frost and the air temperature must not exceed 40 °C.

CAUTION

The machine with the stand is top-heavy.

• There is an increased risk of tipping when transporting the

SM-200 TE grinding and honing machine with the stand.

SM-200 TE Grinding and Honing Machine

10

Product Liability

3

3. Product Liability

All abrasives and other wear parts are excluded from the warranty.

Modifications to the SM-200 TE grinding and honing machine

require the written consent of Friedr. Dick GmbH & Co. KG.

Friedr. Dick GmbH & Co. KG does not accept any liability whatso-

ever for defects or damage caused by incorrect assembly or use of

non-original DICK wear and spare parts or accessories as well as

for improper handling.

Please refer to our General Terms and Conditions of Sale, Delivery

and Payment for further details concerning the product liability and

warranty. These can be downloaded at www.dick.de.

4. Environmental Protection

Used machines, replacement parts and packaging are made of

recyclable materials. The owner is obliged to dispose of them pro-

perly and in an environmentally friendly way in accordance with

the legal regulations.

• All plastic injection-moulded parts bear a recycling symbol.

SM-200 TE Grinding and Honing Machine 11

Safety

5

5. Safety

5.1 Meaning of the warnings

In these operating instructions, a differentiation is made between

warnings depending on the hazard:

5.2 Intended use

DANGER

Imminent risk to the life and health of people.

• Causes serious injuries or death.

WARNING

Possible imminent risk to the life and health of people.

• Could cause serious injuries or death.

CAUTION

Possible dangerous situation

• Could cause minor injuries.

The SM-200 TE grinding and honing machine is designed exclusi-

vely for commercial use.

The SM-200 TE grinding and honing machine may exclusively be

used for grinding and honing hand knives, cleavers, cutting tools,

cutter knives, circular blades and machine knives with a smooth

cutting edge. The grinding arm that is mounted determines the cut-

ting type of machine knife that can be ground:

• Linear cutting edge only with a universal grinding arm

• Radial cutting edge with a universal and radial grinding arm

• Spiral-shaped cutting edge conditionally with a universal and

radial grinding arm.

A special grinding arm (accessory) allows the sharpening of small

circular blades. A guard (accessory) must be mounted for sharpe-

ning large circular blades (Ø 200-500 mm).

SM-200 TE Grinding and Honing Machine

12

Safety

5

5.3 General safety instructions

Circular and sickle-shaped blades as well as linear, flat machine

knives with a smooth cutting edge can be sharpened properly on a

grinding belt with the universal belt grinder attachement UB3F or

UB3F-XL.

A special clamping plate is required for grinding machine knives.

Intended use also includes observing the operating instructions

and adhering to the servicing and maintenance work.

Any other or additional use is deemed to be not as intended and

therefore misuse.

The grinding of large circular blades without the mounted guard is

deemed to be misuse.

The grinding of materials that produce harmful or readily ignitable

dusts is also deemed to be misuse. These include, for example:

aluminium and magnesium.

The SM-200 TE grinding and honing machine may not be switched

on or operated in potentially explosive atmospheres and is exclu-

sively designed for use in dry rooms at temperatures between +3

and +40 °C.

Exclusively original spare parts and accessories from Friedr. Dick

GmbH & Co. KG may be used.

The owner is responsible for any damage caused by misuse

WARNING

Risk of injuries due to incorrect handling

Improper handling of the SM-200 TE grinding and honing machine

can cause serious injury.

• The SM-200 TE grinding and honing machine may only be

used by people who have read and understood the operating

instructions.

SM-200 TE Grinding and Honing Machine 13

Safety

5

• The SM-200 TE grinding and honing machine may only be

operated by people who are familiar with the starting up, oper-

ation, and servicing of machines and the relevant accident pre-

vention regulations, who are able to recognise the hazards

that occur when using the machine and who work reliably.

• The SM-200 TE grinding and honing machine may not be

operated outside the given power ranges (see “Technical

data” on page 19).

• Operate the SM-200 TE grinding and honing machine only

for its approved uses (see “Intended use” on page 11).

• Missing or damaged covers expose rotating parts and can

cause injuries due to crushing and drawing in.

Check the grinding and honing machine for damage before

each use, in particular the:

- Grinding wheel,

- Wet grinding belt,

- Polishing wheel,

- Power cable,

WARNING

Risk of fire in the event of unsuitable environmental influences

Moisture and water can cause a short circuit. Flying sparks can

cause flammable liquids and gases to ignite.

• Do not expose the SM-200 TE grinding and honing machine

to rain or salt water.

• Do not use the SM-200 TE grinding and honing machine near

flammable liquids or gases.

WARNING

Risk of injury due to damaged or incorrectly mounted machine

parts

Using the SM-200 TE grinding and honing machine with damaged

electric parts or power cables can cause injuries due to electric

shocks or malfunctions. Parts of the damaged grinding wheel, grin-

ding belt or polishing wheel may be spun off the machine.

SM-200 TE Grinding and Honing Machine

14

Safety

5

- Correct assembly of all covers and the housing,

- Function of the switches.

• Replace damaged parts before reusing the SM-200 TE grind-

ing and honing machine.

• Do not use any objects to brake rotating abrasives.

• The switched on SM-200 TE grinding and honing machine

must be inaccessible to persons not working at the SM-200

TE grinding and honing machine, especially to children.

• Switch off the SM-200 TE grinding and honing machine and

pull the mains plug out of the socket before leaving the work

area

CAUTION

Risk of injuries due to the poor health of the operator

Lack of concentration, over-tiredness, illness, drunkenness or leg

or arm disabilities as well as mental disabilities cause a high risk

of injuries.

• People who work at the SM-200 TE grinding and honing

machine must be healthy and capable of concentrating.

• Before starting work at the SM-200 TE grinding and honing

machine, ensure that you are in a stable position in which

you can maintain your balance without any effort.

• When grinding and polishing, do not look away from the SM-

200 TE grinding and honing machine and the workpiece.

CAUTION

Risk of injury when touching the SM-200 TE grinding and

honing machine

Touching the grinding wheel, polishing wheel or grinding belt

when the abrasives and SM-200 TE grinding and honing machine

are switched on will cause injuries.

• Do not touch any abrasives when the abrasives and machine

are switched on.

SM-200 TE Grinding and Honing Machine 15

Safety

5

WEAR SUITABLE PROTECTIVE CLOTHING

Rotating machine parts can catch unsuitable clothing or long hair.

Abrasive particles spun off the machine or loud machine noises

can damage eyes and ears.

Sharp and hot workpieces can cause injuries to hands.

Rotating abrasives can pull off pieces of clothing.

• Wear safety glasses or goggles,

• Gehörschutz tragen,

• Wear suitable protective gloves,

• Ensure good lighting is available,

• Wear tight-fitting clothing,

• Do not wear jewellery,

• Wear a hair net on long hair,

• Do not touch rotating machine parts with parts of the body

covered with fabric.

Further information on the safe operation of the SM-200 TE

grinding and honing machine:

• Keep the work area clean. An untidy work area increases the

risk of accidents.

• Do not leave any tool keys in place. Check that all keys and

adjustment tools are removed each time before switching on

the machine.

• Switch off the SM-200 TE grinding and honing machine and

pull the mains plug out of the socket before the machine is

ever transported.

SM-200 TE Grinding and Honing Machine

16

Safety

5

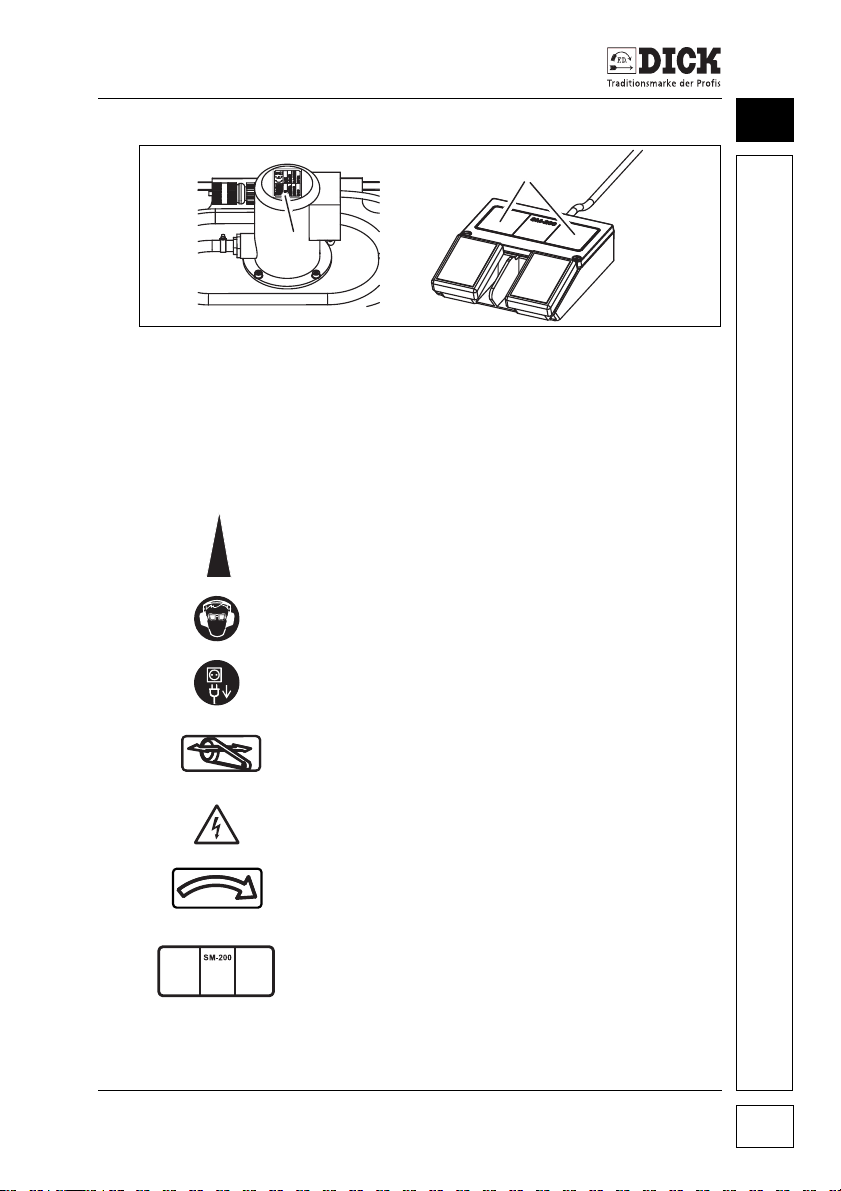

5.4 ::Signs on the grinding and honing machine

Figure 5.1 – Position of the signs

[1] Wear hearing protection and safety goggles when working

with the SM-200 TE grinding and honing machine.

[2] Direction of rotation on the grinding belt and polishing station

[3] Functional description for switches

[4] Note - moving parts under the cover.

[5] Direction of rotation for loosening the grinding belt.

[6] Disconnect the mains plug before opening the cover.

[7] Type plate

[8] Caution: electric shock - parts under the cover may be live.

1

2

3

1

4

5

6

7

8

SM-200 TE Grinding and Honing Machine 17

Safety

5

5.5 Signage

Figure 5.2 – Position of the signs

[9] Type plate on the cooling water tank

[10] Functional description of the foot pedal

Note:

Arrow on the machine housing for the correct

direction of rotation for the abrasives

Mandatory sign:

Use safety goggles

Mandatory sign:

Pull out the mains plug before opening.

Note:

Moving parts under the cover.

Warning sign:

Caution: high voltage

Note:

Direction of rotation to loosen the grinding belt.

Note:

Function of the foot pedal.

9

10

SM-200 TE Grinding and Honing Machine

18

Safety

5

5.6 Covers

The SM-200 TE grinding and honing machine is covered with

sheet metal. The user cannot come into contact with moving parts

inside the machine.

The covers of the polishing wheel and wet grinding belt as well as

the guard plate of the grinding wheel are fastened with tommy

screws. They are very easy to remove for making adjustments or

modifications or for servicing. The belt safety guard on the wet

grinding belt must be mounted in such a way that the SM-200 TE

grinding and honing machine can be started.

WARNING

Risk of injuries due to missing covers

The SM-200 TE grinding and honing machine may only be put

into operation when all covers and guard plates on the grinding

wheel, polishing wheel and grinding belt (see chapter 6.4 Covers)

are fully functional.

SM-200 TE Grinding and Honing Machine 19

Design and Function

6

6. Design and Function

6.1 Technical data

Motor and electrics

Grinding wheel

Grinding belt

Polishing wheel

Machine dimensions / weights

Power: 1.3 kW

Voltage: 3~400 V (three-phase)

Current intensity: 4.13 A

Frequency: 50/60 Hz

Type of operation: S3-70%

Degree of protection: IP 54

Connection: 3.5 m cable H05VV-F5G1.5 incl. 5-

pin CEE plug 16 A

Nominal speed: 2800 1/min (50 Hz)

Art. no.: 9 4601 010

Dimensions: Ø 200 x 60 mm

Rpm: 384 1/min (50 Hz)

Cutting speed: Vc = 4.0 m/s (50 Hz)

Art. no.: 9 4601 120

Dimensions: 1250 x 60 mm - P120

Rpm (spindle): 1440 1/min (50 Hz)

Cutting speed: Vc = 15.1 m/s (50 Hz)

Art. no.: 9 4601 180

Dimensions: Ø 200 x 50 mm

Rpm: 1440 1/min (50 Hz)

Cutting speed: Vc = 15.1 m/s (50 Hz)

Depth: 830 mm

Width: 650 mm

Height: 500 mm (without a stand)

Weight: 98 kg (without a stand)

SM-200 TE Grinding and Honing Machine

20

Design and Function

6

Cooling water unit

Emissions sound pressure level

Sound emission in accordance with EN ISO 11201.

Ambient conditions

Volume of cooling water circulated:

40 I/min

Content of water tank 20 litres

Pump

Power 0.12 kW

Degree of protection IP54

Connection 3~400 V (three-phase)

A-rated emissions sound pressure level at the work

area measured at idling speed LpA:73dB (A)

Uncertainty KpA ; uncertainty in decibels: 3 dB (A)

A-rated emissions sound pressure level at the work

area measured when grinding a hand knife LpA:77dB (A)

Uncertainty KpA; uncertainty in decibels: 3 dB (A)

Temperature

Storage: 3 - 40 °C

Operation: 3 - 30 °C

Usage: indoors

Table of contents

Other Dick Power Tools manuals

Popular Power Tools manuals by other brands

Optimum

Optimum OPTImill MH 22V operating manual

Atlas Copco

Atlas Copco LTP61 H700-25 Product instructions

Parkside

Parkside PT360 Operation and safety notes

Sealey

Sealey GSA634 manual

Scheppach

Scheppach HP3000S Translation from the original instruction manual

Rikon Power Tools

Rikon Power Tools 10-342 Operator's manual