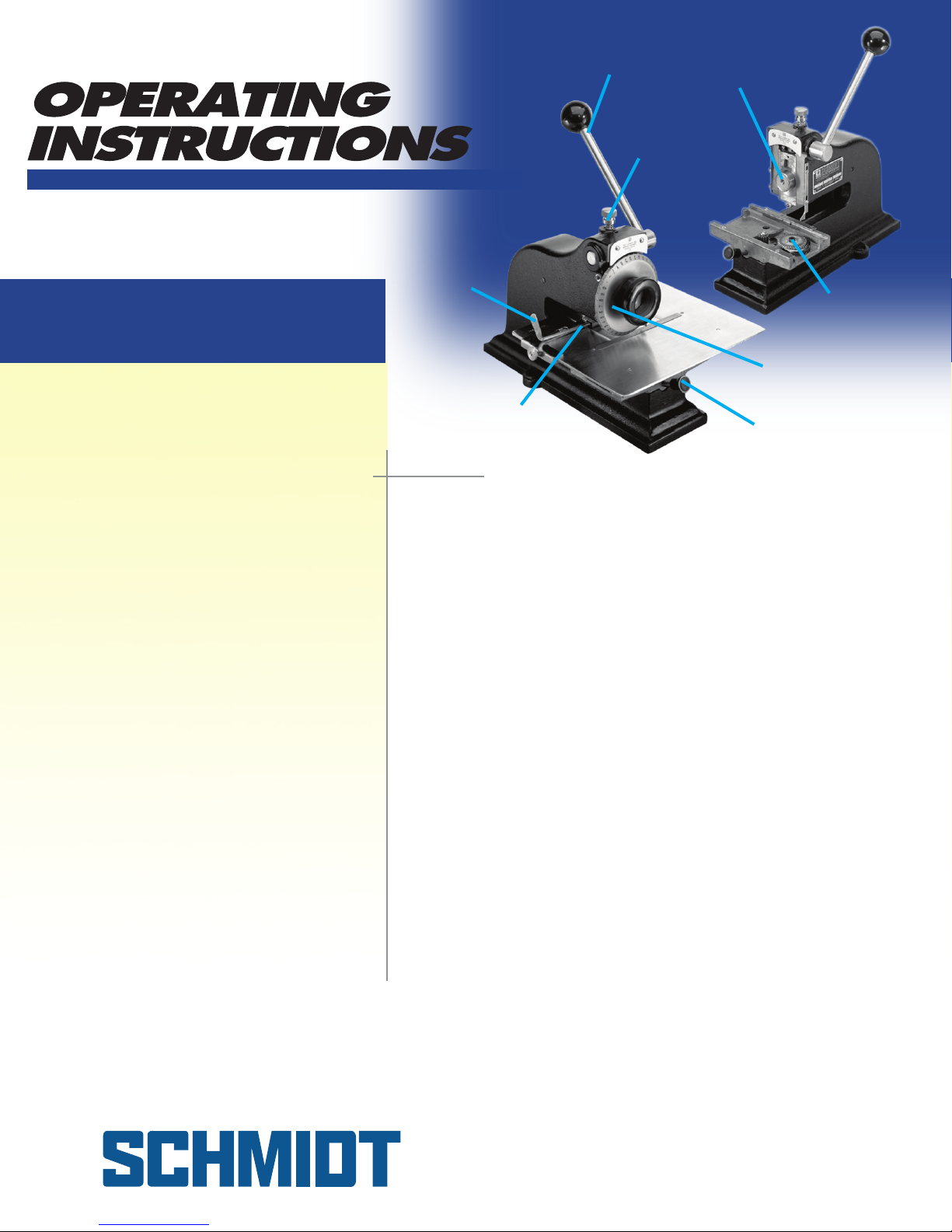

Table Gauge

Assembly

(800) 323-1332 (847) 647-7117

www.gtschmidt.com

EASY FOUR-STEP OPERATION

M O DEL4&6 N AME P L A TE D E T A IL PRE S S E S

Center the Nameplate on the table. Press the

clamp handle down to slide the nameplate into a

new position. Release the clamp handle to lock it in

place. The clamp is fastened to a sliding rectangle

(table gauge assembly), which is tightened by

means of a small thumb screw. The entire table can

be indexed by pressing the space button at the front

of the unit.

CAUTION: When indexing the table, be sure to

grasp the table lightly with your left hand; the table

operates like a typewriter carriage and damage will

result if it is allowed to slam against the limit screw.

Spin the character dial to select the desired

number or letter.

Set marking depth by turning the depth adjust-

ment screw. First, set depth until dial contacts the

nameplate. Then remove the place and make

another 1-1/2 counter clockwise turn to indent the

plate. Turning the screw clockwise makes the

impression shallower.

Move operating handle forward rmly to make

impressions. If the mark is not deep enough, adjust

the depth setting. The handle will return to its

original position, which automatically indexes the

table one notch to the left, placing the nameplate in

position for the next character. Move the handle

forward to backward halfway to leave a blank space

or a space between words.

CAUTION: Forcing the operating handle down or

back will cause damage to the machine.

1.

2.

3.

4.

Operating Flexibility. Your SCHMIDT Nameplate detail press can be

operated eciently by pulling the operating handle from a sitting

position or by pushing the operating handle from a standing position.

Just remember to bring the operating handle to the neutral position -

and not beyond.

To set the plate for stamping a new line of another panel, simply move

the table gauge forward or back to center the locating pointer. For

added exibility, the table gauge can be placed on the right edge of

the table. The clamp is then in front of the dial and plates are gripped

at the bottom, allowing the machine to stamp at the extreme top edge.

With the gauge in this position, the throat capacity is also increased to

4.5 inches.

CHANGING THE MARKING DIAL:

1. Remove screw in the center of the dial and take o dial, knob and

pointer. Place new dial and pointer in position and tighten into place

with retaining screw.

2. Slide table to extreme right and remove table limit screw. Return

table to left to expose spacing mechanism. Remove escapement wheel

and replace with one that matches correct dial size. Replace the limit

screw.

3. Return table to marking position.

EXTRA DIALS: All dial assemblies are interchangeable and include

Knob, Pointer and Escapement Wheel. Sizes available include 3/32”,

1/8”, 3/16”and 1/4”

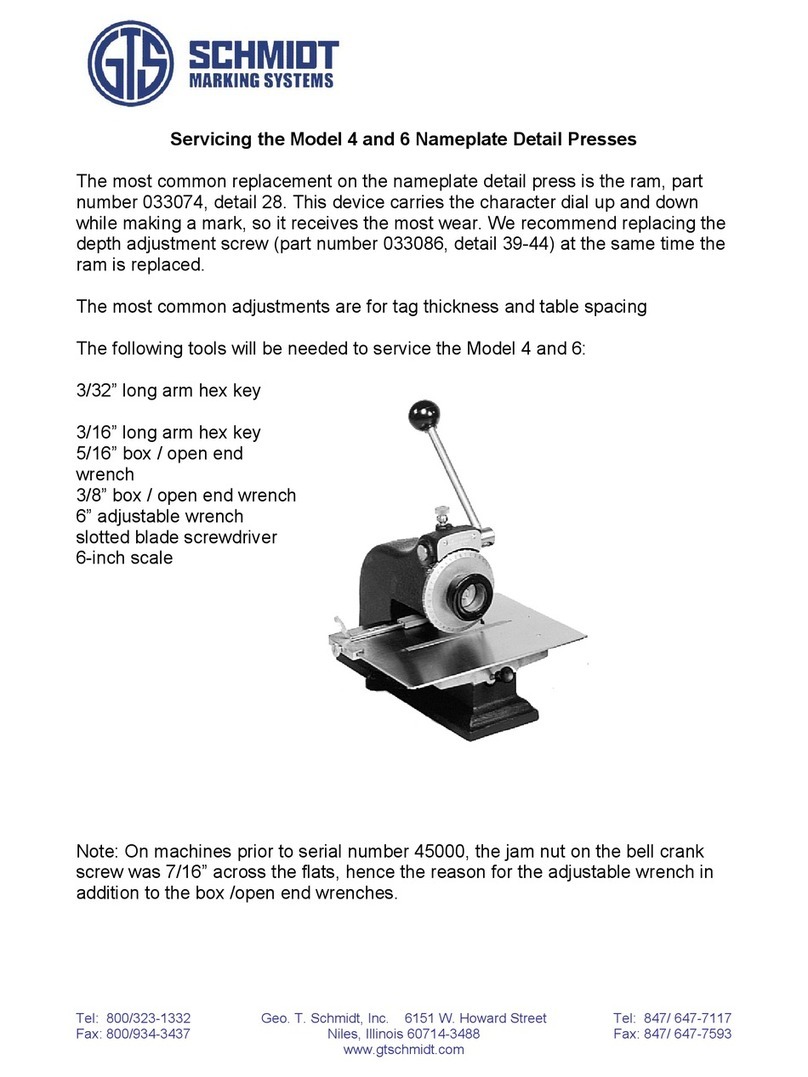

Clamp

Handle

Character Dial

Operating Handle

Depth

Adjustment

Screw

Space Button

Escapement

Wheel

Assembly

Ram (with Ball

Spring)