Page 4 of 8 (Section 1 of 2) Form No.V6928R3 - Sec. 1

50 anover Road, Florham Park, New Jersey 07932 www.ascovalve.com

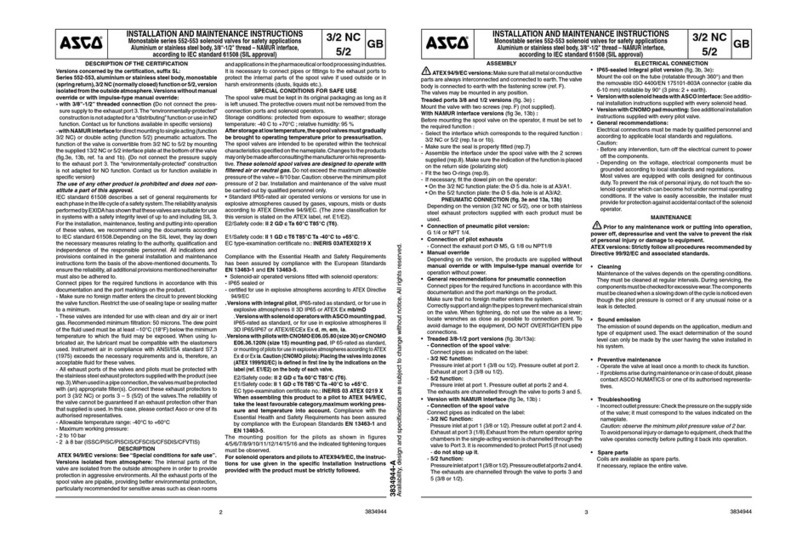

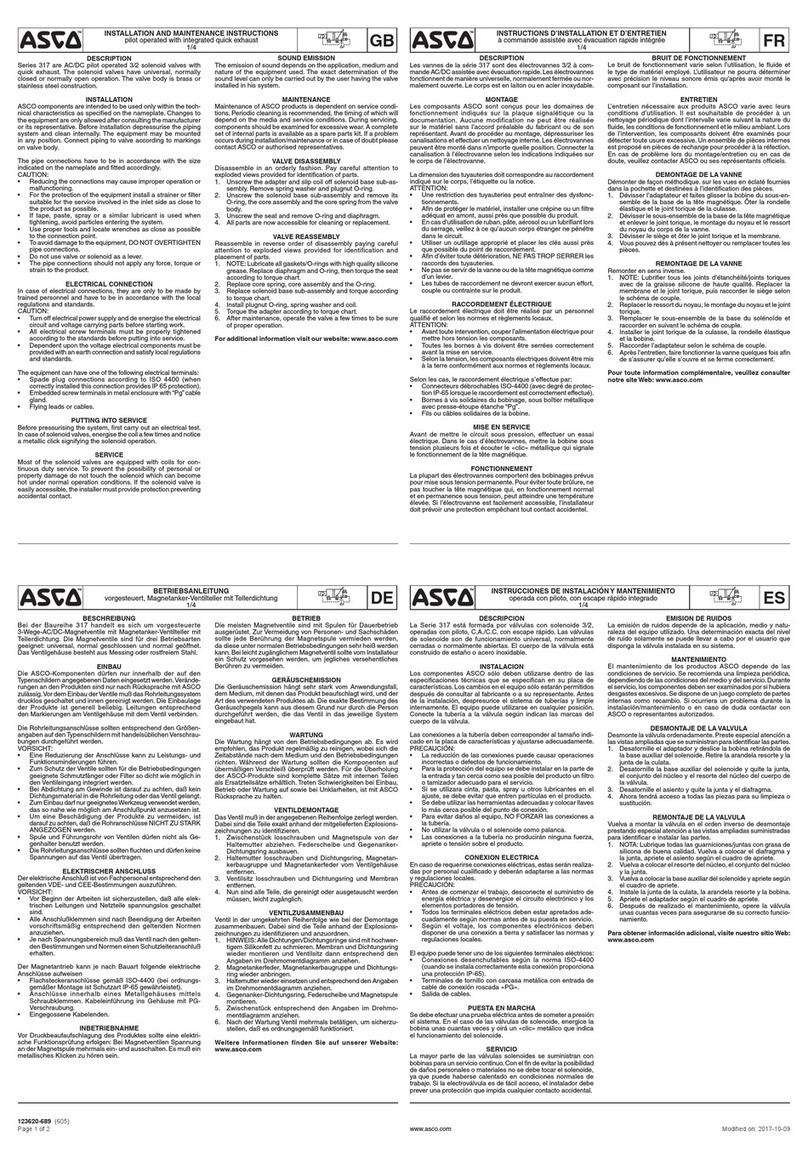

Flow Controls (Speed or Metering Devices)

Flow control valves may e added to control cylinder speed. If

used, these flow control valves must e located in cylinder

piping etween the solenoid valve and the cylinder.

IMPORTANT: Do not install flow controls (speed or

metering de ices) or any type of restricti e de ice in the

pressure (inlet), exhaust or pilot exhaust (outlet) ports of

the al e. Restricting any of these lines may cause al e

malfunction.

Cyl.

Press.

Aux.

Pilot Exh.

Indicates location

of pressure gauge

Indicates location

of filter

Indicates location

of metering device

Main

Exh.

muffler

or piping

Solenoid

Figure 5. Piping diagram

For Internal Piloting Mode only: Full size

piping without restrictions must be used

on pressure and exhaust lines.

MAINTENANCE

W RNING: To prevent the possibility of death,

personal injury or property damage, turn off

electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline

for repairs. However, piping or tu ing must e removed from

pilot exhaust on top of the solenoid if present. See Pi ing

section.

Cleaning

All solenoid valves should e cleaned periodically. The time

etween cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage will

indicate that cleaning is required. In the extreme case, faulty

valve operation will occur and the valve may fail to shift. Clean

filter when cleaning the valve.

Pre enti e Maintenance

SKeep the medium flowing through the valve as free from dirt

and foreign material as possi le.

SPeriodic exercise of the valve should e considered if

am ient or fluid conditions are such that corrosion,

elastomer degradation, fluid contamination uild up or

other conditions that could impede solenoid valve shifting

are possi le. In many cases, solenoid valves are periodically

exercised during normal system use or as part of routine

maintenance or surveillance activities and no additional

exercise is necessary. The actual frequency of exercise

necessary will depend on specific operating conditions. A

successful operating history is the est indication of a proper

interval etween exercise cycles.

SDepending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive

wear is recommended. Thoroughly clean all parts. If parts

are worn or damaged, install a complete ASCO Re uild Kit.

Causes of Improper Operation

SIncorrect Pressure: Check valve pressure. Pressure to valve

must e within range specified on nameplate.

SExcessi e Leakage: Disassem le valve and clean all parts. If

parts are worn or damaged, install a complete ASCO

Re uild Kit.

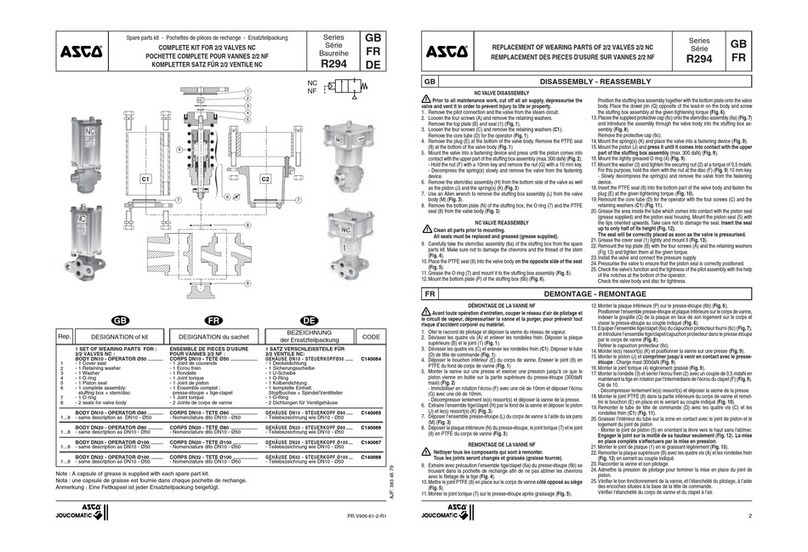

Val e Disassembly

NOTICE: Basic al e constructions are identified by orifice

size and pipe size (NPT). Check al e nameplate for orifice and

pipe size. See Figure 7 for 5/16I orifice, 1/4I or 3/8I NPT;

Figure 8 for 5/8I orifice, 3/8I or 1/2I NPT. For Standard al e

solenoid parts see Figure 6 in addition to Figures 7 or 8. Figures

7 and 8 show Low Power and Intrinsically Safe solenoid parts.

Determine valve construction and proceed as follows:

1. Disassem le valve in an orderly fashion using exploded

views for identification and placement of parts.

2. Low Power & Intrinsically Safe - Using a suita le wrench

hold cartridge assem ly securely y wrenching flats. Then

unscrew muffler or piping from 1/8I NPT connection on

top of cartridge assem ly.

Standard Valves - Hold pipe adapter securely and

unscrew muffler or piping from 1/4I NPT connection on

top of solenoid ase su -assem ly.

3. Remove solenoid, see separate instructions.

4. Low Power & Intrinsically Safe - Unscrew cartridge

assem ly from valve ody. Then remove cartridge gasket

from valve ody and orifice gasket from recess in ase of

cartridge assem ly.

Standard Valves - Unscrew solenoid ase su -assem ly

from valve ody. Then remove solenoid ase gasket and

core assem ly with core spring and core guide. Core guide

present on AC construction only. Remove plugnut gasket

from groove in solenoid ase su -assem ly.

5. Remove cover screws (2), cover, and support containing

large and small flow gaskets from side of valve ody.

6. At exhaust end, remove onnet screws, lockwashers, valve

onnet, ody passage gasket, retaining ring, diaphragm

assem ly, diaphragm support (see note elow) and ody

gasket from valve ody.

NOTE: Retaining ring and diaphragm support are only present

on 5/8I orifice valve constructions. However, they are not resent

on all 5/8I orifice valve constructions.

7. At opposite end remove onnet screws, lockwashers, end

cap, disc spring, ody gasket, disc assem ly and valve stem.

8. All parts are now accessi le for cleaning or replacement.

If parts are worn or damaged, install a complete ASCO

Re uild Kit.

continued on Form No. V6928R3 - Section 2 of 2