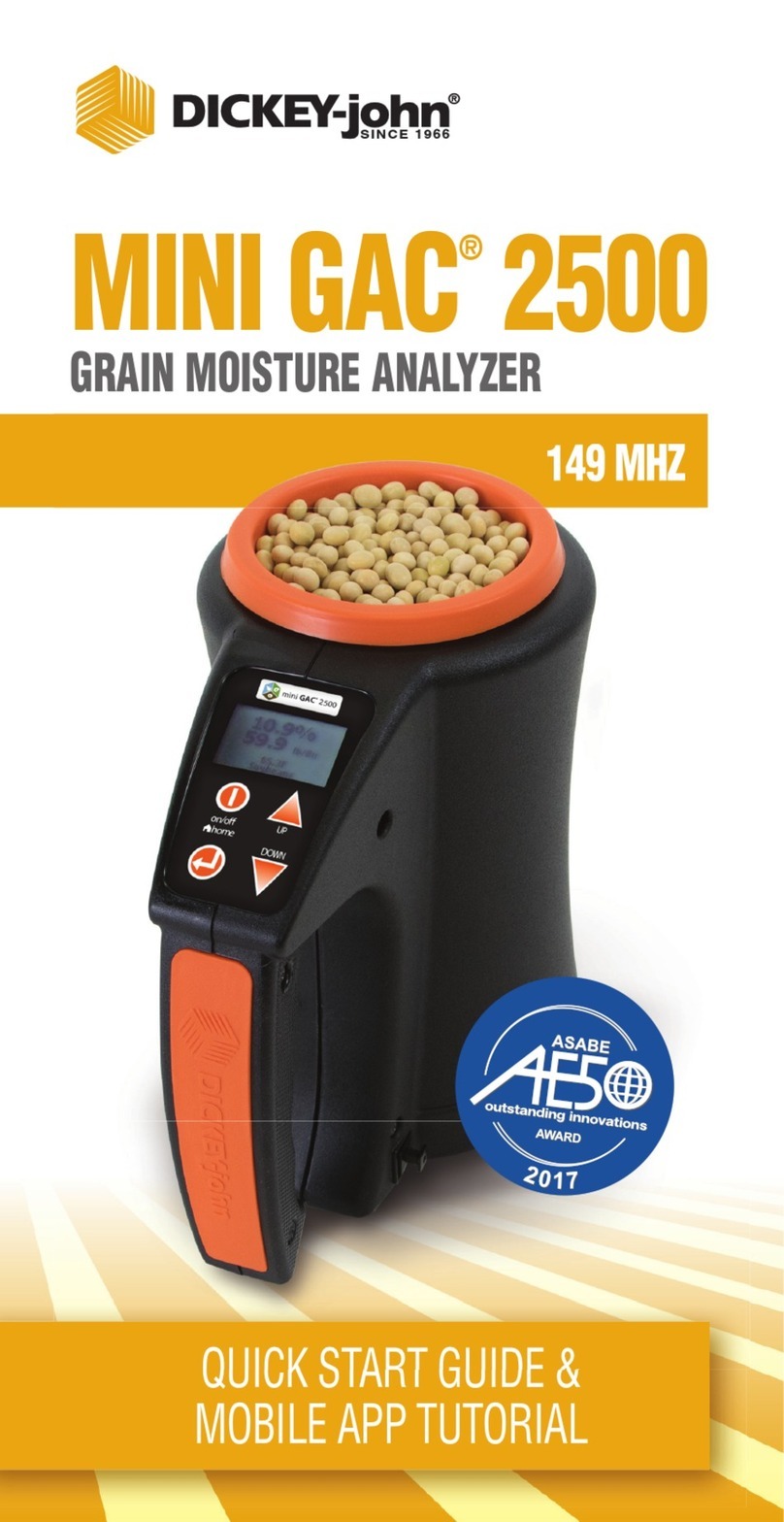

Dickey-John GAC 2500 User manual

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

/I

Safety Notices ..................................................................................................... 1

Introduction ......................................................................................................... 3

Accessories ....................................................................................................................... 3

Unit Overview .................................................................................................................... 3

Features ............................................................................................................................ 4

Specifications .................................................................................................................... 4

Declaration of Conformity ................................................................................................. 4

External Communication Connections .............................................................................. 5

Printer ............................................................................................................................... 6

Installation ........................................................................................................... 7

Unit Positioning ................................................................................................................. 7

Connecting AC Power ...................................................................................................... 7

Grain Drawer .................................................................................................................... 8

Optional Bottomless Grain Drawer ................................................................................................... 8

Navigation ............................................................................................................ 9

Using External Devices ..................................................................................................... 9

Touch Screen Button Functions ...................................................................................... 10

Home .............................................................................................................................................. 10

Power Off ....................................................................................................................................... 10

Initiate.............................................................................................................................................. 10

Print................................................................................................................................................. 10

Back ................................................................................................................................................ 10

Abort................................................................................................................................................ 10

Enter ............................................................................................................................................... 10

USB ................................................................................................................................................ 10

User ................................................................................................................................................ 10

Instrument Information ................................................................................................................... 11

LCD Display Touch Screen Calibration .......................................................................................... 11

Keypad ........................................................................................................................................... 11

Password Restrictions ..................................................................................... 13

Setup .................................................................................................................. 15

Product ............................................................................................................................ 15

Edit Existing Product ...................................................................................................................... 15

Edit Product .................................................................................................................................... 17

Create Product ............................................................................................................................... 18

Delete Product ............................................................................................................................... 19

Load New Product .......................................................................................................... 20

Administrative Settings ................................................................................................... 22

To Change a Known User Name/Password .................................................................................. 22

To Reset a User Name/Password .................................................................................................. 22

System Setup .................................................................................................................. 23

Printer Setup .................................................................................................................................. 23

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

II /

Setup continued ................................................................................................. 25

Printer/Scale Setup ......................................................................................................... 25

Printer Setup ................................................................................................................................... 25

Language Settings .......................................................................................................................... 27

Locale Setting ................................................................................................................................. 28

Time ................................................................................................................................................ 29

Result Settings ............................................................................................................................... 30

Export Data Format ........................................................................................................................ 31

Units ............................................................................................................................................... 32

Sample Setup ................................................................................................................................. 33

Owner Data .................................................................................................................................... 34

Service Data ................................................................................................................................... 35

LCD Display Touch Screen Calibration .......................................................................................... 36

Startup ............................................................................................................... 37

Power Down ................................................................................................................... 38

Analyzing Grain ................................................................................................ 39

User Login (Optional) ..................................................................................................... 39

User Login ...................................................................................................................................... 40

User Log Off ................................................................................................................................... 40

Selecting Product ........................................................................................................... 40

Results .............................................................................................................. 45

Refine Query Options ..................................................................................................... 46

Print Only Last Number of Records ................................................................................................ 46

All Products .................................................................................................................................... 46

Product Like .................................................................................................................................... 46

User Like ........................................................................................................................................ 47

Sample ID Like ............................................................................................................................... 47

Data Storage Capacity ................................................................................................... 48

Audit Trail ....................................................................................................................... 49

View Products ................................................................................................................. 51

Grain Calibrations ............................................................................................ 53

Maintenance ...................................................................................................... 55

External Cleaning ........................................................................................................... 55

Internal Cleaning ............................................................................................................ 55

LCD Display .................................................................................................................... 56

Troubleshooting ............................................................................................... 57

Error Messages .............................................................................................................. 58

Warranty.............................................................................................................. 61

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

SAFETY NOTICES / 1

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards. An absence of specific alerts does not mean that there are no

safety risks involved.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this symbol,

carefully read the message that follows. Be alert to

the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

2 / SAFETY NOTICES

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

INTRODUCTION / 3

INTRODUCTION

The DICKEY-john Grain Analysis Computer GAC®2500 quickly tests grain

and automatically calculates moisture content, temperature, and test weight

(density) of the sample. The unit prompts for sample loading, tests the

sample, and displays the results.

ACCESSORIES

The following list of components are included with the unit and can be

ordered as replacement parts:

• 110V power cord p/n 203150002

• 220V power cord p/n 203150005 (international optional/not currently

available)

• Operator’s manual p/n 11001-1505

• Cleaning brush p/n 206410003

• Grain drawer p/n 468071541

• Grain drawer bottomless (optional) p/n DRAWEROPGAC2500

UNIT OVERVIEW

1. Power (on/off) button

2. Hopper

3. Hopper full sensors

4. Touch screen display

5. USB connections (2) front (2) back

6. Sample drawer

Figure 1

GAC2500 Overview (Front of Unit)

6

1

2

4

5

3

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

4 / INTRODUCTION

FEATURES

• Color touch screen display guides users through testing and setup

• Easy-to-use user interface

• Fast, accurate grain analysis

• One core calibration for all grains

• Alpha/numeric sample identification with the ability to add an optional

extended keyboard or bar code reader via USB

• Error messages display when out-of-limits moisture, grain weight, or

grain temperature occur

• Customizable work environment

• Optional password protection

• Storage of 30,000 grain tests

• Large storage to handle complete grain calibration library

• Internal memory capacity to handle future upgrades

• Printing capabilities

• A variety of external communication options

• English language capability (additional languages to be added)

SPECIFICATIONS

• Operating temperature: 36 to 113 degrees F (2 to 45 degrees C)

• Power: 110/220V, 50/60 Hz, 30/35 VA

• Humidity: 20 to 90% noncondensing

• Grain temperature: 32 to 113 degrees F (0 to 45 degrees C)

• Storage/transit temperature: -4 to +140 degrees F

(-20 to +60 degrees C)

• Moisture range: 5 to 45% (grain dependent)

• Approximate Weight: 25 lbs.

• Approximate dimensions: 17”H x 19”W x 14”D

DECLARATION OF CONFORMITY

The GAC®2500 is in conformity with the provisions of the following

directives and regulations:

• EN2006/95/EC Low Voltage Directive

• EN2004/108/EC EMC Directive

• EN61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use operating at a maximum

altitude of 6562 feet (200 meters)

• CAN/CSA - C22.2 NO. 61010-1 and ISA - 82.02.01 (IEC 61010-1

MOD) and UL61010-1

• NTEP GRAIN ANALYZE (NCWM publication 14 and NIST Handbook

44)

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

INTRODUCTION / 5

EMC

EMC conformity to EN 61326-1:2006 (Electrical Equipment for

Measurement, Control, and Laboratory use) as follows:

Immunity

• Radiated RF field EN 61000-4-3 (2002)

• Conducted RF voltage EN 61000-4-6 (1996) + A1 (2001)

• Fast transient/burst EN 61000-4-4 (2004)

• Electrostatic discharge (ESD) EN 61000-4-2 (1995) + A1 (1998) + A2

(2001)

• Surge EN 61000-4-5 (1995) + A1 (2001)

• Voltage dips and interruptions EN 61000-4-11 (2004)

Emission

• Radiated emission CISPR II:2003 + A1: 2004

• Conducted emission CISPR II:2003 + A1: 2004

EXTERNAL COMMUNICATION CONNECTIONS

• 4 USB connections (2 in front, 2 in back) allow for a keyboard, mouse,

printer or flash drive to be connected.

• 1 USB connection to connect the GAC®2500 to a PC for downloading

of software to the device, installing calibrations, or remotely accessing

data from the instrument.

• 1 RS232 serial port printer connection

Figure 2

External Communication Connections (Back of Unit)

Appropriate space must be left around the input power connector

to allow easy disconnection at the unit.

Power Cord

Connection

(2) USB

(1) LAN

(1) RS232

Serial Port

Printer

Connection

(1) USB (B)

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

6 / INTRODUCTION

PRINTER

An optional printer that is RS232 compatible or a USB printer that supports

Printer Control Language (PCL) can connect to the GAC®2500 to print test

data results to a ticket. The ticket can be setup to include the facility name

and address, product, date and time, sample ID, customer ID, grain

calibration date, percent moisture, grain temperature, test weight, and

errors. The data can be automatically printed at the end of each

measurement cycle or manually initiated by pressing the Printer button.

Figure 3

Printer

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

INSTALLATION / 7

INSTALLATION

The GAC®2500 unit requires minimal setup. The unit is fully assembled

and ready for operation after attaching the AC power cord and inserting the

grain drawer.

NOTE: After unpacking, visually

inspect for damage occurring

during transit. Save all packing

materials until inspection is

complete. If damage is found,

file a claim with the carrier

immediately and notify your

DICKEY-john sales

representative.

Figure 4

Unit Dimensions

UNIT POSITIONING

Place the unit in a clean environment that is protected from rapid changes

in ambient temperature and vibration. Avoid a hazardous (classified)

location as defined in Article 500 of the NFPA Handbook of the National

Electrical Code.

CONNECTING AC POWER

1. Securely connect power cord into the AC plug connection (Figure 2)

located on the back of the unit.

2. Plug the male end into an appropriate 3-wire (grounded) outlet.

16.9”

18.6”

10.5”

16.2”

18.6” 13.9”

SIDE VIEW

FRONT VIEW

TOP VIEW

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

8 / INSTALLATION

The grounding pin on the line cord connects directly to the

GAC®2500 frame. When using an adapter ensure the

grounding wire is connected properly to a good earth ground

to prevent a shock hazard.

GRAIN DRAWER

The unit is equipped with a standard grain drawer with handle. An optional

bottomless grain drawer is available for purchase from DICKEY-john.

OPTIONAL BOTTOMLESS GRAIN DRAWER

Part Number: DRAWEROPGAC2500

A bottomless grain drawer is used with a flow-through work counter that

allows the tested grain samples to fall through to a larger container below.

The size of the hole must be at least equal to the drawer dimension and

located directly beneath the grain sample drawer.

NOTE: Contact DICKEY-john Technical

Support at 1-800-637-3302 for

additional information on grain

drawers.

Figure 5

Flow Through Work Counter

Bottomless

Grain Drawer

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

NAVIGATION / 9

NAVIGATION

The user interacts with the GAC®2500 via the LCD touch screen display.

Screen interaction by finger touch or using a dull, pointed object, such as a

stylus or pen is recommended.

Refer to Maintenance section for cleaning display.

Do not use any sharp objects on the display. Damage to screen

can result.

The following methods are used to navigate through and interface with the

unit:

1. Text input boxes

2. Keypad icon (enables keyboard)

3. Buttons

4. Keyboard

Figure 6

LCD Touch Screen Display

USING EXTERNAL DEVICES

The following external devices can be used to enter data and navigate

through the screens by connecting to the USB ports (2 front/2 back):

• keyboard

•mouse

• barcode scanner

Enter Sample ID

GAC2500

Enter Sample ID

GAC2500

Sample ID

Load Sample

Change Product

View Last Result

Product: Corn

Issue ID:

Customer ID

Sample ID

Customer ID

1

2

3

Enter Sample Name

GAC2500

Enter Sample Name

GAC2500

V

UO P Q SR TN

M

GH I K

JLF

E0 . A CB D9

82 3 4 65 71

Space

4

05182006

W X Y Z -

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

10 / NAVIGATION

TOUCH SCREEN BUTTON FUNCTIONS

HOME

Home button is available on most screens and, when pressed, returns to

the Main Menu screen.

POWER OFF

Power Off button turns the system off from the touch screen display. The

system must be turned on using the On/Off button located on the front panel

but can be turned off from either the screen display or the On/Off button.

INITIATE BUTTON

The Initiate button is used to analyze grain and has 3 states of operation:

Green = proceed to begin test

Yellow = an action is required to proceed

Red = system cannot process; error has occurred

PRINT

Print button allows printing test results to a local printer. Refer to the Setup

section for print requirements.

BACK

Back button returns to the previous screen.

ABORT

Abort button dumps grain from hopper, empties the cell, and aborts test.

ENTER

Enter button accepts action taken and proceeds to next screen.

USB

USB button is used when connecting the unit direct to a computer for

downloading software and installing calibrations.

USER

User button appears on the Main Menu screen only if a User ID has been

enabled in System Setup. Requires a tester to enter a User Name before a

grain analysis can proceed and will print on a ticket.

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

NAVIGATION / 11

INSTRUMENT INFORMATION

Instrument Information button appears on the Main Menu screen

providing details regarding unit service date, serial number, and software

version. Typically used for troubleshooting purposes.

LCD DISPLAY TOUCH SCREEN CALIBRATION

Display Touch Screen Calibration button re-calibrates the display when

screen responsiveness does not occur effectively to a finger touch or stylus.

KEYPAD

The Keypad icon appears on those screens that require text entry.

Pressing the Keypad icon opens the virtual keyboard for typing text on the

screen. The virtual keyboard is used when an external keyboard, mouse, or

barcode scanner are not available.

Figure 7

Keyboard

Enter Sample Name GAC2500

Enter Sample Name GAC2500

V

UO P Q SR TN

M

GH I K

JLF

E0 . A CB D9

82 3 4 65 71

Space

W X Y Z -

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

12 / NAVIGATION

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

PASSWORD RESTRICTIONS / 13

PASSWORD RESTRICTIONS

Setting an Admin user name and password to restrict system settings to be

controlled by an administrator are optional. The unit is shipped with an

Admin user name and password setting of “GUEST”.

Keeping the Admin user name and password as “GUEST” retains the unit in

open access mode allowing any user to enter System Settings and modify

unit settings.

IMPORTANT: To restrict access to System Setup that affects overall

unit functionality, a new Admin user name and password

must be created.

To Create an Admin User Name and Password:

1. At the Main Menu screen, press the Setup button.

2. Leave the Admin Username and Password as GUEST and press the

Enter button.

3. At the Setup screen, press the Admin Settings button.

4. At the Enter New Password screen, press the Admin Username

keypad icon and enter an administrator user name.

5. Press the Enter button to accept.

6. Enter a Password and re-enter password to confirm.

7. Press the Enter button to accept.

NOTE: An external keyboard, barcode

scanner, or mouse can be used

to enter data into the unit.

Once a new password is created, the unit is configured so that an

administrator name and password is required to gain entry into the System

Setup screens. Password and User Name can be any combination of

letters and numbers.

Refer to Administrative Settings in the System Settings section to change

an Administrator user name and password or reset to open access.

IMPORTANT: The following words are restricted to system

functionality and cannot be used as User Names (ROOT,

GUEST, REBOOT, RESET).

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

14 / PASSWORD RESTRICTIONS

Figure 8

Password Screen

System

Setup GAC2500

Setup GAC2500

Admin Settings

Enter New Password

GAC2500

GAC2500

FRED

Enter Admin

Username

New Password

Re- Enter Password

FRED PASSWORD

FRED PASSWORD

Enter Admin Username

Enter Admin Username

GAC2500

Enter Admin Username

GAC2500

Enter Admin

Username

GUEST

GUEST

Enter

Password

Please Log In

Product

Diagnostics

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

SETUP / 15

SETUP

Setup establishes basic unit operating parameters and allows

customization of the user interface by:

• Editing an existing product and loading new products (Product button)

• Setting administrative levels (Admin Settings button)

• Setting system parameters for external devices, language/locale

preferences, time/date, sample result output, unit measurement,

sample/customer ID’s, and printing formats (System button)

• Diagnostics for troubleshooting and unit information (Diagnostic

button)

To View Setup Options:

1. At the Main Menu screen, press the Setup button.

2. Enter User Name and Password, if required, and press the Enter

button to display the Setup screen. If defaulted to Name (Guest) and

Password (Guest) press the Enter button.

Figure 9

Setup Screen

PRODUCT

The Product screen is used to:

• Edit existing products

• Load new products

EDIT EXISTING PRODUCT

If for any reason non-NTEP calibrations need to be adjusted, certain

product parameters can be changed as follows:

NOTE: NTEP calibrations are

regulated and cannot be

altered.

• Modifying moisture and test weight bias and moisture and test weight

slopes

• Creating a new product by copying a similar product (duplicated and

saved using a different name and Issue ID)

• Deleting an existing product from appearing on active screens

System

Setup GAC2500

Setup GAC2500

Admin Settings

Product

Diagnostics

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

16 / SETUP

To Edit an Existing Product:

1. At the Product Setup screen, press the Edit Existing Product button.

2. At the View Product Setup screen an alphabetical product list appears.

Press the Up or Down button to display additional products.

Figure 10

Edit Existing Product Screens

3. Press the desired product to highlight and press the Enter button to

select. Once the product is selected, the product’s parameters display

in a table.

4. Select the desired action:

– Edit product (does not display on screen for NTEP calibrations)

– Create product

– Delete product

Product Setup GAC2500

Product Setup GAC2500

Edit Existing Product

Load New Product

Load New Products

Only appears

if flash drive

is inserted

into unit.

View Product Setup GAC2500

View Product Setup GAC2500

DOWN

UP

LGR Rice

HRW Wheat

HRS Wheat

Corn

6-Row Barley

Product

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

SETUP / 17

EDIT PRODUCT

A product’s moisture bias, test weight bias, moisture slope, and test weight

slope can be changed at this screen. All NTEP calibrations are locked and

cannot be modified. A product’s calibrations should only be changed by an

authorized user.

NOTE: A product’s detail at the View

Product Setup screen can be

printed by pressing the Print

button.

To Edit a Product:

1. At the View Product Setup screen, press the Edit button.

2. At the Edit Product screen, press the keypad icon to modify a product’s

parameters.

3. When finished, press the Enter button.

4. Confirm product replacement by pressing the Replace button at the

Product Already Exists screen. The Skip button returns to the previous

product’s bias and slope setting.

5. The new bias and slope appears in the product table on the View

Product Setup screen. The product name and Issue ID will remain the

same.

NOTE: An external keyboard, barcode

scanner, or mouse can be used

to enter data into the unit.

Figure 11

Edit Product

Edit Product GAC2500

Edit Product GAC2500

0.02

0.99

0.10

0.99

Moisture Bias

Moisture Slope

Test Weight Bias

Test Weight Slope

View Product Setup GAC2500

View Product Setup GAC2500

Product: Peas2100

Issue #: 20101231

Calibration: GAC2100 Emulation

Range: 10-30% Moisture

Test Weight Range: 42 - 73 lbs/bu

Temperature Range: 0 - 50° C

:-66lbs/

Temperature Range: 0 – 45 °C

Moisture Bias: -1.35

Moisture Slope: 1.00

Test Weight Bias: 0.00

Test Weight Slope: 1.00

File Name: CornHM-2100.cal Delete

Edit

Create

Product Already Exists GAC2500

Product Already Exists GAC2500

Skip

Replace

Product Already Exists

Peas2100

Moisture Bias: 0.00

Moisture Slope: 1.00

Test Weight Bias: 0.00

Test Weight Slope: 1.00

File Name: Peas2100.cal

Edit button

is not available

for NTEP

calibrations

OPERATOR’S MANUAL

GAC® 2500

11001-1505B-201011

18 / SETUP

CREATE PRODUCT

A new product can be created by copying a similar product’s parameters.

Creating a new product name and Issue ID prevents an existing product’s

parameters from being overwritten.

NOTE: An external keyboard, barcode

scanner, or mouse can be used

to enter data into the unit.

To Create a Product:

1. At the View Product Setup screen, press the Create button.

2. At the Rename Product screen, the product name and NEW appears

as the default name.

3. Press the keypad icon to enter a different product name, if desired.

4. A new Issue ID is automatically defined for the new product. Press the

keypad icon to enter a different Issue ID, if desired.

5. Press the Enter button to save.

Figure 12

Creating a Product Screen

View Product Setup GAC2500

View Product Setup GAC2500

Product: Popcorn

Issue ID: 20101030

Calibration : UGMA

Range: 5 - 35%

Test Weight Range: 42-68 lbs/bu

Temperature Range: 25 - 125 ° F

Moisture Bias: -1.35

Moisture Slope: 1.00

Test Weight Bias: 0.00

Test Weight Slope: 1.00

File Name: Popcorn-20101030.CAL

Delete

Edit

Create

Rename Product

GAC2500

Rename Product

GAC2500

New Product Name Popcorn NEW

New Issue ID 20100116

Enter New Product Name

Other manuals for GAC 2500

3

Table of contents

Other Dickey-John Measuring Instrument manuals

Dickey-John

Dickey-John gac 2100 agri User manual

Dickey-John

Dickey-John INSTALAB 700 User manual

Dickey-John

Dickey-John Dj F-2000 User manual

Dickey-John

Dickey-John GAC500XT User manual

Dickey-John

Dickey-John Seed Manager SE User manual

Dickey-John

Dickey-John GAC 2700-UGMA User manual

Dickey-John

Dickey-John MINI GAC 2500 NBT User manual

Dickey-John

Dickey-John Instalab 700 NIR User manual

Dickey-John

Dickey-John mini GAC User manual

Dickey-John

Dickey-John GAC 2500 User manual