Dickey-John PM200 User manual

PM200, 200E and 250 Planter Monitors

11001-1444-200702

i

TABLE OF CONTENTS

Safety Notices ...................................................................................................... 1

Introduction .......................................................................................................... 3

System Overview ............................................................................................................... 3

Features............................................................................................................................. 3

Performance...................................................................................................................................... 3

Console/Display ................................................................................................................................ 4

Compatibility...................................................................................................................................... 4

User Aid ............................................................................................................................................ 4

Specifications..................................................................................................................... 5

Key Functions .................................................................................................................... 5

Keypad/Display Navigation................................................................................................ 7

Installation ............................................................................................................ 9

Standard Mounting Bracket ............................................................................................... 9

Optional Mounting 3D Adjustable Bracket ....................................................................... 10

Installing Console Harnesses .......................................................................................... 11

Installing Implement Harness and Sensors ..................................................................... 12

Menu Screen....................................................................................................... 13

Security............................................................................................................... 15

Unlock the Password Screen........................................................................................... 15

Unlock All Screens .......................................................................................................................... 15

Lock/Unlock Individual Screens ...................................................................................................... 16

Create a New Password .................................................................................................. 16

Quick Start Guide............................................................................................... 17

Planter Configuration ....................................................................................................... 17

Number of Rows ............................................................................................................................. 17

Row Spacing ................................................................................................................................... 17

Ground Speed Configuration ........................................................................................... 20

Perform a New Calibration .............................................................................................................. 21

Help Card .........................................................................................................................21

Main Operate Screen ......................................................................................... 23

Upper Display ...................................................................................................................23

Available Planting Readouts ............................................................................................ 23

Lower Display .................................................................................................................. 24

Additional Monitor Features ............................................................................. 25

Population Limits ............................................................................................................. 25

Hi Population/Low Population ......................................................................................................... 26

Target Population (PM250) ............................................................................................................. 26

Population Adjustment (PM250) ..................................................................................................... 27

Population Filter (PM250) ............................................................................................................... 27

Manual Ground Speed Setup .......................................................................................... 28

Maximum Ground Speed Alarm (PM250) ....................................................................................... 29

Area Accumulators .......................................................................................................... 30

Planting ........................................................................................................................................... 30

Non-Planting .................................................................................................................................... 30

Area Accumulator Screen (PM200 and 250) ................................................................................... 31

PM200, 200E and 250 Planter Monitors

11001-1444-200702

ii

TABLE OF CONTENTS

Menu Setup Screen (Optional) ......................................................................... 33

Units, Backlight, and Alarm Volume ................................................................................ 33

Display Setup Screen ...................................................................................................... 33

Accessory Setup (Shaft Sensor) (PM250)....................................................................... 34

Seed Count Mode (PM250)............................................................................................. 35

Service Screen ................................................................................................................ 36

Alarms ................................................................................................................ 37

Troubleshooting ................................................................................................ 43

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

SAFETY NOTICES / 1

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this

symbol, carefully read the message that follows. Be

alert to the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

!

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

2 / SAFETY NOTICES

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

INTRODUCTION / 3

INTRODUCTION

SYSTEM OVERVIEW

The DICKEY-john PM200, PM200E, and PM250 Planter Monitors offer

features to monitor up to 12 seed or fertilizer rows and one frequency input

(shaft speed).

The monitors are compatible with DICKEY-john seed, flow, hopper level,

and speed sensors. Configuration data is stored in nonvolatile memory,

retaining information even when disconnected from power.

Several planting parameters can be monitored on the Operate Screen and

viewed in a large, easy-to-read format. Row monitoring readouts provide

constant feedback and can be viewed in a bar graph or symbol format.

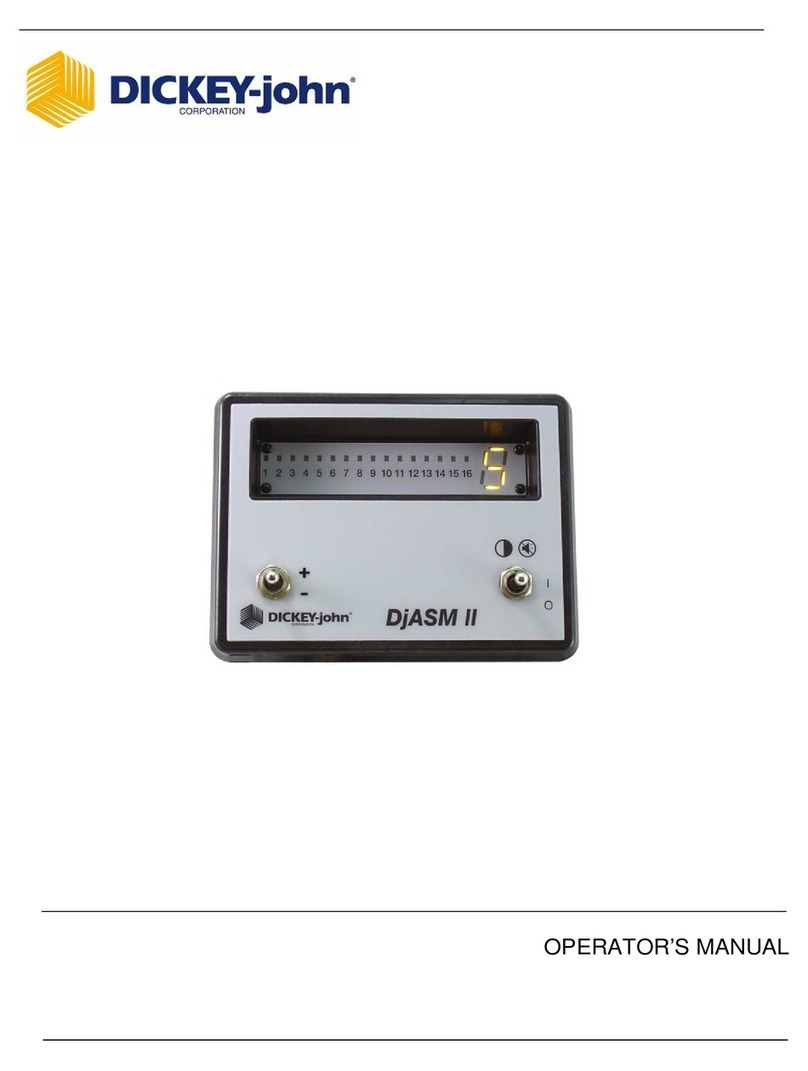

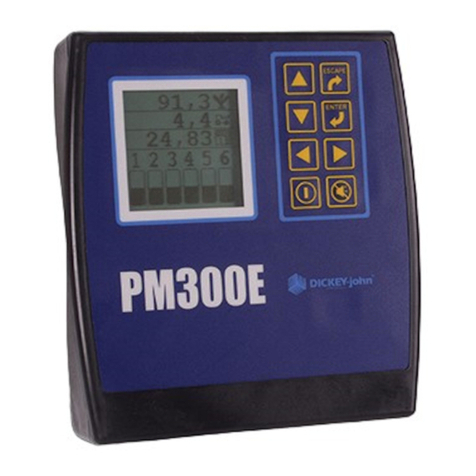

Figure 1

PM200, PM200E, and PM250 Planter Monitors

FEATURES

PERFORMANCE

• Planter monitoring of 12 rows

• Monitoring of ground speed and one shaft speed sensor

• Easy and flexible configuration

• Up and down arrow keys cycle through monitor functions:

– Population

– Field Area 1

– Field Area 2

– Total Area

– Ground Speed

–Menu

• Row status information:

–BarGraph

– Symbols (Failure mode)

– Symbols flashing relative to seeding rates

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

4 / INTRODUCTION

CONSOLE/DISPLAY

• Compact design

• Large, user friendly keys

• Graphic or text-based output labels

• Three-level backlight intensity adjustment

• Large, concise error messages displayed with audible alarm

• English or metric units

COMPATIBILITY

• Compatible with DICKEY-john sensors

• Plug-in replacement for other DICKEY-john monitors

USER AID

• Help card, refer to Figure 15.

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

INTRODUCTION / 5

SPECIFICATIONS

KEY FUNCTIONS

ON/OFF

The On/Off key powers the unit on and off. During power up, the monitor

performs internal self-tests, illuminates the display, sounds the alarm, and

determines which sensors are connected to the system. Pressing and

holding the key for one second when the power is ON will turn the power

OFF, independent of the screen being displayed.

ENTER

From the Main Operate screen, pressing the Enter key displays the

selected function line input screen. Also, the Enter key selects a highlighted

item for data modification. After changing the parameter values, Enter

accepts the modified data.

Power 10–16 VDC, 5 A fused (2A nominal)

Operating temperature range -20°C to 70°C (-4°F to 158°F)

Storage temperature range -40°C to 85°C (-40°F to 185°F)

Size 19.0 cm W x 11.9 cm H x 6.3 cm D

(7.5" W x 4.7" H x 2.5" D)

Weight 3.0 lbs

*Weight includes console and attached

cables (battery power cable and signal

cable that extends to the drawbar).

Wire Harnesses The PM200, 200E, and 250 include

integrated harnesses to supply the unit's

power (fused), ground speed input, and

sensor inputs (to drawbar). The connectors

are compatible with existing DICKEY-john

harnesses. DICKEY-john can supply

custom harnesses required for sensor

inputs.

Sensors Compatible with existing DICKEY-john

sensors

Standard mounting Rear attached horizontal mounting bracket

Mounting bracket weighs 1.0 lb.

Optional mounting Three-axis adjustable mounting bracket

Contrast adjustment Automatic temperature compensation for

contrast

Backlight adjustment Three settings for full sun, daytime, or

nighttime use

Compliant with EU directive 2000/2/EC

Dust and moisture resistant

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

6 / INTRODUCTION

UP/DOWN/LEFT/RIGHT ARROWS

On the Operate (main) screen, the Up and Down Arrow keys are used to

scroll through planting parameters at the top of the display. On Setup

screens, the arrow keys are used to navigate to input boxes to change data

values.

ALARM

During an alarm condition, selecting the Alarm button acknowledges the

alarm condition displayed on the screen. Active row alarms are reset after

an ALL ROWS FAILURE condition or a power down-up sequence occurs. If

the error condition continues, the key must be selected again to cancel the

alarm. When no alarms are active, the volume may be modified by selecting

and holding the Alarm button.

ESC/RESET

On the Operate (main) screen, select and hold the Escape key for four

seconds to clear an area accumulator if it is located on the top line of the

display.

When navigating through sub-menus, the Escape key moves the user back

one selection. After changing parameter values, selecting Escape accepts

the modified data. The Escape key also serves as an alarm cancel key.

Figure 2

Switchpad

On/Off

Acknowledges

alarm

Arrow keys

ESC

Reset

Returns to previous screen

Clears Accumulators on the Operate screen

Acknowledges alarm

Activates data entry

Confirms data entry

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

INTRODUCTION / 7

KEYPAD/DISPLAY NAVIGATION

The term “highlight” used throughout the manual refers to selecting a digit to

change on the various screens by using keys on the keypad. Pressing

Enter allows the “highlighted” value to be changed by using the arrow keys.

Pressing Enter again accepts the new value.

Figure 3

Keypad/Display Navigation

6096

00.0

mph

400ft

=

0.0

mph

=

Highlight a value or input box to change by

using the arrow keys on the keypad.

Press Enter and use the arrow keys

to modify the digit. Press Enter

again to save the new value.

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

8 / INTRODUCTION

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

INSTALLATION / 9

INSTALLATION

The monitor is tested and inspected before shipping to ensure the unit is

fully operational and meets measurement specifications. Inspect for

damage that may have occurred during transit. Save all packing materials

until the inspection is complete. If damage is found, immediately file a claim

with the carrier and notify your DICKEY-john Sales Representative.

MOUNTING BRACKETS

NOTE: When mounted to a vertical

surface, a tie-wrap may be

used to secure the cables to the

bottom of the bracket.

1. Install the mounting bracket at the desired location using locally

acquired hardware.

2. Install the console to the bracket by aligning the console mating

grooves with the bracket and sliding the console onto the bracket until

the snap engages.

Figure 4

Standard Mounting Bracket

The console must not obstruct the view of the operator or interfere

with the operation of the tractor.

To prevent damage to the console, be sure the snap fully engages

during installation.

Slide console

until snap

engages

Mount on vehicle

with locally acquired

hardware

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

10 / INSTALLATION

Figure 5

Optional 3D Mounting Bracket

The console must not obstruct the view of the operator or interfere

with the operation of the tractor.

To prevent damage to the console, be sure the snap fully engages

during installation.

Slide console

until snap

engages

Mount on vehicle

with locally acquired

screws (4)

Hole size .250”

Wing adjustment

bolts

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

INSTALLATION / 11

INSTALLING CONSOLE HARNESSES

Several harnesses are located at the bottom of the monitor. These include

power, ground speed sensor, and sensor inputs (rows, lift switch, two

hopper levels, and one frequency function [shaft]).

Figure 6

Console Harnesses

1. Route the power harness to a +12 V source near the battery if

possible.

2. Route the ground speed sensor harness connection to the radar, Hall

Effect, or GPS ground speed sensor.

3. Route the implement harness to the location of choice, typically near

the drawbar.

The harnesses must not obstruct movement of the operator or of

the moving parts of the tractor or implement. Take care when

routing harnesses to secure them at proper locations; provide

slack as needed to allow for movement.

Poor +12 V connections may cause intermittent console operation.

Be sure to connect the power harness to a clean, well-conditioned

source (direct battery connection is preferred).

+

Ground

Speed

Battery

Implement

(rows and accessories)

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

12 / INSTALLATION

INSTALLING IMPLEMENT HARNESS AND

SENSORS

The implement harness provides custom fit and functions required by the

implement. Each harness branch is labeled for location (row 1, row 2, etc.)

or sensor (lift switch) for routed connection. Some sensors may require

special adapters for connection.

Figure 7

Implement Harness/Sensors

1. Install sensors onto seed tubes using tie-wraps.

2. Route implement harness to the appropriate locations; provide slack

near moving parts to allow for movement. Attach harness to the

implement using tie-wraps.

3. Make sure the hitch connections will connect to the tractor connections

with the proper amount of slack for implement movement.

The harnesses must not obstruct moving parts of the tractor or

implement. Take care when routing harnesses to retain them at

proper locations with adequate slack for movement.

Row

1

Row

2

Row

3

Row

4

Row

5

Row

6

Row

7

Row

8

Implement connector(s)

rows and accessories

Seed sensors

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

MENU SCREEN / 13

MENU SCREEN

The Menu screen is the main access screen to modify planting and console

settings. The Menu screen can be accessed from the Operate screen and

will display on a function line as graphics or text.

To access the Menu screen:

1. At the Operate screen, press the Up or Down Arrow key to navigate

through the function readouts until the Menu line is highlighted.

Figure 8

Menu Function Line (Graphic and Text Mode)

2. Press Enter to access the Menu Setup screen.

Figure 9

Menu Screen

1

7

2

8

3

9

4

10

5

11

6

12

27.3

1

Menu

Graphic

Mode

1

7

2

8

3

9

4

10

5

11

6

12

27.3

Menu

Text

Mode

MENU

4.5 4.5 ac1

s/ac

Function

Readouts

(PM200 and 200E models display 2 lines of function readouts)

PM250 PM250

M

E

E

123.4

43.8

1234

123.4

43.8

1,2,3...

Security

Seed

Count

Accessories

Service

Display

Settings

Row

Setup

Display

Screen Setup

PM250

+

-

M

E

E

123.4

43.8

1234

123.4

43.8 Security

Population

Limits

Service

Display

Settings

Row

Setup

Display

Screen Setup

PM200E

Ground

Speed

+

-

M

E

E

123.4

43.8

1234

123.4

43.8

Security

Population

Limits

Service

Display

Settings

Row

Setup

Display

Screen Setup

PM200

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

14 / MENU SCREEN

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

SECURITY / 15

SECURITY

Security features allow password protection that prevents unauthorized

personnel from modifying key parameters in the field.

IMPORTANT: The monitor is locked at the factory. Prior to using the

monitor, the system MUST be unlocked via the

Password screen before all other screens can be

accessed.

UNLOCK THE PASSWORD SCREEN

1. At the Menu screen, press the Arrow keys to highlight the Security

icon.

2. Press Enter to display the Current Password screen.

Figure 10

Current Password Screen

3. Press Enter again to enter the default password.

– PM200 default password is 5498

– PM200E default password is 9270

– PM250 default password is 1735

Use the Up and Down Arrow keys to edit the selected digit. The Up

Arrow key increases the value; the Down Arrow key decreases the

value. Use the Left and Right Arrows to move to the next digit field.

4. Press Enter to display the Change Password screen.

UNLOCK ALL SCREENS

If no screens require password protection:

1. Use the Arrow keys to highlight the Master Lock icon and press Enter,

refer to (Figure 11). Pressing and toggling the Enter key will lock and

unlock the screens.

2. Press ESC to return to the Menu screen. The Master Lock icon will

appear on the Menu screen display unlocked and no password entry

will be required to use the monitor.

0000

CURRENT PASSWORD

Security icon

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

16 / SECURITY

Figure 11

Change Password Screen

LOCK/UNLOCK INDIVIDUAL SCREENS

Individual screens can be locked or unlocked from the Change Password

screen:

• Row Setup

• Population Limits

• Ground Speed

• Field Area 1

• Field Area 2

• Total Area

To Lock or Unlock an Individual Screen:

1. Use the Arrow keys to highlight the individual screen icon to lock or

unlock.

2. Press Enter to select and the Up or Down Arrow keys to toggle

between the lock and unlock state.

3. Press Enter or ESC to confirm the selection.

4. Continue pressing ESC to return to the Operate screen.

TO CREATE A NEW PASSWORD

1. Press Enter at the New Password field to edit. Use the Right and Left

Arrow keys to select the digit to change. Use the Up and Down Arrow

keys to edit the selected digit. The Up Arrow key increases the value;

the Down Arrow key decreases the value.

2. To save the new password, press Enter and then scroll to the Save

icon and press Enter again. The new password will display in the

current password field as confirmation.

3. Continue pressing ESC to return to the Operate screen.

1735

+

-

1

2

0000

Master Lock icon unlocks all

protected screens

Current

Password

New

Password

Individual Screen

Lock/Unlock

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

QUICK START GUIDE / 17

QUICK START GUIDE

IMPORTANT: The monitor is locked at the factory. Prior to using the

monitor, the system MUST be unlocked via the

Password screen before all other screens can be

accessed.

Three inputs are required for monitor operation.

• Number of rows

• Row spacing

• Ground speed constant

Refer to the Menu Screen section for identifying Operate screen functions.

PLANTER CONFIGURATION

NOTE: The Planter Configuration

screen must include the

number of rows and the row

spacing or implement width for

the console to properly display

population.

NUMBER OF ROWS

1. At the Operate screen, use the Arrow keys to highlight the Menu

function line and press Enter.

2. At the Menu Setup screen, highlight the Row Setup icon and press

Enter.

3. At the Number of Rows field, press Enter. The Up Arrow key increases

the value; the Down Arrow key decreases the value. NOTE: The

maximum number of rows that can be selected are 12.

4. Press the Enter key to accept the selection.

5. Continue pressing the ESC key to return to the Operate screen or

proceed to Row Spacing setup.

Figure 12

Planter Configuration Screen

ROW SPACING

1. Use the Down Arrow key to highlight the Row Spacing field.

2. Press Enter to modify the field. The Up Arrow key increases the value;

the Down Arrow key decreases the value.

3. Press Enter to confirm the selection. An implement width value will

automatically calculate, but can also be changed manually.

#

20.0

in

20.00

ft

12

# of Rows

Row Spacing

Implement

Width

PM200 and 200E

#12

20.0

in

20.00

ft

1 2 3 5 6

4

I/O

PM250

# of Rows

Row Spacing

Row Setup

Implement

Width

OPERATOR’S MANUAL

PM200, 200E and 250 Planter Monitors

11001-1444-200702

18 / QUICK START GUIDE

This manual suits for next models

2

Table of contents

Other Dickey-John Monitor manuals