7

FREQUENTLY ASKED QUESTIONS

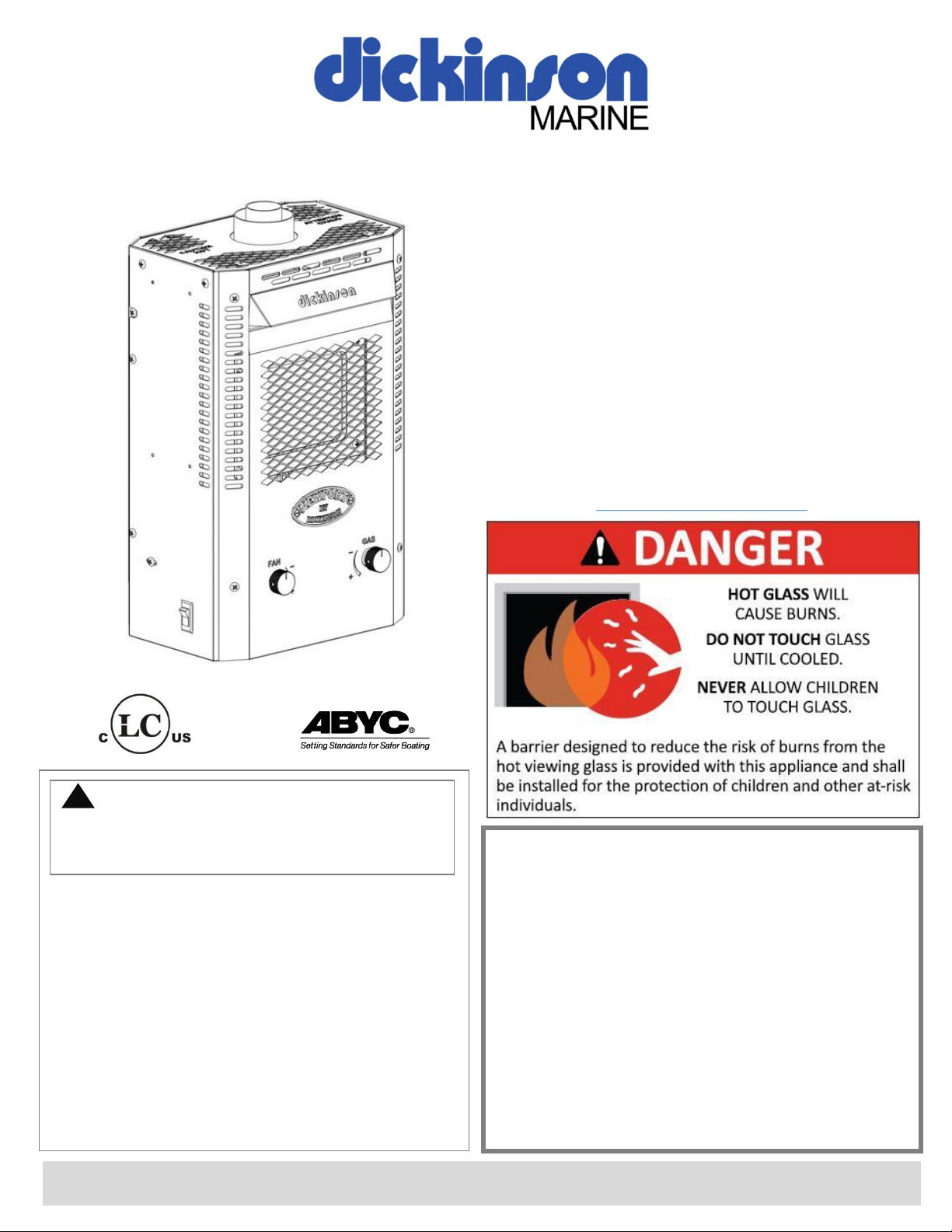

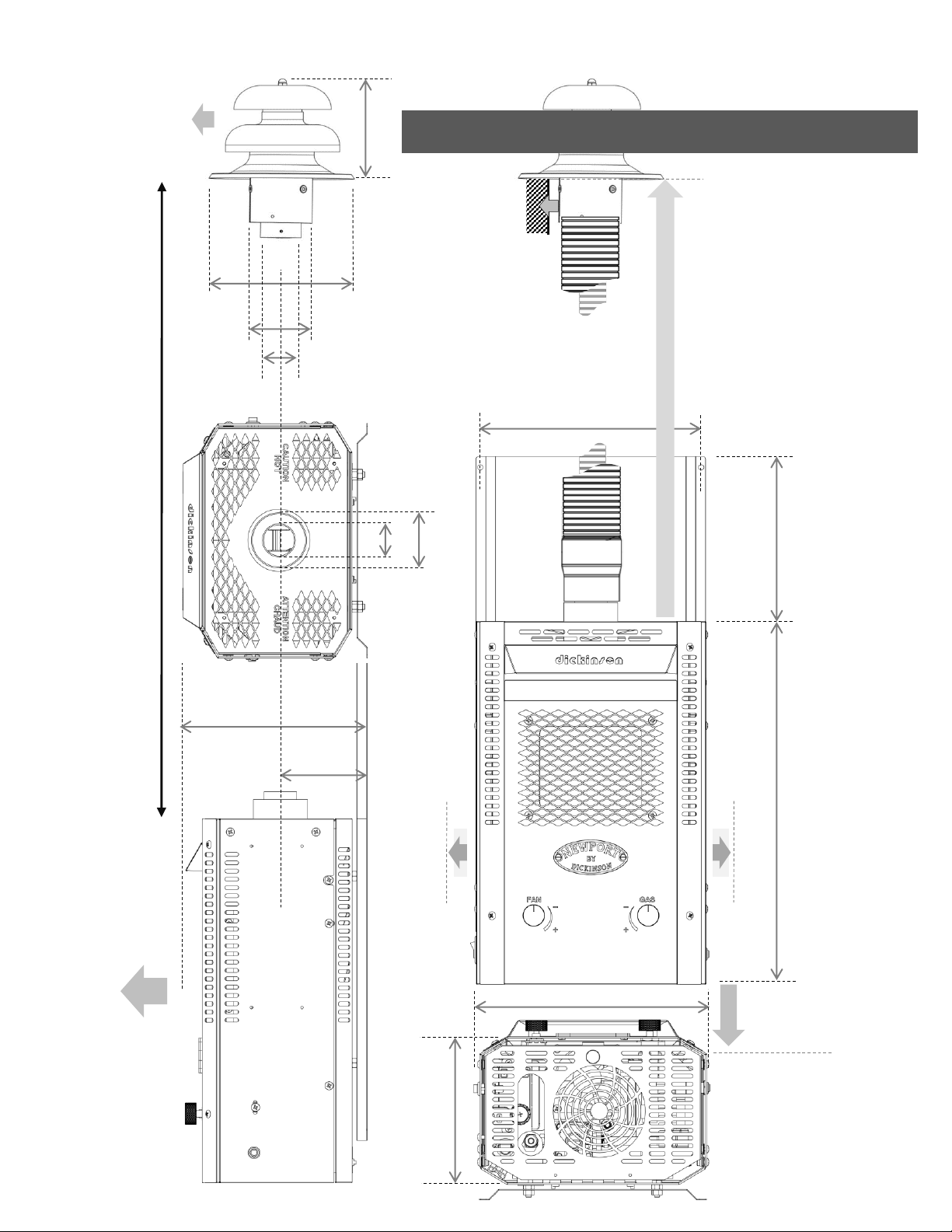

The Explorer propane fireplace

The Dickinson Model Explorer is a direct vent propane gas

fireplace approved for manufactured home, mobile home and

onboard marine installations. Broadly based on the popular

Dickinson propane boat heaters, the Explorer also features

several upgrades that have granted it certification for a use in

a wider range of environments. For decades now, the name

Dickinson has been a byword for reliability among the

fishermen and boaters of the Pacific Northwest. We’re very

pleased to now offer that same legendary reliability to our

valued customers for use on land as well as at sea.

What is a direct vent appliance?

Direct vent means that the fireplace both vents and draws in

air from outside the structure. This means that the fireplace

won’t deplete the room’s oxygen, allow exhaust or smoke to

enter the space or introduce additional moisture into the air.

The fire inside the Explorer burns completely isolated from the

atmosphere in the room.

What parts do I need to install this

fireplace?

The Explorer fireplace comes with everything it needs to be

installed into a structure or vehicle. Additionally, in order to

connect the fireplace to a fuel tank, you’ll need to obtain and

install a low pressure regulator and low pressure fuel hose as

well. These are not included with this appliance

(see pages 23-24)

Where can this fireplace be installed?

The Explorer is ANSI/CSA approved for install in manufactured

homes, mobile homes and ABYC approved for use aboard

boats. The fireplace is capable of heating a maximum area of

approximately 230 square feet. This is assuming a ceiling

height within the normal range and a location within temperate

climate zones. The ability to build and accumulate heat within

the space will also depend on the age and quality of the

structure’s construction and insulation. This fireplace is

intended for Indoor use only.

How safe will Children, at risk individuals

and pets be around this fireplace?

During its design and development the Explorer fireplace was

subjected to extensive in house and independent safety tests.

The Explorer fulfills all safety requirements and has passed all

safety tests stipulated in ANSI Z21.88-2019 / CSA 2.33-2019;

CSA 2.17-2017 and ABYC A-26-2018. The outer shell and

interior parts pf the fireplace can become a potential burn

hazard when the fireplace is or has been in operation. Every

effort has been made to reduce the burn hazard potential of

the fireplace shell. The operational controls of the fireplace are

prevented from absorbing heat and remain safe to operate at

all times.

Every appropriate precaution should be taken to protect

children, at risk individuals and pets from coming into contact

with the fireplace or its controls. Additional barriers may be

required to keep them away from danger. This fireplace must

never be left to run unattended for any length of time.

How important is the chimney?

The length and shape of your chimney is the most important

consideration when choosing a spot to install your fireplace. In

order to burn reliably the fireplace requires both its venting

and air intake to conform to the manufacturers venting

requirements. Chimneys must be no shorter than 21”and no

longer than 56”. Within this range any bends introduced to the

chimney should be gradual not sharp. 90 degree bends and

horizontal, wall exits are not feasible. Ensuring your chimney

is able to vent and draw in air freely is key to reliable fireplace

operation.

Does this fireplace need a low pressure

regulator?

Yes, this fireplace is rated for fuel input of no more than 11

inches of water column, which is equivalent to 0.39 pounds

per square inch (PSI) The pressure of a refillable propane

bottle ranges from 100-200 PSI, so a low-pressure regulator

must be used to reduce incoming pressure to 0.39 PSI. YOU

MUST NEVER ATTEMPT TO CONNECT THE FIREPLACE TO

FUEL WITHOUT A LOW PRESSURE REGULATOR!

Can this fireplace be used at higher

altitudes?

Yes, the Explorer fireplace is tested and approved under CSA

2.17-2017 for use at an altitude range of to 0-5000 feet above

sea level. No fuel input reduction or modifications are required

to operate the fireplace at elevations within this range. For

elevations above 5000 feet a 4% reduction in fuel volume

would be recommended per every 1000 feet of elevation.

How will the fireplace be affected by

rain, wind and snow?

The Explorer fireplace has been designed to keep working in

poor weather conditions. The chimney cap is designed to resist

rain and has a wind splitter to ensure it can still vent in high

winds. If the chimney cap becomes covered with snow, expose

a small area beneath both bells on one side to allow exhaust

to exit and air to enter –the heat of the cap will melt the rest

of the snow away from it, preventing snowmelt from entering

the chimney.

Can the Fireplace operate without

electrical power?

Yes, the appliance can be run as normal without the optional

blower fan being connected to power. The appliance will still

require power from 1 AA battery to generate a spark inside the

combustion chamber and ignite the flames.

Have other questions?

If you have any questions about our product that are not

answered by this manual, we’d be happy to answer them!

Email info@dickinsonmarine.com with your Dickinson Product

enquiries.