Dictator SQUARE 940-2 User manual

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.1

Technical Manual

SQUARE 940-2

You can find the current version of our manual on our website under «Downloads»:

https://en.dictator.de/products/door-drives-gate-drives/control-systems/

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.2

General product description ......................................... 04.046.04

I. Basic safety instructions, terms and definitions.............. 04.046.08

I/1 General information .......................................... 04.046.08

I/2 Safety instructions ............................................. 04.046.08

I/3 Overview control system .................................... 04.046.11

II. Mechanical mounting............................................... 04.046.13

III. Controller functions ................................................. 04.046.14

IV. Electrical connection .............................................. 04.046.16

IV/1 Fuse protection/main switch....................................... 04.046.16

IV/2 Connection of external devices................................... 04.046.16

IV/3 Cables .................................................................... 04.046.16

IV/4 Carrying out the teach-in run...................................... 04.046.16

IV/5 Termination of wiring................................................. 04.046.16

IV/6 Mains connection ..................................................... 04.046.17

IV/7 Motor connection...................................................... 04.046.18

IV/8 Connection motor brake ............................................ 04.046.19

IV/9 Connection temperature sensor................................... 04.046.20

IV/10 Rotary encoder....................................................... 04.046.20

IV/11 Reference limit........................................................ 04.046.20

IV/12 Limit switch ............................................................ 04.046.21

IV/13 Safety edge ........................................................... 04.046.22

IV/14 Light barriers/Light curtain ....................................... 04.046.22

IV/15 Control signals ....................................................... 04.046.25

IV/16 Membrane keys...................................................... 04.046.25

V. Menu system and description ................................... 04.046.26

V/1 Navigation ............................................................... 04.046.26

V/2 Menu structure .......................................................... 04.046.27

V/3 Main menu ............................................................... 04.046.28

V/4 Submenu .................................................................. 04.046.28

V/5 Display indication...................................................... 04.046.29

V/6 Express menu............................................................ 04.046.30

V/7 Main menu ............................................................... 04.046.31

V/8 System Status ............................................................ 04.046.31

V/9 Door type ................................................................. 04.046.33

V/10 Door positions......................................................... 04.046.33

V/11 Limit Setup .............................................................. 04.046.34

V/11 Limit Setup - Operation mode ............................... 04.046.35

V/12 System Setup........................................................... 04.046.36

V/12 System Setup - Timer............................................ 04.046.36

V/12 System Setup - Outputs ........................................ 04.046.37

V/12 System Setup - Inputs................................................ 04.046.39

V/12 System Setup - Displacement sensor....................... 04.046.41

V/12 System Setup - References .................................... 04.046.42

V/12 System Setup - Safety devices ............................... 04.046.43

V/12 System Setup - Motor adjustment........................... 04.046.44

V/12 System Setup - Frequencies................................... 04.046.47

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.3

V/12 System Setup - Ramps.......................................... 04.046.47

V/12 System Setup - Specials........................................ 04.046.48

V/12 System Setup - System.......................................... 04.046.49

V/13 Wireless Setup ........................................................ 04.046.49

VI. Setup.................................................................... 04.046.51

VI/1 Placing into operation with encoder - General information ..............

.................................................................................. 04.046.51

VI/2 Placing into operation with encoder - Preparation .......... 04.046.51

VI/3 Placing into operation with encoder - Quick Setup ......... 04.046.52

VI/4 Placing into operation with limit switches - General information. ......

......................................................................... ........ 04.046.54

VI/5 Placing into operation with limit switches - Preparation.....04.046.54

VI/6 Placing into operation with limit switches - Quick Setup .. 04.046.55

VII. Troubleshooting..................................................... 04.046.57

VII/1 Error codes ............................................................. 04.046.57

VII/2 Repair and maintenance ........................................... 04.046.60

VII/3 Change log............................................................. 04.046.60

VIII. Appendix ............................................................ 04.046.61

VIII/1 Technical Specifications................................... 04.046.61

VIII/2 Declaration of Incorporation ............................ 04.046.63

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.4

Summary

SQUARE 940-2 Control System

with Frequency Converter According to EN 12453

The SQUARE 940-2 control system has

been developed for the DICTAMAT AC-21

door operators (sliding door operator DIC-

TAMAT 900-21 and hinged door operator

DICTAMAT 310-21). It meets the de-

mands of the EN 12453 concerning

the safety of powered doors.

Its main advantages are:

- Autocontrol, i.e. it shuts itself down

automatically upon detecting an error

that might lead to a dangerous situation.

- Direct connection of safety equipment

according to the EN 13849-1 wit-

hout additional evaluation device.

- Different "Stops" of the door

adjustable. This protects door and

door operator during normal operation

from unnecessary wear and tear due to

an abrupt Stop. In case of danger the

maximum stopping distance according

to the EN 12453 is observed.

- Connection possibility for a mechanical

braking device.

- The SQUARE 940-2 allows for a position

control by an encoder and thus a very

exact positioning.

- Graphic display on the casing lid with

status and error indication.

- The membrane keys on the lid of the

casing serve for operating the door.

Motors to be connected three phase 230/400 VAC, max. 0.75 kW

Main features

position control: encoder or separate limit switches

integrated frequency converter

password protected acces to adjustment facility

deadman, impulse or automatic operation

emergency service in case of faulty safety equipment

5 adjustable relay contacts

Meets the safety demands of EN 12453.

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.5

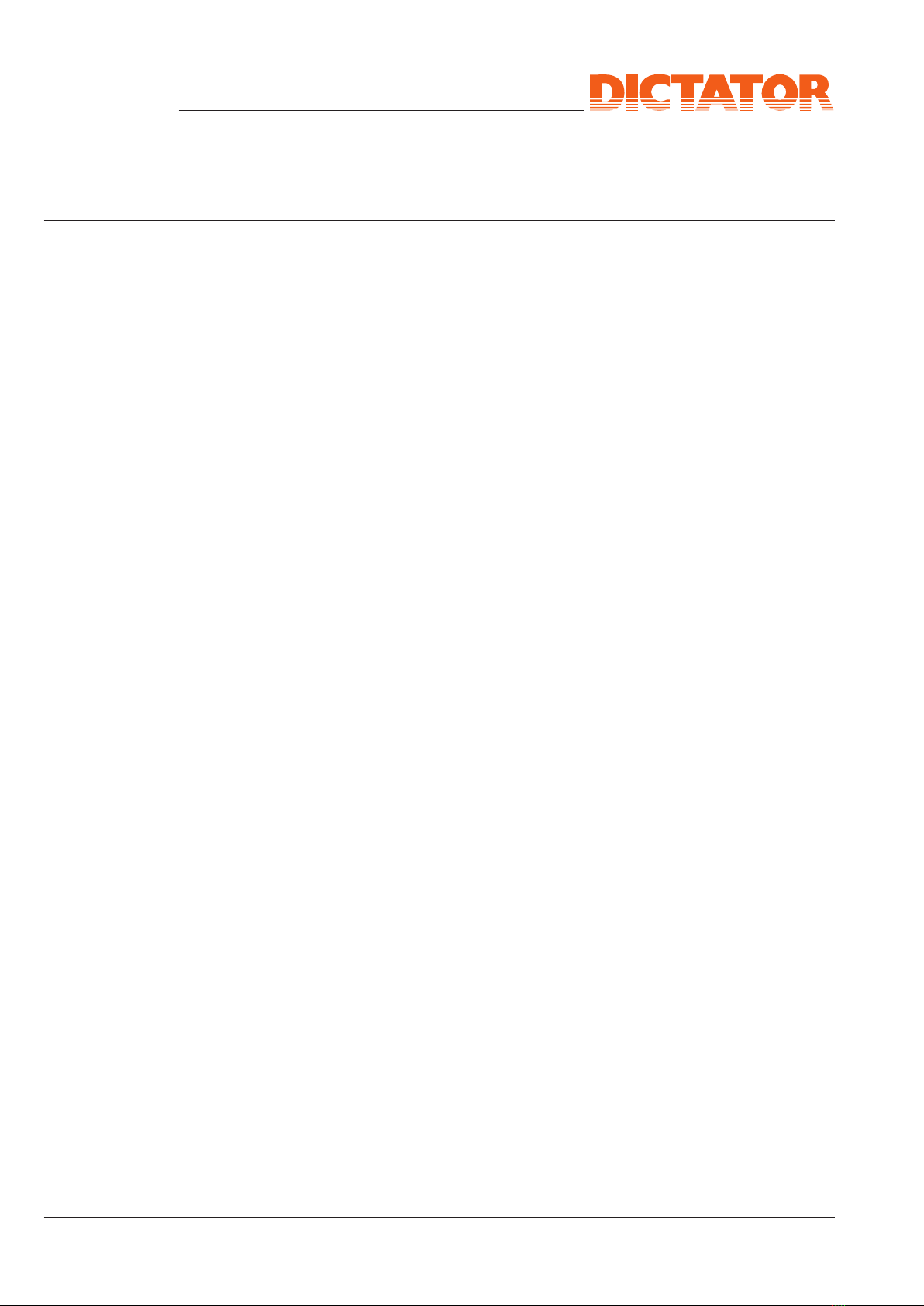

335

118335

STOP

SQUARE

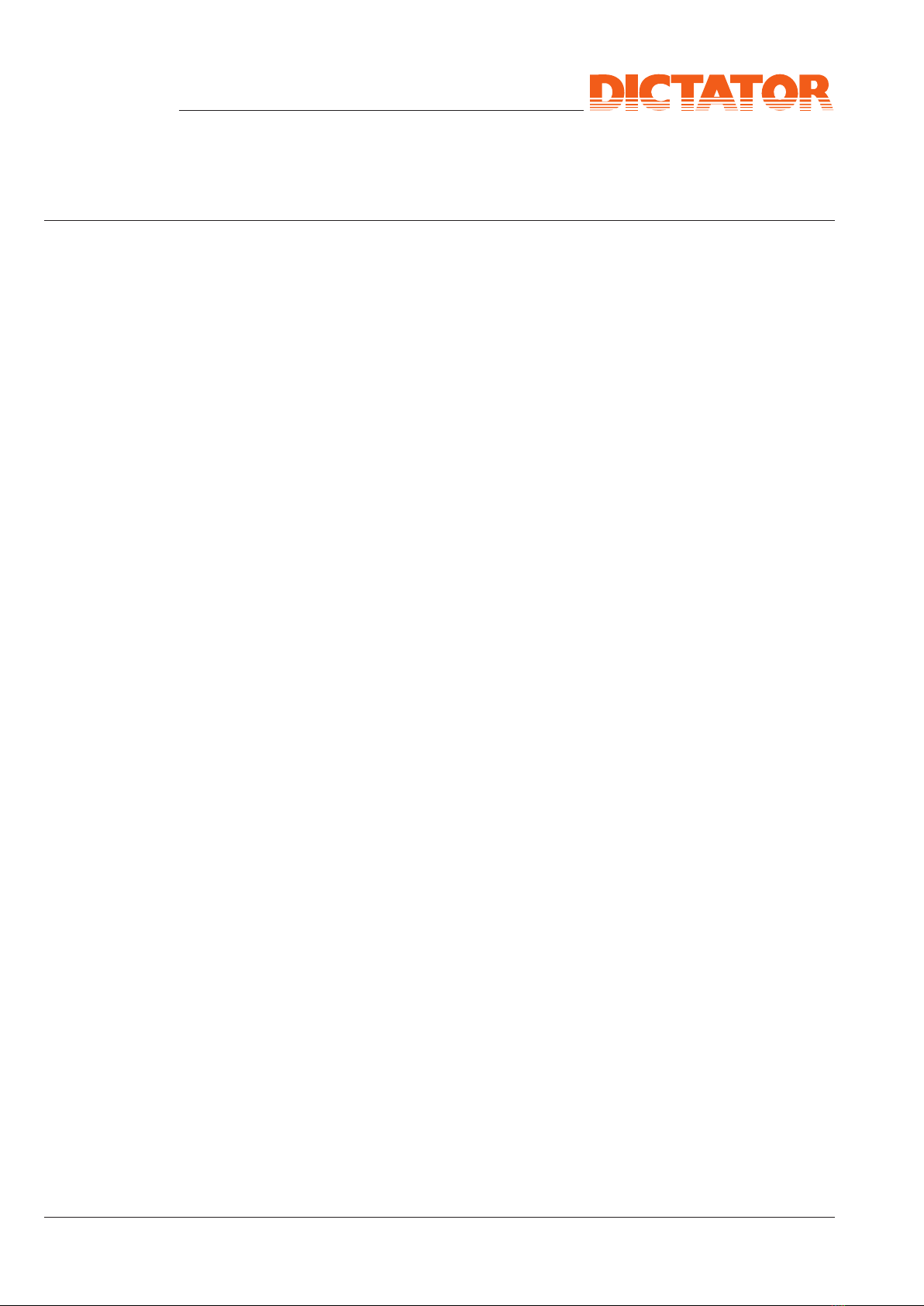

Dimensions / Installation

The casing of the SQUARE control systems has been designed with as small as possible

outer dimensions, in order to fit also into limited space. The interior of the casing,

however, offers sufficient space to house - if necessary - additional devices or batteries.

The carrier board is provided with threaded holes for standard top hat rails. This saves

the expenses for additional casings, their installation and connection.

The installation of the control system

is very easy, as the electronics

are fixed on a board that can

be removed completely from the

casing. The lid of the casing can

also be taken off, as the flat cable

connection to the display in the lid

just has to be unplugged. The now

very light casing can be fixed to the

wall, without the danger of dama-

ging the electronics by chance with

e.g. a screw driver.

The control system should be placed

not farther than 30 m from the door

operator.

Door operator, operating elements

and safety equipments are connec-

ted to the removable binders.

The blocks of binders are coded and

therefore cannot be plugged into a

wrong position.

Dimensions of the Casing

Installation / Electrical

Connection of Door

Operators

Dimensions in mm

Marked holes for

10 screw cable inlets M20

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.6

Functions, Programming and Adjusting

Programming and

Adjusting

The SQUARE 940-2 control system permits to adjust the DICTATOR DICTAMAT door

operator exactly to each door. This is a vital condition for the safety at powered doors.

The increased demands concerning the safety of the "machine door" due to the EN12453

standard require a control and putting into operation by a trained and authorised techni-

cian. Therefore all safety relevant parameters are only accessible through a password. The

below mentioned functions and parameters only give a general idea as the SQUARE940-2

offers a much larger range of adjustments/functions.

All adjustments are done with the three adjustment keys on the control module.

•Dead Man or Impulse Function

for the keys

OPEN

and

CLOSE

(can be choosen separately

for both directions, e.g. impulse OPEN, dead man CLOSE)

•Automatic Closing: As soon as the position OPEN has been reached the door closes

automatically after a preset time (adjustable between 1 - 999 seconds)

•Alternating Impulse OPEN/CLOSE

, also in combination with automatic closing

•Partial Opening: The door opens only partially after pressing a separate push button

(additional Open position for persons) (separately adjustable hold-open-time for this

position)

•STOP (Normal Stop when opening, Fast Stop when closing).

•EMERGENCY STOP: This works the same way as the safety equipment on the closing

edge. Stopping distance according to EN 12453.

•Safety Equipment (SHE): Different safety equipment can be connected to meet the

EN12453. The function of the safety equipment is cancelled in the final positions.

After the safety equipment has been activated a new operating command is necessary

to get the door moving again.

Securing the closing edge (direction CLOSE): When this SHE is activated, the door

stops within the required distance and then reverses until it is again completely open.

This SHE is in function only during closing.

Securing the opening edge (separate connection): When activated, the door reverses

until it is again completely closed. SHE in function only during opening.

Additional safety type D, e.g. by a light barrier in closing direction (see table on page

04.007.00): Door stops with a Fast Stop (see below).

If the safety equipment should fail, an emergency service for the door can be adjusted

(dead man operation). The door moves at creep speed only. As long as the emergency

service has not been adjusted, the door can no longer be operated by motor.

In order to achieve an optimum adjustment of the door drive to the door different

motor parameters can be adjusted. Amongst them are e.g.:

- Motor Rating (adaption to the connected motor)

- OPENING Speed / CLOSING Speed (separately adjustable)

- Creep Speed before reaching the positions OPEN and CLOSED (speed is reduced

before reaching the final position, so that no separate final dampers are required,

separately adjustable)

- Acceleration and Deceleration Ramps: Depending on the door weight and its easy

movement

- Fast Stop: Adjustment of the Stop in closing and opening direction (separately adjustable)

- EMERGENCY STOP: Adjustment of the STOP characteristics upon activation of the safety

equipment or by the Emergency Stop push button

Motor Parameters

Operating Options /

Safety Features

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.7

SQUARE 940-2 control system for the AC-21 door operators part no. 706094-2

Functions (cont.), Technical Data, Order Information

The SQUARE 940-2 control system permits a great deal of different operating functions.

When choosing the operating mode the required safety equipment has to be provided.

See also the summary on the requirements of the EN 12453 on page 04.007.00. A

change to a "more dangerous" operating mode (e.g. from dead man to impulse opera-

tion) is only permitted when providing the required safety equipment.

The control system offers a high operating standard due to additional adjustment and

connection possibilities.

Order Information

Application Range

SQUARE 940-2

Technical Data

Components Included Control system in casing IP 54 with membrane keys and display on the casing

Diagnostics

Position Control The SQUARE 940-2 control system is designed for a position control via encoder, integrated

in the door operator. This permits a very precise positioning of the door (depending on

the travel and the power transmission: max. 2 mm). However it is also possible to use

separate limit switches (4 pcs. required).

The SQUARE 940-2 disposes of 5 relay contacts for controling signalling and warning

devices. There exists a large variety of adjusting possibilities. This permits e.g. the con-

nection of signals, warning sirens, the connection to a building surveying central, a floor

conveyor system etc.

The display on the lid of the casing indicates error codes or different diagnostic codes for

the input and output terminals. This helps also to locate a problem, even by telephone.

The SQUARE 940-2 control system with integrated frequency converter is designed for

door drives for sliding doors (beginning on page 04.027.00) and for hinged

doors (beginning on page 04.041.00) with a three phase current motor. It can

control motors up to 0.75 kW.

Relay Contacts

Voltage 230 VAC, 50 - 60 Hz

Power consumption 8 A

Output voltage (secondary) 24 VDC

Power supply (secondary) max. 500 mA

Output voltage motor 230/400 VAC (three phase)

Motor rating max. 0.75 kW

Dimensions H x W x D = 335 x 335 x 118 mm

IP rating IP 54

Recommended fuse protection 16 A

Operating temperature -10 °C to +40 °C

AC-21 series DICTAMAT 900-21

DICTAMAT 310-21

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.8

I. Basic Safety Instructions, Terms and Definitions

The installation and commissioning of the SQUARE 940-2 control sy-

stem may only be carried out by trained, expert personnel. All relevant

standards and other valid regulations must be strictly observed. During

commissioning, some safety devices are inactive, so that an additionally

increased hazard potential must be taken into account.

Access to the menu by means of a system-specific password is required

for carrying out commissioning work.

The scope of delivery of each controller supplied includes a separate

supplementary sheet on which the respective password is listed.

The installing specialist company is obliged to ensure that neither the

respective password nor the description falls into unauthorised hands

(e.g. operator), since safety-relevant settings can be changed in the menu.

Improper changes can result in considerable danger to persons and

material.

The SQUARE 940-2 control system was developed exclusively for door ope-

rators that meet the requirements of EN 12453. It is only intended for use

in dry rooms and must be installed inside or on the inside of buildings. The

manufacturer or distributor accepts no liability for applications outside the

defined application purposes or application limits. Proper use also includes

compliance with the operating conditions specified by the manufacturer.

Unauthorized modifications to the SQUARE 940-2 controller exclude

any liability on the part of the manufacturer for any resulting damage.

This door control may only be installed by qualified personnel with

experience with automatic door controls and knowledge of the relevant

EC regulations.

Please read the safety instructions carefully before installation.

• The installer is responsible for the CE marking of the door. The in-

staller must explain the operation of the door to the end customer.

• The SQUARE 940-2 complies with the requirements of EN 13241-1.

I/1 General Information

I/2 Safety Instructions

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.9

I. Basic Safety Instructions and Terms

- cont.

• All components used must be CE approved to provide full CE marking

of the installed equipment.

• The safety edges must comply with EN 12978 and must only be

connected to the terminals provided. These inputs are safety class II

and are monitored internally for correct functioning before each step.

• The control system must be set up in accordance with EN 12453.

The control parameters must be disabled before being handed over

to the customer.

• The cable between motor and control system must be screened and

connected as described in this manual.

• Do not install the controller in direct sunlight as this may cause the

controller to overheat.

• The control unit must not be modified.

• The mains voltage must be switched off before work can be carried

out on the door.

• The connection terminals can carry high voltages up to 5 minutes

after switching off.

• The control panel does not work if the internal 24V-power supply is

short-circuited. The display shows an error message and an alarm

signal sounds.

• The door control must be kept in a good condition to ensure safety

and health.

• The door control may only be used to open and close industrial doors.

• Before use, the door control parameters must be configured in ac-

cordance with EN 12453.

• The door control may only be operated if all safety elements are

functional.

• The door control must not be used if cables connected to the device

are damaged.

Control System

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.10

I. Basic Safety Instructions and Terms

- cont.

Installation • The main switch must be switched off during installation.

• The mains connection may only be carried out by an authorised

electrician.

• During configuration, all personnel must be outside the direction

of travel.

• The door controller must not be mounted on moving or vibrating

parts.

• The door controller must not be installed in a place where it blocks

escape routes.

Cleaning and Maintenance • Before maintenance, cleaning and repair of the installation, the

power supply must be interrupted for at least 5 minutes.

• Do not expose the door control unit to steam or moisture during

cleaning. If necessary, use a cloth moistened with soapy water or

cleaning alcohol.

• Repairs should only be carried out by qualified and trained techni-

cians who have a sound knowledge of the system.

• A complete maintenance/safety check must be carried out at inter-

vals of 12 months by an authorised specialist.

• Only use original spare parts for repairs.

• During the repair, the main switch must be switched off and securely

locked in this position, i.e. the key must be removed.

Inspection and

Repair

Environment and Storage • The door controller must not be installed in a housing that complies

with protection class IP 65 or higher.

• The door controller must not be installed outdoors.

• The door controller must not be installed in hazardous areas.

• Installation and operation may only be carried out in rooms with

less than 90 % humidity.

• The device must be stored under the same conditions as during

operation.

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.11

I/3 Overview Control

System

I. Basic Safety Instructions and Terms

- cont.

Factory setting

User parameters (profile «Std. 50 Hz»)

Revolutions: 1330 r/min.

V/F open: 100 Hz

V/F close: 100 Hz

Boost open: 15 %

Boost close: 15 %

High boost: 0

Switch Frequency open: 8.0 kHz

Switch Frequency close: 8.0 kHz

Position Tol: 2 Pos.

Relay Tol: 10 Pos.

DC Brake Cur: 0 %

DC Brake Time: 0.1 sec, program with 1.0 sec!

Motor Heat: 0 %

Force close: 0.0 sec

Force open: 0.0 sec.

Door speed open: 35 Hz

Door speed close: 25 Hz

Door speed pre open: 15 Hz

Door speed pre close: 15 Hz

Minimum: 10 Hz

Run Timer: 40 sec

Position Sensor: Type 2ph Sensor

Pulse count: 16

Position per meter: 2000

Scale: 0

Referenz: mec. Close

Ramp Acc open: 20 Hz/s

Ramp Acc close: 20 Hz/s

Dec open: 20 Hz/s

Dec close: 20 Hz/s

Dec Stop open: 30 Hz/s

Dec Stop close: 30 Hz/s

Dec emergency: 150 Hz/s

Input configuration beginning with SN 51XXX:

NO Fully open (Input X2/1)

NO Close (Input X2/2)

NO Stop (Input X2/3)

NO Open fully aut (Input X4/1) -> Timer 0.0 sec

NC Stop (Input X4/2)

NO Close (Input X4/3)

NO Open Part 1 aut (Input X4/4)

NO Open/Stop/Close (Input X4/5)

NC Emergency Stop (Input X4/6)

All unused NC inputs must be bridged to X5!

Output functions beginning with SN 51XXX:

Power Relay: Door moving

Relay 4: Door closed

Relay 3: Door opened

Relay 2: Door idle

Relay 1: Door moving

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.12

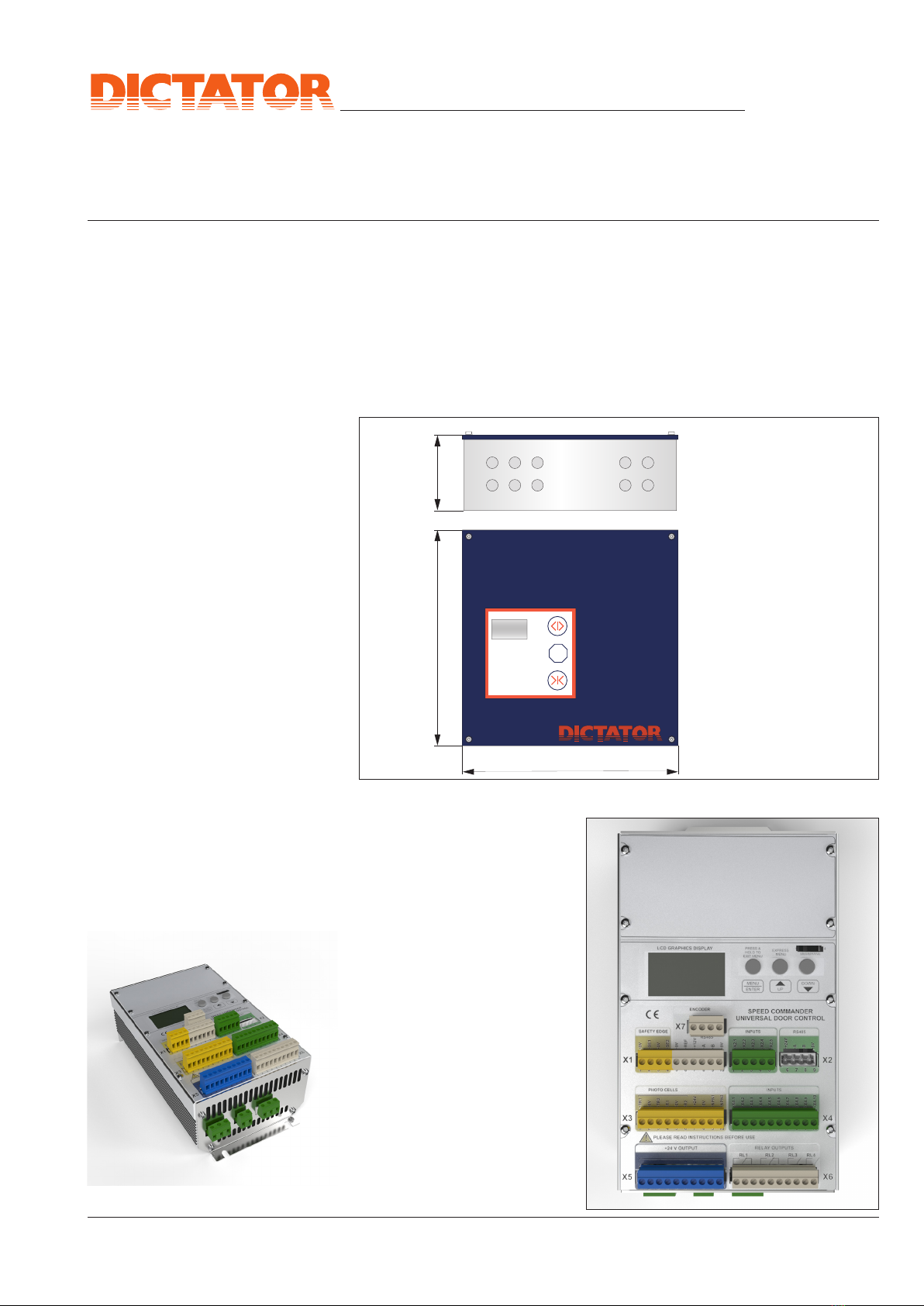

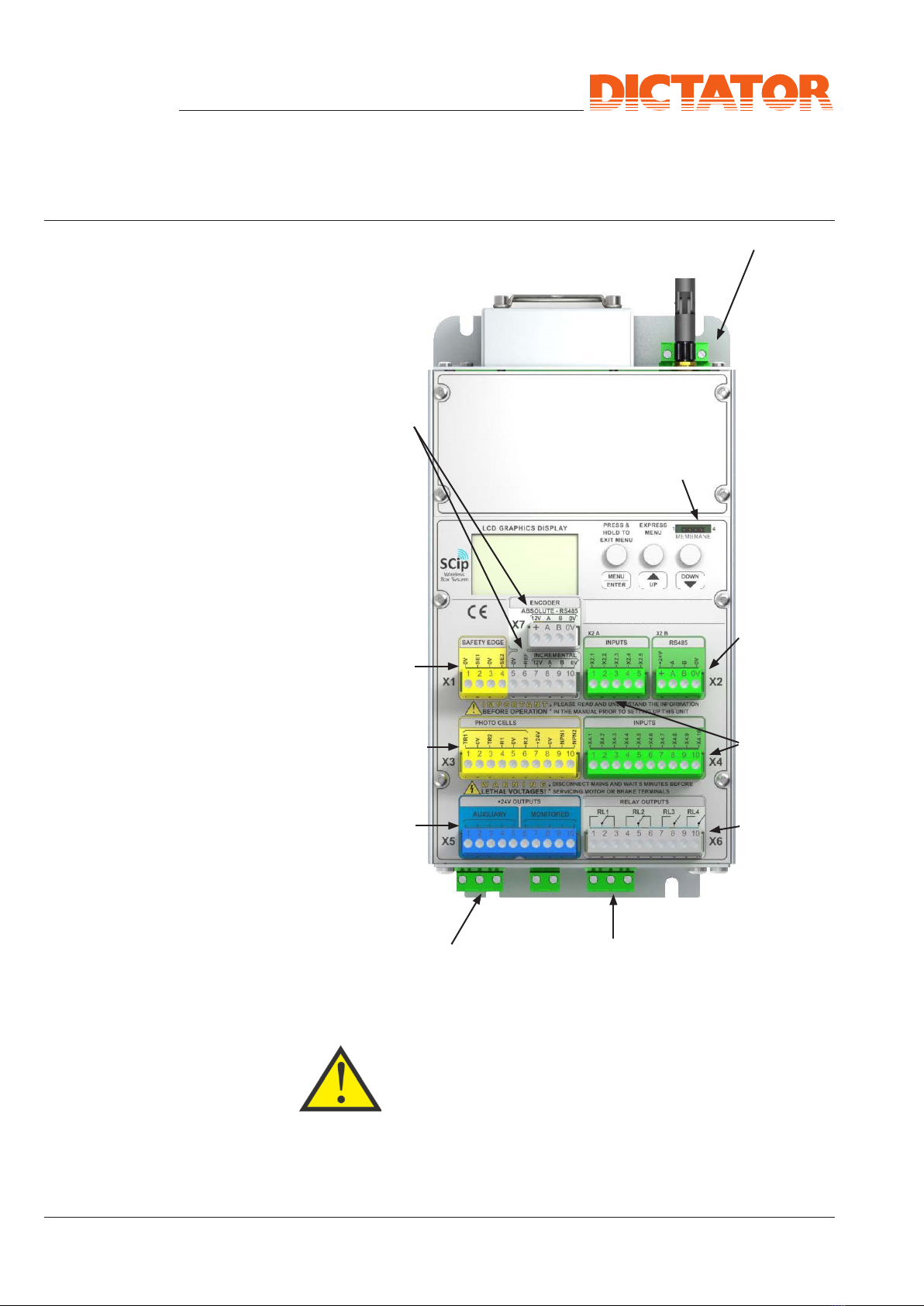

Mains connection

Membrane

keys connection

Rotary encoder

connections

Safety edge

connection

Integrated

photocell

amplifiers

+24 VDC

output

Motor connection Programmable

power relays

Remote

communi-

cation (SCip

protocol)

Programm-

able inputs

Programm-

able relays

It is recommended to use a main switch or CEE plug within

reach of the controller. Connectors and cables must be able

to meet the performance requirements of the control model.

I/3 Overview Control

System - cont.

I. Basic Safety Instructions and Terms

- cont.

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.13

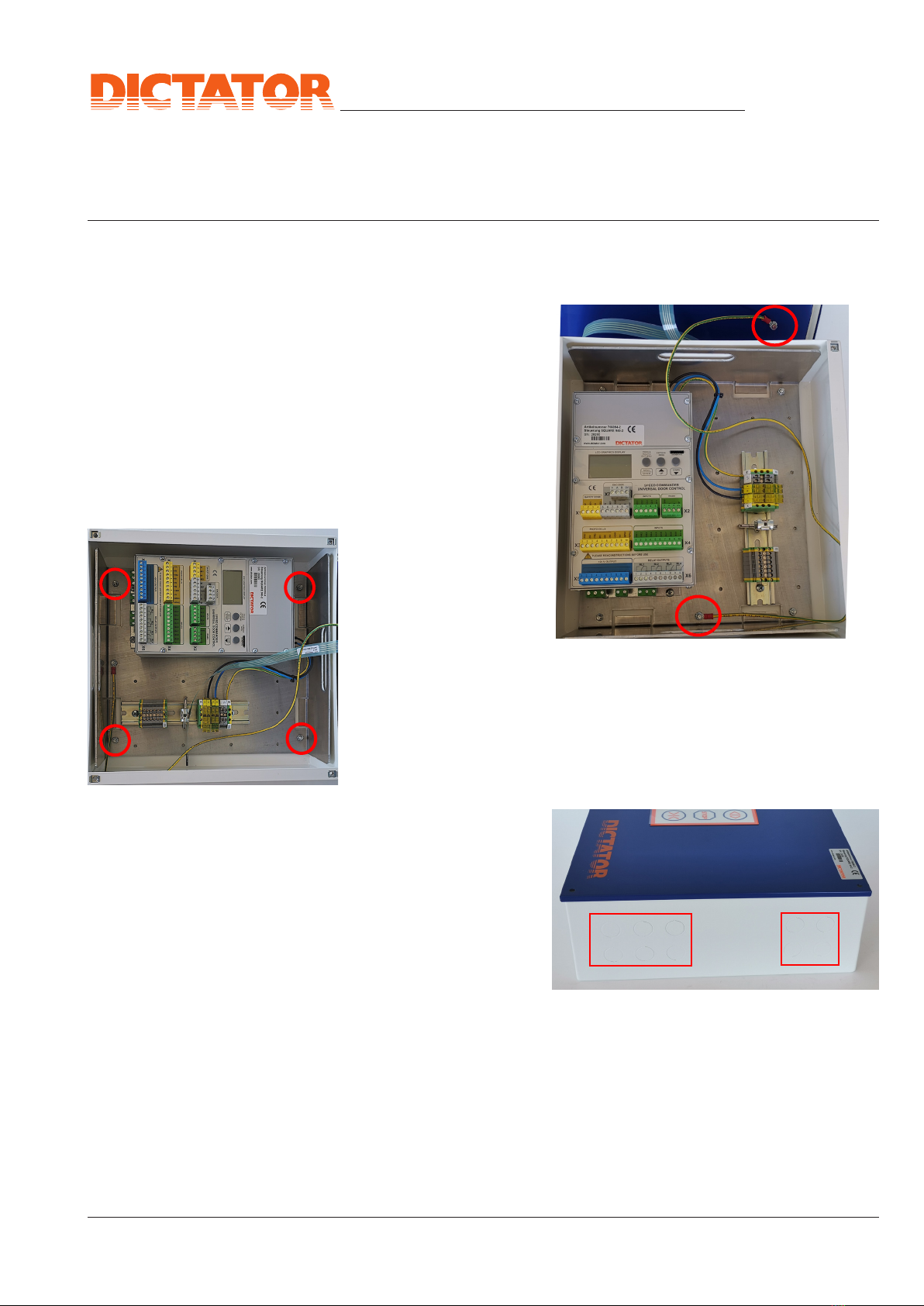

1) Loosen the 4 cover screws and carefully lift the housing cover. Dis-

connect the protective conductor connection on the carrier. Never pull

the cable itself!

The flat cable to the

display is sufficient to

place the cover direct-

ly next to the controller

housing and therefore

does not usually have

to be disconnected.

2) Loosen the four

nuts with which the

carrier is fastened in

the housing with a

socket wrench SW 8

and then lift it comple-

tely out of the housing.

3) Fix the now empty

housing to the wall (4

holes in the bottom of

the housing).

If necessary, use additional sealing washers.

4) Make the required openings for screw connections or strangulation

nipples by breaking out the pre-stamps in the side surface of the housing

with a light blow. A total of 10 M20 screw connections are available.

5) Now insert the carrier

back into the housing

and fasten it with the two

nuts to the bottom of the

housing. Reconnect the

protective conductor of

the carrier!

6) There are threaded

holes on the right side of

the carrier for mounting

top-hat rails. This makes it easy to install additional components such as

relays etc. in the control housing and connect them directly. However, ple-

ase pay attention to possible heat generation and the EMC compatibility.

II. Mechanical Mounting

II/1 Mounting of the

SQUARE 940-2

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.14

III. Controller Functions

The most important functions that can be executed with the SQUARE 940-

2 are described below. Basically, the door can be operated in automatic

mode (a short press on the respective operating element triggers the

operation command) or deadman mode (door moves only as long as

the respective button is pressed). In addition, it is also possible to mix

both operation modes (automatic/deadman) (e.g. automatic OPEN/

deadman CLOSE). If changes occur to certain functions in deadman

mode, these are expressly mentioned.

OPEN: Door moves to the stored OPEN position or until the OPEN limit

switch is reached and automatically stops there.

Person OPEN: Door moves to the end position stored for person ope-

ning and stops there automatically.

CLOSE: Door moves to the stored CLOSED position or until the CLOSED

limit switch is reached and automatically stops there.

Automatic closing: Different times can be stored for the positions

OPEN and PERSON OPEN. The programmed time starts to run as soon

as the door has reached the respective position. When the time has

elapsed, the door closes automatically.

Stop: The stop command can be programmed to stop at different speeds

in the OPEN and CLOSE directions. With a stop command, the door

stops with a corresponding stopping distance.

Emergency-STOP: When the EMERGENCY STOP button is pressed,

the door stops immediately (set max. permissible slowing-down path in

accordance with EN 12453).

Flip Flop: Alternating impulse OPEN/CLOSED. Door can only be closed

when completely open (see reversal of movement).

Safety device(s) (SHE): Stopping distance see EMERGENCY STOP.

The SHE can be parameterised for the closing direction, the opening

direction and the opening and closing directions. The activation of the

SHE can be hidden shortly before reaching the end position.

If the safety device is defective, the control unit displays an error code.

Emergency operation of the door can be achieved by setting the emer-

gency operation in the control unit.

III/1 Controller Functions

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.15

III/1 Controller Functions -

cont.

Motion reversal: As an additional safety function, the direction of a

door movement in progress can only be changed in the OPEN direc-

tion (closing command can be overwritten with opening command). An

opening command CANNOT be overwritten with a closing command.

Reference run: After each power failure, the controller first requests

a reference run. In this case it searches for the reference point (normally

the mechanical stop in position OPEN or CLOSED). The door must be

moved to the reference point by continuously pressing the respective

direction key (stop CLOSED = CLOSE key, stop OPEN = OPEN key) at

the jog frequency speed. Normal door operation is then possible again.

If limit switches are used instead of an encoder, a reference run after

power failure is only required if the door is between the end positions

OPEN and CLOSED. In limit switch operation, the pre-close limit switch is

automatically defined as the reference point. This is always approached

by constantly pressing the CLOSE key (even if the Pre close limit switch

has already been actuated and overrun).

III. Controller Functions

- cont.

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.16

IV. Electrical Connection

The control unit must be fused with 16 A on the mains side. In addition,

a switch or a socket for a pluggable connection cable should be installed

in the immediate vicinity of the control unit, since some error messages

require the control unit to be completely switched off and on again.

Connect all supply lines of your external devices (door

operator, operating buttons, SHE safety devices, limit

switches... if necessary) to the pluggable terminal blocks.

Maximum cable length 30 m.

Please make sure that you use a separate screened cable for the cable

to the motor and to the encoder in the motor.

When inserting all screened connecting cables into the control housing,

use a metal EMC cable gland.

- Motor connection: 4 x 1.5 mm2incl. protective conductor (screened).

Connect the screen both to the motor and to the controller.

Connect the motor in delta connection.

- Motor temperature sensor connection: 2 x 0.5 mm2

- Encoder connection: 4 x 0.25 mm2(screened). Only connect the screen

in the control system.

- Connection of operating elements in controller: 0.5 mm2

A lockable main switch must be connected upstream to the control unit,

which switches off the mains voltage to the control unit at all poles. In

addition, a fuse must be provided on site in the supply circuit to protect

the supply line and terminals.

After connecting the external devices, the teach-in run is carried out while

the housing cover is still open.

After completion of the teach-in run, the protective conductor connection

to the housing cover must be re-established.

Before closing the cover, check again whether all protective

conductor connections have been made reliably!

Now screw on the housing cover again. Make sure that the screws are

tightened only slightly in order not to damage the seal.

The assembly of the device is now completed.

IV/2 Connection of External

Devices

IV/3 Cables

IV/4 Carrying Out of the

Teach-In Run

IV/1 Fuse Protection/

Main Switch

IV/5 Termination of Wiring

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.17

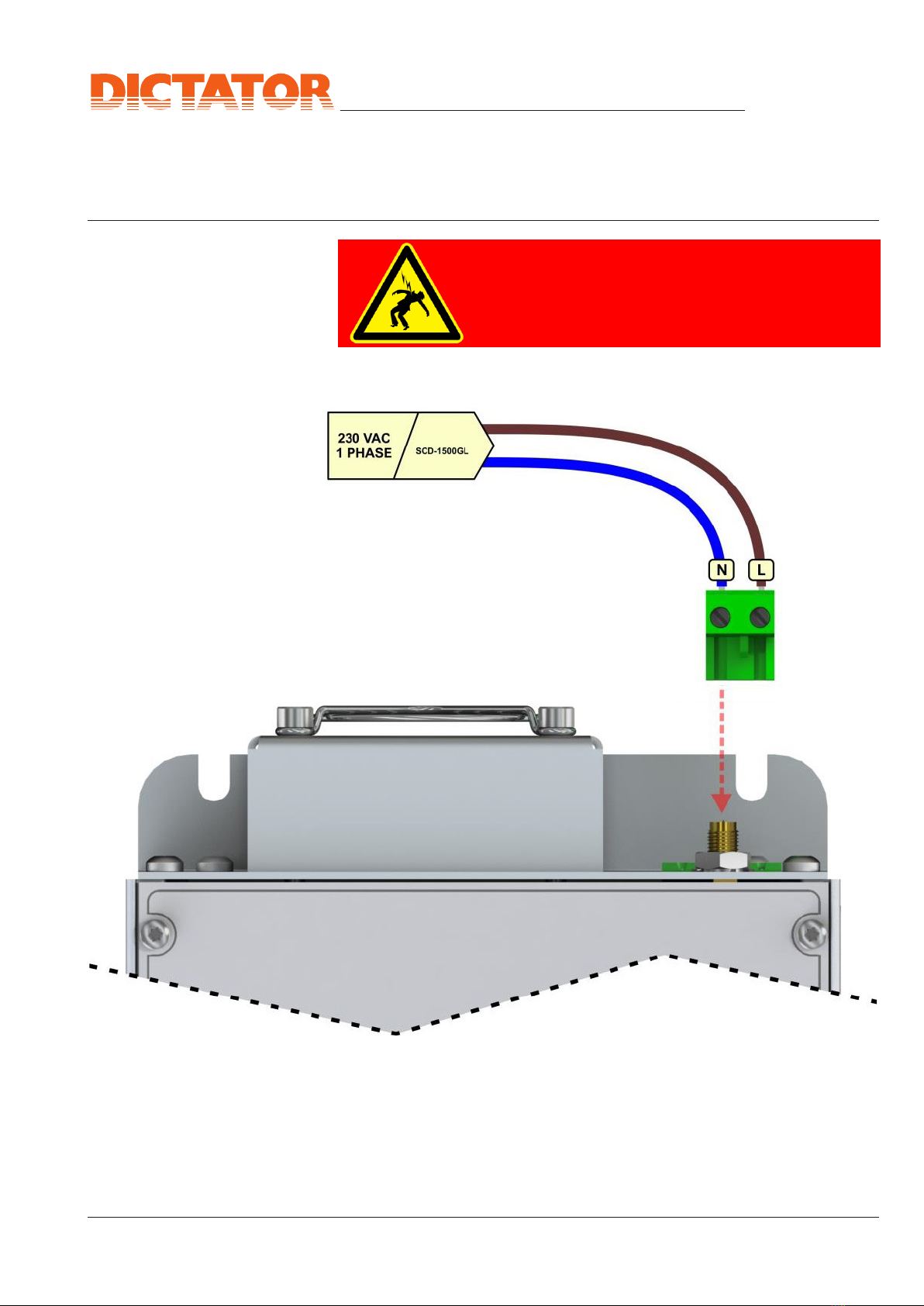

IV. Electrical Connection - cont.

WARNING! ELECTRIC HAZARD!

The mains supply has to be disconnected before

the start of electrical work.

IV/6 Mains Connection

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.18

IV/7 Motor Connection

Earthing

IV. Electrical Connection - cont.

Motor phases

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619 Page 04.046.19

Delta connection

230 VAC

Important:

Proper earthing/grounding is required when in-

stalling frequency converter drives. Not only for

personal safety, but also to ensure reliable ope-

ration.

• Always connect the motor ground and the

motor housing to a common ground point

with the lowest possible impedance.

• Never lay the motor cable parallel to the ro-

tary encoder cable.

• Do not separate or damage the cable. The

cable must be one-piece and uninterrupted

over its entire length.

Note: The cables are already in-

stalled at the factory as standard.

Some door applications require the motor to be equipped with an elec-

tromechanical brake that keeps the motor at standstill.

The example shows the application of a power relay to control a

230VAC motor brake.

Set System Setup › Outputs › Power Relay = 1

Thus the power relay is active if the output frequency is > 0.

IV/8 Connection Motor

Brake

IV. Elektrischer Anschluss - Forts.

IV/7 Motor Connection -

cont.

Technical Manual

SQUARE 940-2

© DICTATOR Technik GmbH • Gutenbergstr. 9 • 86356 Neusäß • Germany

Tel. +49(0)821-24673-0 • Fax +49(0)821-24673-90 • E-mail info@dictator.de • 20200619

Page 04.046.20

IV. Electrical Connection - cont.

IV/10 Rotary Endcoder The encoder MIG is used for the SQUARE 940-2. This is connected to

terminal strip X1 as shown below:

Name Type 7(+12V) 8(A) 9(B) 10(0V)

MIG Incremental Brown Yellow Green White

IV/11 Reference Limit When using an incremental rotary encoder, it is necessary to use a

reference switch/mechanical limit stop, as the door controller cannot

detect where the door is when it is switched on. Therefore, the controller

first searches for the reference position (position value 0). This reference

run is performed at slow speed until the door activates the reference

position.

If a reference switch is used, please note that the reference switch con-

tact may only change once during the entire travel of the door. If the re-

ference switch is mounted in the open position, a normally open contact

must be used. If the reference switch is mounted in the closed position of

the door, a normally closed contact must be used. This means that the

controller always detects the direction in which it must move in order to

reach the reference point.

You set up the correct function for the desired reference under

Set System Setup › Reference.

Reference limit

switch

connection

IV/9 Connection

Temperature Sensor

All DICTATOR AC drives are supplied as standard with a temperature

sensor in the motor. The temperature sensor (NC) should always be

connected to a stop input in the controller (input freely configurable)

to prevent any motor movement when triggered (protection against

overheating).

Other manuals for SQUARE 940-2

1

Table of contents

Other Dictator Control System manuals

Popular Control System manuals by other brands

Lutron Electronics

Lutron Electronics Pico PJL-2B quick start guide

Carel

Carel WM00E 00 Series quick start guide

Compool

Compool Cp3800 Installation & operating instructions

Carel

Carel PlantVisorPRO Technical leaflet

Hydronix

Hydronix Hydro-Control HC07 Operation manual

progressive automations

progressive automations PA-40 user manual

Pilz

Pilz PNOZ m ES CC-Link operating manual

OPTICLIMATE

OPTICLIMATE ZEVOMAX II Installation & user guide

Carson

Carson Reflex Stick Multi Pro LCD 14 Channel instruction manual

Pentair

Pentair EasyTouch Appliance Upgrade Guide

Charger

Charger WS1 Quick start manual

Celestron

Celestron NexStar GT owner's manual