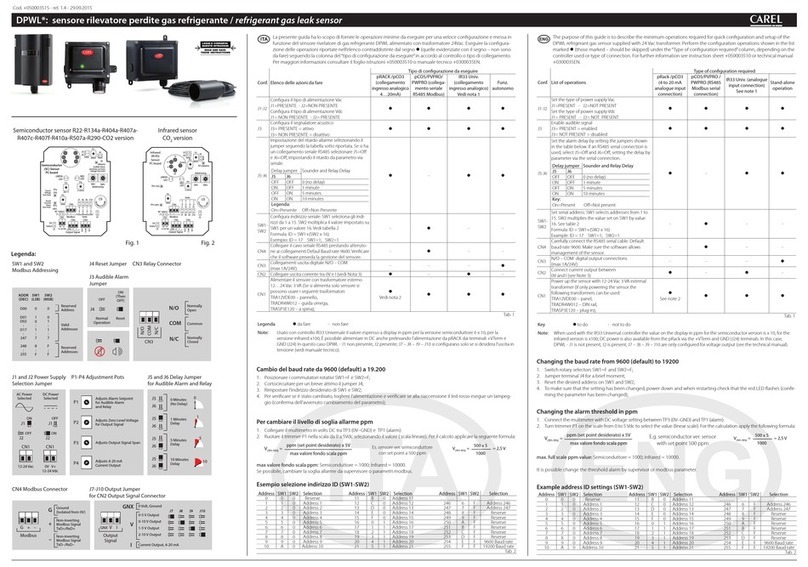

G

G0

VBAT

COMA

NOA

132 4

GND Tx/Rx

DI1

S4

S3

S2

S1

GND

DI2

VREF

2 AT

24 Vac

25 VA

shield

NTC

ratiometric pressure

transducer

S

ExV

giallo/yellow

bianco/white

verde/green

marrone/brown

FieldBus

24 Vac

BMS

R6

R5

R4

R3

R2

R1

230 V

20 A max

EN60730-1

UL 873 250 V

R5 - R6

12 (10) A

12 A res. 2HP

12FLA 72 LRA

CAREL NTC, PT1000

CAREL NTC, PT1000

CAREL NTC, PT1000

CAREL NTC, analog input 0 to 10 Vdc

B5 analog input

(4 to 20 mA)

OUT

M

+V

0 to 5 Vdc

DI1

Door switch

B3

B2

B1

48 47 46 45 44 43

49 50 51 52 53 54

VL

GND

GND

Rx/Tx+

Rx/Tx-

GND

Rx/Tx+

Rx/Tx-

GND

Rx/Tx+

Rx/Tx-

GND

Y1

B4

B5

DI1

DI2

DI3

GND

5 VREF

+ Vdc

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

analog output (0 to 10 Vdc)

EN60730-1

UL 873 250 V

R3 - R4

10 A res.

5 (3) A

10 A res. 5FLA

18 LRA

EN60730-1

UL 873 250 V

R1 - R2

8 (4) A N.O.

8 A res. 2FLA

12 LRA

CMP

DEF

FAN

LIGHT

UltraCella Control

EVD Module

BLIND VERSION

WM00ENNI00

30

29

28

27

26

25

21

20

19

24

23

22

34

35

36

37

38

39

40

41

42

33

32

31

GND

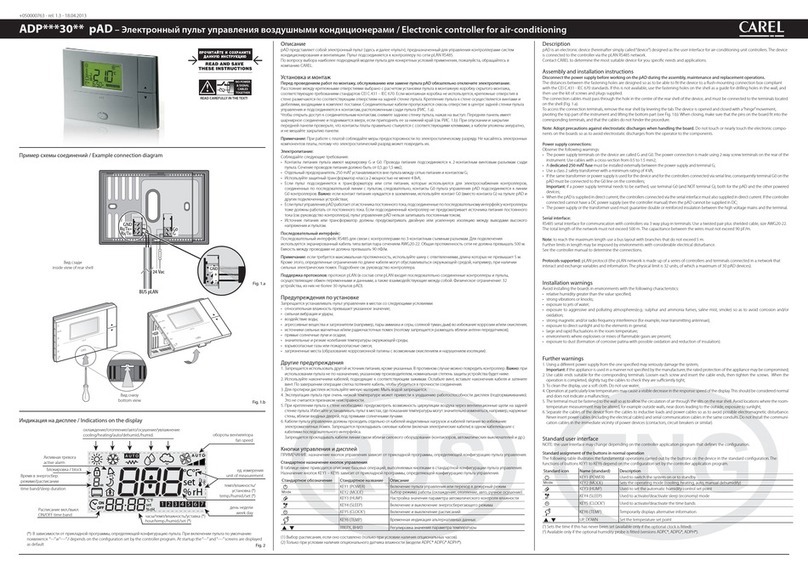

COLLEGAMENTI ELETTRICI

E CONFIGURAZIONE

WIRING CONNECTION

AND CONFIGURATION

FUNZIONAMENTO STAND ALONE O CON SMARTCELLA

WM00ENSI00, WM00ENS000, WM00EUS000 e WM00EUC000:

Collegare l’uscita compressore di SmartCella ad un relè d’appoggio

da collegare a sua volta all’ingresso digitale DI1 dell’EVD EVO (come

contatto pulito).

Utilizzo del display EVD EVO per la configurazione del driver.

FUNZIONAMENTO CON ULTRACELLA

WM00ENNI00, WM00EUN000 e WM00EUK000

Collegare UltraCella al modulo EVD in seriale secondo lo schema

elettrico seguente.

Configurazione del driver EVD EVO da UltraCella

Fare riferimento alla tabella parametri seguente per la configurazio-

ne del driver EVD EVO.

Se connesso in seriale, i parametri del driver potranno solo essere visua-

lizzati (non modificati) dal display locale dell’EVD EVO. Una volta abilita-

to il driver (parametro P1=1) i suoi parametri saranno quelli comunicati

da UltraCella, in accordo alla tabella parametri seguente (modificabili

unicamente da UltraCella); i parametri eventualmente configurati pre-

cedentemente tramite display dell’EVD EVO saranno persi.

STAND ALONE OR SMARTCELLA FUNCTIONING

WM00ENSI00, WM00ENS000, WM00EUS000 and WM00EUC000:

Connect SmartCella compressor output to a support relay to be

connected to the digital input DI1 of the EVD EVO (as a free-contact).

Driver commissioning by EVD EVO display.

ULTRACELLA FUNCTIONING

WM00ENNI00, WM00EUN000 and WM00EUK000:

Connect UltraCella to EVD module by serial cable in according with

following wiring diagram.

EVD EVO driver commissioning by UltraCella

Refer to below parameters table about EVD EVO driver commissio

-

ning.

If its’ connected by serial cable, driver parameters can be displayed

only (not modifiable) by local EVD EVO display.

Once driver is abled by UltraCella (parameter P1=1) its parameters

are ones communicated and set by UltraCella, in according with

below parameters table (modifiable by UltraCella only); parameters

eventually previously set by EVD EVO display will be lost.

DATI TECNICI

TECHNICAL SPECIFICATIONS

Per i dati tecnici elettrici riferirsi al foglio istruzioni EVD Evolution.

(cod.+050004150).

Alimentazione: tensione: 230 V~ (+10/-15%), 50/60 Hz;

potenza: 4,5kW max.

Nota: la massima corrente assorbibile contemporaneamente da tut-

ti i carichi comandati dal controllo e dai moduli di espansione non

deve superare i 20 A.

Classif. secondo la protezione contro le scosse elettriche: Classe II

Contenitore: plastico, dimensioni 128x290x110 mm

Grado di protezione frontale: con contenitore plastico: IP65

Categoria di resistenza al fuoco: Categoria D

Pulizia frontale del modulo: utilizzare esclusivamente detergenti

neutri ed acqua

Condizioni di funzionamento: -10T40°C, <90% U.R. non cond.

Condizioni di immagazzinamento: -20T60°C, <90% U.R. non condens.

PTI dei materiali di isolamento: circuiti stampati 250, plastica e

materiali isolanti 175

Per i modelli con UltraCap (WM00EUN000, WM00EUS000,

WM00EUK000 e WM00EUC000)

Tempo di carica minimo UltraCap: 4 minuti

Numero di azionamenti chiusura valvola consecutivi in funziona-

mento tampone: 1

Corrente di chiusura di emergenza sulla valvola: 280mA

Valvola Max ΔP* Valvola Max ΔP*

E2V03

35bar

E2V35 24bar * Max ΔP = massima

pressione differenzia-

le consentita su EXV

per la completa chiu-

sura di emergenza

tramite UltraCap

E2V05 E3V45 35bar

E2V09 E3V55 26bar

E2V11 E3V65 20bar

E2V14

E2V18

E2V24

E2V30

Nota: quando avviene la chiusura di emergenza, i condensatori si scari-

cano completamente. Quindi la carica assicura una sola chiusura della

valvola. Al ritorno dell’alimentazione i condensatori iniziano a ricaricar-

si, è necessario quindi un certo tempo, prima di poter garantire una

nuova chiusura in caso di black-out. E’necessario quindi assicurarsi che

nel controllo macchina (es. in UltraCella) sia impostato un ritardo di ac-

censione compressore, dopo il power-on, di almeno 4 minuti. In que-

sto modo è garantito dal controllo macchina che la valvola rimanga

chiusa per tutto il tempo necessario alla ricarica del modulo UltraCap.

For the electrical specifications see the EVD Evolution instruction

sheet (+050004150).

Power supply: voltage: 230 V~ (+10/-15%), 50/60 Hz;

power: 4.5kW max.

Note: The maximum simultaneous current draw by all the loads

connected to the controller and the expansion modules must not

exceed 20 A.

Classif. according to protection against electric shock: Class II

Case: plastic, dimensions 128x290x110 mm

Front panel ingress protection: With plastic case: IP65

Fire resistance category: category D

Cleaning the module front panel: Only use neutral detergents and

water

Operating conditions: -10T40°C, <90% rH non-condensing

Storage conditions: -20T60°C, <90% RH non-condensing

PTI of insulating materials: Printed circuits 250, plastic and insula

-

ting materials 175

For P/N including UltraCap (WM00EUN000, WM00EUS000,

WM00EUK000 and WM00EUC000)

Minimum UltraCap charge time: 4 minutes

Maximum number of consecutive valve closure during emergency

operation: 1

Emergency valve closing current: 280mA

Valve Max ΔP* Valve Max ΔP*

E2V03

35bar

E2V35 24bar

* Max ΔP = max

differential pressure

on EXV allowed for

complete emergency

closing by UltraCap

E2V05 E3V45 35bar

E2V09 E3V55 26bar

E2V11 E3V65 20bar

E2V14

E2V18

E2V24

E2V30

Nota: when emergency closing occurs, the capacitors discharge

completely. Consequently the charge can only ensure one valve clo

-

sing operation. When power returns the capacitors start recharging,

meaning a certain amount of time is needed before being able to

guarantee another closing operation in the event of blackout. As a

result, make sure that the control unit (e.g. c.pCO) is set with a com

-

pressor start delay after power-on of at least 4 minutes. This gua

-

rantees that the valve remains closed for the entire time needed to

recharge the Ultracap module.

CAREL INDUSTRIES HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy) - Tel. (+39) 0499716611

Fax (+39) 0499716600 - e-mail: carel@carel.com - www.carel.com +0500087IE - rel. 2.5 - 22.07.2019

Carel reserves the right to modify the features of its products without prior notice.

TABELLA CONFIGURAZIONE

PARAMETRI EVD

EVD PARAMETER TABLE

CONFIGURATION

Par Descrizione

Description

Def Min Max U.M.

P1 Abilitazione comunicazione con modulo

EVD 0/1= no/si

Enable communication with EVD module

0/1=no/yes

0 0 1 -

P1t Tipo sonda S1

S1 probe type

0 0 3 -

0RAZ. 0...5 V 24...20 mA REMOTE

14...20 mA 3 4...20 mA EXTERNAL

P1M Valore max sonda S1

Max value of S1 probe

12,8 -20 200 bar/psi

P1n Valore min sonda S1

Min value of S1 probe

-1 -20 200 Bar/psi

PVt Tipo valvola

Valve type

1 1 1 -

1 Carel exv

PH Tipo refrigerante

Refrigerant type

3 1 41 -

1 R22 15 R422D 29 R455A

2 R134a 16 R413A 30 R170

3 R404A 17 R422A 31 R442A

4 R407C 18 R423A 32 R447A

5 R410A 19 R407A 33 R448A

6 R507A 20 R427A 34 R449A

7 R290 21 R245Fa 35 R450A

8 R600 22 R407F 36 R452A

9 R600a 23 R32 37 R508B

10 R717 24 HTR01 38 R452B

11 R744 25 HTR02 39 R513A

12 R728 26 R23 40 R454B

13 R1270 27 R1234yf 41 R458A

14 R417A 28 R1234ze

PrE Tipo regolazione principale

1 banchi/ celle centralizzati

2 banchi / celle monoblocco

3 banchi / celle perturbati

4 banchi /celle a CO2 subcritico

Main regulation type

1 centralized cabinet /cold room

2 self contained cabinet /cold room

3 perturbated cabinet /cold room

4 subcritical CO2 cabinet/cold room

2 1 4 -

P0 Indirizzo EVD Modbus

EVD Modbus address

198 1 247 -

P3 Setpoint di surriscaldamento

Superheat setpoint

10 -72 324 K

P4 Guadagno proporzionale

Proportional gain

15 0 800 -

P5 Tempo integrale

Integral time

150 0 999 sec

P6 Tempo derivativo

Derivative time

2 0 800 sec

P7 LSH: soglia basso surriscaldamento

LSH: threshold low superheat

3 -72 324 K

P8 LSH: tempo integrale

LSH: protection integral time

600 0 800 sec

P9 LSH: ritardo allarme basso surriscaldamento

LSH: low superheat alarm delay

600 0 999 sec

PL1 LOP: soglia per bassa temp.evaporazione

LOP: threshold for low temp. of evaporat.

-50 -60 200 °C/°F

PL2 LOP: tempo integrale

LOP: integral time

600 0 800 sec

PL3 LOP: ritardo allarme bassa temp. evapor.

LOP: low evaporation temp. alarm delay

600 0 999 sec

PM1 MOP: soglia per bassa temp. evaporaz.

MOP: threshold for low temp. of evapor.

50 -60 200 °C/°F

PM2 MOP: tempo integrale

MOP: integral time

600 0 800 sec

PM3 MOP: ritardo allarme bassa temp. evapor.

MOP: low evaporation temp. alarm delay

10 0 999 sec

cP1 Posiz. iniziale valvola ad inizio regolazione (%)

Open valve startup, Percentage

50 0 100 %

Pdd Ritardo post sbrinam. (solo per driver singolo)

Post defrost delay (only for single driver)

10 0 60 min

PSb Posizione della valvola in stand-by

Valve position in stand-by

0 0 100 step

PMP Abilitazione posizionamento manuale

Enable manual positioning

0 0 1 -

PMu Posizione valvola manuale

Manual valve positioning

0 0 999 step

Pnr Reset EVD setting 0 -> 1 Reset di tutti i

parametri EVD EVO

Reset EVD setting 0 -> 1 Reset all EVD

parameters

0 0 1 -