ProFire 1100 User manual

PROFIRE 1100

IGNITION FLAME SAFETY

CONTROLLER

REV 0 October 2009

P R O F I R E C O M B U S T I O N I N C .

2

CAUTIONS

EXPLOSION HAZARD: DO NOT SERVICE UNLESS AREA IS KNO N TO BE NON-

HAZARDOUS

DO NOT OPEN HEN ENERGIZED

SUBSTITUTION OF COMPONENTS MAY IMPAIR THE

SUITABILITY FOR ZONE 2 (Class 1 Division 2)

REPLACEMENT FUSES MUST BE SAND-FILLED

INSTALLATION WARNING

TERMINALS: MUST CONFORM TO THE DIRECTIONS IN THIS

MANUAL

THE UNIT MUST BE PROPERLY CONNECTED TO

EARTH-GROUND FOR EFFECTIVE IONIZATION

OPERATION

ELECTRICAL DEVICES CONNECTED TO THE

CONTROLLER MUST MEET ELECTRICAL STANDARDS

AND BE ITHIN VOLTAGE LIMITS

CONTACT NUMBER

For any questions call:

780-960-5278

P R O F I R E C O M B U S T I O N I N C .

3

Table of Contents

1Features & Specifications....................................................................................................................4

1.1 General Features...................................................................................................................................... 4

1.2 Specifications............................................................................................................................................ 4

1.3 Model Comparison .................................................................................................................................. 6

1.4 Thermocouples......................................................................................................................................... 7

2Installation ...........................................................................................................................................8

2.1 Design Code P&IDs and Wiring Diagrams........................................................................................... 8

2.2 Bill of Materials...................................................................................................................................... 31

2.3 Mounting locations ................................................................................................................................ 33

2.4 System Installation................................................................................................................................. 33

2.5 Pilot & Coil (Optional) .......................................................................................................................... 34

3Keypad & Display.............................................................................................................................36

3.1 Keypad Layout....................................................................................................................................... 36

3.2 Programming Parameters..................................................................................................................... 38

3.3 Messages ................................................................................................................................................. 40

3.4 Error Messages ...................................................................................................................................... 42

4Operations ..........................................................................................................................................43

4.1 Operation Instructions .......................................................................................................................... 43

4.2 Resets ...................................................................................................................................................... 43

4.3 Normal Operation Description ............................................................................................................. 43

4.4 Cause & Effect Diagrams...................................................................................................................... 46

5Troubleshooting .................................................................................................................................49

P R O F I R E C O M B U S T I O N I N C .

4

1 Features & Specifications

1.1 General Features

The following general features are common to all Profire 1100 models:

•Designed for the fire-tube heater industry

•Meets or exceeds all relevant codes and standards

•Easy installation with clearly mar ed component I/O

•Large, easily accessible terminal connections

•Rapid 1.8 second shut-down on flame-out

•DC voltage spar generator

•Ultra-low power design to accommodate solar panel or TEG applications

•Auto relight or manual operation

•Equipped with AVD (Advanced Visual Display) for improved operating functions and signals

•Transient protected and fail-safe circuits

1.2 Specifications

The following specifications are common to all Profire 1100 models:

E N C L O S U R E

Fiberglass

200 x 150 x 100 mm (8" x 6” x 4") overall dimensions

2.3 g (5 lb)

CSA and UL compliant for Class 1 Zone 2 locations

Enclosure type 4, 4X, 12, 13

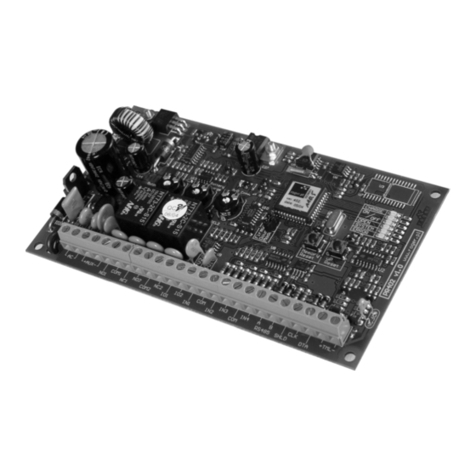

C I R C U I T B O A R D S

All solid state

CSA compliant for Zone 2 (Class 1, Division 2) locations

I G N I T I O N B A S E A N D C O I L

For non-hazardous mounting area only

P O E R R E Q U I R E M E N T S

+10 to + 28 volts DC (voltage must match solenoid rating)

2.0 amps surge (limited), 0.015 - 2 amps run

P O E R C O N S U M P T I O N

See the Design Code Features table on pg 9 for the power required for each design code.

12V 24V

Controller only, display ON 1.3 W 1.6 W

Controller only, display OFF 0.6 W 0.9 W

System maximum using design codes See pg9 See pg9

P R O F I R E C O M B U S T I O N I N C .

5

T E M P E R A T U R E R A T I N G

-40°C to 55°C

A P P R O V A L S

Zone 2 (Class 1, Division 2) locations approval (CSA 213-92)

Burner Safety approval (CSA 22.2-199) - can be used on B149.3 compliant system

Industrial Process Equipment approval (CSA 14-95)

I N P U T S & O U T P U T S

(4) digital inputs for safety interloc device connections

(4) digital outputs

See Section 1.4 for thermocouple inputs

P R O F I R E C O M B U S T I O N I N C .

6

1.3 Model Comparison

The following table can be used to determine model functionality:

1100 s

(standard)

1100 b1

(bath 1)

1100 b3

(bath 3)

Ionization flame detection

X X X

Thermocouple flame detection

X X

Pilot output off when bath temperature > HH2

X X

Main output off when bath temperature > HH1

X X

Alarm output when fault detected

X X X

Alarm output when bath temperature > HH3

X X

Bath temperature monitored

X X

Separate temperature controller required

X X

Separate over temperature protection required

X

* HH1, HH2 & HH3 are user programmable bath temperature setpoints

P R O F I R E C O M B U S T I O N I N C .

7

1.4 Thermocouples

T E 1 0 1

Type “K”

Measures bath liquid temperature

Primary temperature control device

Connected to an external temperature controller (not included) on Models s & b1

Connected to terminals TC+(yellow) & TC-(red) on card on door on Model b3

20 ga or larger Type “K” extension wire must be used

Provides temperature control

Will not alarm if the wires are shorted together or if an open circuit is detected

A large error will result if either lead is shorted to ground.

T E 1 0 2

Type “K”

Measures bath liquid temperature

Connected to terminals TC+(yellow) & TC-(red) on card on door on Model b1

Connected to terminals TC+(yellow) & TC-(red) on main board on Model b3

Connected to an external temperature controller (not included) on Model s

20 ga or larger Type “K” extension wire must be used

Provides over temperature protection

Not the primary temperature control device

Will alarm if an open circuit is detected

A large error will result if either lead is shorted to ground

T E 3 0 6

Type “K”

Measures pilot temperature

Connected to terminals TC+(yellow) & TC-(red) on main board on Models s & b1

14 ga extension wire without a shield is sufficient

Will fault if an open circuit is detected

A large error will result if either lead is shorted to ground

* TE101 and TE102 may be different elements in the same head of a type “K” thermocouple

* For all thermocouples avoid locating extension wire near high voltage and shield if necessary

P R O F I R E C O M B U S T I O N I N C .

8

2 Installation

2.1 Design Code P&IDs and Wiring Diagrams

The design codes are not exhaustive but only a sample of recommended designs that have been used. Any

design used should be chec ed by a qualified person and approved by the gas authority having jurisdiction at

the site where the system is to be installed. The design used should be clearly mar ed and available to

maintenance and service personnel.

The following tables show and compare the features of each design code for selection and identification

purposes.

P R O F I R E C O M B U S T I O N I N C .

9

Design Code Features

Design

Code Model Burner Size SSV Type Temp Control Type TCV Type Pilot Type Instrument

Gas

Power

Required

301A b1 < 10MM Btuh 2 x electric electric 2- state pneumatic separate separate 30W

301B b1 < 10MM Btuh 2 x electric I/P modulating pneumatic separate separate 15W

301C b1 < 10MM Btuh 2 x electric pneumatic pneumatic separate separate 15W

302A b1 < 10MM Btuh 1 x pneumatic c/w ZSC electric 2- state pneumatic separate separate 10W

302B b1 < 10MM Btuh 1 x pneumatic c/w ZSC I/P modulating pneumatic separate separate 10W

302C b1 < 10MM Btuh 1 x pneumatic c/w ZSC pneumatic pneumatic separate separate 10W

303A b1 < 10MM Btuh 2 x electric + LFSSV electric 2- state LFSSV separate n/a 30W

304A b3 < 1MM Btuh 2 x electric electric 2- state b3 none slipstream n/a 15W

305A b3 < 1MM Btuh 1 x pneumatic c/w ZSC electric 2- state b3 none slipstream separate 15W

306C b1 < 1MM Btuh 2 x electric pneumatic pneumatic slipstream separate 15W

P R O F I R E C O M B U S T I O N I N C .

10

Design Code Advantages & Disadvantages

Design

Code Advantages Disadvantages

301

1) Choice of HI/LO/OFF, electronic or pneumatic modulating temperature control

2) Uses less instrument gas than 302

3) Can be used with remote bath temperature monitoring and setpoint control

4) Less wiring than 302

5) Incorporates triple setpoint HIHI temperature protection

1) Uses an external temperature controller

2) 301A uses more electric power

3) Needs clean and dry instrument gas or air at minimum 35 psig

4) More difficult to install in 6” fire-tubes

302

1) Choice of HI/LO/OFF, electronic or pneumatic modulating temperature control

2) Uses less electric power than 301A

3) Can be used with remote bath temperature monitoring and setpoint control

4) Incorporates triple setpoint HIHI temperature protection

1) Uses an external temperature controller

2) Uses more instrument gas than 301

3) More wiring than in 301

4) Needs clean and dry instrument gas or air at minimum 70 psig

5) More difficult to install in 6” fire-tubes

303

1) No instrument gas needed

2) Suitable for all sour sites

3) Saves cost and GHG emissions

4) Incorporates triple setpoint HIHI temperature protection

1) Limited to HI/LO/OFF temperature control from an external temperature

controller

2) Uses same higher amount of electric power as 301A

3) More difficult to install in 6” fire-tubes

304

1) No instrument gas needed

2) Suitable for all sour sites

3) +/-1°C temperature control deadband built into the BMS controller

4) Reduces pilot freezing problems

5) Allows turning pilot OFF when not needed, then restarting it automatically. (especially for

propane pilots)

6) Ideally suited for 6” fire-tube

7) Save instrument gas cost and GHG emissions

8) Incorporates triple setpoint HIHI temperature protection

1) Limited to HI/Pilot/OFF temperature control.

2) Suitable only for burners up to and including 3” in size and maximum 1 MM Btuh

fuel input.

305

1) +/-1°C HI/pilot/OFF temperature control deadband built into the BMS controller

2) Reduces pilot freezing problems

3) Allows turning pilot OFF when not needed, then restarting it automatically. (especially for

propane pilots)

4) Ideally suited for 6” fire-tube

5) Incorporates triple setpoint HIHI temperature protection

1) Suitable only for burners up to and including 3” in size and maximum 1 MM

Btu/hr fuel input.

2) Needs clean and dry instrument gas or air at minimum 35 psig.

306

1) Uses less instrument gas than 302

2) Can be used with remote bath temperature monitoring and setpoint control

3) Less wiring than 302

4) Incorporates triple setpoint HIHI temperature protection

5) Allows turning pilot OFF when not needed, then restarting it automatically. (especially for

propane pilots)

6) Ideally suited for 6” fire-tube

1) Uses an external temperature controller

2) Needs clean and dry instrument gas or air at minimum 35 psig

P R O F I R E C O M B U S T I O N I N C .

11

FUEL GAS

MAIN

BURNER

PILOT

BURNER

Fire-Tube Heater with

< 10,000,000 BTU/hr (HHV)

Fuel Input

With Electric Safety Shutoff

Valves and HI/LO/PILOT/OFF

Electro-Pneumatic Temperature

Control

PILOT GAS

STACK

STACK

SAMPLE

PORT

ALTERNATE

PILOT FUEL

SUPPLIES

(ONLY ONE

CONNECTED)

DESIGN CODE:

301A

P R O F I R E C O M B U S T I O N I N C .

12

P R O F I R E C O M B U S T I O N I N C .

13

FUEL GAS

MAIN

BURNER

PILOT

BURNER

PILOT GAS

STACK

STACK

SAMPLE

PORT

ALTERNATE

PILOT FUEL

SUPPLIES

(ONLY ONE

CONNECTED)

Fire-Tube Heater with

< 10,000,000 BTU/hr (HHV)

Fuel Input

With Electric Safety Shutoff

Valves and Modulating I/P

Temperature Control

DESIGN CODE:

301B

P R O F I R E C O M B U S T I O N I N C .

14

P R O F I R E C O M B U S T I O N I N C .

15

FUEL GAS

MAIN

BURNER

PILOT

BURNER

PILOT GAS

STACK

STACK

SAMPLE

PORT

ALTERNATE

PILOT FUEL

SUPPLIES

(ONLY ONE

CONNECTED)

Fire-Tube Heater with

< 10,000,000 BTU/hr (HHV)

Fuel Input

With Electric Safety Shutoff

Valves and Modulating

Pneumatic Temperature

Control

DESIGN CODE:

301C

P R O F I R E C O M B U S T I O N I N C .

16

P R O F I R E C O M B U S T I O N I N C .

17

FUEL GAS

MAIN

BURNER

PILOT

BURNER

PILOT GAS

STACK

STACK

SAMPLE

PORT

ALTERNATE

PILOT FUEL

SUPPLIES

(ONLY ONE

CONNECTED)

Fire-Tube Heater with

< 10,000,000 BTU/hr (HHV)

Fuel Input

With Pneumatic Safety

Shutoff Valve and with

HI/LO/PILOT/OFF

Electro-Pneumatic

Temperature Control

DESIGN CODE:

302A

P R O F I R E C O M B U S T I O N I N C .

18

P R O F I R E C O M B U S T I O N I N C .

19

FUEL GAS MAIN

BURNER

PILOT

BURNER

PILOT GAS

STACK

STACK

SAMPLE

PORT

ALTERNATE

PILOT FUEL

SUPPLIES

(ONLY ONE

CONNECTED)

Fire-Tube Heater with

< 10,000,000 BTU/hr (HHV)

Fuel Input

With Pneumatic Safety

Shutoff Valve and with

Modulating I/P Temperature

Control

DESIGN CODE:

302B

P R O F I R E C O M B U S T I O N I N C .

20

Table of contents

Other ProFire Control System manuals