Digga Torque Hub User manual

Installation, Operating

and Troubleshooting

Manual

PM-000199 September 2019

PAGE INTENTIONALLY

LEFT BLANK

2

PM-000199 September 2019

PREFACE

Please read and follow this Operations Manual carefully, before installation and operation of the

Product. Not following theindividual points and recommendation in the operations manual can

lead to personnel accident or damaged to the product and equipment.

Operation of the system is only permitted with equipment and spare parts supplied by Digga or listed

in the spare parts and its consumables lists. Using other peripherals or alternative parts may void the

warranty of the product.

The specifications and descriptions inthis manual are subject to change without prior notice. Digga

reserves the right to improve the product in order to sustain the highest quality, delivered to our

customers.

Some product improvements may have been in place after this manual was printed. For the updates

and information about the product,please contact Digga oryour local Digga Dealer.

PRODUCT INTRODUCTION

The Torque Hub utilises the same technology as our Torque Logic, it delivers over 99% accurate

torque readings. Data is sent over a robust 2.4 GHz RF FHSS signal to the hand held display / data

logger. The Torque Hub measures not only torque, but also inclination.

TECHNOLOGY

Utilising strain gauges, internal CPU, RAM and other electronics, the Torque Hub can guarantee

highly accurate, real time torque readings. An inclinometer built into the Torque Hub ensures that you

maintainaconsistent angle of insertion. The Torque Hub software records important data such

aspile number, final torque, peak torque and elapsed time. This data can be exported to an

Excel spread- sheetand transferred by e-mailor memorystick to your engineer/customer.

SAFETY

Consistent andreal time monitoring oftorque will prevent over-torque which can often resultin pile

failures (piles sheared or buckled). The inclinometer also removes the need (and associated risk) for

personnel tostand beneath the drive head toassist the operator in maintaining a proper insertion

3

PM-000199 September 2019

4

TABLE OF CONTENTS

Preface/Product Introduction.........................................................................................................................................3

Table of Contents .............................................................................................................................................................4

Safety Symbol and Statements .................................................................................................................................... 5

General Safety and Precautions ....................................................................................................................................6

Product Waste Disposal ................................................................................................................................................. 8

INSTALLATION MANUAL

Torque Hub Installation………..…....................................................................................................................................9

7” PR3820 DISPLAY OPERATING MANUAL

Main Screen Functions………………..…...........................................................................................................................13

Connect to Hub ..........…..…………...................................................................................................................................14

Job Creation and Selection……………………………………………………………………………………………….........……………...16

Setting Target/Optimum Torque/Torque Range.…………….………………………………………………………...........…….18

Inclinometer Bull’s Eye Resolution Selector………………………………………………………………….........……….…………..19

Add aJoint…………………….……………………………………………………………...……………………………….........……….……….20

Setting Units of Measurement and Language…………..…………………………………………………..…...…........………….21

Exporting Piling Jobs…………………………………………………………………………………………………………………….........….22

TROUBLESHOOTING/ MAINTENANCE/ GENERALPOLICIES

Troubleshooting Guide…………………………………………………………………………………………………………….……………….26

Warranty Policies.......................................................................................................................................................... 28

Return Goods Policy ...................................................................................................................................................... 29

Notes.......... ..................................................................................................................................................................... 30

PM-000199 September 2019

Spare Parts ..................................................................................................................................................................... 32

SAFETY SYMBOLS AND STATEMENTS

DANGER

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

WARNING

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

CAUTION

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF THE IN- STRUCTIONS ARE NOT

FOLLOWED PROPERLY.

THIS STATEMENT REPRESENTS TO CALL YOUR ATTENTION INVOLVING US- ERS SAFETY

AND PRODUCT PERFORMACE REQUIREMENTS. FAILURE TO FOL- LOW THE INSTRUCTIONS

CAN RESULT TO INJURY, DEATH OR PRODUCT PER- FORMANCE DEGRADATION.

5

PM-000199 September 2019

GENERAL SAFETY PRECAUTIONS

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

Always wear the proper personalprotective equipment for the job

you’re doing.

When working on or near heavy equipment, approved hard hat

and steel toe boots are recommended.

Lower the boom of the machine on to solid footing before

attempting toattach the hub.

Turn off the power and apply the parking brake.

Use your knees not your back when picking up and placing

heavy Torque Hub.

Inspect tools, besure proper guards are in place.

WARNING

Safety is the responsibility of the individual. Observe all safety pro-

cedures as outlined by your employer.

6

PM-000199 September 2019

GENERAL SAFETY PRECAUTIONS

WARNING

WARNING

WARNING

WARNING

WARNING

Inspect the product prior use for any defects such ascracks,

chipped, open wirings, deformation, etc.

Inspect all parts, be sure all parts are installed properly and ina

safe condition.

Follow decal labels on the product and safety signs in the work area.

Emergency preparedness is necessary and be sure to follow all

instructions from the safety officer during evacuation.

Remove all tools and unused parts from equipment before begin-

ning the operations.

7

PM-000199 September 2019

PRODUCT WASTE DISPOSAL

Disposal of Product

Do not dispose the torque hub,screens and harnesses in the domestic waste!

Electronics devices and batteries have to be dispose according tothe regional direc-

tives onelectronic and electrical waste disposal.

In case of further questions, please ask your local waste management authorities.

8

PM-000199 September 2019

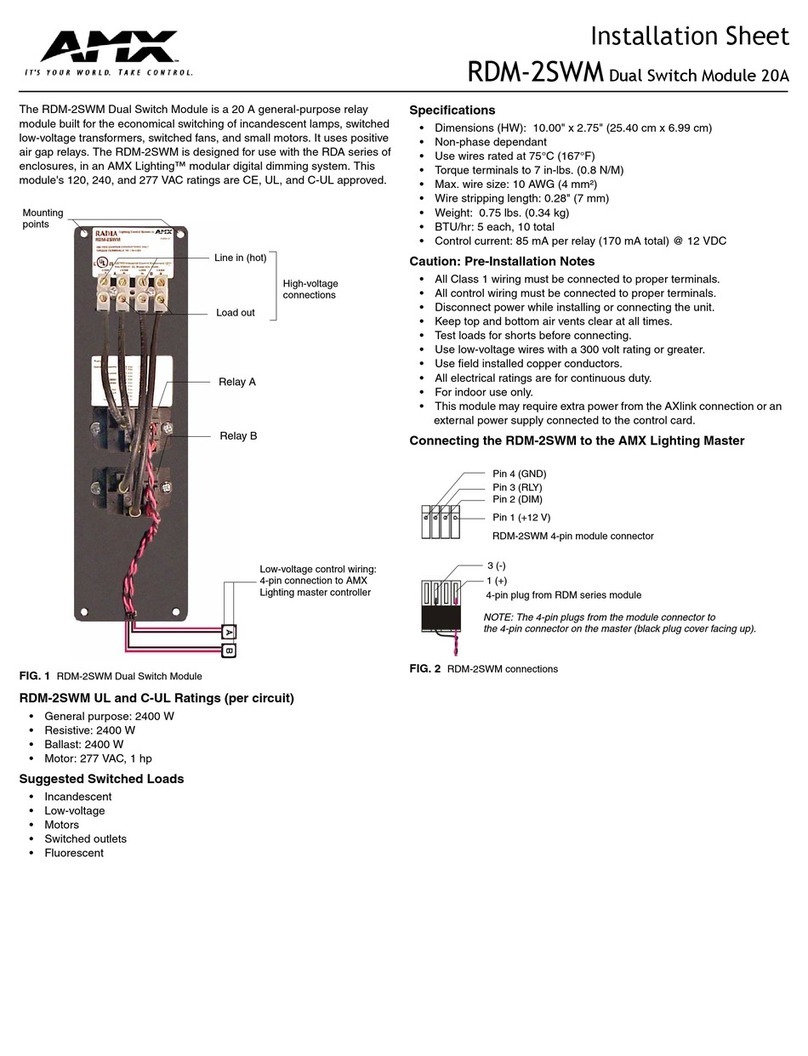

TORQUE HUB INSTALLATION

1.Attach the harness to

the back of the display,

making sure the male and

female pins line up and

the connectors are tight.

2.Securely mount the display

using the magnet or suction

cup assembly. Try to point the

back of the display so it's

facing the hub.

3.If your unit comes with an

antenna. Make sure it is not

adjusted and laying down in

the horizontal position. Also

make sure the antenna is not

damaged, crushed or covered

in clay or grease.

9

PM-000199 September 2019

4.Connect your power using

a cigarette lighter, hard

wiring or digger derrick plug

adaptor.

3. Mount the hub to the drive

units shaft and secure it with

locking pin and R Clip.

TORQUE HUB INSTALLATION

10 PM-000199 September 2019

5.Turn the hubs power on.

Make sure the power switch

has a solid red light. If the

light is flickering or does not

come on there is a problem.

Give the hub some movement

by patting it with your hand or

movement with the drive. This

wakes the hub up.

6.Turn display power on.

Check for solid red light on

the switch.

Make sure the power cable is plugged securely into the power connections and the cable is

not going to be caught on anything. Wait for the display to load.

Once the display is running go to the “menu” button, then to “connect to pin or hub” button.

You will see a white screen with “please wait…” connecting may take a couple minutes.

A screen will come up with a hubs serial number, highlight it and “connect” button. Do not

select “channels” that is for multiple hub connections. Sometimes for difficult connections,

removing the display from the ball mount assembly can help speed up connection. Replace it

when you are connected. Note: If a “failed to connect” message comes up go back to the main

display and wait, the display and hub are exchanging data and they will connect.

You will know if the hub is connected when you see the hubs serial number in the top middle

of the main screen. The battery charge will appear under it. You may also see some torque

fluctuation in the gauge. Some noise is normal operation. Some torque may show depending on

how tight and even the adapter was installed. Note: The process of connecting is faster if the

hub and display stay together as a unit. Displays and hubs can be mix and matched but

connecting may take longer when this is done.

TORQUE HUB INSTALLATION

11

PM-000199 September 2019

Operating Manual

DIGGA 7” MULTI TOUCH DISPLAY

MAIN SCREEN FUNCTIONS

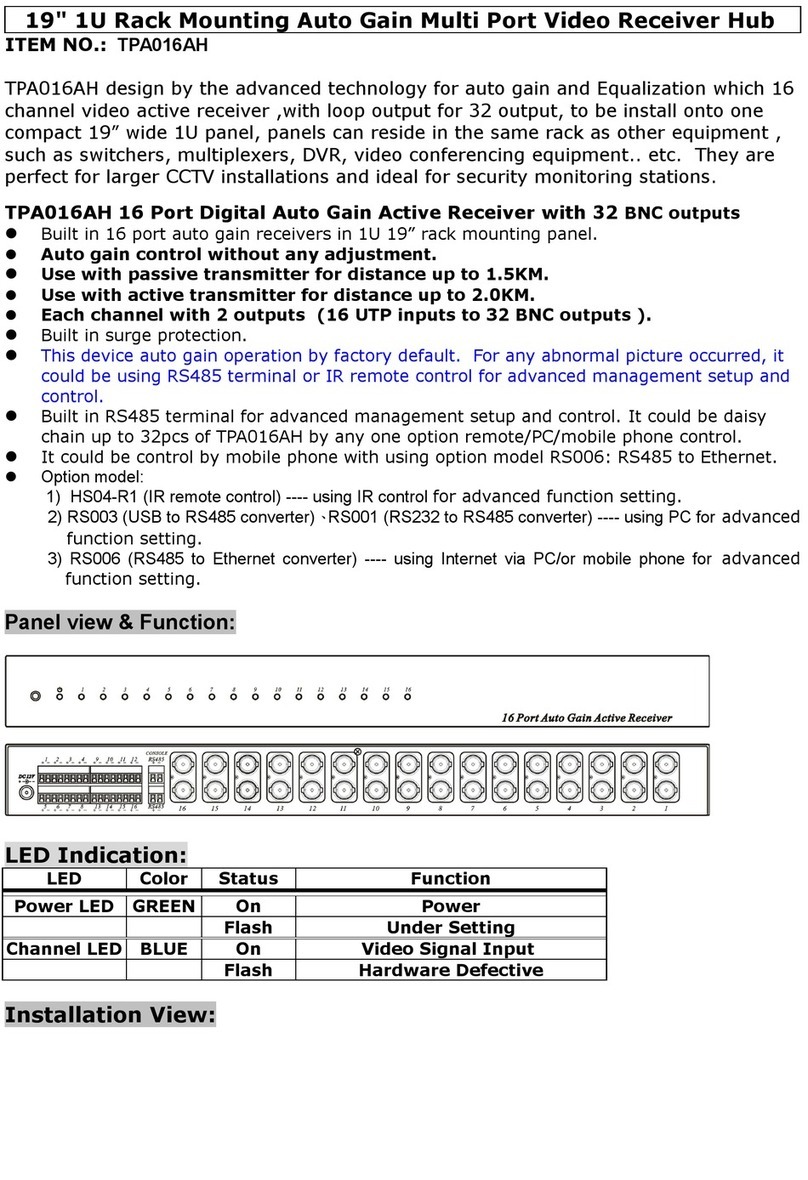

The DIGGA PR3843 ColourDisplay at a Glance

1. Date

2 Pile Name

3. Dial Indicator Live Torque

4. Change dial range or Set Zero Calibration

5.

Numeric Indicator Live Torque

6.

Target Torque for Indicator

7.

Main Menu

8. Manually Enter Joint length

9. Depth

10. X-Y

11. New pile

12. Inclinometer

13. Current job

14. Add Joint

15. Serial # for wireless

16. Pin orientation

2

1

15

13

9

3

16

12

8

5

4

14

10

6

11

7

13

PM-000199 September 2019

Step 1

Attach the black harness to the back of the display and plug the other end into the cigarette lighter

in the machine, it must beplugged it at alltimes towork.

Step 2

Turn on the display the power button is located on the top left of the display. Be sure when turning

it off you use the shutdown button located in the menu or on the top left side of the display, select

shutdown. Using the power button to turn off could cause the display to corrupt.

1. Hardwired version will

connect automatically.

NOTE: If you are using a Torque Hub or wireless pin be sure to fully charge the

battery inside the hub or wireless box before starting your job should be 16.5V

NOTE: Letting the cell reach OV can permanently reduce the CELL’S capacity.

Most protection cells are not designed to let the CELL be recharged after the

cell’s voltage is below OV.

*These will not be covered under warranty.*

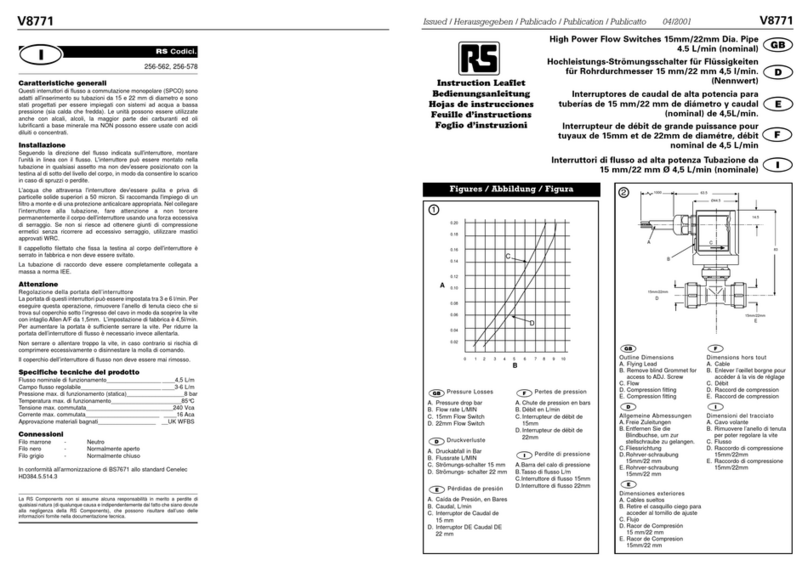

Connect to Hub

1. Touch on menu

14

Be sure when turning it off that you use the shutdown button: touch menu

then shutdown, wait approx. 2 mins before turning power switch off.

You must turn the switch off to be sure that when starting up again the display

does not get a power surge.

Using the power button to turn off the display before following the above

instructions could cause the electronics in the display to be corrupt.

*Doing this will void the warranty*

PM-000199 September 2019

2. Touch

Connect to pin or hub.

NOTE: Torque Hub or

wireless pin only.

4. Highlight the on

that matches either

your pin or Hub

serial number.

5. Touch Connect

6. Touch close

NOTE: Torque Hub or

wire-less pin only

Connect to Hub

Hardwired version will

connect automatically.

DIGGA 7” DISPLAY OPERATING

GUIDE

15

PM-000199 September 2019

DIGGA 7” DISPLAY OPERATING

GUIDE

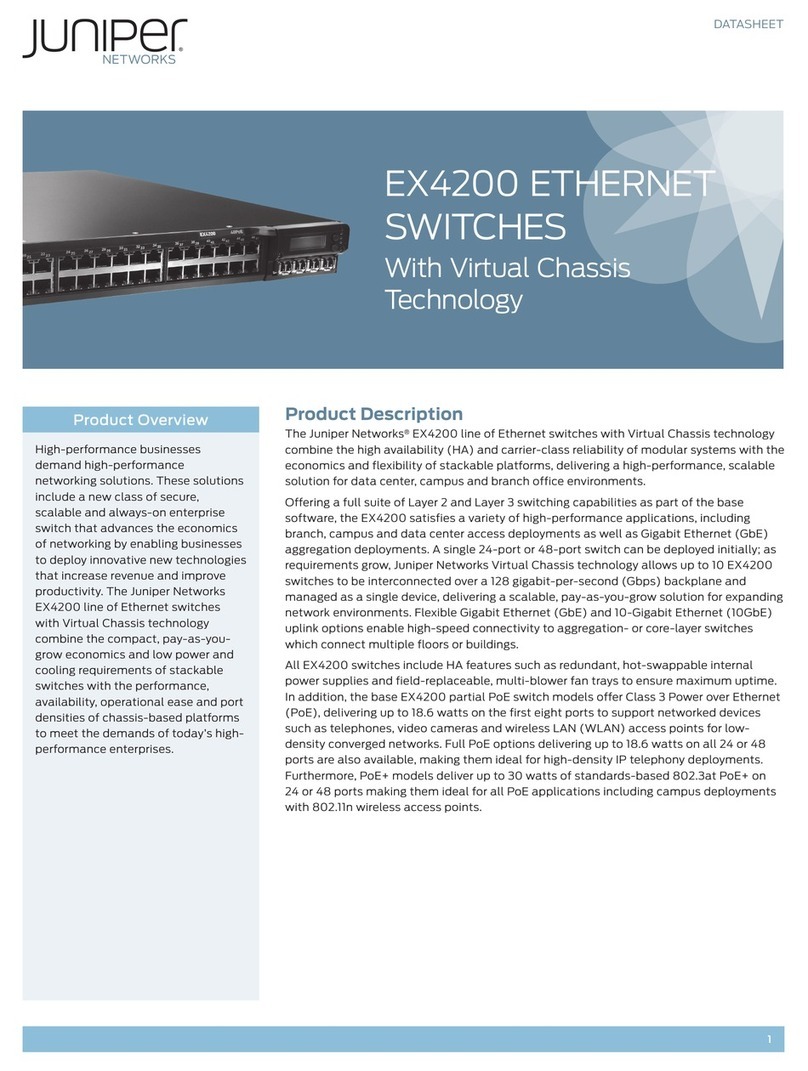

Job Creation and selection

1.Touch the menu button.

2.Touch the Job Management

3.Touch new job

Job information Screen will

appear, enter job name. Touch

select job.

Note: As many new jobs many be

entered as required

16 PM-000199 September 2019

DIGGA 7” DISPALY OPERATING GUIDE

Job Creation and Selection

5. Touch new pile from main screen.

6. Touch new pile enter pile name

using the pop up keyboard.

Note: Pile name is a mandatory entry

as it appears on your data report

when downloaded to the Excel

Report.

8. Touch Save when complete.

Note: Filling out the rest of the fields is

not mandatory, but is recommended

for data export to the Excel Report

After completing the Data

information Input. Touch the

save button

Highlight the Job that you’ve created.

Touch Select pile to show it on

the Current Job

Note: At any time you can click

on the pile name on the main screen

to see the information of that pile

Note: If at any time you need toed

edit the pile, touch menu, job

management, highlight the pile

that needs edit click edit, enter

the information and click save.

17

PM-000199 September 2019

DIGGA 7” DISPLAY OPERATING GUIDE

Setting Target/Optimum Torque/Torque Range

1. On the main screen, touch anywhere

in the circle on left to Zero calibration,

then click Zero calibration, this may

take up to 20 seconds.

2. To Set the Torque Range Selector

Touch anywhere on the live torque

dial indicator Main screen to bring up

the Range

Use the arrow keys to set the desired

range. Press close

3. To set the target Torque

On main screen touch anywhere in

the circle on the left, click Set target

torque, enter desired Torque.

Touch Set target torque, touch close

When target is reached the indicator

will turn green.

Note:If the torque shows a non-zero

value whenthe drive is hanging free,

user may press ZERO CALIB tocalibrate

the display. This may take a few

seconds.

18 PM-000199 September 2019

DIGGA 7” DISPLAY OPERATING GUIDE

Inclinometer Bull’s Eye Resolution Selector

1. To zero the Bull’s Eye:

Insertion touch anywhere on the

Inclinometer. (Click center bullseye)

2. To set resolution:

Use the arrow keys to set resolution.

Resolution available: (degree

allowance):

3. To set the filter, this is to increase

or decrease the sensitivity of the

bullseye only

Note:

For angled (battered) piles:

User can select the desired angle of

insertion by centering the green dot

in the Bull’s Eye.

Move prime mover forward or back

until the desired angle is achieved,

as indicated in the upper corner of

the display. Once the angle is

reached, touch the Inclinometer,

Center Bull’s Eye & OK on pop up.

This will make the chosen angle the

new “center” of the bull’s eye.

19

PM-000199 September 2019

DIGGA 7” DISPLAY OPERATING GUIDE

Add a joint.

1.In the event you need to add

Joint. Touch add joint.

2. Enter the extended joint

length on the on screen

keypad.

3. Click enter

Once joint is added you can use

the Plus or minus to add in 1

foot increments.

20 PM-000199 September 2019

This manual suits for next models

1

Table of contents