digico D5 Live User manual

INTERCONNECTION

SYSTEM SETUP &

INSTALLATIONMANUAL

INCLUDING QUICKSTARTGUIDE

ISSUEB

DIGITAL CONSOLE

Setup&InstallationManual

Page2

Page3

Copyright © 2002 Digico (UK) Ltd

Allrightsreserved.

Nopartofthispublicationmaybereproduced,transmitted,transcribed,storedinaretrievalsystem,ortranslatedintoanylanguageinany

formby anymeanswithout thewrittenpermission ofDigicoUKLtd. Informationinthismanual issubjectto changewithoutnotice,and

doesnotrepresentacommitmentonthepart ofthe vendor. DigicoUKLtdshallnotbeliableforanylossordamagewhatsoever arising

fromtheuseofinformationoranyerrorcontainedinthismanual.

All repairand service ofthe D5product should beundertaken byDigico UK Ltdor itsauthorised agents. Digico UKLtd cannotaccept any

liabilitywhatsoeverforanylossordamagecausedbyservice,maintenance,orrepairbyunauthorisedpersonnel.

Digico UK Ltd

The School House

4 Dorking Road

Epsom

Surrey

KT187LX

England

Telephone: +44(0)1372845600

Fax: +44(0)1372845656

Email: [email protected]

WWW: http://www.digiconsoles.com

All trademarks are acknowledged as the property of their respective owners

Manual Issue: Issue B, Jan 2003

D5 Connection and Installation Manual Contents

Quick Start Guide ............................................................................ 4

Introduction ..................................................................................... 6

Worksurface Notes .......................................................................... 6

RackNotes ....................................................................................... 7

Synchronisation Connections ........................................................ 9

Connector Tables .......................................................................... 10

Optical connections ...................................................................... 11

Multiple Rack Optical setup ......................................................... 11

External Displays .......................................................................... 13

Miscelaneous Notes ...................................................................... 15

Hardware confirgurations ............................................................. 16

Index ............................................................................................... 17

Diagrams

Electrical Safety Warning .............................................................

Unlike most large conventional analogue consoles, the D5 worksurface

contains its own mains power supply, and a variety of internal supply units

and converters. These are fully insulated and covered to meet the relevant

electrical safety standards, but technicians working within the console should

be aware of the presence of mains voltage.

Note also the rack PSU if operated removed from the chassis has heatsinks

exposed that are live to mains voltage.

Also, D5 contains a number of back-lit flat screen displays. The illumination

system of these displays uses line voltages of up to several KV, generated by

high frequency DC - DC converters located close to the displays. Touching or

tampering with these circuits will put a technician at risk of very damaging RF

burns to the skin and/or high voltage electric shock.

Setup&InstallationManual

Page4

D5QUICK START GUIDE.

If you trying to get sounds from the mixer without reading the whole installation and operating manuals,

Pleaseat least readthis page first!

CONNECTINGUP

TheDigicoD5consists oftheMixer,2or 3audiointerfaceracksand variouscables.Refertotheconnectiondiagramfollowing.

The“Local” Rack hasanapproximately equal mixofXLRinputs andoutputsandfew AES/EBU connectionson1 module. This isused

adjacenttothemixerforlocal inputsandoutputssuchasFXsend/returns. Ithas noopticalconnection.

The“Stage”Rack(s)havemostlyXLRmicinputsandjust8XLRlineoutputs.Thisisformicconnectionsandamplifieroutputsatthe

stage. Ithas2opticalconnections.

1.Connecttheoptical cable between console optical B to optical A of the firststagerackwith56inputs(7x8way input modules). The

Opticals operatein 2 directionsat once,so there isonly 1 cablefor inand out!

2. In the larger D5-96, thesecond (40 input) stage rack is connected tothe first stage rack by a short optical cablefrom rack 1 optical B to

rack2 opticalA. Asshipped, themixerand secondrackshould beconfiguredto sendandreceive signalstothis secondindependent

rackcorrectly.

3.Connect2xBNCcables betweenMADIinput/outputBontheconsoleengineback panelandlocalrackMADIinput/outputB. Send

fromtheconsoleoutput tothe rackinputandsoon.

Thereisnoneedatthisstagetoaddtheoptionalredundantsecondopticalringconnection,ifthisoptionhasbeenprovided.

4. Eachunit has 2mains input cables.Whilst the systemis designedto be ableto operate withjust 1 supplyswitched on anyone unit,

useboth mainssuppliesonallunitstoensureallfansareworkingtokeepthesystemproperlycooled.

Connectallmainscablestothesupply.Therearenoadjustments,thesystemhasautomainssensing.

5.Switchon! The mixer will start upinexactlythesameconfiguration as last switched off.

GETTINGABASICAUDIOSIGNALSETUP

Asdefault,allinputsareroutedtomasters.

6. Connecta CD toinput channels 9& 10 onthe local rack,touch the topof channel 9and the inputrouting will appear. Scroll untilyou

find Local1-8 and touch,then scroll untilyou findLocal 1 andtouch. Now repeat forchannel 10 andassign to Local2, youshould see

signalonthemeters.

The masters must now be routedto an output so go to the outputscreen, let’s use matrix 1 for L and matrix2 for R.

7. Touch“Matrix Inputs” alongthe topof theoutput screen. Touchthe toplabel on Matrix1, therouting assignwill appear. Scroll down

untilyou see“StereoBussandtouch. Nowtouch“MasterL”.

8.Touch the top label onMatrix2,the routing assign will appear. Scrolldownuntilyou see “Stereo Buss” andtouch. Nowtouch“Master

R”.

9.TheMatrixsends must now be turned on. Touch the screen controlknob on Matrix 1 and it will light up(touch to assign-touch to de-

assign). Make surethe sendis turnedon by touchingon/off switch.Look forthe Matrix controlpanel onthe extremeright of theconsole

on theoutput section, thereis aphysical control andan on/offbutton plus aMatrix assignbutton. Once the screenmatrix sendis

assigned,youcancontrolthelevelviathephysicalknob,switchitonandoffandmaximiseorminimisethescreenmatrixdisplay.

10.Now turnMatrix1up ordownand repeat forMatrix2.

Nowwe havetoroutetheMatrixoutputs,sotouch“BussOutputs”along thetopof theoutputscreen.

11.Touch thelabelonMatrix 1andtheoutput routingwillappear.Scroll down untilyousee “Stage 1-8”andtouch. Now touchoutput1.

12.Touch the labelonMatrix 2 andtheroutingwill appear. Scrolldownuntilyou see “Stage1-8”andtouch. Nowtouchoutput2.

Youshould now have the stereobusscomingoutof 1 & 2onthestagerack.

Remember,adigitalconsolecanbeconsideredasahugematrixanditmustbe toldwhere toreceive fromand whereto outputto.

(Above notes refer to for V 1.02 screen software, V1.05 Optocore firmware)

Page5

Setup&InstallationManual

Page6

SystemDescription .......................................................................

The Digico D5 console consists of a Worksurface, and 2 or 3 Input/Output Rack Units

All the console's audio inputs and outputs are connected to the Rack units, and each Rack units is con-

nected to the Worksurface via a pair of digital MADI links in either coaxial or within an Optocore optical

format. Each pair can carry up to 56 audio inputs and outputs.

There are 2 or 4 pairs of MADI connectors available on the Worksurface rear panel, including 2 bidirec-

tional optical MADI connectors allowing the connection of up to 3 Rack units and an alternative madi

connection. This gives a total capacity of 224 input and output sockets. However, the console is only able

to assign up to 64 or 96 audio channels (dependent on version), so not all the channels in a 4-madi system

can be used simultaneously.

Each Rack module contains input and output cards, which allow the same Rack unit to connect to different

types of analogue and digital audio devices.

As well as connecting the Worksurface MADI links to Rack Units, you can also connect them directly to

any other MADI equipped device, such as a digital multitrack recorder.

Introduction

Welcome to the Digico D5 Installation and connection manual. This manual is provided for purchasers of

the D5, in order to help their installation and connection of their new console.

Digico hope that this manual answers all the questions which may be asked by system designers and

installers, but should there be any issues unresolved for your particular installation, the local distributor or

the factory will be pleased to assist.

In general the installation of a D5 presents no problems which are significantly different from those of any

other large format live sound console when used exclusively for analogue systems and when used in

digital systems, is not significantly different from other digital consoles.

TheWorksurface ...........................................................................

The D5 Worksurface is in many ways very similar to any large analogue mixing console. One key differ-

ence, however, is that no analogue signals are connected directly to the worksurface - all analogue I/O is

via the Rack units. The Worksurface rear panel does include a number of signal connectors, but these

should be used only for synchronisation, not for audio I/O.

The Worksurface is supplied in one chassis size, for 24 input + 16 master section faders.

Console Power Supply and Cooling ...........................................

Unlike most analogue consoles, the D5 Worksurface is powered directly from the mains, with no external

supply unit. The internal mains supplies are highly efficient and require no forced cooling, which means

that the Worksurface is silent in operation. However, it is important that convection airflow to the finned

heatsinks on the rear of the Worksurface are not restricted in any way. This heatsink normally runs at

around 25C above ambient temperature, and will be hot to the touch, though not hazardous. Note there are

2 x IEC mains inlets for the dual redundent supplies.

WorksurfaceConnections ............................................................

Apart from headphones and remote talkback, no audio is connected to the worksurface. Sync and control

connections are detailed later in this manual.

Headphone Connections ..............................................................

There are 2 parallel heaphone connectors with a 1/4" (6.3mm) stereo jack at each end of the console under

the armrest. These will drive down to 8 ohm loads, but note there is considerable power/voltage available

at low impedance. External volume limiting should be provided where required by local regulations.

Keyboard...................................................................................

The Worksurface unit includes a small computer keyboard with integral trackerball. This is fitted to a

slide-out tray which is set into to the bottom of the console.

Lighting...................................................................................

The worksurface includes an innovative illumination system comprising a series of white LED's in an

adjustable fully shaded fitting along the full length of the meterbridge. The brightness is adjustable by

an on screen control. There is no need for provision of addition lighting in normal applications.

Page7

Worksurface

Interface Rack Units and Modules ...............................................

Audio signals are connected to the console via Rack Units. Each Rack Unit is a 19-inch chassis with a

control panel at the bottom. Above this panel are 14 card slots, each of which can accept a Rack Module.

Each Rack is a standard 19" wide, and 9U (353mm) high. The units are 365mm deep, excluding connec-

tors.

Rack Power Supply, Cooling .......................................................

Rack Units have their own mains power connections, 2 x IEC mains inputs per rack, for the dual redundent

supplies. The Rack should NOT be operated with only 1 supply under normal conditions as there is only 1

fan operating. At least 1U (45mm) of space should be left above and below the rack unit to allow ventila-

tion, and to prevent heat transfer from adjacent equipment.

RackEarthing ................................................................................

The analogue earthing requirements of the Rack unit is similar to those of a conventional large analogue

console. All analogue inputs and outputs are balanced and symmetrical, but not floating, because of their

transformerless design. Installers should use good earthing practice, as with any large audio installation.

Digico can provide copies of AES papers on this subject upon request. -

Rack Control Panel Connections ................................................

The Rack Unit control panel provides connectors as follows:

MADI A IN & OUT (2 x BNC)

MADI B IN & OUT (2 x BNC)

OPTOCORE® A IN & OUT (HMA Optical) (stage rack only)

OPTOCORE® B IN & OUT (HMA Optical) (stage rack only)

WORD SYNC IN & OUT (2 x BNC)

The MADI IN and OUT connections carry audio to/from the Worksurface. There are 2 sets, A & B. The

Coax and Optical (where fitted) are effectively in parallel. A or B are selected in software. Only 1 MADI

connection can be active at 1 time,

The Word Clock Out socket can be used to synchronise other digital devices in the system to the console.

The Word Clock In socket is only used to synchronise the rack system in special stand alone mode. It is

NOT available to sync tthe main system.

The LED indicator on the panel shows the condition of the Rack Unit's power supplies, whether the unit is

synchronised and information of the Rack Status via the 4 buttons and a simple menu system.

Input / Output Slots

Above the panel, the Rack Unit has seven Input and seven Output slots. Each of these slots can be filled

with a different Rack Module, providing an I/O system which is configured according to D5 model.

RackModules ................................................................................

There are different Rack Modules for interfacing to different digital and analogue devices. Each Rack

Module carries eight channels of audio.

Setup&InstallationManual

Page8

I/ORackUnits

MADI Cabling Considerations .....................................................

The MADI (Multichannel Audio Digital Interface) standard was devised to operate using standard video

coaxial cable installations. For short cable runs of up to 5m, any good quality video cable should be

sufficient. The absolute maximum length of a MADI cable connection between the Worksurface and a

Rack Unit is 50m.

MADI uses 75ohm cable. 50ohm cable such as that used for computer networks is not acceptable.

The bandwidth of a MADI signal is such that care must be exercised when installing long cable runs. In

general, for maximum length cable runs, a high performance video cable such as RG59/U cable should be

used. If in doubt about the suitability of a particular cable type, a sample of the correct length can be tested

with the system prior to installation to prove its suitability.

The MADI signal should NEVER be routed via video distribution amplifier or switching arrangements, and

any form of plug and socket patching of MADI signals should be avoided if at all possible. There should be

NO common earth connection with other systems (including video) made via the sleeves of MADI cables.

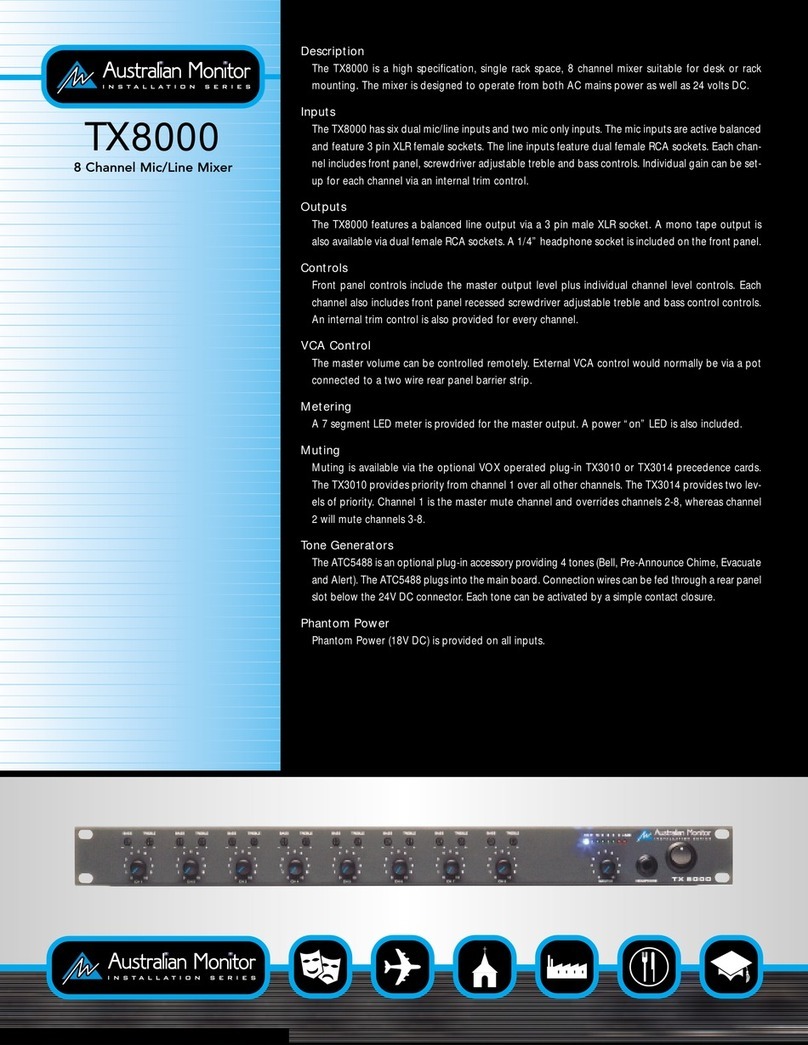

Example Installation.......................................................................

This shows the standard "Stage 1" rack, with 56 Mic inputs and 8 line outputs.

Rack Module Connections ...........................................................

Audio connections to the Rack Modules are made using appropriate connectors for the type of module.

See the Connector Tables for a list of the different connectors used in the Rack Modules.

Page9

Timecode Connections ................................................................

(not Normally used on the D5 for conventional Live use)

With appropriate optional software, the console can slave to external timecode, and generate it's own

timecode outputs. All timecode connections are made via the Worksurface rear panel, which has input and

output connections for LTC (SMPTE), MIDI timecode, and Sony 9-pin (RS422). The MIDI and 9-pin

systems also provide Machine Control inputs and outputs.

Rack Module Inputs and Outputs ...............................................

The modules fall into two broad groups - those which carry only inputs or outputs, and those which carry

both input and output signals. Output modules must be installed in Output slots, while Input and I/O

modules must be installed in Input slots.

Digital Sync Connections .............................................................

Using current firmware (V1), if the Optocore® optical system is in use to connect to the stage rack(s) then

the Optocore clock MUST be selected as clock source in the console software.

The following notes are relevent if the system is being used with only Coax MADI connections in use. The

console can be configured to use any of its digital inputs as a sync or word-clock source. The sync source

is set up when the console is installed, but can be reconfigured in the Worksurface Master section.

External Sync via Worksurface Rear Panel...................................

The Worksurface rear panel has connectors for Word Clock and Video Sync, either of which can be used

as the master sync source. Although the Video Sync input carries only a frame boundary signal, the

console generates a full digital word-clock from it.

The Worksurface has an input for AES/EBU. If connected to outputs from other digital audio units or

house clock, you can choose to sync the console to these inputs. The AES/EBU input acts as word-clock

even if there is no actual audio present (null signal). Note a signal connected to this rear panel cannot act

as an audio input to the console - this can only be used for sync.

External Sync via an I/O Rack........................................................

Any digital audio input can be selected as the digital sync master for the console, and each rack unit also

has a separate Word Clock output - these are located on the Rack Control Panel. See the Rack section

for more information.

Synchronisation Connections .....................................................

When the D5 is used with only analogue siganls connected to both inputs and outputs

syncronisation does not need to be considered. In this case the mixer is run from its own internal

master or Optocore clock.

There are, in fact, two separate synchronisation systems which use different connections - the Sample

Word Clock (or Digital Sync) and the Timecode system (not usually used for conventional live sound

applications).

The issues surrounding synchronisation in a digital system are complex, and do not fall within the scope of

this manual, but this section gives a basic description of the console's different sync inputs and outputs.

Setup&InstallationManual

Page10

Connections.....................................

WorksurfaceRearPanel ...............................................................

Function Connector Comments

MADI Audio I/O FemaleBNC 2 or 4 Pairs of I/O

Optocore StratosHMA 2 Bidrectional dual connector

RS-422MachineControl FemaleD-9 SonyP2Protocol

LTC Time Code In FXLR Balanced, Pin 2 Hot

LTC Time Code Out MXLR Unbalanced, Pin 2 Hot

MIDIIn/Out/Thru 5 pinDIN MMC,MTC

AES/EBUInput FemaleXLR SyncinputONLY

AES/EBUOutput MaleXLR Null signal sync output ONLY

Word Clock Input BNC External clock input

Word Clock Output BNC Clock output follows console (5Vp-p)

VideoClockInput BNC Housevideosync

ExternalMonitors 15 pin HD D Overview, adjustable resolution

Ideally use 1280 x 1024 SVGA

15 pin HD D x 4 Duplicateinternalscreens

Standard 640 x 480 VGA output

External Talkback Mic 9-pin D Female See separate page

Modem RJ11 See separatepage

Network RJ45 Ethernet compatible (Not implemented for general

use)

MainsPower IEC power x 2 Dualredundant supplies.

250VA(fadrersidle)

300 (all faders active)

90V-260V50-60Hzauto sense

Requires 2 separate mains connections. Mixer will operate on only 1 supply. Supply units can be switched

off, removed and replaced whilst the other is use (hot swappable)

I/O Rack Control Panel .................................................................

Function Connector Comments

MADII/O BNCsocket 2 Pairs of I/O to Console

Optocore StratosHMA 2 Bidrectional dual connector

Word Clock Out BNCsocket 48/44.1 KHz 5V p-p

Word ClockIn BNCsocket 48/44.1 KHz 5V p-p max

MainsPower IEC power x 2 Dualredundant supplies.

Stage rack 175VA run

FOH rack 175VA run

90V-260V50-60Hzauto sense

I/O Rack Audio Connections ........................................................

The number and type of Rack Modules in each type of rack varies according to requirements. See Stand-

ard Configuration details elsewhere.

Function Connector Comments

AnalogueLineInputs 8 xXLR female 8 Channels per card, electronic balanced, Pin 2 Hot

AnalogueMicInputs 8 xXLR female 8 Channels per card, electronic balanced, Pin 2 Hot

These modules look identical except for Mic or Line ID label on the panel.

AnalogueLineOutput 8 x XLR male 8 channels per card, electronic balanced, Pin 2 Hot

NOTE: Analogue cards are either input or output and these must be fitted in the correct side of the rack.

AES/EBU Input / Output* 8xXLR 4 Female (input) + 4 Male (Output) floating balanced

TDIFand ADATmodules areoptionallyavailable tospecial order.Contactyour dealerorthefactoryfor information.

Page11

Connecting Optocore® Redundant Optical Audio Data System......................................................

For basic connections to the optical cables between the mixer and 1 or 2 racks, refer to the Quick Start

section.

It should be noted that all coax MADI connections remain available for use (with the 50m / 160' cable

length limitation) and can be considered a backup to the optical system, if required.

The Optocore® system used in Digico mixers is a high speed digital audio data system that allows multiple

interface racks to be connected “daisy chain” along a single optical system.

The Stratos HMA battlefield cable and connectors system is a dual in/out (2 lens) bayonet style connector.

2 multichannel audio signals, 1 input 1 output, are carried on each single plug, so there is only 1 connec-

tion required per rack. The system actually carries many more than the single rack capacity of 56 channels

in and out. By using an “address” setting on each rack equipped with optical connectors, 1 optical signal

can be sent to several racks, with each rack taking and sending signals independently. All units on the

Mixer system have 2 bi-directional connectors, allowing the optical cable to come from the mixer to the

first rack, then out to the second and so on. All optical connectors are interchangeable, therefore the order

of cables and connectors in use does not matter. The system will always work.

Redundent Optical Operation............................................................................................................

A key feature of this system is that, optionally, the Optocore interface provides the ability to have a dual

redundant optical path, so that the system will continue to operate unaffected in the event of a complete

cable or connector break. This system combined with Stratos HMA ensure the utmost reliability, even in

the event of a cable being destroyed. (This option is to be implemented in 1st quarter 2003)

The final rack in the daisy chain can be connected back to the mixer with an extra (optionally supplied)

cable. This forms a complete “ring” of data flowing in both directions. In the event of a cable break, the

data will continue to flow on the remaining part of the ring without interruption.

Adjusting Settings in a Multiple Rack System..............................................................................

The madi interface on the Rack has a “menu” type programming and setting system using 2 pairs of up/

down buttons, page and data, and an LED display.

The Menu is a series of “pages”. Use the page ^ and v keys to navigate the pages. This is fully docu-

mented in a separate Technical Note.

DO NOT be tempted to change ANY other setting without good reason and then only after studying the

detailed notes. It is possible to make the rack unusable in a normal system by accident!

The display will show the page item and the data associated with it. The data ^ and v keys are used to

change the displayed setting, where this is possible.

The default display is the primary system status and active sync input. Typically this will read OK:RxA

The LED readout will default to the primary status display, from any previous setting and the buttons will

go to a “locked” mode, where the buttons are disabled, to prevent tampering.

Pressing any button in this state causes dDEC/INC to display.

This is a prompt to unlock (data - Decrement + Increment)

Press both data ^ and v buttons together to release the menu system.

Next press the page up (or down as required) button to show: OptID=30 (or some other number) this sets

the Optocore ID. Use the data up or down button to set the correct number.

The stage rack 1 is normally set for ID=30, stage rack 2 (used on dual rack systems) is normally set for

ID=32. Note Mixer is normally set to ID=20 (set in the mixer software), do not use this in a rack.

Setup&InstallationManual

Page12

Care of the optical cable system.....................................................................

Whilst the system is very robust, like all connector systems it should be treated with care, the show de-

pends on it!

The Stratos HMA connector is a precision machined device containing 2 lenses and an 1/2 turn bayonet

style screw locking device. Because it is an in/out connection, a plug will fit into a socket in 1 direction

only.

All connectors have captive dust covers. These MUST be fitted to the exposed connector any time the

connector is not in use. This is to prevent dust landing on the lenses and to give mechanical protection to

these expensive devices.

The cable is 2 separate “light pipes” in 1 very strong lightweight outer jacket. The armour just inside the

surface of the jacket itself is nearly impossible to cut by hand with any sort of blade or pull apart except

with the aid of machines. However the glass strands inside can be broken by hard hits or tight bending (like

any type of glass!).

Typical optical cable breaks do not have the cable broken right through and it may look OK externally.

Typical causes of optical cable breakage are being run over by a wheel in a rail (such a sliding doors used

in loading bays) or by trapping in heavy tight fitting door, such as used in recording studios. Very tight

bends caused by pulling a cable very tight with a knot tied in it can also cause the light pipe to break.

It should be noted that the optical cable is not repairable on site. It is best considered that it is not repair-

able at all, and treated with due care. In general it is not considered economic to repair broken optical

cables.

Repair and making of these cables is a highly skilled job requiring specialised tools and materials. Because

the lenses are bonded with an optical glue, the internal parts of connectors cannot be re-used. It is not

possible to “splice” broken cable sections without using a connector to terminate the broken ends of the

glass strands. The usual fix for a break near a cable end is to shorten the cable past the break and fit a

new plug. A break in the middle leads to 2 cables half the length with 2 new plugs or just scrapping the

cable.

Checking the Optical cables................................................................................

Note that the data transmission system uses IR laser light sources and is scattered light system. This

means the data signal cannot be seen, unlike Toslink cables used for CD players for example. This means

looking at cable connected to a live source will not show if the signal is getting through. As with all laser

sources users should not look directly into the end of cable with the other end end connected

To test the integrity of a Stratos HMA cable, use a regular light source (torch/flashlight or table light) at one

end and see if the light emerges from both lenses at the other end. Because the cables uses lenses, this

will normally appear as the light is quite distant down a tunnel. Which in a way it is!

Page13

SETTING UP EXTERNAL DISPLAY MONITORS..................................

The Mixer is provided with outputs 5 external PC monitors. These are standard SVGA analogue 15 pin HD

Dee connectors. 4 outputs are simply repeaters (parallel) outputs of the internal screens. These are for

display only, not touch screen control operation. The 5th screen is the system overview screen. This a

special purpose screen, set up from the mixer system to display information useful to the operator.

Most operators will wish to connect a monitor to the overview output. Typically this is set up to show the

operation of all input channels simultaneously, which cannot be seen continuously on the mixer itself. If

other screens are shown on external monitors, most typically the master screen is output to a large screen

to show lists of pre-sets and other master set-up displays in a large easy to read manner.

Connecting external screens.................................................................

Mixer repeater screens are fixed at 640 x 480 VGA format. This is a exact copy of the internal digital

screen and cannot be changed. Simply connect any modern SVGA monitor to the required output socket

and place this in a convenient position, usually above the mixer.

The overview output has adjustable resolution. This is shipped set to 1024 x 760 as this suits the majority

of modern monitors for “plug-in and go” use. This offers the possibility to display more information, includ-

ing all 96 input channels.

However it is recommended that, if available, a 1280 x 1024 XVGA monitor is used to allow the maximum

capabilities of the overview to be used. This change is pre-set in mixer set-up files and is not assessable

from the mixer operating screens.

Note about LCD Monitors..............................................................................

In Digico’s experience, if a modern LCD monitor (as opposed to conventional CRT based units) is used at

a resolution below its specified design figure, this may actually prove not to work correctly. Typical prob-

lems are poor vertical edge definition and shimmering of the picture. This does not usually affect CRT

screens run below maximum resolution. There is no adjustment in the mixer to correct this, and the only

solution is to try a different screen.

This may be relevent in touring systems where operators may wish to borrow a monitor. If in doubt, use a

CRT unit. The ideal is to carry known good monitor(s) with the mixer.

Setup&InstallationManual

Page14

The change the resolution requires changes to internal set up files of the embedded control computer and

this should only be done by a technician familiar with PC software set-up operations. See setup notes

following.

Changing Overview screen set-up..................................................

The change the overview screen resolution requires changes to the Windows set-up and the D5 set-up

files.

Note that D5 uses a “stripped” version of Windows98. This is for reliablity and speed of loading. For exam-

ple, right clicking on the desktop will not get to properties to allow change of screen settings. The following

shows how this can be done in the D5. Read these instructions before trying to change the settings!

1 With system running, Quit from D5 to Windows (touch system, service, quit to Windows).

2 Using the trackball, Open Explorer by double clicking the desktop icon. The touch screens do not work

outside of D5 itself.

3 go to c:\admin and find desk.clm This is an executable file. This runs the desktop display properties

window. Tab to settings.

4 Settings shows the 5 screens. Light the top screen, by clicking on it 1 time. This the over screen. With

the slide bar below, setting the correct resolution for your screen. Use 256 colours or High colour only.

5 If the position of screen number 1 changes, ensure the left hand edge of this screen lines up with the

other 4 sceens (the mixer internal screens). Note all left hand edges should be in straight line vertically.

6 click on apply, click on OK to change desktop settings and close this and the Poperties window.

7 Return to Explorer. Find C:\D5\D5.ini this is the set-up file for the D5. We recommend making a copy of

this file in the c:\backup folder before proceeding.

8 Double click on D5.ini, this will open in Notepad.

9 find the lines

overviewwidth=nnn

overviewhieght=nnn

change the value of nnn to the appropriate value

e.g.

overviewwidth=1280

overviewvhieght=1024

These values MUST match what has been set in the display properties.

DO NOT change any other settings in D5.ini, otherwise the mixer may stop working completely! (hence to

need to back this file up first)

10 click on Notepad file drop menu, click on save

click on Notepad file drop menu, click on exit

11 The new settings should not be in place. Click on the D5 to restart the program.

Page15

Important Note for Installers ........................................................

D5 is a large format product of considerable complexity and is subject to constant revision and changes to

improve performance and the manufacturing process.

As a result, the product as delivered may vary in small ways from the details in this manual. Any specifica-

tion which is critical for a user's application should be confirmed with Digico at the time of ordering. If there

is the slightest question that might significantly affect the installation of the D5 in its new home, please

ask!

Possible examples include critical dimensions with respect to custom-made furniture and fitments, or fitting

details in relation to a vehicle in mobile studio applications.

ModemConnection .......................................................................

In order to help D5 to be correctly installed, commissioned and maintained a telephone line should be

provided for its internal modem. The is particularly recommended for permanently installed systems to

allow remote real time diagnostics to be run.

This is a standard 33.6K analogue modem, which requires a standard (not ISDN) telephone line which

must be accessible by a directly dialled incoming call, and be able to dial out directly. A line connected via

a switchboard or PABX has often been found to not work correctly with data.

A cable from a standard US socket (normal modem RJ11 type) to the local telephone outlet should be

provided by the user.

Note that the use of 9.6Kb GSM mobile phone type connections are not fast enough, the absolute mini-

mum required for meaningful use is approximately 20Kb.

In addition, a separate speech telephone should be provided to allow an operator to communicate with

factory engineers at the same time as the console's modem is in use.

External Talkback Connection

In addition to the internal microphone, the console is provided with a 9-pin socket for connecting an exter-

nal Talkback microphone. The microphone input is balanced, and the socket also has a pair of pins which

are used to preset the analogue amplifier gain. Use a male cable connector.

Pin Function

1 Mic+

2 MicGround

3 GainA

4 Ground

5 nc

6 Mic-

7 Ground

8 GainB

9 nc

You must set the gain range for the microphone by wiring a resistor between pins 3 and 8 - the gain can be

fine-trimmed within the console's Talkback control screen. The resistor should be wired within the 9-pin

connector itself, as the microphone signal runs through it. Example resistor values are shown below.

Resistor (Pins3-8) Gain

ShortCircuit 50dB

100Ohm 40dB

330Ohm 30dB

1K Ohm 20dB

Paint Finishes & Colours ............................................................

For the purposes of matching furniture and other surrounding equipment in a permanent installation, the

following paint specifications are used in the D5.

The Worksurface Panels, rack face panels and audio In/Out modules are painted using metallic "sparkle'

effect dark grey by Cromadex, code V6000

The Chassis Frame and End Cheeks are painted in a standard Automotive paint, Citroen "Pearl Grey"

metallic, using a deep spatter finish laquer coat.

The Armrest is black matt finish leather.

Setup&InstallationManual

Page16

D5 Standard Hardware Configurations............................

D5 56 - 64 Processing Channels + 2 x MADI interfaces (2 optical Optocore® System)

D5 56E - 96 Processing Channels + 4 x MADI interfaces (2 optical Optocore® System)

1StageRack

56MicInputs

8 Analogue Line Outputs

Optical MADI Interface and optical cable drum with 100m

1 Local FOH Rack

8MicInputs

24 Line Inputs configured as 8 Line Inputs and 16 Insert Returns

32 Line Outputs configured as 8 Line Outputs, 8 Matrix Outputs and 16 Insert Sends

8 (4 pairs) AES Inputs with SRC

8 (4 pairs) AES Outputs with SRC

Coax MADI Interface

D5 96 - 96 Processing Channels + 4 x MADI interfaces (2 optical Optocore® System)

1stStageRack

56MicInputs

8 Analogue Line Outputs

Optical MADI Interface and optical cable drum with 100m

2nd Stage Rack

40MicInputs

8 Analogue Line Outputs

Optical MADI Interface with 2m optical link cable to first rack

1 Local FOH Rack

8MicInputs

40 Line Inputs configured as 8 Line Inputs and 32 Insert Returns

48 Line Outputs configured as 8 Line Outputs, 8 Matrix Outputs and 32 Insert Sends

8 (4 pairs) AES Inputs with SRC

8 (4 pairs) AES Outputs with SRC

Coax MADI Interface

Worksurface.Shipping and Packaging .......................................

The Worksurface is delivered in its own flight case with 19" interface units and optical cable drums packed

separately. Dimensions when packed:

Worksurface road case 1.60 x 0.64 x 1.16 m

Rack carton (original factory shipping only)

0.64 x 0.72 x 0.71m

Optical cable drum (original factory shipping only)

0.35 x 0.35 x 0.50 m

Page17

Index

A

AES/EBU Sync 9

C

Cables, MADI 8

Connector Tables 10

Cooling

I/ORack 7

Worksurface 6

D

Digital Sync Connections 9

Display monitors 12

E

External display 13

H

Headphones 6

I

I/O Rack 7

L

Lighting 6

M

MADI Cables 7

Modem 15

O

Optical cables 12

Optical cables 12

Optocore System 11

Overview screen 14

P

Paint Finishes 15

R

Rack connections 7

Rack setup 11

S

Synchronisation Connections 9

T

Talkback connection 15

Timecode Connections 9

W

Word Clock Connection 9

Setup&InstallationManual

Page18

Table of contents

Other digico Mixer manuals