digico SD7 Specification sheet

TN198 Page 1 of 11

TN198.doc\

TECHNICAL NOTE

Date 14th Nov 08 (rev 6th Feb 09)

ref 198

Raised by: RA/DP

Distributed to: as required

Soundtracs - Digico(UK) Ltd. unit 10 Silverglade Business Park Chessington Surrey KT9 2QL England

Tel: +44 1372 845600 Fax: +44 1372 845656 email: support@digiconsoles.com

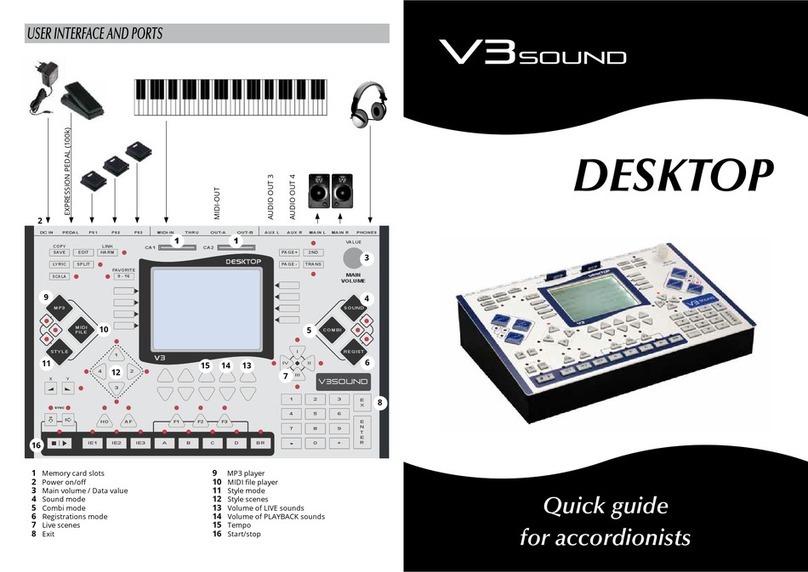

SD7 Mixer

Installing Optocore® Hardware and Software

These instructions will guide you through fitting the Optocore option to SD7 Engines.

The Standard SD7 Optocore upgrade kit (per Engine) consists of :

1 x Optocore PCB

2 x HMA to LC Duplex Fibre Cables

1 x Grey 10 Way Serial Cable

1 x RJ45 Loom : RJ45 Socket to RJ45 Plug

4 x M2.5x6mm Screws

4 x Shakeproof Washers

1 x Screwlock Assembly

1 x Length of spiral cable wrap

If you have paid extra for the Optional 2nd Optical Loop Option, in addition to the kit contents above,

you will receive 2 Additional HMA to LC Duplex Fibre Cables.

Tools required :

2mm Hex driver

Medium Flat blade screwdriver

Medium (1pt) Pozidrive screwdriver

34mm spanner to suit HMA optical connectors (see text)

Leave yourself plenty of time to perform this upgrade.

Read all the instructions before proceeding.

TN198 Page 2 of 11

TN198.doc\

Power Down Console and remove Engine.

The Engines are secured with 3 screws across the top and 3 screws across the bottom.

Carefully slide the Engine out. There are 3 ribbons and 1 Power Connector to unplug. Take care as

the cables may be quite tight, meaning you cannot slide the Engine out very far to unplug the

connectors.

The 3 ribbons are secured with two clips each. To release the ribbons, ease the clips outwards. This

will push the ribbon header out of the socket. Then carefully release the ribbon connector.

Remove the Engine Lid : There are 8 captive quarter-turn screws securing the lid.

In the front right hand corner of the Engine, locate the 3 ribbons that need unplugging.

These ribbons are unplugged from the Engine Board (the lowest card in the Engine Chassis).

See three pictures below for clarification.

These are :

• 2 x multi-coloured ribbons, labeled with “Local I/O” and “Video”.

The Video connector is closer to the front of the chassis, the Local I/O connector is closer to the rear

(fan end) of the chassis.

• 1 x Grey ribbon (The Linkport Ribbon, unlabelled)

Wide 34 way ribbon

TN198 Page 3 of 11

TN198.doc\

Location of engine connection cables

Locate the Fan Power Connector (at the rear of the Engine Chassis). This is the top connector, as

shown on the picture below. Un-plug this connector.

TN198 Page 4 of 11

TN198.doc\

Then unscrew all the screws on the Engine Fan Plate and remove. Ensure the Fan Power Cable

comes away with the Fan Panel without getting caught on other cables.

Release the Engine board tray by unscrewing the following 4 screws :

2 Screws on the front of the Engine, each side of the rows of BNC connectors.

2 Thumb-screws inside the rear of the Engine.

Once the four retaining screws have been released (two on the front, two at the rear), the Engine

Board will slide out from the rear of the Engine chassis. You may need to lift the Engine Board tray

slightly.

TN198 Page 5 of 11

TN198.doc\

Slide out engine PCB taking care of power connector. Unplug this connector when accessible.

The Engine Board should now slide completely out from the Chassis.

Place the Engine Tray on a flat surface with the BNC connectors furthest away from you.

The Optocore Board installs onto the Engine Board on the edge closest to you, next to the Power

connectors.

Ensure the connector is clean of dust and fit optical card :

Lay the Optocore Board in place, and once you are sure the connector alignment is correct, apply

pressure to the Optocore Board. You should apply the pressure to the area above the mating

connector. You will have to apply a reasonable amount of pressure, and the board will click into

place. Apply the pressure slowly and firmly.

Once the Optocore card is seated, secure it with the four screws provided, using the shakeproof

washers included with the kit.

TN198 Page 6 of 11

TN198.doc\

The image below shows the Engine with the Optocore Board fitted.

The Following Connections now need to be made :

1 x Serial Connection from Optocore Board to PC

2 x Optical Fibre Connections from Optocore Board to Rear Panel of Engine*

* If you have ordered a 2 Loop Upgrade Kit, you will be provided with 4 HMA-LC Fibre Cables

Note that the network (RJ45 / Cat 5 connections) are not implemented at this time.

No RJ45 cables need to be connected.

Install Ribbon cable provided to connect between the Upper serial port (COM1) of the PC and the

10 way header on the optical card. It is easiest to fit the PC end of the cable first. When connected,

secure with the hex head bolts provided.

TN198 Page 7 of 11

TN198.doc\

Next then feed the Optocore end down and out the rear to the removed Engine Card.

Note that the Red trace (pin1) goes to the right looking from the connector end of the optical card.

Slide the Engine tray partially back into the Engine Drawer. Continue to slide the Engine PCB in until

the Power connector can be re fitted.

Before fitting the Optical connectors, replace the RJ45 cable and socket asembly. This is to allow for

the future system enhancements.

Remove the RJ45 Socket and cable from the rear of the Engine (secured by 2 screws) and replace

using the new assembly supplied with the kit. The new version is the same save that it has a longer

cable.

Next install the Optical Connectors

Remove the blanking plates that cover the HMA optical connector mounting holes taking note of the

connector order.

If you are only installing Loop 1, only remove the blanking plate for the 2 Optocore Connectors. If

you are installing the optional 2 loop system, remove blanking plates for all 4 connectors.

To fit each HMA Connector to the rear of the Engine. Remove the large Nut / Dust Cap Retainer

from the HMA Connector and insert from the rear. Then place the Nut on the outside and tighten to

secure. Repeat for the other connector(s) you are installing.

Note these nuts are made of soft aluminium and are easily damaged during fitting. Tighten with

fingers to start, then finally tighten with either a slim fit 34mm socket or use a large adjustable

spanner (wrench) with soft protection, such as card, on the jaws.

TN198 Page 8 of 11

TN198.doc\

Routing of internal cables (dual Optic option shown)

Note above pictures show spiral wrap, this is only fitted AFTER the connections have been

completed to the Optocore PCB.

Ensure all cables are routed to avoid sharp edges. The correct route takes the cables around

chassis parts with protective plastic edging. If this does not appear to be present, please contact the

factory.

The cables are routed down to the top of the engine PCB.

As you look at the back of the Optocore Card, the 8 optical sockets are laid out from left to right. The

optical cables attached to each HMA connector are labelled A and B on the cables themselves.

Loop1 Socket A

Loop1 Socket B

Loop2 Socket A

Loop2 Socket B

A Loop1

Leg A

A Loop1

leg B

B Loop1

leg A

B Loop1

leg B

A Loop2

leg A

A Loop2

leg B

B Loop2

leg A

B Loop2

leg B

Connect the optical cables according to the table above as per the picture below.

The picture shows the 2 loop option connected. Only 2 pairs are fitted for a single loop version.

Note the A leg cables have black sleeves.

Re-check the optical cables are connected in the correct order. This is very important!

Slide the engine tray in whilst ensuring optic fibres are arranged to avoid the fan when it is re

installed.

TN198 Page 9 of 11

TN198.doc\

Continue to re install the Engine tray. Tighten the fixing screws to the rear panel of the engine once it

is fully home.

Next re connect the Video, Local I/O and Linkport ribbon cables, via the hole in the PC base plate

floor. This sometimes a little awkward, do not try to rush this.

Carefully fit spiral wrap to the optical cables in the top of the engine to ensure these are secured

neatly out of the way, as shown in the pictures above.

Screw down the engine tray with the internal fixing screws and re-fit the fan panel making sure that

the fan power is connected.

Replace the engine lid and re fit the engine into the console.

Repeat whole procedure for second engine

See next page for Software Upgrade Instructions

TN198 Page 10 of 11

TN198.doc\

Application Software Upgrade

This Optocore upgrade requires SD7 software 1.1.75+.

This package will include the relevant files for the latest Optocore upgrade and the application will

allow for the setup of Optocore ports.

Do not attempt this upgrade without having an ICD2 programming device available as any firmware

upgrade problems may require use of this device.

To install the software:

1) Quit both engines to Windows - On the A Engine - Open Explorer and make a backup copy of

the complete SD7 folder in the D:\Backups folder.

2) Copy the new SD7 self extractor to the D:\Incoming folder –double click on this file and allow it

to extract to D:\SD7.

3) Delete Startup.ses and _session.ses (if present) from the D:\SD7 folder.

4) Run the UpdateHardware.exe program from the D:\SD7 folder and the following panel will open.

This shows elements of the console where the firmware needs upgrading. Any item which has a tick

next to it should be updated by pressing the Update button and waiting for the process to complete.

This should be done one item at a time starting from the top of the list and working down.

If any process halts before it has finished, please wait for at least one minute to confirm that it does

not restart automatically and if it is still stopped then close the Update Hardware program, reopen it

and start the process again.

If the process halts a second time then please contact DiGiCo Support for advice –you may need to

use the ICD2 programming device to perform this part of the upgrade.

When all updates are complete, close the Update Hardware program and shut down the console,

power off and on again.

5) The console should boot into an empty session in the software version that you have just

installed.

6) Open the Setup>Audio I/O panel and press the ADD PORT button to add a new Optocore Port

to the session –an entry will appear for Port 5 in the Port list.

7) This port will default to Optocore ID30 on Loop 1 but can be adjusted using the Connections

drop down box to change the Optocore loop number of the Optocore ID number.

TN198 Page 11 of 11

TN198.doc\

8) Set the Setup>Audio Sync of the session to Optocore.

9) Connect the Optocore equipped rack to the relevant engine and loop number and set the ID of

the rack itself (eg Engine A –Loop 1 –Rack ID 30)

10) Check audio functionality of the inputs and outputs to the rack by selecting them in the SD7

channel routing panels under Port 5.

11) Repeat for the other engine if fitted.

Optocore Software Upgrade (if required)

1) Quit to Windows.

2) Right click on ‘Start’ and choose ‘Explore all’

3) Locate the APP (D) drive and expand the view

4) Click on the SD7 folder to view its contents

5) Look for DI7_211.exe and run this

A window will open and you will see that the application has started communications with

Optocore via a serial Com port.

6) At the bottom of this window is a button ‘Update Firmware’ Click on this and wait for a message

to confirm the download is complete

7) Repeat for the other engine if fitted.

8) Re boot the console from power down.

Other manuals for SD7

1

Other digico Mixer manuals