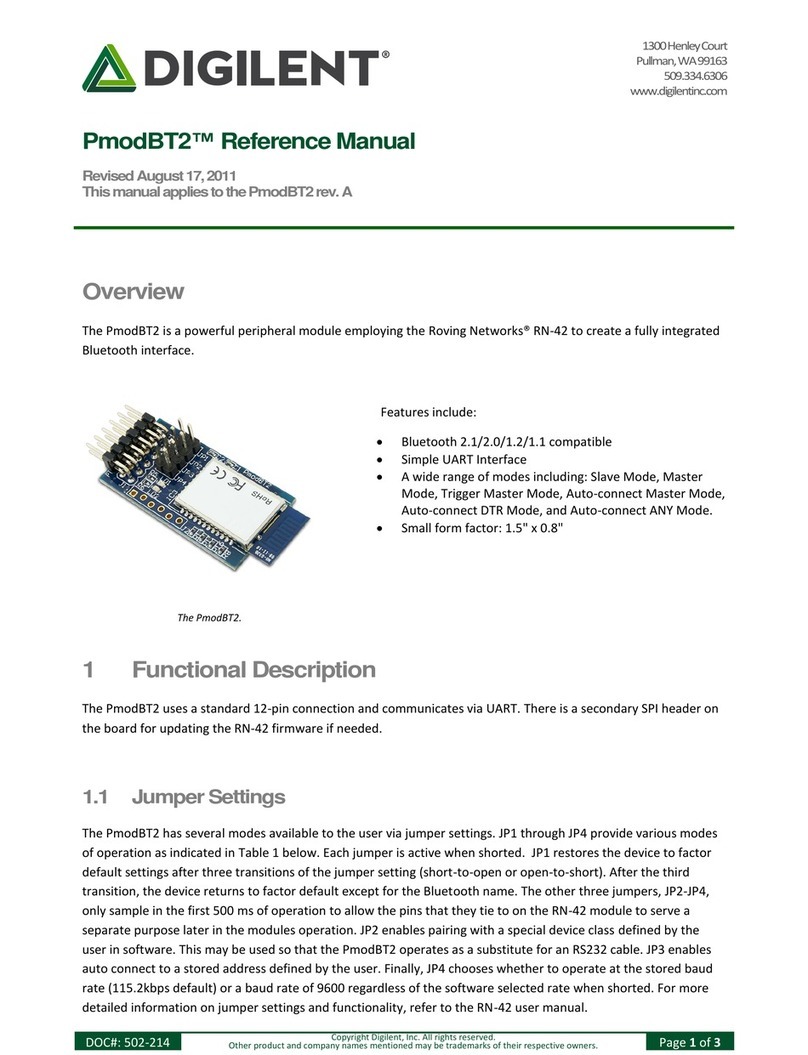

PmodBT2™ Reference Manual

www.digilentinc.com Copyright Digilent, Inc. page 2 of 2

on jumper settings and functionality, refer to

the RN-42 user manual.

UART Interface

By default, the UART interface uses a baud

rate of 115.2 kbps, 8 data bits, no parity, and a

single stop bit. The startup baud rate may be

customized to predefined rates or set to a

specific user customized baud rate. Predefined

baud rates range from 1200 to 921k.

The reset pin (RST) on J1 is active low. If the

RST pin is toggled, the device will undergo a

hard reset. This hard reset performs similarly

to a power cycling of the device. The second

interface besides the standard UART signals is

the STATUS pin also on J1The STATUS pin

directly reflects the connection status of the

device. STATUS is driven high by the device

when connected and is driven low otherwise.

For more information on the devices UART

interface and RST and STATUS pins refer to

the RN-42 user manual on the Roving

Networks website.

Command Mode

In order to enter the command mode, the

PmodBT2 must receive “$$$” to which it will

respond “CMD”. When in command mode, the

module will respond to a large number of

commands allowing the user to customizing

the module for specific applications. In order

to exit command mode, send “---<cr>” (three

minus signs in a row and where <cr> stands

for the carriage return character) to which the

device will respond “END”. Remote

configuration, or configuration over a Bluetooth

connection, is possible through the command

mode but has several restrictions. The

configure time, which defaults to 60 sec,

defines the time window in which the

PmodBT2 may be configured remotely.

Outside of this time, the PmodBT2 will not

respond to any remote commands. It is

important to note that any of the “set”

commands available for the PmodBT2 must be

followed by a power cycle to take effect in any

design.

The various modes of operation are accessed

by using the “SM,<5,4,3,2,1,0>” command

while in command mode. The PmodBT2 can

be put into one of six available modes of

operation. The modes in order, 0 to 5, are:

slave, master, trigger master, auto-connect,

auto-connect DTR, and auto-connect ANY. For

more detailed information on the different

modes of operation, refer to the RN-42 user

manual. For the full list of device commands,

how to use remote configuration, and more

detailed information on the different modes of

operation, see the RN-42 data.

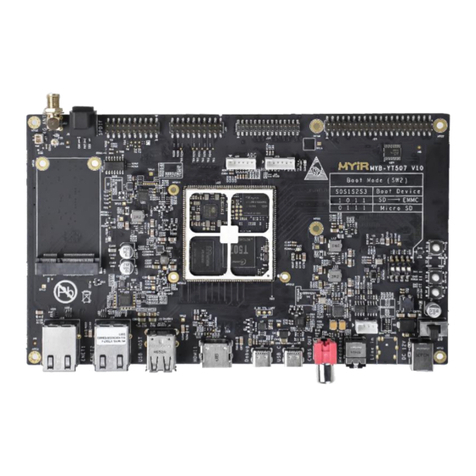

1 RTS Ready to Send

2 RX Receive

3 TX Transmit

4 CTS Clear to Send

5 GND Power Supply

Ground

6 VCC Power Supply

(3.3V)

7 STATUS Connection

Status

8 ~RST Reset

9 NC Not Connected

10 NC Not Connected

11 GND Power Supply

Ground

12 VCC Power Supply

(3.3V)

(Firmware Update Only)

1 MISO Master in/

Slave out

2 MOSI Master out/

Slave in

3 SCK Serial Clock

4 ~CS Chip Select

5 VCC Power Supply

(3.3V)

6 GND Power Supply

Ground

Table 2: Connector Descriptions