Digital-Ally DVM-250 User manual

Copyright © 2010-2015, Digital Ally, Inc. All Rights Reserved. This publication may not be reproduced, stored in a retrieval

system, or transmitted in whole or part in any form or by any means electronic, mechanical, recording, photocopying, or in any

other manner without the prior written approval of Digital Ally, Inc.

Installation Guide

DVM-250 and DVM-250Plus

860-00129-00 Rev C

Digital In-Vehicle Event Recorder Video System

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. i

Table of Contents

SECTION - 1: BEFORE YOU BEGIN ..............................................................................................1-1

TOOLS NEEDED....................................................................................................................................1-1

CAUTIONS AND NOTES ........................................................................................................................1-1

SECTION - 2: PARTS, CABLES AND ACCESSORIES..................................................................2-2

DVM-250 ............................................................................................................................................2-2

Parts and Accessories List.............................................................................................................2-2

Optional Accessories.....................................................................................................................2-4

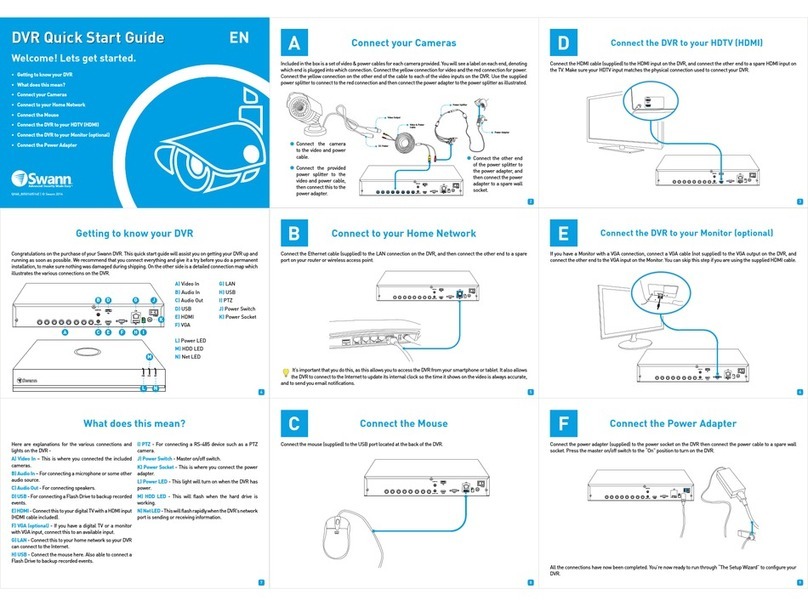

DVM-250 Basic Wiring Diagram.................................................................................................2-5

DVM-250Plus Basic Wiring Diagram..........................................................................................2-6

SECTION - 3: INSTALLATION INSTRUCTIONS.........................................................................3-1

STEP 1: FACTORY MIRROR REMOVAL..................................................................................................3-1

Screw Mount Rearview Mirror Removal......................................................................................3-1

Wedge (Screwless) Mount Rearview Mirror Removal.................................................................3-1

Cam Lock Rearview Mirror Removal ..........................................................................................3-1

STEP 2: DVM INSTALLATION...............................................................................................................3-2

STEP 3: INTERFACE BOX INSTALLATION..............................................................................................3-4

Interface Box.................................................................................................................................3-4

Mount the IF Box..........................................................................................................................3-4

DVM to Interface Box Cable Installation.....................................................................................3-4

Interface Box Power Cable Installation........................................................................................3-5

STEP 4: INTERFACE BOX EXTERNAL TRIGGER WIRING.......................................................................3-5

Determine the Device Trigger(s) Signal Level.............................................................................3-5

Trigger Wiring Installation............................................................................................................3-6

RJ45 to Terminal Connector Adapter (optional)...........................................................................3-7

Siren Adapter Interface.................................................................................................................3-7

STEP 5: WIRELESS MICROPHONE INSTALLATION (OPTIONAL)FOR USE WITH 001-00042-32 ONLY ...3-8

STEP 6: BACKUP CAMERA INSTALLATION (DVM-250PLUS ONLY) .....................................................3-9

Route the Camera Cable ...............................................................................................................3-9

Mount the Backup Camera ...........................................................................................................3-9

Connect the Backup Camera.......................................................................................................3-10

SECTION - 4: TESTING THE INSTALLATION ..........................................................................4-11

INITIAL POWER UP.............................................................................................................................4-11

RECORD AN EVENT............................................................................................................................4-11

VIEWING THE BACKUP CAMERA (DVM-250PLUS ONLY) .................................................................4-11

SENSOR/OUTPUTALARM TESTING....................................................................................................4-11

SECTION - 5: SUPPORT..................................................................................................................5-11

How to Reset the DVM-250 System ..........................................................................................5-11

Basic Troubleshooting ................................................................................................................5-12

SECTION - 6: CONTACT INFORMATION ..................................................................................6-13

SECTION - 7: INTERFACE BOX SENSOR WORKSHEET .......................................................7-14

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 1-1

Section - 1: Before you Begin

This document covers the installation of the DVM-250 or DVM-250Plus systems only, including the

Interface Box (if required) and the cabling.

Tools Needed

#2 Phillips head screwdriver

#20 Torx screwdriver or bit

1/8" (4 mm) flat-blade screwdriver

Digital Volt Meter

Cautions and Notes

Please read and follow the instructions and precautions in this installation guide when installing DVM-

250 /DVM-250Plus products.

For assistance, a qualified installation technician or mechanic should be consulted.

Do not use excessive force when removing the mirror from the windshield. The mirror mounting

plate may become separated from the windshield and/or the windshield may break if excessive

force is used. If you are unfamiliar with rearview mirror removal seek professional assistance.

Do not route wiring and cabling over sharp metal edges where they may become damaged or cut.

To prevent electrical shorts or breakage in the wiring and cabling, do not allow wiring and cabling to

be pinched behind trim pieces, panels, or other physical objects.

Do not run wires or cables in areas where they may become damaged by heat from the engine or

the exhaust system.

Do not install any DVM components or wiring in the deployment path of the air bag(s).

When installing the cables or making wire connections, it is recommended you leave a little ‘slack’

in the cable connections to allow for service loops and for movement of the mirror so the

connections do not get pulled or accidentally disconnected.

Where possible, avoid running cables parallel to other wiring and/or antenna coax that may be

installed in the vehicle.

Where possible, do not leave excessive cable above the headliner.

We recommend at least 2 feet of distance between our cabling and that of other systems which

may carry a signal for transmit and/or receive.

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 2-2

Section - 2: Parts, Cables and Accessories

DVM-250

Parts and Accessories List

The table below outlines the parts that are included with the DVM-250 and DVM-250Plus Packages.

MODEL NUMBER

Part Number

Description

001-00026-32

001-00028-32

001-05420-00

001-00042-32

001-00250-32

001-00250-32-A

001-54510-00

006-08172-32

DVM-250, 32GB, Main Unit

x

x

x

006-08174-32

DVM-250Plus, 32GB, Main Unit

x

x

x

x

259-00148-00

Windshield Mounting Puck

x

x

x

x

x

x

x

006-08140-00

Lanyard and Shielding Strap

x

x

x

x

x

x

x

259-00176-00

Security Tamper Resistant Screw

and Key Kit

x

x

x

x

x

x

x

363-00050-00

SD card, 32GB

x

x

x

x

x

x

x

860-00112-00

Quick Start Guide

x

x

x

x

x

x

x

008-01410-00

GPS Module

x

x

x

x

x

x

x

008-01360-00

USB-A to Mini-B Cable

x

x

x

x

x

x

x

001-00010-20

Wi-Fi Assembly

x

x

x

006-08176-00

or

006-08210-00

IF Box 250Plus IFE-10

IF Box 250Plus IFE-20

x

x

x

x

x

008-01388-00

Cable, Main Power to IF Box

3.1m (10.1ft.)

x

x

x

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 2-3

MODEL NUMBER

Part Number

Description

001-00026-32

001-00028-32

001-05420-00

001-00042-32

001-00250-32

001-00250-32-A

001-54510-00

008-01384-00

Cable, Vehicle Power to DVM

4.7m (15.4ft)

x

008-01464-00

Cable, IF Box RJ45 Sensor

x

x

566-00134-00

Surface Mount Backup Camera

x

x

008-01390-00

20ft Backup Camera Cable (x2)

x

008-01390-01

40ft Backup Camera Cable

x

x

002-05099-55

Auxiliary 2-Camera Switch Box V2

x

002-05153-00

Auxiliary 4-Camera Switch Box V3

w/Adapter Cable

566-00143-00

Camera, Side Mount

Adjustable for right or left side

mounting. W/Adapter Cable

x

008-01386-01

Cable, IF Box to DVM

4.6m (15.0ft.)

008-01386-02

Cable, IF Box to DVM

6.1m (20.0ft.)

x

x

008-01386-03

Cable, IF Box to DVM

8.1m (26.5ft.)

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 2-4

Optional Accessories

The table below outlines optional accessories for the DVM-250 and DVM-250 Plus packages.

008-01382-00

008-01382-01

008-01382-02

008-01382-03

Backup Camera 25ft Extension Cable

Backup Camera 40ft Extension Cable

Backup Camera 60ft Extension Cable

Backup Camera 15ft Extension Cable

002-05095-00

DWM-800 System, Wireless Microphone and charging cradle

Can only be used with package 001-00042-32

002-05091-00

Charger, RMT Desktop Charger, 120Vac For DWM-800

008-01455-00

Cable, DWM-800 Wireless Microphone to DVM-800

025-00004-00

External Antenna for DWM-800 Wireless Microphone

004-09058-00

Cable, Back Seat Microphone to DWM-800, 20ft. 2.5mm plug

566-00141-00

License Plate Backup Camera w/Adapter Cable

566-00144-00

Mini Backup Camera w/Adapter Cable

002-00028-00

SD Card Reader for PC

740-00388-00

Panel Mount Remote Activation Switch

740-00399-00

Footswitch, Maintained (18/2AWG, 6ft, bare leads)

002-05030-00

Drop Mount Adapter

002-05112-00

Windshield Mount Adapter Kit, Dodge Charger

006-08267-00

Windshield Mount Adapter Kit, Dodge Sprinter

006-0030

Visor Mount For external front camera

006-0050

Siren Adapter Interface

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 2-5

DVM-250 Basic Wiring Diagram

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 2-6

DVM-250Plus Basic Wiring Diagram

Interface Box

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-1

Section - 3: Installation Instructions

The current factory rearview mirror must be removed from the windshield mounting plate. There are

several versions of mirror mounting systems. Below are the most common methods of rearview mirror

removal. If you are unfamiliar with rearview mirror removal, seek professional assistance.

Be very careful and do not use excessive force when removing the mirror from the

windshield. The mirror mounting plate may become separated from the windshield

and/or the windshield may break if excessive force is used.

Use one of the following methods below that matches the mirror mounting configuration of your

vehicle:

Screw Mount Rearview Mirror Removal

1. Using a Philips screwdriver or #20 Torx bit, loosen the screw in the base of the mirror.

2. After loosening the screw, gently lift upward to slide mirror off of mirror mount.

Wedge (Screwless) Mount Rearview Mirror Removal

1. Using a small 1/8" (4 mm) flat-blade screwdriver, insert the flat end into the opening at the

bottom of the mirror mount next to the windshield.

2. Slide the screwdriver into the center of the mirror mount until resistance is felt.

3. Gently apply a small amount of additional upward force to lift away the locking spring inside the

mount.

4. While still applying upward pressure with the screwdriver, grasp the mirror bracket and wiggle

side to side. Lift the mirror up toward the headliner and off the windshield mount button.

Cam Lock Rearview Mirror Removal

1. With your right hand, grip the mirror and keep it stabilized.

2. With your left hand, grip the base of the factory mount where it meets the glass.

3. Apply a small amount of inward pressure toward the glass and rotate the base clockwise.

4. The spring loaded factory mount should release from the windshield puck. See picture below.

Step 1: Factory Mirror Removal

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-2

1. Remove the protective film covering from the :

a. Mirror glass

b. Road facing camera

c. Passenger facing camera.

2. Slide the new rearview DVM (Digital Video Mirror) onto the existing windshield mounting plate

and secure your DVM to the vehicle windshield. For some 2011 - 2013 Dodge vehicles, attach and

orient the optional adapter to factory windshield as shown. Use Loctite™ to secure the adapter to

the factory windshield mount. If needed, attach optional drop down bracket as shown.

3. Use a #20 Torx screw driver to tighten the mounting screw.

4. Adjust the viewing angle for the rearview mirror.

In some vehicles, the position of the manufacturer’s windshield mounting plate may not allow

for proper rearview DVM adjustment for some individuals, especially when the vehicle is

equipped with an overhead console and/or interior emergency lighting. In these cases, the

mounting plate included with the DVM-250 package must be glued to the windshield in a

location that will allow proper adjustment. Loctite #03346 glue is recommended. Please

follow instructions on their package.

5. The unconnected end of the DVM shielding strap must be

securely connected to the vehicle chassis. The strap should be routed and attached to the metal

structure above the windshield.

The shielding strap must be connected to a metal surface of the vehicle chassis to prevent EMI

and RF interference. Failure to properly connect the shielding strap may cause system

operation issues.

6. If an Interface Box (IF Box) will be installed, skip to #16. Then proceed forward to Step 3

(Interface Box Installation).

7. If no external sensors are required, an IF Box is not required. If an IF Box will not be installed

continue to the next installation instruction.

8. Place the connector end of the Vehicle Power cable in proximity to the mating connector on the

back of the DVM. Do not plug the cable in at this time.

9. Leave enough slack in the cable as a service loop for the rearview

mirror adjustment.

10. Begin routing the cable under the front edge of the headliner and

down the windshield pillar to the desired location for connection to

vehicle power. To conceal the cable it may be necessary to loosen the sun visor mounting

bracket and/or other trim pieces to allow the cable to be tucked in behind the headliner.

Do not route wiring and cabling over sharp metal edges. Where possible, avoid running the

cable parallel to other wiring and/or antenna coax that may be in the vehicle. To prevent

electrical shorts or breakage in the wiring and cabling, do not allow wiring and cabling to be

pinched behind trim pieces, panels, or other physical objects.

Step 2: DVM Installation

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-3

11. Secure the cable and in-line fuse housing using Velcro or standard tie wraps as required. The

cable contains a filter to help minimize unwanted RF noise and 3 amp fuse.

12. Remove 4 to 5 inches of the outer jacket at the bare end of the power cable. Separate the

braided shield from the individual conductors, attach an electrical terminal to the end of the

braided shield, and attach the terminal to the chassis of the vehicle.

13. The Red wire of the DVM power cable should be connected to the vehicle +12Vdc and the Black

wire of this power cable connects directly to the vehicle’s chassis. It is preferred that the power

wire be tied in with DVM interface box connection with no obstructions to battery such as a

cutoff switch or charge guard system.

It is recommended that these connections are made directly to the engine compartment

battery wiring harness for best results. These wires should be used ONLY for the DVM system

and not be tapped into for installation of any other equipment in the vehicle. Doing so, could

result in possible radio frequency interference from the other equipment.

14. Connect the White wire to the ignition switch where +12vdc is only present when the vehicle

ignition Key is in the ON position.

Do not connect the White wire directly to the vehicle battery. For proper operation this wire

must be connected to the vehicle ignition switch.

15. Re-connect the cable to the connector on the back of the DVM.

16. GPS Module and optional WIFI assembly

a. Use full length of cable to locate as GPS away from DVM

b. Upper right or left corner of windshield below the black "frit" of the top windshield.

c. Do Not mount the GPS:

i. In the headliner

ii. Under metal

iii. Near the DVM or Wi-Fi adapter

17. Clean the windshield glass with alcohol and use the supplied tape to attach the GPS module and

optional WIFI assembly to the windshield. See below.

18. If external triggers are not being used, proceed to “Section - 4: Testing the Installation"

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-4

Interface Box

The Interface Box (IF Box) must be securely mounted on a solid area of the

vehicle structure in a moisture free location where it can be easily accessed.

Possible mounting locations include:

•Under the dash on the passenger side.

•Behind the kick panel on the passenger side (or driver side).

•Screwed into the transmission tunnel sheet metal below the dash.

On some vehicles this may not be possible due to extreme heat radiated from the transmission.

•Under the seat on some SUV-type vehicles.

•Behind a panel on the right hand side of the dash (nearest to the door).

Do not place the IF Box directly on floorboard or mount it in areas where it could be

exposed to moisture such as air conditioner condensation, accidental liquid spills,

rain, snow, mud, or other elements that could be tracked into the vehicle from

outside the vehicle.

Do not place the IF Box in an area that will subject the unit to excessive heat such

as a transmission tunnel or engine firewall.

Do not drill into any hoses or wiring that may exist below the mounting screws.

Mount the IF Box

1. Use the IF Box to DVM cable as a gauge to estimate an appropriate location for mounting the IF

Box.

2. Once a suitable mounting location has been identified for the IF Box, verify that the shielding

strap can be securely connected to the metal surface of the vehicle chassis. If the shielding strap

does not reach a suitable metal surface, reposition the IF Box

appropriately.

3. Secure the unconnected end of the shielding strap to the vehicle chassis.

The shielding strap must be connected to a metal surface of the vehicle chassis to

prevent electrical interference. Failure to properly connect the shielding strap may

cause system operation issues.

DVM to Interface Box Cable Installation

1. Plug the connector of the IF Box to DVM cable into the back of the DVM.

2. Leaving slack in the cable at the mirror mounting bracket for DVM

adjustment, begin routing the cable from the DVM under the front edge

of the headliner down the windshield pillar towards the mounting

location for the IF Box. To conceal the cable, it may be necessary to

loosen the sun visor mounting bracket and/or other trim pieces to allow

the cable to be tucked in behind the headliner.

Do not route wiring and cabling over sharp metal edge. Avoid running the cable

parallel to other wiring and/or antenna coax from other equipment in the vehicle. To

prevent electrical shorts or breakage in the wiring and cabling, do not allow wiring

and cabling to be pinched behind trim pieces, panels, or other physical objects.

3. Secure the cable using Velcro or standard tie wraps as required.

4. Plug the remaining end of the IF Box to DVM cable into the IF Box.

Step 3: Interface Box Installation

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-5

Interface Box Power Cable Installation

1. Plug the connector of the Vehicle Power cable into the IF Box.

2. Route the cable to a suitable location for electrical connection.

3. Remove 4 to 5 inches of the outer jacket at the bare end of the power

cable. Separate the braided shield from the individual conductors,

attach an electrical terminal to the end of the braided shield, and

attach the terminal to the chassis of the vehicle.

4. Connect the Red wire of the power cable to the vehicle +12Vdc and

the Black wire of this power cable connects directly to the vehicle’s chassis or a ground wire. It is

preferred that the power wire be tied in with DVM interface box connection with no

obstructions to battery such as a cutoff switch or charge guard system.

It is recommended that these connections are made directly to the engine

compartment battery wiring harness for best results. These wires should be used

ONLY for the DVM system and not be tapped into for installation of any other

equipment in the vehicle. Doing so could result in possible radio frequency

interference from the other equipment.

5. Connect the White wire to the ignition switch where +12vdc is only present when the vehicle

ignition key is in the ON position.

Do not connect the White wire directly to the vehicle battery. For proper operation

this wire must be connected to the vehicle ignition switch.

6. Secure the cable and the inline fuse housing using Velcro or standard tie wraps as required. The

cable contains a filter to help minimize unwanted RF noise and 3 amp fuse.

7. Re-connect the cable to the connector on the back of the DVM.

The IF Box provides multi-purpose sensor inputs that allow external devices

to trigger an event record in the mirror. It also provides an Output Alarm

to turn devices on or off when an event trigger occurs. Common external

sensors include; brake lights, turn signal indicators, reverse gear, covert

foot‐switch, or door sensors.

Determine the Device Trigger(s) Signal Level

For the administrator to configure each of the six (6) multi-purpose input sensors, the signaling from the

external device must be found and documented. Determine the signaling of each external device that

will be used and document the signal information on the Sensor Worksheet that has been provided on

page 7-14.

Reverse Gear Signal (DVM-250Plus only)

Tap into the reverse gear signal, with the vehicle started measure and record the DC voltage of

the signal with the vehicle in park; measure and note the DC voltage when the vehicle is in

reverse gear. Record both voltage levels on the Sensor Worksheet. Refer to the vehicle

manufacturer’s wiring diagram specific details for your vehicle.

Sensor #1 is reserved for the Reverse Gear Signal for use with the Backup camera option on

the DVM-250Plus.

Step 4: Interface Box External Trigger Wiring

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-6

Trigger Wiring Installation

Once the administrator has received the signal information of each device, they will complete the lower

section of the Sensor Worksheet on page 7-14. Use the information they have provided to connect the

IF Box Sensor cable to the devices.

1. Position RJ45 end of the sensor cable near the IF Box RJ45 jack, but do not plug it into the IF Box.

2. Leaving a service loop for connection to the IF Box, begin routing the un-terminated end of the

sensor cable to the desired location in the vehicle for connection for each of the input sensor

devices.

3. Cut off excess cable as required, and strip the cable jacket from the un-terminated end of the

sensor cable to access the individual wires.

4. The devices can then be connected to the sensor interface cable based on the lower section of the

Sensor Worksheet on page 7-14.

5. Use the following table for wiring connections to the sensor cable and connect the external

devices to the appropriate wire of the RJ45 sensor cable.

6. When all external devices have been connected, plug the RJ45 into the jack labeled “SENS A” on

the IF Box.

Pin

Sensor Number

Wire Color

1

Sensor #1 (Reverse Gear)

RED

2

Sensor #2

ORANGE

3

Sensor #3

BLUE

4

Sensor #4

YELLOW

5

Sensor #5

WHITE

6

Sensor #6

GREEN

7

Output #1

BROWN

8*

GND

BLACK

Pin 8 (GND) can be used to provide a signal ground.

Remote Accessory Out

In addition to activating the DWM-800 wireless microphone, A DVM-250Plus can be configured to

activate or deactivate an auxiliary device when an event record begins. Below is a general outline

showing how the Output Alarm Trigger can be wired using an interposing relay.

The device, relay, and fuse are optional customer provided items. Be sure to select a relay

which can handle the power requirements of your device.

Example wiring diagrams:

1. Activate during Event Recording: To activate low power devices when an Event Trigger is active,

the example diagram below shows how to connect it to the IF Box. When the Output alarm is

active the relay will be energized and the device will be powered on. If the Output Alarm is not

active, the relay will not be energized and the device will not be powered.

+12V, (2A max.)

To Vehicle Battery

To Pin 7 of the IF Box

SENS A connector cable

(BROWN wire)

85 86

30 87a

87 Device

GNDPower IN

NC

Fuse 2A Fast Blow

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-7

2. De-Activate during Event Recording: To de-activate low power devices when an Event Trigger is

active, the example diagram below shows how to connect it to the IF Box. When the Output

alarm is active the relay will be energized and the device will not be powered. If the Output

Alarm is not active, the relay will not be energized and the device will be powered on.

+12V, (2A max.)

To Vehicle Battery

To Pin 7 of the IF Box

SENS A connector cable

(BROWN wire)

85 86

30 87a

87

Device

GNDPower IN

NC

Fuse: 2A Fast Blow

RJ45 to Terminal Connector Adapter (optional)

If heavier gauge and jacket wiring is required, an optional terminal connector adapter kit

(P/N 002-05107-00) is available for purchase from Digital Ally. The adapter allows

customer provided wire to be used for wiring sensors from the vehicle to the IF Box. For

more information and installation instructions, refer to the DVM-250 Terminal Block Kit

Installation Instructions included with the kit.

Siren Adapter Interface

If an acceptable DC output cannot be obtained from the siren controller, the optional siren adapter

interface (Digital Ally P/N 006-0050) can be used to connect the siren speaker to the interface box.

Follow the diagram below to install the siren interface.

The sensor must be configured for a High to Low, Standard Threshold within the

Configuration Manager software.

Terminal Block

DVM IF Box

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-8

1. Attach the mounting bracket to the back of the BTR (base

transceiver cradle); the assembly can then be mounted at your

preferred location, such as the side of the center console. Do not

mount the cradle in close proximity of a cup holder or other area

which may be exposed to moisture. Damage caused by a liquid

spill is not covered under warranty.

2. Attach the antenna. If you are using the external In-Car Microphone, connect it to the BTR In-Car

Microphone jack and route the microphone to your preferred location in the vehicle. The typical

mounting location for the external in-car microphone is in the rear seat area along the headliner

& below the weather strip.

DWM-800 Wireless Microphone Cable Installation

Carefully route the BTR-800 cable to the back of the DVM. Make the following

connections listed in figure 3-8.

Step 5: Wireless Microphone Installation (Optional)

For use with 001-00042-32 only

Connection

Wire Color

POWER

Connect to +12vdc battery terminal

RED

GND

Connect to vehicle chassis

BLACK

REMOTE ACCESSORY OUT

Connect to auxiliary equipment

(optional connection, see next page)

VIOLET

MIC trigger out

Connect to GREEN wire of IF Sensor

Cable (see figure 3-6)

GREEN

MIC trigger in

Connect to BROWN wire of IF Sensor

Cable (see figure 3-6)

BROWN

Transmit/Receive

Connect to RJ45 input jack on the

BTR800 microphone charger

RJ45

Audio Out

Connect to 3.5mm audio jack on the

back of the DVM

3.5mm audio plug

Figure 3-8: BTR800 Cable Input Connections

Antenna Connection

In-Car Microphone Connection

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-9

Connect the 3.5mm Audio Plug to the audio input jack on the back of the DVM. Be sure to leave

enough slack in the cable to allow for movement of the mirror.

Route the Camera Cable

1. Plug the connector on the DVM end of the Backup Camera cable into the back of the DVM. This

cable will connect to the short cable attached to the Backup Camera.

2. Leave slack in the cable as a service loop and for DVM adjustment; then begin routing the cable

to the rear of the vehicle.

3. If possible, route the camera cable to the opposite direction of other cables connected to the

DVM under the front edge of the headliner.

4. Depending on your vehicle you may be able to route the cable down the side of the headliner to

a rear compartment of the vehicle. Otherwise find a suitable route on the floorboard of the

vehicle.

5. To conceal the cable it may be necessary to loosen interior trim and other components within

the vehicle.

6. Secure the cable using Velcro or standard tie wraps as required.

7. The cable connector for the Backup Camera should be routed to a rear compartment of the

vehicle such as the trunk of a car, to a location within 3 feet of the rear license plate.

Mount the Backup Camera

LICENSE PLATE BACKUP CAMERA

1. Remove the top two screws holding the rear license plate to the vehicle.

2. Position the backup camera bracket along the top edge of the license plate.

3. Replace the license plate mounting screws to complete the bracket installation.

It may be illegal in your local area or state to cover up the State, County, Year, etc. on the vehicle license

plate. Depending on the design of the license plate for your particular state, you may need to use the Mini Backup

Camera in order to ensure compliance with your local and state laws.

Step 6: Backup Camera Installation (DVM-250Plus only)

License Plate Backup Camera

Mini Backup Camera

Do not route wiring and cabling over sharp metal edges. When possible, avoid running the cable parallel to other wiring and/or

antenna coax from other equipment in the vehicle. To prevent electrical shorts or breakage in the wiring and cabling, do not

allow wiring and cabling to be pinched behind trim pieces, panels, or other physical objects.

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 3-10

EXTERNAL MOUNT BACKUP CAMERA

1. Identify a flat surface to attach the mounting bracket.

2. For exterior mounting where the cable must be routed through a panel to

the interior of the vehicle:

a. Position the mounting bracket, locate the ¾” hole in the

bracket, and mark the center on the mounting surface.

b. Place the bracket aside. Prepare the center mark on the

mounting surface using a hole punch, and then drill the hole using a ¾” drill bit.

3. Using the camera hardware provided:

a. For installations with a ¾” cable hole drilled through from the exterior to the interior

of the vehicle, the black mounting grommet and gasket should be used to provide a

weather resistant seal between the vehicle surface and the camera’s mounting

bracket.

b. Install the camera bracket to the vehicle (see pictures below).

c. Attach the camera to the mounting bracket.

Connect the Backup Camera

1. The pigtail from the Backup Camera will connect to the camera cable routed from the DVM. The

connection between the pigtail and camera cable should be made inside the vehicle in a dry,

moisture free location.

2. Route the pigtail from the Backup Camera to the selected area inside the vehicle.

3. Connect the pigtail cable connector to the mating connector of the Camera Cable routed from

the DVM.

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 5-11

Section - 4: Testing the Installation

1. Turn the vehicle ignition switch to the ON position. The vehicle does not have to be running.

2. The DVM will begin the boot-up process; all 3-LEDs will flash in unison at a 1 second interval

until boot up is complete.

3. Once the boot-up process is complete, the Green LED will be lit indicating the DVM is powered

on, is ready, and in standby mode.

1. Press the RECORD button.

2. The Red status indicator will flash to indicate the manual event is being

recorded.

3. After 10 seconds, press the RECORD button to stop the manual event record.

4. The Red status indicator will extinguish, indicating the DVM has returned to standby mode.

1. Start the vehicle and leave the transmission in Park.

2. Apply the brake and put the transmission into Reverse gear.

3. The LCD monitor will turn on and the live-video from the backup camera will be displayed.

4. The Red status indicator will begin flashing at 3 second intervals, indicating the back-up event is

being recorded.

5. Put the transmission back into Park.

6. The LCD monitor will turn off and the Red status indicator will extinguish, indicating the DVM has

returned to standby mode.

The Administrator is able to provide you with a configuration for the DVM to test Input Sensor Triggers

that have been connected to the DVM system. Below are basic instructions for testing these ports:

1. Activate a trigger input device to begin an Event Record.

2. The Red status indicator will flash to indicate the manual event is being recorded.

3. If the DVM was configured to activate the Output Alarm for the input trigger verify for the

proper functionality.

4. After the Event Record Time has been reached the event record will stop.

5. The Red status indicator will extinguish, indicating the DVM has returned to standby mode.

6. Repeat this process above for each of the input devices.

Section - 5: Support

How to Reset the DVM-250 System

Using a small blunt object such as a small eye-glass screwdriver or

a paper clip, press the reset button on the DVM. The reset button

is recessed and located on the road facing, driver’s side of the

housing as shown here.

Initial Power Up

Record an Event

Viewing the Backup Camera (DVM-250Plus only)

Sensor/Output Alarm Testing

DVM-250/DVM-250Plus Installation Guide 860-00129-00 Rev C

Copyright © 2010-2015 Digital Ally, Inc. 5-12

Basic Troubleshooting

Symptom

Resolution

System will not power up.

Verify the power cable connector is connected to the back of the DVM.

Check the power cable fuses located in the in-line fuse housing on the

power cable.

Verify there are no breaks, pinches, or cuts in the wiring or cable harness.

Check the wiring and voltage levels to the vehicle power and ignition

switch wiring.

All LEDs are flashing rapidly in

unison

DVM is configured to use an external SD card and the SD card is missing.

The external SD card does not have enough free available storage for

uploading the events from internal memory. Replace the external SD card

with a blank SD card.

Yellow LED on Solid

Memory is full. Upload event files from the DVM or replace the external

memory storage device.

DVM powers up but doesn’t

record

Check the LED status indicators and clear accordingly

Reset the system.

DVM powers up and goes directly

to an event record (Red LED

Flashes)

An event record has been triggered from either an internal sensor or from

an IF Box:

Disconnect the Sensor Cable RJ45 connector from the IF Box and reset the

DVM. If the problem doesn’t re-occur, check the wiring from the vehicle

to the sensor cable.

Check the DVM configuration parameter values for all internal sensors

and/or IF Box sensors.

Backup Camera not visible on the

LCD when the vehicle is in

Reverse gear

Verify the DVM is powered ON and operational.

Note: Backup camera operation will only occur when

vehicle ignition is on and running.

Verify the reverse gear wiring is connected to the Red wire of the RJ45

sensor cable.

Verify the Reverse Gear signal voltages.

Verify there are no breaks, pinches, or cuts in any of the wiring or cable

harnesses for the backup camera, IF Box, reverse gear wiring, vehicle

power and ignition wiring.

Verify the IF Box is connected to the DVM.

Verify the camera cable connector is connected to the back of the DVM.

Verify the camera cable from the DVM is connected to the connector on

the hard-wired harness from the camera.

Verify the DVM sensor inputs are configured correctly through the

Configuration Manager software. Refer to the Administrator Guide for

additional details for configuring the DVM.

Backup Camera is visible when

the vehicle is in Park

The default operation for the IF Box reverse gear signal is from High to

Low (+12vdc to 0vdc). If the reverse gear signal that is connected has

+12VDC when in reverse, the DVM will need to be re-configured. Refer to

the Administrator Guide for additional details for configuring the DVM.

Backup Camera video is garbled

or not intelligible

Verify backup camera, cabling, and connectors.

IF Box may be defective

DVM is unresponsive

Verify the cables and cable connections.

Verify vehicle power.

Press the reset button.

False Triggering of Event

Recordings

Determine which trigger is causing the false trigger by viewing the event

recording.

The unit can be reconfigured to default settings and enable each trigger

to determine which one is causing the false trigger.

If the Accelerometer is causing false triggering, verify the mirror is in the

normal rearview mirror orientation.

Other manuals for DVM-250

1

This manual suits for next models

1

Table of contents

Other Digital-Ally DVR manuals