Digital Electronics Corporation ST Series User manual

E-1

WARNINGS

System Design

• Do not create ST touch panel switches that could possibly endanger the safety

of equipment and personnel. Damage to the ST, its I/O unit(s), cable(s), and

other related equipment can cause an output signal to remain continuously ON

or OFF and possibly cause a major accident. Therefore, design all monitoring

circuits using limit switches, etc. to detect incorrect device movement. To pre-

vent accidents related to incorrect signal output or operation, design all switches

used to control vital machine operations so they are operated via a separate

control system.

• Do not create switches used to control machine safety operations, such as

an emergency stop switch, using a ST touch screen icon. Be sure to install

these switches as separate hardware switches, otherwise severe bodily in-

jury or equipment damage can occur.

• Please design your system so that equipment will not malfunction due to a

communication fault between the ST and its host controller. This is to pre-

vent any possibility of bodily injury or material damage.

• Do not use the ST unit as a warning device for critical alarms that can cause

serious operator injury, machine damage or production stoppage. Critical

alarm indicators and their control/activator units must be designed using stand-

alone hardware and/or mechanical interlocks.

• The ST is not appropriate for use with aircraft control devices, aerospace

equipment, central trunk data transmission (communication) devices, nuclear

power control devices, or medical life support equipment, due to these de-

vices' inherent requirements of extremely high levels of safety and reliability.

• When using the ST with transportation vehicles (trains, cars and ships), di-

saster and crime prevention devices, various types of safety equipment, non-

life support related medical devices, etc. redundant and/or failsafe system

designs should be used to ensure the proper degree of reliability and safety.

• After the ST backlight burns out, unlike the ST's standby Mode, the touch

panel is still active. If the operator fails to notice that the backlight is burned

out and touches the panel, a potentially dangerous machine operation error

can occur. Therefore, do not use ST touch switches for the control of equip-

ment safety mechanisms, such as Emergency Stop switches, etc. that pro-

tect humans and equipment from injury and damage. If your ST's backlight

suddenly turns OFF, use the following steps to determine if the backlight is

actually burned out.

1)If your ST is not set to Standby Mode and the screen has gone blank, your

backlight is burned out.

2)Or, if your ST is set to Standby Mode, but touching the screen does not

cause the display to reappear, your backlight is burned out.

Installation

• Do not modify the ST unit. Doing so may cause a fire or an electric shock.

• Do not use the ST in an environment where flammable gasses are present,

since operating the ST may cause an explosion.

Wiring

• To prevent an electric shock, be sure to confirm that the ST's power cord is

not connected to the main power when connecting any cords, cables or lines

to the ST.

• Do not use power beyond the ST's specified voltage range. Doing so may

cause a fire or an electric shock.

Maintenance

• The ST uses a lithium battery for backing up its internal clock data. If the battery is

incorrectly replaced, the battery may explode. To prevent this, please do not

replace the battery yourself. When the battery needs to be replaced, please con-

tact your local ST distributor.

E-2

CAUTIONS

Installation

• Be sure to securely connect all cable connectors to the ST. A loose con-

nection may cause incorrect input or output.

Wiring

• Ground the ST's FG line separately from other unit FG lines. Locating FG

lines too close may cause an electric shock or a unit malfunction. Be sure to

use a grounding resistance of 100Ωor less and a 2mm2or thicker wire, or

your country applicable standard.

• When wiring the ST, be sure that the rated voltage and terminal layout are

within the designated range. If the voltage supplied differs from the rated

voltage, or incorrect wiring or grounding is performed, it may cause a fire or

unit malfunction.

• Use only the designated torque to tighten the ST's terminal block screws. If

these screws are not tightened firmly, it may cause a short-circuit, fire, or ST

malfunction.

• Be careful that metal filings and wiring debris do not fall inside the ST, since

they can cause a fire, ST malfunction, or operation error.

Maintenance

• The liquid crystal panel contains a powerful irritant and if for any reason the

panel is damaged and this liquid contacts any part of your body, be sure to

wash that area with running water for 15 minutes. If any of this liquid enters

your eye, flush your eye for 15 minutes with running water and contact a

physician.

Unit Disposal

• When this unit is disposed of, it should be done so according to your country's

regulations for similar types of industrial waste.

Other

• Among backlight units there may be slight variations in illumination color,

however, this does not effect the performance or quality of the ST unit.

General Safety Precautions

• Do not strike the touch panel with a hard or pointed object, or press on the

touch panel with too much force, since it may damage the touch panel or the

display.

• Do not install the ST where the ambient temperature can exceed the al-

lowed range. Doing so may cause the ST to malfunction or shorten its op-

eration life.

• Do not restrict or limit the ST unit naturally occurring rear-face ventilation, or

storing or using the ST in an environment that is too hot.

• Do not use this unit in areas where large, sudden temperature changes can

occur. These changes can cause condensation to form inside the unit, pos-

sibly causing the unit to malfunction.

• Do not allow water, liquids, metal or charged particles to enter inside the ST

case, since they can cause either a ST malfunction or an electrical shock.

The allowable pollution degree is 2.

• Do not use or store the ST in direct sunlight, or in excessively dusty or dirty

environments.

• Do not store or use the unit where strong jolting or excessive vibration can

occur.

E-3

• Do not store or use the ST where chemicals (such as organic solvents, etc.)

and acids can evaporate, or where chemicals and acids are present in the

air.

Corrosive chemicals: Acids, alkalines, liquids containing salt

Flammable chemicals: Organic Solvents

• Do not use paint thinner or organic solvents to clean the ST.

• Do not store or operate the LCD display in areas receiving direct sunlight,

since the sun's UV rays may cause the LCD display quality to deteriorate.

• Storing this unit in areas at a temperature lower than is recommended in this

manual's specifications may cause the LCD display liquid to congeal,

which may damage the panel. Conversely, if the storage area temperature

becomes higher than the allowed level, the LCD liquid will become isotro-

pic, causing irreversible damage to the LCD. Therefore, be sure to store

the panel only in areas where temperatures are within those specified in this

manual.

• After turning the ST OFF, be sure to wait a few seconds before turning it

ON again. If the ST is restarted too soon, it may not start up correctly.

• Due to the possibility of unexpected accidents, be sure to back up the ST

screen data regularly.

About the ST’s Display Panel

• The ST's currently displayed data, its voltage*1 and brightness setting each

affect the intensity of Contouring. (i.e, when some parts of the screen are

brighter than others, creating a wavelike pattern)

• There are minute grid-points (dark and light) on the Display Panel’s surface.

This is part of the ST’s design and not a defect.

• Extended shadows, or “Crosstalk” may appear on the sides of screen im-

ages. This is normal for an LCD display.

• Sometimes the display area may look as if the display colors have changed.

This is a common attribute of LCD’s and is not a defect.

• Displaying a single image for long periods can cause an afterimage to re-

main when the display is changed to another screen.

* Use the ST’s “Stand-by Mode”, which automatically turns the screen OFF

when there is no input for a specified period of time.

* Do not display any single screen for a long period of time. Try to

periodically change the screen display.

This mark is applicable only in Taiwan.

E-4

UL/c-UL Application Notes

The ST400-AG41-24V/ST401-AG41-24V/ST402-AG41-24V/ST403-AG41-24V units are

UL/c-UL listed product.

When applying for UL approval for a product that includes one of these ST units, please be

sure to pay special attention to the fact that all products with built-in ST units require UL

inspection of the combination of the ST and the product. This Unit conforms as a compo-

nent to the following standards:

UL508 UL File No.220851

Safety of Industrial Electrical Equipment.

- The ST's front face is evaluated as an Enclosure, and all other areas are evaluated as an

Open Enclosure.

- Be sure to supply 24V power from a Class II circuit. The ST's front face satisfies

NEMA#250 TYPE 4X/12 requirements.

UL1604*1 UL File No.182139

Safety of Information Technology Equipment for use in Class I and II, Division 2, and Class

III Hazardous (classified) locations.

CAN/C22.2, No.14 and No.213-M1987

Safety of Information Technology Equipment for use in Class I and II, Division 2, and Class

III Hazardous (classified) locations.

ST400-AG41-24V (UL Registration Model : 3180053-02)

ST401-AG41-24V (UL Registration Model : 3180053-03)

ST402-AG41-24V (UL Registration Model : 3180053-04)

ST403-AG41-24V (UL Registration Model : 3383102-01)

<Cautions>

If the ST is mounted so as to cool itself naturally, please mount it on a vertical panel. Also,

insure that the ST is mounted at least 100 mm away from any other adjacent structures or

machine parts. If these conditions are not met, the heat generated by the ST's internal com-

ponents may cause it to fail to meet UL standards.

UL1604 Conditions of Acceptability and Handling Cautions:

1. Power and input/output wiring must be in accordance with Class I, Division 2 wiring

methods - Article 501-4(b) of the National Electrical Code, NFPA 70 within the United

States, and in accordance with Section 18-152 of the Canadian Electrical Code for

installallations within Canada and in accordance with the authority have jurisdiction.

2. Suitable for use in Class I, Division 2, Groups A, B, C, and D Hazardous Locations or

non-Hazardous Location only.

3. Confirm that the power supply has been turned OFF before disconnecting equipment, or

confirm that the location is not subject to the risk of explosion.

4. WARNING: Explosion hazard - substitution of components may impair suitability for

Class I, Division 2.

5. WARNING: Explosion hazard - when in hazardous locations, turn power OFF before

replacing or wiring modules.

6. WARNING: Explosion hazard - DO NOT connect/disconnect equipment unless area is

known to be nonhazardous or the power has been switched off. TOOL port is for system

set-up and diagnostics in a nonhazardous location area only.

*1 ST400-AG41-24V/ST401-AG41-24V/ST402-AG41-24V/ST403-AG41-24V units with revision

code “A” or later are all UL1604 compliant. “Revision Information”

E-5

The following items are included in the ST's package. Before using the ST, please

confirm that all items listed here are present.

The ST400-AG41-24V/ST401-AG41-24V/ST402-AG41-24V/ST403-AG41-24V

are CE marked, EMC compliant products. These units also conform to EN550011

Class A, EN61000-6-2 directives. For detailed CE marking information, please

contact your local ST distributor.

DIGITAL ELECTRONICS CORP.

ST Unit (1)

<ST400-AG41-24V/ST401-AG41-24V/

ST402-AG41-24V/ST403-AG41-24V>

Installation Guide (1) <This Guide>

Installation Fasteners (4)

Installation Gasket (1) <Attached to the ST Unit>

Power Plug (1) <Attached to the ST Unit>

F1

F1

F2

F2

F3

F3

F4

F4

F5

F5

F6

F6

Installation

Guide

Use the metallic label attached to the rear of the GP to identify your unit’s revision

code. This code is at the bottom of the label, to the right of “REV”. In this example,

the asterisk mark (*) is in the “D” position, which means this unit’s revison code is

“D”.

CE Marking Notes

Revision Information

Package Contents

This unit has been carefully packed, with special attention to quality. However,

should you find anything damaged or missing, please contact your local ST distribu-

tor immediately.

E-6

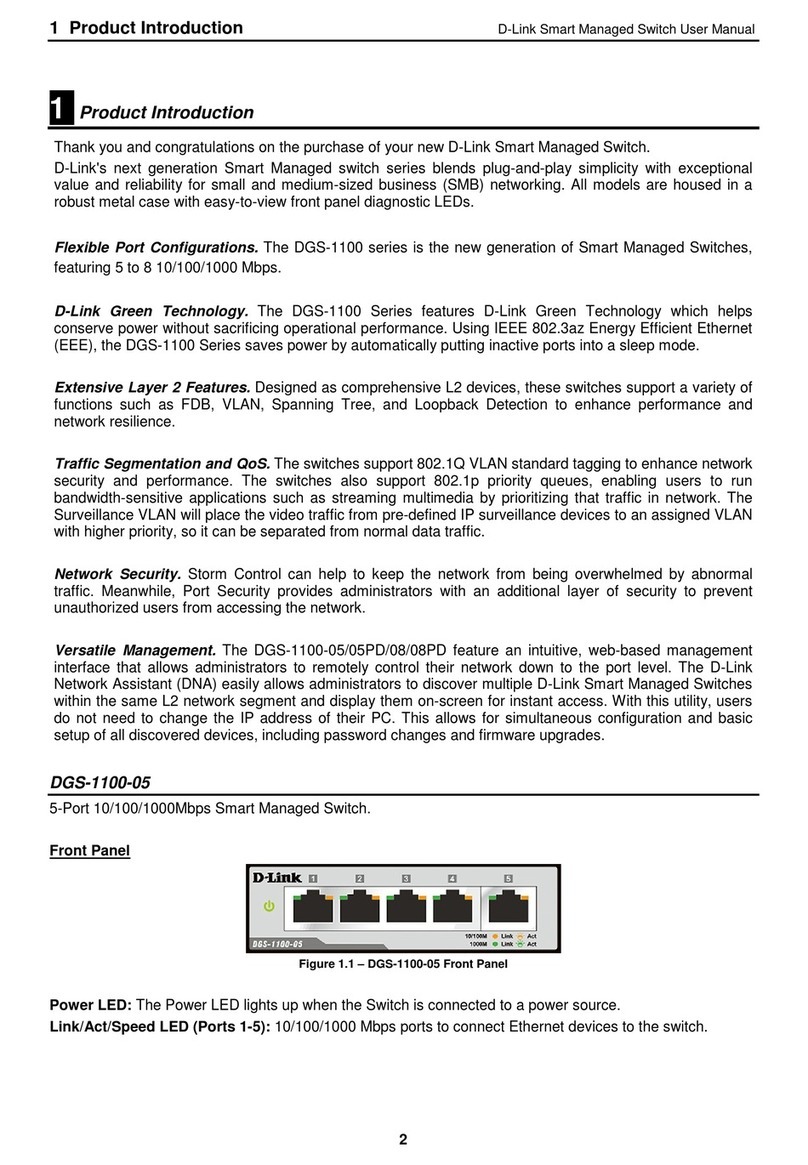

A : Display

B : Touch Panel

C : Function Switches (F1 to F6)

D : Power Lamp

E : Power Plug

F : RS-422 Interface (X)

G : RS-232C Interface (Y)

H : RS-485(MPI) Interface (X)

I : RS-422 Interface (Y)

J : Ethernet Connector (X)

K : RS-232C/RS-422 Interface (Y)

L : Tool Connector (TOOL)

1Part Names

L

Rear

ST400-AG41-24V Bottom

EF

ST401-AG41-24V Bottom

EG

ST402-AG41-24V Bottom

EI H

C

D

A, B Front

F1

F1

F2

F2

F3

F3

F4

F4

F5

F5

F6

F6

ST403-AG41-24V Bottom

J

K

E

E-7

129[5.08]

64.5[2.54]

139[5.47] 5[0.20]

41[1.61]

21.5[0.85]

43[1.69]

104[4.09]

To p

Front Right Side

Unit:mm[in.]

F1

F1

F2

F2

F3

F3

F4

F4

F5

F5

F6

F6

2Dimensions

The ST unit dimensions are follows.

The following drawing shows the ST unit with installation fasteners.

118[4.65]

Top

Front Right Side

104[4.09]

5[0.20]

41[1.61]

Unit:mm[in.]

130[5.12]

92[3.62]

F1

F1

F2

F2

F3

F3

F4

F4

F5

F5

F6

F6

E-8

ST400-AG41-24V

Serial Interface

RS-422 Interface (X)

Recommended Connector : Dsub 9 pin socket-type XM2D-0901 <made by OMRON Corp.>

Recommended Cover : Dsub 9 pin cover XM2S-0913 <made by OMRON Corp.>

• Use inch-type screws (#4-40UNC) as set screws.

• This unit is not equipped internally with termination resistance. Attach termina-

tion resistance to the cable.

ST401-AG41-24V

Serial Interface

RS-232C Interface (Y)

Recommended Connector : Dsub 9 pin socket-type XM2D-0901 <made by OMRON Corp.>

Recommended Cover : Dsub 9 pin cover XM2S-0913 <made by OMRON Corp.>

• Use inch-type screws (#4-40UNC) as set screws.

3Interfaces

59

16

59

16

Pin Connection Pin No. Signal Signal Name Direction

1 CD Carrier detect Input

2 RD Receive data Input

3 SD Send data Output

4 ER Enable receive Output

5 SG Ground -

6 DR Data set ready Input

7 RS Request send Output

8 CS Clear send Input

9 RI Ring indicate Input

Pin Connection Pin No. Signal Signal Name Direction

1 RDA Receive data A Input

2 RDB Receive data B Input

3 SDA Send data A Output

4 ERA Enable receive A Output

5 SG Ground -

6 CSB Clear send B Input

7 SDB Send data B Output

8 CSA Clear send A Input

9 ERB Enable receive B Output

E-9

6

59

1

ST402-AG41-24V

Serial Interface

RS-485(MPI) Interface (X)

*2

*1 When providing power via the Seimens Co.'s Profibus connector, power cannot be connected

to the Device/PLC.

*2 The connector of the ST side is socket type.

Recommended Connector : Dsub 9 pin pin-type XM2A-0901 <made by OMRON Corp.>

Recommended Cover : Dsub 9 pin cover XM2S-0913 <made by OMRON Corp.>

• When using an MPI interface, the Seimens Co.'s Profibus connector can be used.

• Use inch-type screws (#4-40UNC) as set screws.

• This unit is not equipped internally with termination resistance. Attach termina-

tion resistance to the cable.

Expansion Serial Interface

RS-422 Interface (Y)

Pin Connection Pin No. Signal Signal Name Direction

1 RDA Receive data A Input

2 RDB Receive data B Input

3 SDA Send data A Output

4 ERA Enable receive A Output

5 SG Ground -

6 CSB Clear send B Input

7 SDB Send data B Output

8 CSA Clear send A Input

9 ERB Enable receive B Output

*1

*1 The connector of the ST side is pin type.

Recommended Connector : Dsub 9 pin socket-type XM2D-0901 <made by OMRON Corp.>

Recommended Cover : Dsub 9 pin cover XM2S-0913 <made by OMRON Corp.>

• Use inch-type screws (#4-40UNC) as set screws.

• This unit is not equipped internally with termination resistance. Attach termina-

tion resistance to the cable.

Pin Connection Pin No. Signal Signal Name Direction

1 NC No connection -

2 NC No connection -

3 LINE(+) Line (+) In/Output

4 RTS Request Send Output

5 SG Ground -

65V

5V External Output*1 Output

7 NC No connection -

8 LINE(-) Line (-) In/Output

9 NC No connection -

6

59

1

E-10

ST403-AG41-24V

Ethernet Interface

This is the Ethernet Interface of 10 BASE-T. LED lights up or blinks according to the status.

Serial Interface

RS-232C/RS-422 Interface (Y)*1

Recommended Connector : Dsub 9 pin socket-type XM2D-0901 <made by OMRON Corp.>

Recommended Cover : Dsub 9 pin cover XM2S-0913 <made by OMRON Corp.>

• Use inch-type screws (#4-40UNC) as set screws.

• This unit is not equipped internally with termination resistance. Attach termination

resistance to the cable.

*1Transmission method is used by changing in software.

LED Contents

orange W hen the power supply is on, LED lights up.

W hen sending or receiving, LED blinks.

green W hen linking, LED lights up.

Pin Connection Pin No. Signal Signal Name Direction

1 CD/RDA Carrier detect/Receive data A Input/Input

2 RD/RDB Receive data/Receive data B Input/Input

3 SD/SDA Send data/Send data A Output/Output

4 ER/ERA Enable receive/Enable receive A Output/Output

5 SG/SG Ground/Ground -

6 DR/CSB Data set ready/Clear send B Input/Input

7 RS/SDB Request send/Send data B Output/Output

8 CS/CSA Clear send/Clear send A Input/Input

9 RI/ERB Ring indicate/Enable receive B Input/Output

6

59

1

E-11

Confirm the Installation Gasket's Positioning

It is strongly recommended that you use the gasket. It absorbs vibration in addition

to repelling water.

Place the ST on a level surface with the display panel facing downward. Check that

the ST’s installation gasket is seated securely into the gasket’s groove, which runs

around the perimeter of the panel’s frame.

• Before installing the ST into a cabinet or panel, check that the instal-

lation gasket is securely attached to the unit.

• A gasket which has been used for a long period of time may have

scratches or dirt on it, and could have lost much of its dust and drip

resistance. Be sure to change the gasket periodically (or when

scratches or dirt become visible).

• Be sure the gasket's seam is not inserted into any of the unit's cor-

ners, only in the straight sections of the groove. Inserting it into a

corner may lead to its eventually tearing.

• To ensure the installation gasket's maximum level of moisture resis-

tance, be sure the gasket's seam is inserted as shown into the

panel's bottom face.

4Installation

Create a Panel Cut and insert the ST into the panel from the front

92.5 [3.64 ]

+1

0

118.5 [4.67 ]

+1

0Under 4-R3 [0.1

2]

Unit:mm[in.]

+0.04

0

+0.04

0

F1

F1

F2

F2

F3

F3

F4

F4

F5

F5

F6

F6

1.6mm[0.06in.]

to 5.0mm[0.2in

.]

Gasket

Rear face of ST

E-12

Attach the Installation Fasteners from Inside the Panel

1. Refer to the following drawing when inserting installation fastener hooks in the ST

unit's right side (2) and left side (2) installation fastener holes.

• Tightening the screws with too much force can damage the ST's

plastic case.

• The necessary torque is 0.5 N•m.

Insertion Slots

RightLeft

2. Insert each fastener's hook into the installation fastener hole and tighten it with a

screwdriver.

Installation fasteners are sold by your local ST distributor.

As shown in the following figure, attach the Installation Fastener in

the right position. If not, the ST unit may be drop out.

Installation

fastener

Panel

ST

E-13

• To avoid an electric shock, prior to connecting the ST's power

cord confirm that the ST's power supply is completely turned OFF,

via a breaker, or similar unit.

• The ST400-AG41-24V/ST401-AG41-24V/ST402-AG41-24V /

ST403-AG41-24V units are designed to use only DC24V input.

Any other power level can damage both the ST and the power

supply.

• Since there is no power switch on the ST unit, be sure to attach a

breaker-type switch to its power cord.

• When the FG terminal is connected, be sure the cord is grounded.

• If the power cord is pulled strongly, the power plug may fall out.

• When the FG terminal is connected, be sure the wire is grounded.

Not grounding the ST unit will result in excess noise and vibration.

5Wiring

WARNINGS

• The power cord should be equivalent to the specification shown above. Be

sure to twist the power cords together, up to the power plug. (See illustration

on next page)

• Recommended power plug is Phoenix Contact Co.'s MSTB2,5/3-ST-5,08.

Power Plug Specifications

Power Cord Specifications

7mm

+

-

F

G

Insertio

n

Directio

n

Power Cord Diameter 0.2 to 2.5 mm2 (24 – 12 AWG)

Conductor Type Simple or Stranded Wire

Conductor Length

+ 24V

-0V

FG Grounding Terminal connected to the ST chassis

E-14

Connecting the ST Power Cord

When connecting the power cord, be sure to follow the procedures given below.

1. Confirm that the ST's power cord is unplugged from the power supply.

2. Remove the power plug from the ST unit.

3. Remove the vinyl cover of each of the power cord's wires and insert each wire

into the power plug's wire hole.

4. Replace the power plug.

• Use a flat screwdriver (Size 0.6 x 3.5) to tighten the terminal block wire set screws.

The torque required to tighten these screws is 0.5 to 0.6 N•m.

• Do not solder the wire itself.

Rear of ST

FG

Terminal block

wire set screws

+

-

Power Plug

E-15

• When attaching a wire to the ST's rear face FG terminal, (on the Power Input

Terminal Block), be sure to create an exclusive ground.*1

• The FG terminal and the ST's internal 0V power are connected. Be sure to con-

firm that this type of connection is allowed in your current system.

Please pay special attention to the following instructions when connecting the power

cord. Use the power plug and connects to the ST power connector.

• Between the line and the ground, be sure to use a low-noise power supply.

• Input and Output signal lines must be separated from all power control cables

used for operational circuits.

• To increase noise resistance, be sure to twist the ends of the power cord wires

before connecting them to the ST power connector.

• The ST's power supply cord should not be bundled with or kept close to main

circuit lines (high voltage, high current), or input/output signal lines.

• Connect a surge absorber to handle power surges.

• To reduce noise, make the power cord as short as possible.

• All ST Input and Output signal lines must be separated from all operating circuit

(power) cords.

• If this is not possible, use a shielded cord and ground the shield.

9Maintenance and Periodic Inspection

8Input/Output Signal Line Cautions

7Grounding Cautions

6Power Supply Cautions

When dirt collects on the surface or the frame of the display, soak a soft cloth in

water with a neutral detergent, wiring the cloth tightly, and wipe the display.

• Do not use paint thinner, organic solvents, or strong acid com-

pounds to clean the unit.

• Do not use hard or pointed objects to operate the touch-screen

panel, since it can damage the panel surface.

*1 Use a grounding resistance of 100

Ω

, a cord diameter should be 0.2 to 2.5 mm2 , or your

country's applicable standard.

10 Backlight

• The ST unit's backlights cannot be replaced by the customer. When the back-

lights need to be replaced, please contST403-AG41-24Vact your local ST dis-

tributor.

E-16

Note

Be aware that the Digital Electronics Corporation shall not be held liable for any real or

estimated damages or losses, or third party claims resulting from the use of this product.

©2005 Digital Electronics Corporation

This manual suits for next models

4

Table of contents