3

3.

1

3.2

3.2.1

3.3

4

4.

1

4.2

4.2.1

4.2.2

4.3

4.4

4.5

4.6

4.7

4.8

5

5.

1

5.2

5.3

5.3.1

5.3.2

5.4

Figure

1-1

1-2

1-3

1-4

1-5

DECTAPE

TRANSPORT

TU55

CON

TEN

TS (Continued)

OPERATION

.•••.•..••..•••••...•.•••.•.••••.••.•..•...

'

..•..•........

Introduction

....•.•...•...••.•....................•.

'

..........•...

Controls and Indicators

...•..........•....••......•........•........

Operating

Notes

....•.•....•..••.•.•....•..••...•..•••..•.....

Loading Tape

........•.......••.•.•.•........•.•..•.......•..•...•

MAINTENANCE

•..•....•..•.........••...••.............•.•......••..

Equipment Required

•.•.•..••...•..•..••••.•..•...•.•.•

','

••..••••..•

Preventive

Maintenance

•••••••.•.••..•..•.•.•......•..•..•.•..•....

Weekly Schedule

...•.•...•••......•.....•.•...••..•..•.•...•..

Monthly Schedule

..•.••.••••.••.•..••...••...•................

Tape Tension and Transport Stop

Ad

justment

.•••.•.•.•.•.•.•.•..•..•.•.

Head

Output

Check

..•..•••••.••.•...•.••..•.••••.••.•..••.••••.•.

Head-Skew

Check

..•.•••..••••.••••....•.••..•.••••••••.•.•.•..••.

WRITE

ENABLE

Circuit

Check

.••••••..•.••..••.•.••.••...••.••••..••

Troubl eshooti

ng

••.••.•..•••••••.•...•.••.•...•.••••...•...•.•..•..

Recommended Spares

..•.••••••••••.•..•.•••••••••.•.•.•..•••..•••••

ENGINEERING DRAWINGS

••.•••••.••••••.•..••••..•.••••.••••..•••••.

Introduction

.•••••••••••••••••••.•••..••••••••.••.•.••...••••••.••

Circuit Symbols

......•.•........•.•......•....••..•.•.••..••••.•••

Logic Signal Symbols

..•.•.••.••.••.•..••.•••.•.•..•....•........•.

Logic Levels

.•..•..•..•.•..••••.•....•••....•......•..••......

FLIP

CH

IP

Pulses

.•..••••••..•••..••••••••.•••••••.•....•••....

Semiconductor Substitution .........................................

ILLUSTRATIONS

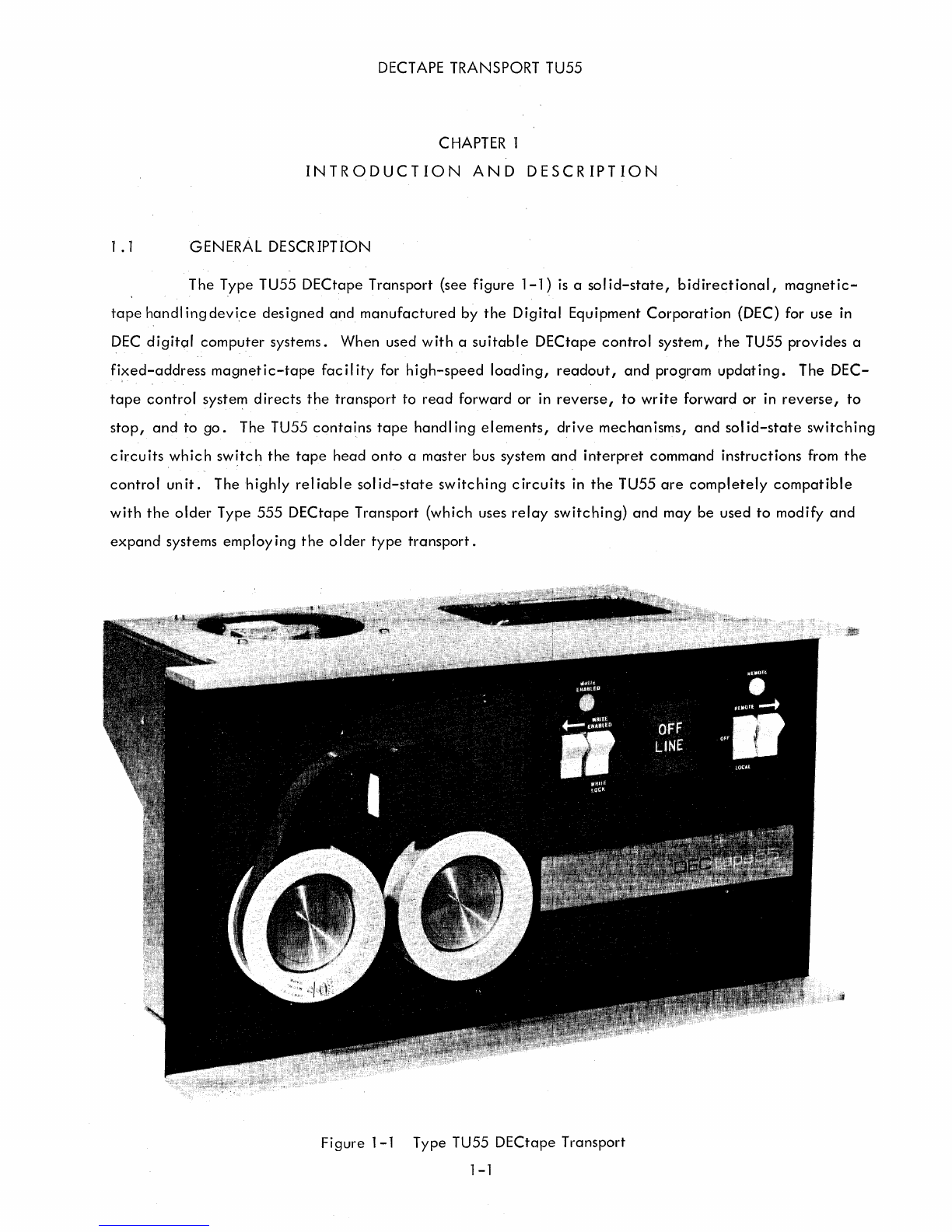

Type

TU55

DECtape Transport

••.•.•.••••..•...•••.•..••...•.••..•..•.•..

Hub and

Reel

Assembly

......................•..........................

Arrangement

of

DEC

tape

Head

.••••.••...•••....•...•....•.•.••..••.....

Type

TU55

DECtape TransportI Rear View

.•••••..•.•••.•••...•.......•.••.

TU55 Interface Connections

.•....•••.•••••.•••..••.••••.•••••••.•.•.••••

iv

Page

3-1

3-1

3-1

3-1

3-1

4-1

4-1

4-1

4-1

4-2

4-2

4-3

4-4

4-5

4-6

4-7

5-1

5-1

5-1

5-1

5-1

5-1

5-4

1- 1

1-5

1-6

1-7

1-8