Digital Identification Solutions EDIsecure X ID 8300 User manual

XID 8300

Retransfer

Printer

Instruction

Manual

•

Thank for purchasing this product.

•

Please read this manual carefully before use to ensure correct operation.

It is particularly important to read the Safety Precautions for safe operation. After

reading, retain this manual carefully for future reference.

•

The product number is important for quality control. Upon purchase, check the back of

the unit to make sure that the product number is correctly displayed.

Notes about this manual

(1)This manual may not be reprinted in any way without permission.

(2)The contents of this manual, as well as the specifications and design of this product,

may change without notice.

(3)The illustrations used in this manual may differ slightly from the actual product.

Before Use

2

About this Manual

● "Contents of this manual"

A

page 3

● "How to read this manual"

A

page 3

Precautions

● "Safety precautions"

A

page 3

● "Precautions during use"

A

page 4

Disclaimer

● "Disclaimer"

A

page 6

Name and functions of parts

● "Internal mechanism diagram"

A

page 6

● "Front"

A

page 7

● "Rear"

A

page 7

● "Right"

A

page 7

● "Left"

A

page 7

● "When printer door is open"

A

page 7

● "Ink ribbon cassette"

A

page 8

● "Retransfer film cassette"

A

page 8

Specifications

● "Main specifications"

A

page 9

● "Outline dimensional drawing"

A

page 9

Accessories/separately sold items

● "Accessories"

A

page 9

● "Sold separately"

A

page 9

Options

● "Functions"

A

page 10

● "Options"

A

page 10

Contents

Before Use

Contents .................................................................................. 2

About this Manual ................................................................... 3

Precautions ............................................................................. 3

Disclaimer ............................................................................... 6

Name and functions of parts ................................................... 6

Specifications .......................................................................... 9

Accessories/separately sold items .......................................... 9

Options .................................................................................. 10

Operation

Operation Panel .................................................................... 10

Setting Mode ......................................................................... 12

Setting Mode Flow ............................................................. 13

Setting using the operation panel .......................................... 16

Printing a Card ...................................................................... 25

Replacement

Precautions on cards ............................................................ 25

Ink Ribbon ............................................................................. 26

Retransfer Film ...................................................................... 29

Maintenance

Servicing of Parts .................................................................. 32

Servicing Based on Print Output ........................................... 41

Troubleshooting?

When an Error Message is Displayed ................................... 41

Precautions on cards ............................................................ 43

Ink Ribbon ............................................................................. 49

Retransfer Film ...................................................................... 49

Unable to produce desired printing results ............................ 50

Printer not operating as desired ............................................ 50

Before sending printer for repair ........................................... 51

Setup

Installation and Connection ................................................... 51

Printing Media ....................................................................... 52

Printer and Computer Connection ......................................... 56

Printer Setting ....................................................................... 57

Operation Panel ................................................................. 57

Setting using the operation panel ...................................... 57

List o Error Codes ……………………................................. 58

Before Use

3

About this Manual

Contents of this manual

● The copyright of this manual belongs to DIS. Reprint and duplicate of

this manual in part or full without the prior consent of DIS is strictly pro-

hibited.

● Windows is the registered trademark of Microsoft Corporation in the

United States.

● Product names of other companies described in the manual are the

trademarks or registered trademarks of the respective companies.

Symbols such as

E

, T, and

R

are omitted in this manual.

● Designs, specifications, or other details described in this manual may

be modified for improvement without prior notice.

How to read this manual

● Information in this frame is for reference purposes, such as information

on functions and usage restrictions.

● Precautions are described in this frame.

● Click this frame to display the details page.

● Click this icon to return to the top page.

● Click this icon to open the PDF file for printing.

● The 「Adobe Reader」 application is needed to browse the PDF file.

Precautions

Safety precautions

● Please read through all the following items before using the

printer.

Graphical symbols

Warnings

Before Use

4

Caution

Precautions during use

● Please read through all the following items before using the

printer.

Handling instructions

● Pay careful attention of the following when handling a printing media

(retransfer film or ink ribbon) or card.

Before Use

5

● Using a deformed or scratched card may cause card feed er-

rors.

● Touching the printing surface of the printing media or card di-

rectly with your hand may cause the print to turn out uneven.

● Foreign particles attached to the printed areas may result in

printing voids. Attach the printing media in a clean environ-

ment.

● Use of electrically-charged printing media or cards may cause

printing errors. Do not allow static to occur, such as due to

cards rubbing against each other.

● When replacing or replenishing a printing media or card that is

stored under a low temperature, use after leaving the media or

card at the operating ambient temperature of the printer for at

least one hour.

Otherwise, condensation may occur, causing printing errors or

malfunction of the printer.

Storage

Storage instructions

● The storage conditions of the printing media (retransfer film or

ink ribbon) and card have a significant effect on the printing

quality. Store the printing media or card in one of the following

locations.

Storage environment

● Temperature: 5

7

C to 25

7

C

● Relative humidity: 40 % to 60 %

Storage location

Do not store the printing media or card in the following locations.

Doing so may cause the media or card to deteriorate.

● Places exposed to direct sunlight.

● Places with a high humidity.

● Places near organic solvents or diazo copiers.

Storage period

● Use the printing media (retransfer film or ink ribbon) within half

a year after purchase. For details on the cards, please consult

our authorized dealers.

Printer Installation

● When the printer is not in use, it is recommended that you turn off the

power, and cover it with a plastic sheet.

● Do not place the printer unit in the following locations. Doing so may

have adverse effects on the printer.

● Carpeted room.

● Places with a busy flow of people.

● Places where paper (corrugated boards, etc.) is handled or stor-

ed.

● Places near photocopiers.

● Places exposed to direct sunlight or near a heating equipment

(such as a stove).

● Inclined or unstable surfaces.

● Places exposed directly to cold air, such as near an air-condi-

tioner outlet, or places subject to high temperatures.

Precautions on retransfer films/ink ribbons

● Put on the supplied gloves when handling the retransfer film/ink ribbon.

Direct contact of your hand with the printing surface may result in print-

ing errors.

When retransfer film/ink ribbon is dismantled

● Winding misalignment may occur. If an improperly wound re-

transfer film/ink ribbon is installed, the resulting color may vary,

or errors may occur.

When attaching the retransfer film/ink ribbon

● Use your hands to adjust the media at the supply and take-up

sides so that they are parallel to each other.

When doing so, make sure you do not touch the printing sur-

face.

● Refer to the label adhered to the cassette for alignment of the

screen position. Printing errors may occur if the position is not

properly aligned.

During transport or moving

● Make sure to set to the transport mode.

"Transport mode setting"

(

A

page 24)

Precautions on cards

Handling and storage of cards after printing

Avoid storing cards at places that are exposed to direct sunlight

or subject to high temperatures and humidity.

Discoloration or fading may occur if a card comes into contact

with the following chemicals or stationery.

● Organic solvents, including alcohol, film cleaner, or diazo cop-

ies.

● Files, document cases, pass holders, or erasers made of flexi-

ble polyvinyl chloride.

● Hair wax or cosmetic products.

Card types

Thin cards and certain card materials may not be suitable for

printing using this printer. For details on the card material to use

and other specifications, please consult our authorized dealers in

advance.

Note:

● If the card thickness is not properly adjusted, printing error or

printer malfunction may occur.

"Adjusting Card Thickness"

(

A

page 55)

When a card is jammed inside the printer

Cards may not be discharged correctly such as when the retrans-

fer setting for the card is inappropriate.

Stop using and remove the jammed cards immediately. Otherwise,

you may have problems removing the cards, and fire or electric

shock may also occur as a result.

● When a card jam occurs, make use of the jog dial to remove the

jam.

● If the card cannot be removed, consult a servicing personnel or

our authorized dealers.

Before Use

6

Disclaimer Name and functions of parts

Internal mechanism diagram

① Card feeder unit

● This is the roller for feeding cards. Each of the feed rollers needs to

be cleaned daily.

② Warpage correction heating roller

● Some types of cards may warp. Adjust accordingly until warpage is

eliminated. Set using the host computer.

③ Retransfer heating roller

● You can adjust the temperature and retransfer time for some retrans-

fer films and cards. Set using the host computer.

④ Non-contact IC encoder

● You can adjust the position to stop the card when a non-contact IC

card is used. Set using the host computer.

⑤ Contact IC

● You can adjust the position to stop the card when a contact IC card

is used. Set using the host computer.

⑥ Magnetic encoder

● You can select the coercivity when writing data to the magnetic stripe

card. Set using the host computer.

⑦ Card turnover unit

● Inverts the card.

⑧ Cleaning roller

● Removes any dust or dirt attached to the card. The cleaning roller

needs to be cleaned daily.

⑨ Card hopper

● For loading cards.

⑩ Retransfer film (take-up side)

● For attaching the take-up side of the retransfer film.

⑪ Retransfer film (supply side)

● For attaching the unused side of the retransfer film.

⑫ Ink ribbon (take-up side)

● For attaching the take-up side of the ink ribbon.

⑬ Thermal head

● The thermal head is a consumable part. For details on its replace-

ment, please consult our authorized dealers.

⑭ Ink ribbon (supply side)

● For attaching the unused side of the ink ribbon.

⑮ NG card outlet

● Discharges NG cards, such as during card jams.

Before Use

7

Front

① Operation buttons

● For selecting and confirming information on the operation panel.

② Operation panel

● Displays menus and error messages.

③ Sliding knob

● Opens/Closes the printer door.

● Slide it upward, and pull toward you to open the printer door.

④ Card hopper

● For loading cards.

⑤ Printer door

⑥ Power switch

● Turns the power On/Off.

Rear

① USB cable connection terminal

● For connecting a USB 2.0 interface cable.

② LAN cable connection terminal

● For connecting an Ethernet interface cable.

③ Cable clamp

● For securing the supplied USB cable.

"Connection"

(

A

page 56)

④ [AC INLET] power supply terminal

● For connecting the power cord.

Right

① NG card outlet

● If a card is left inside the printer when the power is turned on or re-

set, the card will be automatically discharged.

● Cards in the printer are discharged when an error occurs on the

magnetic card or IC card.

② Air suction fan opening

● This is the air inlet for the internal cooling fan.

③ Filter cover

● This is the cover of the fan filter.

④ Security slot

● For attaching the Kensington lock.

Left

① Card outlet

● Outlet for discharging the cards.

② Card stacker (supplied) attachment slot

● For attaching the supplied card stacker.

When printer door is open

① Cassette buttons

● Press these buttons in order to pull out the ink ribbon cassette or re-

transfer film cassette.

② Cleaning unit

● Removes any dust or dirt attached to the card.

③ Ink ribbon cassette

Before Use

8

● For attaching the ink ribbon.

④ Jog dials

● When there is card jam in the cleaning unit, turnover unit, or retrans-

fer unit, detach the jog dial from the printer body, and attach it ac-

cordingly to turn the rollers of the corresponding parts.

⑤ Retransfer film cassette

● For attaching the retransfer film.

Ink ribbon cassette

① Guide shaft

● Provides guide to the position for attaching the cassette.

② Shafts

● When attaching an ink ribbon, unwind it along the shafts.

③ Bobbin holder (black)

● For securing the take-up side of the ink ribbon.

④ Bobbin holder (yellow)

● For securing the unused side of the ink ribbon.

Retransfer film cassette

① Bobbin holder (black)

● For securing the take-up side of the retransfer film.

② Guide shaft

● Provides guide to the position for attaching the cassette.

③ Shafts

● When attaching a retransfer film, unwind it along the shafts.

④ Bobbin holder (green)

● For securing the unused side of the retransfer film.

Before Use

9

Specifications

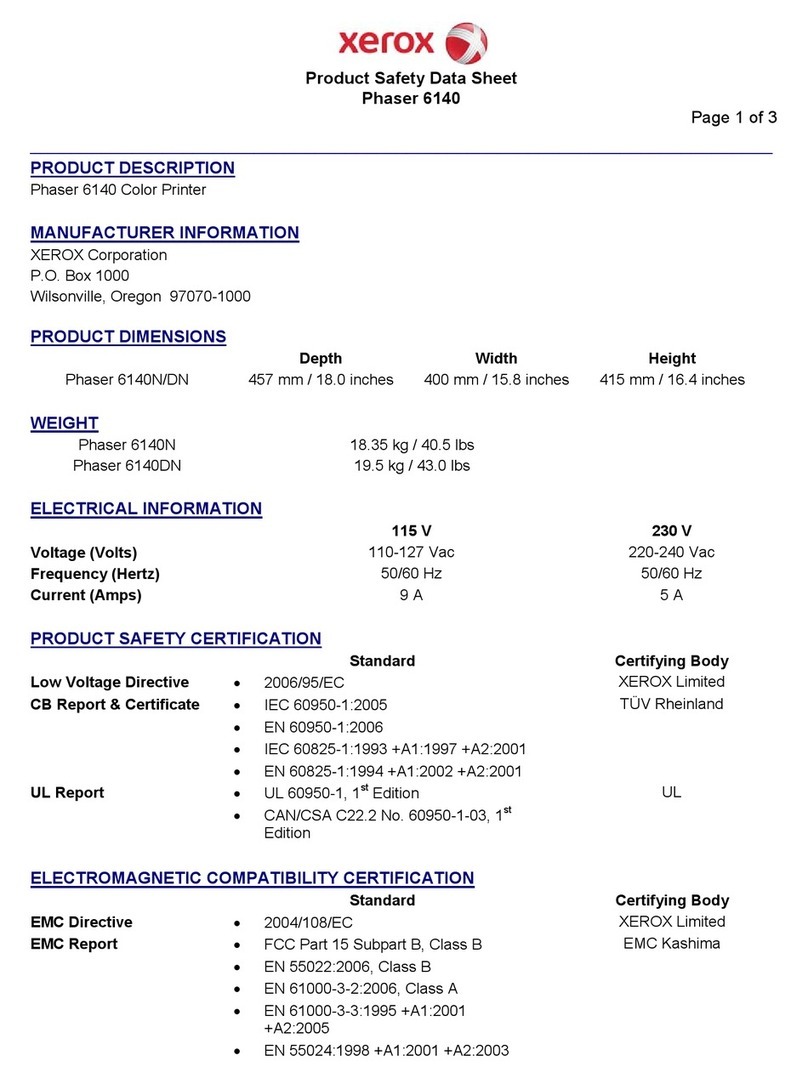

Main specifications

Item Description

Recording system Dye sublimation retransfer

Paper feed mode Automatic

Recording density 300 dpi

Reproduction gradation 256 levels each for Y, M and C: 2 levels for Bk

Interface USB 2.0 (Hi-Speed/Full-Speed)

Interface Ethernet(100BASE-TX/10BASE-T)

Operating environment conditions Temperature between 15

7

C and 30

7

C

Temperature between 17

7

C and 28

7

C (When using peel-off ink)

Operating environment conditions No condensation

Humidity between 35 % and 70 %

Humidity between 35 % and 60 % (When using peel-off ink)

Storage environment conditions Temperature between -15

7

C and 55

7

C

Storage environment conditions Humidity between 20 % and 80 %

Power supply AC 100 V - 120 V/AC 220 V - 240 V(tolerance:

5

10 %) 50 Hz/60 Hz (

5

5 %)

Current consumption 3.5 A (100 V system)

Power consumption 310 W (max.)

Mass (Standard) approx. 13.9 kg (excluding optional built-in items)

Dimensions (cm) 343 mm x 360 mm x 322 mm (W x H x D)

Outline dimensional drawing

Accessories/separately sold items

Accessories

Please check to ensure that the printer accessories are in place

when unpacking the product package.

● CD-ROM x 1

● Getting started guide x 1

● Read Me First(LST1013) x 1

● Power Cord (2 m) x 2

● Cleaning Card x 1

● Card Stacker x 1

● USB 2.0 Cable: QAM1196 (2 m) x 1

● Gloves x 1 Pair

Products sold separately

To purchase these items, please consult our authorized dealers.

● Ink Ribbon (YMCK), 1,000 frames/roll (Model: DIC10216)

● Ink Ribbon (YMCKK), 750 frames/roll (Model: DIC10217)

● Ink Ribbon (YMCK-PO), 750 frames/roll (Model: DIC10218)

● Ink Ribbon (YMCK-UV), 750 frames/roll (Model: DIC10313)

● ART Retransfer Film, 1,000 frames/roll (Model: DIC10319)

● Cleaning Kit (Model: DIK10044)

Set incl. 10 print head cleaning swabs, 10 cleaning tissues for

rollers and 10 special cleaning cards

● Magnetic Stripe Encoder Head Cleaning Cards (Model:

DIC10311)

Box of 10 cards

Before Use

10

Options

Functions

● Double-sided printer

Printer that supports double-sided printing.

● Single-sided printer

Printer that supports single-sided printing.

Options

● Warpage correction

Device for correcting card warpage after printing.

● Magnetic encoder

Device for writing data to a magnetic stripe card.

Installation is applicable only for double-sided printer.

● Contact IC encoder

Device for writing data to a contact IC card.

● Non-contact IC encoder

Device for writing data to a non-contact IC card.

Operating the printer

● "Operation Panel"

A

page 10

● "Setting using the operation panel"

A

page 16

● "Printing a Card"

A

page 25

Operation Panel

Name and functions of parts

① Operation panel

● Displays the mode settings, operating status, and error messages.

② Status icon/operation button display

● Displays the status icon or the function of the operation button during

mode setting.

③ Operation buttons

● For selecting the operation button displayed on the operation panel.

Operation buttons

Resets the printer.

● After clearing an error, press in the order of [Reset]

DB

.

Displays the setting mode mode.

Exits setting.

Displays the setting mode in the next lower level.

Confirms or executes a setting.

● The display does not change if an item cannot be altered using the op-

eration panel.

Pressing it each time displays the next setting item.

Pressing it each time displays the next setting value.

Displays the settings change mode.

● If [Change] is not displayed for an item, you can adjust the settings

on the status monitor of a PC.

Displays the scroll mode for the displayed characters.

11

Operation

Scrolls to the next displayed character on the left.

Scrolls to the next displayed character on the right.

Operation Panel Display

USB connection

● IP address established

Printer information can be viewed through the network. However, printing

is performed through USB connection.

● IP address not established

Network connection

● IP address established

● IP address not established

Security status

● Locked

● Unlocked

Operation panel operation display

Starting up

Initializing

Preheating

Ready

Printing

Loading

Encoding

Adjusting heat roller to the preset temperature

Retransferring

Cleaning

Heater OFF

1

2

Operation

Setting Mode

● Settings can be viewed on the printer’s operation panel.

● Settings can be changed on the status monitor of the computer.

"Setting using the operation panel"

(

A

page 16)

Cleaning

● For setting during cleaning of the card feed roller or magnetic head.

Setting values

● Rollers

Select this value when cleaning the card feed roller.

● MG

Select this value when cleaning the magnetic head.

Counter Reset

● Resets the free counter and error counter.

Test Print

● Prints the printer’s built-in test pattern, or the different setting values.

● When system troubles occur, printing can be performed using settings

on the printer or computer by operating only the printer.

Setting values

● Test Print: Test Pattern, Printer Setting, Network, Lami Setting

Down load

● Updates the firmware.

Transport Mode

● For setting the transport mode.

Media

● Displays the settings of the printing media.

Setting values

● Ink Type: YMCK, YMCKPO, YMCKK, YMCKUV

Set according to the type of ink ribbon.

● Film Type: 1000, 750

Set according to the type of retransfer film.

● Card Thickness: Standard, Thin

Set according to the thickness of the card.

Standard: Supports card thickness of 0.76 mm

Thin: Supports card thickness of 0.25 mm

Print

● Displays the printing settings.

Setting values

● YMC Level: -3, -2, -1, 0, 1, 2, 3

For setting the YMC (color) concentration level.

Selecting a larger value increases the concentration level.

● Black Level: -3, -2, -1, 0, 1, 2, 3

For setting the K(Black) concentration level.

Selecting a larger value increases the concentration level.

● Black Mode: Standard, Fine

For setting the K(Black) printing mode.

If the characters still appear faded after raising the [BlackLevel],

set to [Fine].

However, printing time required will be longer than the [Stand-

ard] setting.

● UV Level: -3, -2, -1, 0, 1, 2, 3

For setting the UV ink concentration level.

Selecting a larger value increases the concentration level.

During UV printing, card warpage may increase if the card has a

low heat resistance or under an environment with high tempera-

ture.

● PO Level: -3, -2, -1, 0, 1, 2, 3

For setting the concentration level of the peel-off ink.

Selecting a larger value increases the concentration level.

Retransfer

● Displays the retransfer mode settings.

Setting values

● Temp Level: -2, -1, 0, 1, 2

For setting the retransfer roller temperature.

Selecting a larger value increases the temperature.

Retransfer may fail depending on the card used. If retransfer fails,

raise the setting to the next higher value.

A higher retransfer roller temperature helps to enhance card re-

transfer, but the stronger heat may also cause the card to deform.

If the printer is not initialized after changing the temperature set-

ting, temperature is adjusted after the printing operationstarts.

● Speed (Front): -3, -2, -1, 0, 1, 2

For setting the surface retransfer speed.

Selecting a larger value increases the speed.

Retransfer may not be successful for some parts of thecard de-

pending on the card used. Lowering the setting value helps to en-

hance retransfer, but the stronger heat may also cause the card to

deform.

● Speed (Back): -3, -2, -1, 0, 1, 2

For setting the rear surface retransfer speed.

Selecting a larger value increases the speed.

Some types of cards may warp during double-sided printing. If

card warpage occurs, raise the setting to the next higher value.

● MG Peel Mode: Standard, MG Stripe

For setting the method for peeling the retransfer film.

● Standby Mode: Front wait, Back wait

For setting the laminator standby position.

Select whether to standby at the front or rear surface during dou-

ble-sided printing.

Bend Remedy

● Displays the warpage correction mode settings.

Setting values

● Temp Level: -5, -4, -3, -2, -1, 0, off

For setting the warpage correction roller temperature.

Selecting a larger value increases the temperature.

If the printer is not initialized after changing the temperature set-

ting, temperature is adjusted after the printing operationstarts.

● Speed: -2, -1, 0, 1, 2

For setting the warpage correction mode speed.

Selecting a larger value increases the speed.

Heat Roller

● Displays the settings of the power save mode or low temperature

standby mode.

Setting values

● Power Saving: 5 mins, 10 mins, 15 mins, 20 mins, 25 mins,

30mins, 45 mins, 60 mins, off

For setting the time of the power save mode.

While in the [Ready] mode, if the printer is not operated during a

specific time interval, the retransfer roller, warpage correction

roller, and backlight of the operation panel are turned off to save

power.

● HR Control: Off, On

1

3

Operation

For setting whether to standby the printer by lowering the retrans-

fer heat roller temperature if cards are not issued for 30 minutes

or longer.

The printer will automatically restored to the original mode during

the next card issuance, but it may take a longer time before the

first card is printed. Set this to On during normal use.

Setting

● Displays the printer settings.

Setting values

● Display:

Mode: Counter

Counter: Total Cnt, Head Cnt, Free Cnt, Cleaning Cnt, Error Cnt

Contrast: -3, -2, -1, 0, 1, 2, 3

For setting the display status the operation panel.

● Buzzer: On, Off

For setting whether to sound the buzzer when an error occurs or

when settings are changed.

● Unit No: No.1 to No.10

For setting the printer’s unit number according to the USB envi-

ronment.

Option

● Displays the optional settings.

Setting values

● MG: None, ISO

Displays the availability of a magnetic encoder or the type of en-

coder used.

● IC Antenna: None, Installed

Displays the availability of a non-contact IC encoder.

● IC Contact: None, ISO Type

Displays the availability of a contact IC encoder or the type of en-

coder used.

● Contact IC R/W: None, Installed

Displays the availability of an IC contact.

● Bend Remedy HR: None, Installed

Displays the availability of a warpage correction heat roller.

● Turn Over: None, Installed

Displays the availability of retransfer unit.

MG

● Displays the coercivity settings.

Setting values

● ISO Type: Loco, Hico

For setting the coercivity when writing data to an ISO magnetic

stripe card.

● Retry Count: 0, 1, 2, 3

For setting the number of retries during data writing.

Network

● Displays the network settings.

Setting values

● Printer Name: ASCII character strings (10 characters)

For setting the printer name.

● Host IF: LAN, USB

For setting the interface.

If the printer is connected via USB interface, the setting switches

automatically to the USB setting even if it is set to LAN during ini-

tialization.

● [@TREX[OSD::]IPv4:

DHCP: On, Off

Setting: IP Address, Subnet Mask, Gateway

Efective IP: IP Address]

For setting IPv4.

● [@TREX[OSD::]IPv6:

Adrs Config: Auto, Manual

Setting: IP Address, Prefix Len, Gateway

Efective IP: IP Address1, IP Address2, IP Address3]

For setting IPv6.

● Session Time Out: Off, 10 mins, 20 mins, 30 mins, 60 mins

For setting the session timeout interval.

● MAC Address: Hexadecimal character strings

Displays the MAC address.

● IP Sec Mode: Off, On

For setting the availability of IP Sec.

● IP Sec Type: not Setting, Preshard, Certificate

Displays the method for IP Sec verification.

Setting Mode Flow

● Settings can be viewed on the printer’s operation panel.

● Settings can be changed on the status monitor of the computer.

1 Press [Menu]

● A setting item appears.

2 Press [Next]

● Pressing it each time displays the next setting item.

● Pressing [Enter] or [Change] displays the setting value.

● Pressing [Next] or

A

displays the next setting value.

● Pressing [Exit] displays the setting mode of the next higher level.

1

4

Operation

15

Operation

1

6

Operation

Setting using the operation panel

Initialization

● Whenever the power is turned on, cue (initialization) is per-

formed automatically on the ink ribbon and retransfer film.

● You can also perform initialization using the operation button

on the operation panel.

1 Press [Reset]

● A [Initialize] message appears.

2 Press

B

● An [Initializing] message appears, and initialization of the printer starts.

Initializing printer when attaching the cassette

Memo:

● When detaching the ink ribbon cassette or retransfer film cassette from

the printer body, dust may adhere to the ink ribbon or retransfer film.

Printing errors such as discoloring and retransfer error may occur de-

pending on the size of the dust particles.

To prevent printing errors from occurring, initialize the printer when you

attach the cassette.

● When attaching a new retransfer film, it is recommended that you for-

ward the film by one or two images before printing.

1 Turn on the power.

2 Check to ensure that [Ready] or [Preheating] is displayed on the

operation panel of the printer.

3 Press [Reset]

● A [Initialize] message appears.

Initializing printer without feeding the image

① Press

B

● An [Initializing] message appears, and initialization of the

printer starts.

Initializing printer after feeding by one image

① Press [Next]

17

Operation

● A [Next Panel, OK?] message appears.

② Press

B

● An [Initializing] message appears, and the printer is initialized

after feeding the ink ribbon and retransfer film by one image.

Initializing printer after feeding by two images

① Press [Next]

● A [2'nd Panel, OK?] message appears.

② Press

B

● An [Initializing] message appears, and the printer is initialized

after feeding the ink ribbon and retransfer film by two images.

Firmware update

1 Press [Menu]

● A [Cleaning] message appears.

2 Press [Next] to set to [Down load]

● Pressing the [Next] button each time displays the next screen.

3 Press [Enter]

● Data download from the host computer starts.

● A [Downloading] message during data download from the host com-

puter.

Note:

● Do not turn off the power during data download from the host comput-

er.

Doing so may damage the printer firmware and cause malfunction.

● A [Please Power Off] message when data download from the host

computer is complete.

1

8

Operation

4 Press [Exit]

● Pressing [Exit] each time returns you to the previous screen.

Counter setting

● This is used for setting the type of counter displayed on the operation

panel.

Counter types

● Total Cnt: total counter

Displays the total number of cards that are correctly printed.

● Head Cnt: Head counter

Displays the total number of printed sides for the same head.

● Free Cnt: free counter

Displays the number of cards that are correctly printed. This num-

ber can be reset.

● Cleaning Cnt: Cleaning counter

Displays the number of cards that are correctly printed. This num-

ber can be reset.

● Error Cnt: Error counter

Displays the number of cards that are not correctly printed. This

number can be reset.

1 Press [Menu]

● A [Cleaning] message appears.

2 Press [Next] to display [Setting]

● Pressing the [Next] button each time displays the next screen.

3 Press [Enter]

● A [Display] message appears.

4 Press [Enter]

● A [Mode] message appears.

19

Operation

5 Press [Next]

● A [Counter] message appears.

6 Press [Change]

● A setting change screen appears.

7 Press

A

and select a setting value.

8 Press

B

to confirm the setting value.

● Pressing

B

confirms the setting and returns you to the previous

screen.

9 Press [Exit]

● Pressing [Exit] each time returns you to the previous screen.

20

Operation

Resetting the counter

● Resets the free counter and error counter.

1 Press [Menu]

● A [Cleaning] message appears.

2 Press [Next] to set to [Counter Reset]

3 Press

B

● Resets the free counter and error counter.

Checking reset

● Select [Free Cnt] or [Erorr Cnt] under [Counter setting].

Test print

● Prints the printer’s built-in test pattern, or the different setting values.

● When system troubles occur, printing can be performed using settings

on the printer or computer by operating only the printer.

Test types

● Test Pattern:

Prints color patterns on a single side of a card.

● Printer Setting:

Prints according to the values preset in the setting mode.

● Network:

Prints according to the values preset through the network.

● Lami Setting:

Prints according to the values preset in the laminator’s user

mode.

1 Press [Menu]

● A [Cleaning] message appears.

2 Press [Next] to display [Test Print]

3 Press [Change]

● A [Test Pattern] message appears.

4 Press

A

and select a test type.

5 Press

B

● Test print starts.

Contrast setting

● This is used for setting the contrast of the operation panel display.

Setting values

-3, -2, -1, 0, 1, 2, 3

● Selecting a larger value increases the contrast.

1 Press [Menu]

● A [Cleaning] message appears.

2 Press [Next] to set to [Setting]

● Pressing the [Next] button each time displays the next screen.

Table of contents

Other Digital Identification Solutions Printer manuals

Digital Identification Solutions

Digital Identification Solutions DCP360i User manual

Digital Identification Solutions

Digital Identification Solutions EDIsecure DCP 240 User manual

Digital Identification Solutions

Digital Identification Solutions EDI secure XID580i User manual

Digital Identification Solutions

Digital Identification Solutions XIDi User manual

Digital Identification Solutions

Digital Identification Solutions XID8300-DS User manual

Digital Identification Solutions

Digital Identification Solutions XID 8300 User manual

Digital Identification Solutions

Digital Identification Solutions EDIsecure XID5xxie User manual