DIGITEN DTC-101 User manual

Manual Index

Features·························································································1

Technical Specications·····································································1

Panel Instructions·············································································2

View Setting Parameters····································································2

Setting Instructions ······································································3

How to change temperature unit ·····················································3

Setup Flow Chart ········································································ 3

Setting the RUN temperature(RV) and STOP temperature(SV) ·············3

Setting Other Functions ································································3

For example ···············································································4

Function range and setting ·································································4

Function Introduction ········································································5

Cooling Mode ·············································································5

Heating Mode ·············································································5

High/Low Temperature Alarm (AH/AL) ·············································5

Time of Compressor Delay Starting (DP)··········································5

Temperature Calibration (CA)·························································6

Display in Fahrenheit or Centigrade unit (CF) ····································6

LCD Backlight Control ·······································································6

Application······················································································6

Troubleshooting ···············································································7

Green LED ash when power on ·························································7

Err Alarm ························································································7

HL Alarm ························································································ 7

Heating and refrigeration equipment don’t work ······································7

WARRANTY····················································································8

WARNING ·····················································································8

-1-

The Thermostat is simple-stage, electronic temperature controller. The large,

lighted LCD screen display is easy to read. The case is designed with reproof

ABS material for human engineering. Temperature sensor is waterproof with

high quality, high-accuracy.

Features

●Large LCD screen

Display the sensed temperature, setting temperature, and custom icons on the

display indicate working mode.

●Support reading with Centigrade or Fahrenheit unit;

●Easy to use and program

Only 2-steps setting for your application, and plug and play design.

●With a temperature correction function

Allow user to adjust measuring accuracy base to on dierent probe, etc.

●Delay starting protection

Protect refrigerating compressor lifetime, avoid compressor to compressor

start frequently.

●High and low temperature alarms are available;

●Over-temperature and sensor fault alarm

Technical Specications

Temperature Control Range -40~120°C, -40~248°F

Temperature Resolution 0.1°C, 0.1°F

Temperature Accuracy ±1°C, ±1°F

Temperature Control Mode Heating and Cooling

Input Power 100~240VAC, 50/60Hz

Temperature Control Output Max.10A/15A, 100-240VAC

Maximum output load DTC-101, 1100W@110V, 2200W@220V;

DTC-151, 1650W@110V, 3300W@220V

Buzzer Alarm High and Low Temperature Alarm

Sensor Type Waterproof NTC sensor (Including)

Sensor Length 2m, 6ft

Relay Contact Capacity DTC-101(10A, 100-240VAC)

DTC-151(15A, 100-240VAC)

Input Power Cable Length 150 cm/5ft

Output Power Cable Length 18cm/7”

Note: The waterproof temperature sensor works with water, seawater, weak

acid or weak base liquid.

-2-

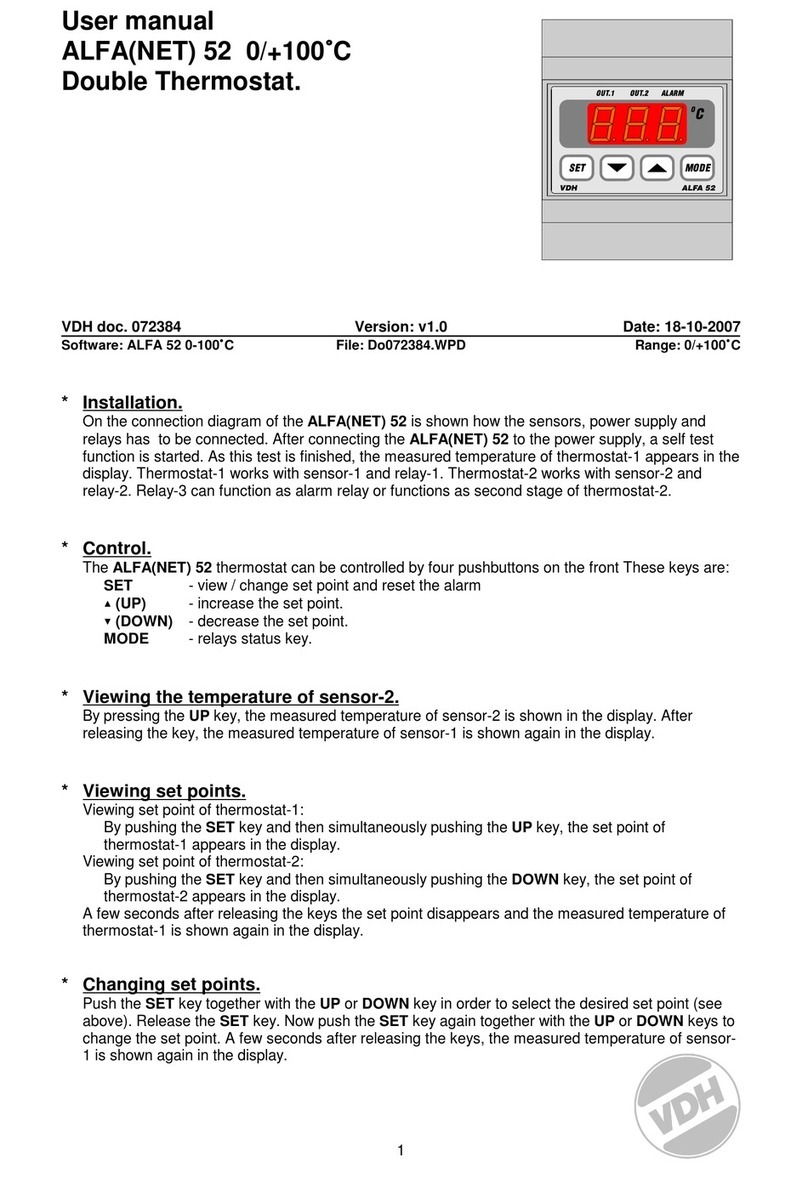

Panel Instructions

1. PV: Current Temperature.

2. RV: Run Temperature

3. SV: Stop Temperature

4. AH: High Temperature Alarm

5. AL: Low Temperature Alarm

6. DP: Time of Compressor Delay Starting

7. CA: Temperature Calibration

8. Mode: Cooling: Working Mode

9. Mode: Heating: Working Mode

View Setting Parameters

When the controller is working normally, short press SET and you can look at

the parameter values in order.

-3-

Setting Instructions

How to change temperature unit

To convert to Fahrenheit unit, press the and buttons simultaneously.

Press them again to return to Celsius unit.

Notice: When temperature unit has been changed, all the setting value will be

recovered to factory settings.

Setup Flow Chart

Setting the RUN temperature(RV) and STOP temperature(SV)

1. Long press the SET button until RV value “ ” ashing.

2. Press and to adjust the temperature value.

3. Press SET button to set SV “ ”.

4. Long press SET button to save and exit.

Note: If no entries are made for 30 seconds while programming is in progress,

the control reverts to the normal temperature display.

Setting Other Functions

To set Low temperature Alarm(AL), High temperature Alarm(AH),

Calibration(CA), Compressor Delay Starting(DP), use the method illustrated

-4-

and outlined below.

1. Long press the SET button until “

” ashing.

2. Press and to adjust the temperature value.

3. Press SET button to set next function.

4. Long press SET button to save and exit.

For example

User want to start cooling equipment when PV=28°C, and stop cooling

equipment when PV=22°C, DP=3 minutes.

1. Long press the SET button until “ ” ashing.

2. Press and to change the run temperature (RV) to 28°C.

3. Press SET button to set “ ” stop temperature (SV).

5. Press and to change the SV to 22°C.

6. Long press SET button to save and exit.

7. Connect the cooling equipment to the outlet.

How to restore default settings

Keep pressing SET key until connect the power to this device, controller

will restore factory setting after BI-BI-BI sound.

Function range and setting

CODE Function Setting Range Default Setting

RV Run Temperature Value -40~120°C 20°C

-40~248°F 68°F

SV Stop Temperature Value -40~120°C 40°C

-40~248°F 104°F

AH High Temperature Alarm -40~120°C 120°C

-40~248°F 248°F

AL Low Temperature Alarm -40~120°C -40°C

-40~248°F -40°F

DP Time of Compressor Delay

Starting 0~10minutes 0

CA Temperature Calibration -15~15°C 0°C

-15~15°F 0°F

-5-

Function Introduction

1.Cooling Mode

Set RV(RUN temperature) > SV(STOP temperature), the temperature

controller enter cooling mode. The LCD will display ,

When PV(measuring temperature) is higher than RV, the cooling

equipment starts working, and run LED will be turned on. When PV(measuring

temperature) reaches to SV(STOP temperature), the cooling equipment stop

working, and stop LED will be turned on.

Note: When run LED is flashing, it means the cooling equipment enter

compressor delay protection function.

2.Heating Mode

Set RV(RUN temperature) < SV(STOP temperature), the temperature

controller enter cooling mode. The LCD will display ,

When PV(measuring temperature) is lower than RV, the heating

equipment starts working, and run LED will be turned on. When PV(measuring

temperature) reaches to SV(STOP temperature), the heating equipment stop

working, and stop LED will be turned on.

3.High/Low Temperature Alarm (AH/AL)

When measuring temperature (PV) ≥ high temperature alarm value (AH),

high temperature alarm will be triggered, buzzer will alarm with tone “bi-bi-Biii”

, press any key to cancel the alarm sound, if user want to close alarm, please

reset the AH value or wait until the PV is lower than AH.

When measuring temperature (PV) ≤ low temperature alarm value (AL),

low temperature alarm will be triggered, buzzer will alarm with tone “bi-bi-Biii”

, press any key to cancel the alarm sound, if user want to close alarm, please

reset the AL value or wait until the PV is more than AL.

4.Time of Compressor Delay Starting (DP)

Under refrigeration mode, after power on, if the measuring temperature (PV)

is higher or equal to Run Temperature (RV), the cooling equipment won’t start

refrigeration immediately, but it will wait for a delay time(DP) to work.

When the time interval between two refrigeration operations is larger than

-6-

preset delay time, the equipment will start refrigeration immediately; when the

time interval between two refrigeration operations is less than preset delay

time, the equipment won’t start refrigeration until achieve the preset delay time.

Delay time will be recorded at the moment that refrigeration stops.

5.Temperature Calibration (CA)

When there is deviation between current temperature and actual temperature,

use temperature calibration function to correct the current temperature and

actual temperature. Corrected Temperature = Temperature (before Calibration)

+Corrected Value (corrected value could be positive value, 0 or negative

value).

6.Display in Fahrenheit or Centigrade unit (CF)

Users can select display with Fahrenheit or Centigrade temperature value

according to their own habit. Default setting is display with Centigrade

temperature value.

LCD Backlight Control

Press and SET buttons simultaneously about 3 seconds until the symbol

disappears, the LCD light will shut o automatically after 30 seconds.

Press and SET buttons simultaneously about 3 seconds until the LCD

appears , the LCD will be stay on.

Application

The thermostat can be used to control a wide variety of dual-stage refrigeration

and heating, or HVAC equipment. Typical applications include:

●Retail store display freezers and coolers

●Supermarket display cases for product/meats

●Retail store walk-in freezers and coolers

●Boiler operating control

●Condenser fan cycling or staging

●Cooling tower pump and fan control

●Space and return air temperature control

●Aquarium water temperature

●BBQ

●Over temperature control/protection

-7-

Troubleshooting

If you have a problem with thermostat, there’s usually a quick and simple

solution.

Green LED ash when power on

It is a normal phenomenon, Delay Starting Protection function for Refrigerating

Compressor is working. you could enter Setup Mode directly, or wait 3

minutes(base on DP setting value) until it doesn’t flash green light before

setting the temperature controller.

Err Alarm

When temperature sensor is in short-circuited or open-circuited, the controller

will prompt sensor fault mode, and the buzzer will alarm, and LED displays

Err. Buzzer alarm could be dismissed by pressing any key. After faults solved,

the system will return to normal working mode. So make sure that the sensor

is plugged into the hole fully, if it still displays Err, you can change another

sensor.

HL Alarm

When current temperature exceeds the measuring range (less than -40°C /-40°

F or higher than 120 °C/248 ° F), the controller will prompt over-temperature

alarm mode, and cancel all the actions. The buzzer will alarm, LED displays

HL. Buzzer alarm could be dismissed by pressing any key. When temperature

returns to measuring range, the system will return to normal working status.

Heating and refrigeration equipment don’t work

1.Please make sure the setting value is correct. If thermostat works ne, the

green LED(RUN) is on.

2.Please check if the loading is contacted reversely to heating or cooling

outlet.

If thermostat does not operate properly after trying the troubleshooting steps,

-8-

WARRANTY

The DIGITEN products are guaranteed to the original owner for one year

against defects in workmanship and materials. Please contact us:

www.digit-en.com/support

WARNING

Do Not Overload

This unit works with load up to 10A(DTC-101) / 15A(DTC-151). If load is larger

than rated value, it would become very hot even burn the thermostat. That is

very dangerous. It is best that the load is less than or equal to 7A(DTC-101)

/ 12A(DTC-151), if you require the temperature controller to work stably for a

long term.

The probe is waterproof, but controller is not waterproof, so don’t get water

into the controller and outlet.

COPYRIGHT 2020 DIGITEN CO., LTD ALL REIGHTS RESERVED

This manual suits for next models

1

Table of contents

Other DIGITEN Thermostat manuals