DigiWeigh A12 User manual

A12-51007 V1.0

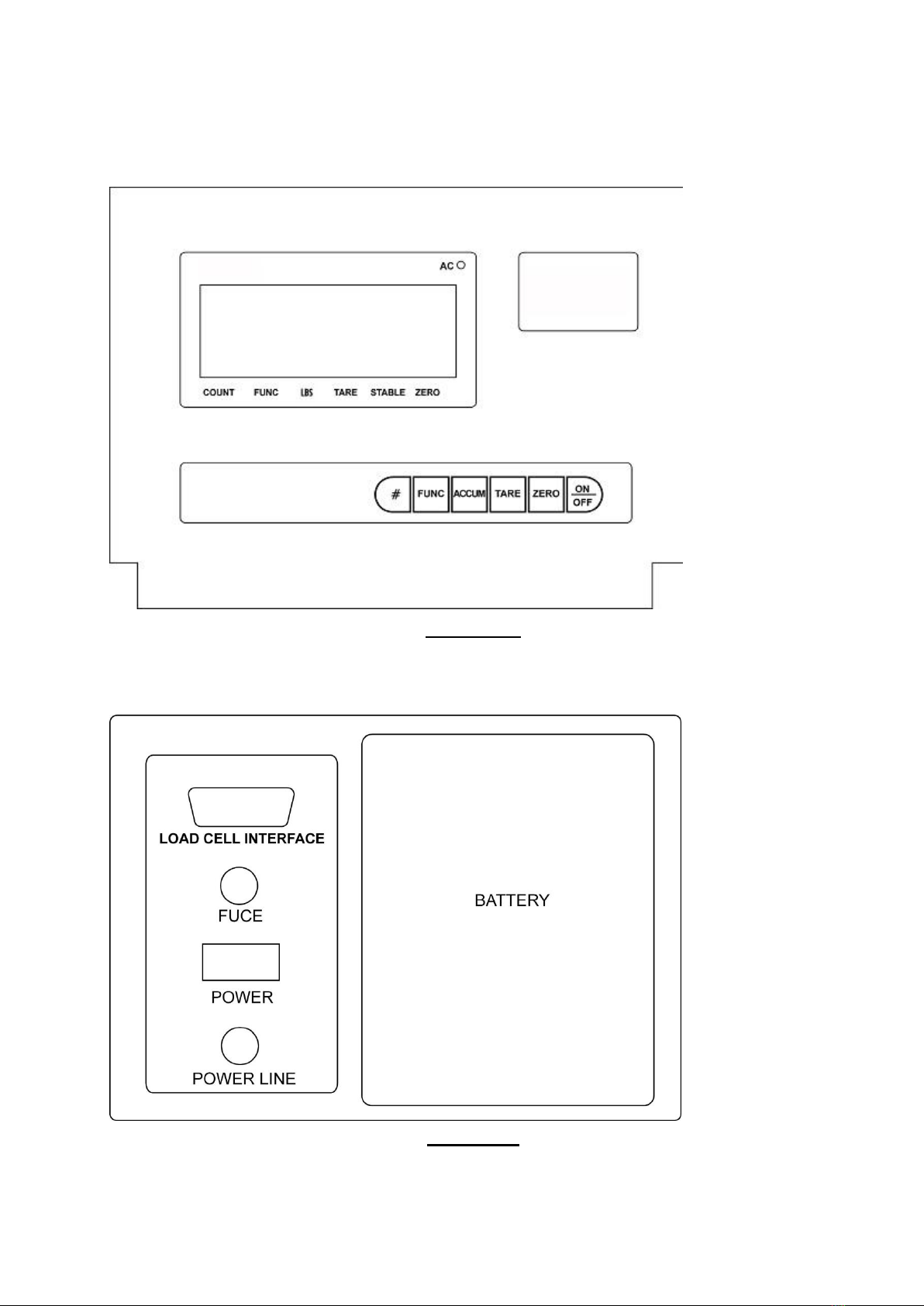

1.1 FRONT AND BACK VIEW OF THE INDICATOR

Front View

Back View

Floor / Pallet Scale 1

1.2 KEY FUNCTIONS

[UNIT] Switch between weighing units.

[FUN] Select or enter the function and save the setting values of parameters.

In counting mode, press to view unit weight, counts and total weight when “F3

Key”=1.

In the accumulation mode, press to view numbers when “F3

Key”=2.

Press to enter/exit animal mode when “F3 key”=5

[MOD] Enter/exit counting mode when in weighing mode when “F3 Key”=1.

Accumulate and print when “F3 Key”=2.

Hold/release the readout when “F3 Key”=3.

Enter pre-tare value when “F3 Key”=4.

Parameter setting for animal weighing when “F3 Key”=5

[TARE] Enter fast calibration when pressed in warming up.

Tare off the container weight.

When setting parameters press to change the value.

[ZERO] Press to enter parameter setting during warming up.

Zero the readout

When setting parameters, press to move the cursor.

[ON/OFF] Turn on/off the scale.

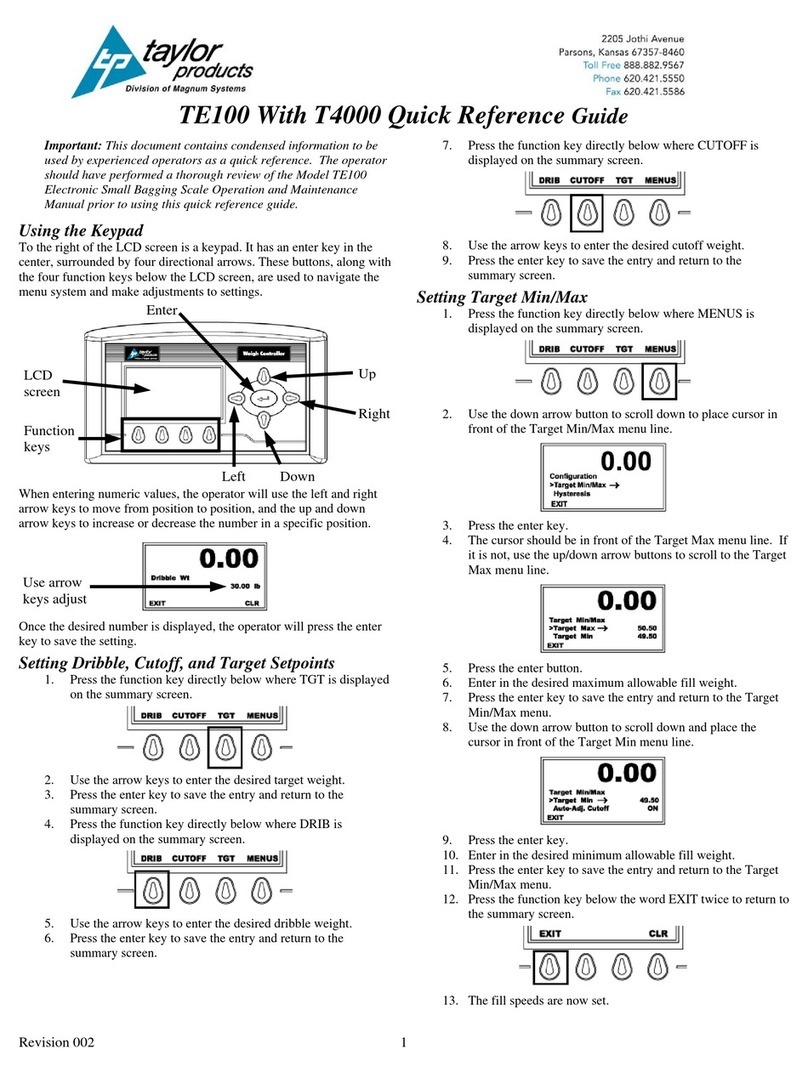

1.3 CONNECTING LOAD CELL TO INDICATOR

1. The 9-pin socket is used to hook up load cell, please refer to graph 2-3.

2. The 4-pin shielded cable is used, and the indicator does not have the function of

long distance compensation.

3. Indicator must be reliably connected to Load cell and shielded-cable of load cell

must be reliably grounded.

4. Sensor and indicator are static sensitive devices. Sodering operation is prohibited.

Port of Indicator Port of load cell

- V Shielded ⑥ +V Excitation Voltage+

① - V Excitation Voltage-

① ② ③ ④ ⑤

⑥ ⑦ ⑧ ⑨

⑨ +IN Output Signal+

⑧ -IN Output Signal -

+V -IN +IN ⑤shielded

Floor / Pallet Scale 2

(Graph 2-3) Drawing of connecting of load cell

Chapter 2 Operation

2.1 POWER ON AND AUTO ZERO-SETTING

1 The indicator will perform countdown self-checking when turned on. Then it will

enter weighing mode.

2 When powered on, if loading weight on the scale deviates from the zero point, but

still within zero set range, the indicator will set zero automatically; if it is out of

range, it is necessary to adjust the zero point or recalibrate or reset.

3 Press UNIT button to select your weighing unit. There is indication on the readout

panel showing the current weighing mode.

2.2 MANUAL ZERO SETTING

1 In weighing mode, you can press [Zero] anytime to zero the readout.

2 If the displayed value deviates from zero point, but still within zero-range, pressing

[Zero] key is available. Otherwise, [Zero] key is invalid. (In this status, please

recalibrate or reset zero parameters)

3 Zero function works only when the STAB sign is on.

2.3 TARE FUNCTION

When Indicator is in weighing mode, press the [Tare] key, the indicator will deduct the

displayed weight value as tare weight. Then indicator displays net weight as “0”, and

Tare sign is on.

2.4 COUNTING FUNCTION (WHEN F3 KEY=1)

Sampling: Tare the weight of any container that is used and leave the container on the

scale. Place samples on the scale. The quantity of the samples should match the

options for the pre-set values: 10, 20, 50, 100 or 200 pieces. Press [MOD] key and

the screen will show “P10”, which means the requirement of the sample size. If the

sample quantity on the scale is not 10 pieces, press [TARE] key to select the

according sample size. Press [FUN] key to confirm.

Counting: Remove the samples from the container and place the items need to count into

the container. You can see the counts on the display. Press [FUN] key to view Unit

Weight (in gram), Counts and Total Weight. You may exit counting mode anytime by

pressing [MOD] key.

2.5 ACCUMULATING FUNCTION (WHEN F3 KEY=2)

Floor / Pallet Scale 3

In weighing mode, press [FUN] key to enter accumulating mode. Place the first item

onto the scale and wait until the STAB sign on. Press MOD key to store the weight

into memory. Remove the first item and place the second item onto the scale then

repeat the previous procedure. Maximum loads for one accumulating is 200.

Clear the scale platform and press [FUN] key to view the number of loads and total

weight. Press [ZERO] key to clear the memory.

2.6 WEIGHT HOLDING FUNCTION (WHEN F3 KEY=3)

Press [MOD] key to hold the readout, press [MOD] again to release.

2.7 PRE-TARE FUNCTION (WHEN F3 KEY=4)

Press [MOD] key to enter Pre-pare Setting. Press [ZERO] to move the editable digit

(blinking) and press [TARE] to change the value. Make the displayed value equal to the

container which needs to be tare for every load. Press [FUN] to confirm. The display

will show the negative number for tare value.

2.8 ANIMAL WEIGHING (WHEN F3 KEY=5)

Press [MOD] key to set parameters of animal weighing.

1. Stable time: “Fil n” (n value can be changed). “n” value options: 1/2/3/4/5. 1

is the fastest and 5 is the lowest. Press [TARE] to select the desired value and

press [FUN] to confirm and move to the next parameter.

2. Display Range: “Rang n”. “n” value options: 1/2/3. 2 is recommended. Press

[TARE] to select the desired value and press [FUN] to confirm and move to the

next parameter.

3. Lock Range: If the change of weight exceeds the input value, the indicator will

refresh the display. Press [FUN] to confirm.

4. Press [FUN] to start animal weighing. Press [FUN] again to exit.

2.9 CHECK-WEIGHING

Check-weighing is a function to control the items to be weighed within or without the

pre-set range. If the high-limit and the low-limit are set as same value, the indicator will

set alarm for one key point. If the high-limit is set higher than the low-limit, the indicator

will set alarm for a weighing range.

To set check-weighing parameters: when the indicator is off, turn it on and press

[ZERO] key when the indicator is still warming up. You will see “F1CLK” on the screen.

Press [TARE] key 3 times and the screen will show “F4 CHK”. Press [FUN] key to

enter beep mode setting:

Beep 1: No beep. When the weight is higher than the high-limit, HI will be on. When

the weight is lower than the low-limit, LO will be on. Otherwise both HI and LO will be

on.

Floor / Pallet Scale 4

Beep 2: Beep when the weight falls into the weight range.

Beep 3: Beep when the weight falls out of the weight range.

Press [TARE] key to select desired mode then press [FUN] key to set High-limit:

Now there are 6 zeros on the screen. Press [ZERO] key to move the editable digit

(blinking) and press [TARE] to change the value. When you are done, press [FUN] to

set Low-limit. When you are done, press [FUN] to confirm. The screen will go back to

“F4 CHK”

To disable the check-weighing function, press [UNIT] key to set both high-limit and low-

limit to zero.

2.10 PRINTING (WHEN F3 KEY=2)

Set P 10 as “RS” (We will show to how to set P value later on.)

In the weighing mode, press [MOD] to print.

Chapter 3 Setting Parameters

To enter parameter setting: Turn on the indicator and press [ZERO] key when the

indicator is still warming up.

3.1 “F1 CLK” DATE AND TIME SETTING

Press [FUN] key to show the current time. If it is not correct, adjust it as following:

Press [ZERO] key to change hour (the hour is blinking). Press [TARE] to add up until it

shows the correct hour. Press [ZERO] to move to the minutes (the minutes are blinking).

Press [TARE] to add up until it shows the correct minute. Press [ZERO] to move to the

seconds (the seconds are blinking). Press [TARE] to add up until it shows the correct

second.

Press [FUN] to confirm and move to date mode setting. There are 3 date showing

modes:

“YY-MM-DD”, “MM-DD-YY” and “DD-MM-YY”. Press [TARE] key to switch between and

press [FUN] to confirm then move to date setting. Use the same way as timing setting

to set the date. Press [FUN] to confirm and exit. During the time or date setting, you

may press [MOD] anytime to cancel and exit. System will not save the changes. Press

[TARE] to move to the next parameter.

3.2 FAST CALIBRATION FOR ZERO POINT AND FULL RANGE POINT

Press [#] while it is initialization, it enters into the calibration mode.

3.2.1 Fast calibration for zero point:

At any time before it shows [nOLOAD], press [FUNC], it keeps the original division,

decimal point, full range and enter into the zero point calibration mode. Press [ZERO]

Floor / Pallet Scale 5

when the stable signal is on, it displays [End] and keeps the original full range point

calibration. Press the calibration switch under the lead sealing board at the back of the

indicator, it saves the setting and back to the weighing status.

3.2.2 Fast calibration for full range point:

At any time before it shows [AdLOAD], press [ACCU], it keeps the original division,

decimal point, full range, zero point calibration and enter into the full range point

calibration mode. When it is finished, press the calibration switch under the lead sealing

board at the back of the indicator, it saves the setting and back to the weighing status.

Chapter 4 Error Indication

EER 1

The AD value is too small when calibrated.

EER 2

The zero point is out of range when calibrated.

EER 3

The zero point is out or range upon starting

EER 4

The imputed sample number is zero when sampling n counting

mode.

EER 5

The imputed weight is zero when full scale calibrated in

calibrating mode.

EER 6

The unit weight is less than 0.25e when sampling in counting

mode

bAt-lo

Low power

Chapter 5 Recharge Battery

5.1 Turing on the AC power, the indicator will recharge the battery automatically. So if

you don’t use battery frequently, you should take battery out.

■ Note: red end is +, black end is -. Wrong connection will destroy indicator.

■ Note: The built-in battery should be fully charged before it is used for the first time.

5.2 Only when you turn off the AC power, and push start key, battery works. Displaying

[LouoL] means the insufficient of voltage, it needs charge.

5.3 When you use the battery first time, you should charge the battery for 20 hours in

order to prevent low voltage resulted from the self leakage of the battery.

5.4 If you don’t use battery for a long time, you should charge the battery for 10-12

hours for each 2 month to prolong using life of battery.

5.5 The battery is easily exhausted products. And it is not granted free guarantee.

Floor / Pallet Scale 6

Chapter 6 Maintenance

6.1 To guarantee indicator clarity and using life, the indicator shouldn’t be placed directly

under sunshine and should be set in the plain space.

6.2 The indicator can’t be placed into the place where the dust pollution and vibration

are serious.

6.3 Load cell should connect with indicator reliably, and the system should be well

connected into ground. The indicator must be protected from high electrical field and

high magnetic field.

In order to protect the operator, indicator and relevant device, you should mount

lightning rod in thunderstorm frequently happening area.

Load cell and indicator are static sensitive device, you must adopt anti static

measures.

6.4It is strictly forbidden to clean the case of indicator with intensive solvents (for

example: benzene and nitro oils)

7.1 Liquid and conducting particle should not be poured into the indicator, otherwise the

electronic components will be damaged and electric shock is likely to happen.

7.2 You should cut off power supply of indicator and relevant device before you pull-in

and out the connecting line of indicator and external device.

■You must cut off power supply of indicator, before pulling out connecting line of load

cell.

7.3 During operation, if trouble occurs, operator must pull off the power supply plug

immediately, and user should return this indicator to our company for repair. Non-

weighing manufacturer should not repair it, or by yourself, otherwise further

destruction may happen.

7.4 The storage is not granted the free repair guarantee, because it is easily exhausted

products.

■ In order to prolong using life, please charge the cell fully before using it. If you don’t

use the indicator for a long time, you must charge the cell every two month and for

eight hours/each charging time.

■ Moving or installation must be carefully taken and must avoid strong vibration, impact

and bump in order to protect the storage cell from being damaged.

7.5 From invoice date, the indicator has a one-year free repair period. If any non-

artificially obstacle about the indicator happens under correct using conditions within

this period, the user is allowed to send the product with its guarantee card (of the

correct number) back to our corporation for free repair. The indicator shouldn’t be

taken apart, otherwise free guarantee will be cancelled.

Other DigiWeigh Scale manuals

Popular Scale manuals by other brands

DS Produkte

DS Produkte TY6120 instructions

RADWAG

RADWAG AS series user manual

Redmond

Redmond RS-730-E user manual

Integrated Visual Data Technology Inc.

Integrated Visual Data Technology Inc. SkidWeigh ED2E-AT Elite Installation & Calibration Manual

Pitney Bowes

Pitney Bowes INTEGRA N500 user guide

HOFFEN

HOFFEN BBS-8545 instruction manual

Taylor Products

Taylor Products TE100 Quick reference guide

wesmartify

wesmartify es Smart Cooking user manual

Xavax

Xavax Dena operating instructions

DAY Useful Everyday

DAY Useful Everyday 753073 instruction manual

Soehnle Professional

Soehnle Professional 7871 user manual

KERN

KERN MPC 250K100NM operating instructions