Dillon Quantrol AFG Series User manual

Advanced Force Gauge (AFG/AFTI)

User’s Manual

Advanced Force Gauge User’s Manual

2

Risk of electrical shock. Do not remove cover. No user serviceable

parts inside. Refer servicing to qualified service personnel.

Weigh-Tronix reserves the right to change

specifications at any time.

CAUTION

EUROPEAN COUNTRIES

WARNING

This is a Class A product. In a domestic environment this

product may cause radio interference in which the user

may be required to take adequate measures.

07/22/04 AFG2003_U.P65 PN 29814-0013D e2 Printed in USA

Advanced Force Gauge User’s Manual 3

Table of Contents

Table of Contents...........................................................................................3

Introduction ....................................................................................................5

Before Use..............................................................................................5

Operation Overview ................................................................................5

Powering the AFG..........................................................................................5

Inserting and Charging the Batteries......................................................6

Using the AFG ...............................................................................................6

Fitting Accessories .................................................................................6

Mounting to a Test Stand ........................................................................7

Powering up............................................................................................7

Basic Functions ......................................................................................8

Optional Settings ..................................................................................12

Additional Force & Torque Sensors......................................................13

Advanced Menu Options ......................................................................14

ALARM ..........................................................................................15

PLC (Programmable Limit Controller) ...........................................20

STAND...........................................................................................21

FREEZE ........................................................................................23

% DROP ........................................................................................23

AVERAGE/TIME ............................................................................25

RATE .............................................................................................26

FOOTSWITCH 1 ...........................................................................26

FOOTSWITCH 2 ...........................................................................27

COMMS .........................................................................................27

INFORMATION..............................................................................28

CALIBRATION...............................................................................28

x/CONSTANT ................................................................................29

CONTRAST...................................................................................29

AFG Specifications ......................................................................................30

Appendix: Menu Flowcharts ........................................................................33

Advanced Force Gauge User’s Manual

4

Advanced Force Gauge User’s Manual 5

Powering the AFG for the First Time

Introduction

Before Use

Operation

Overview

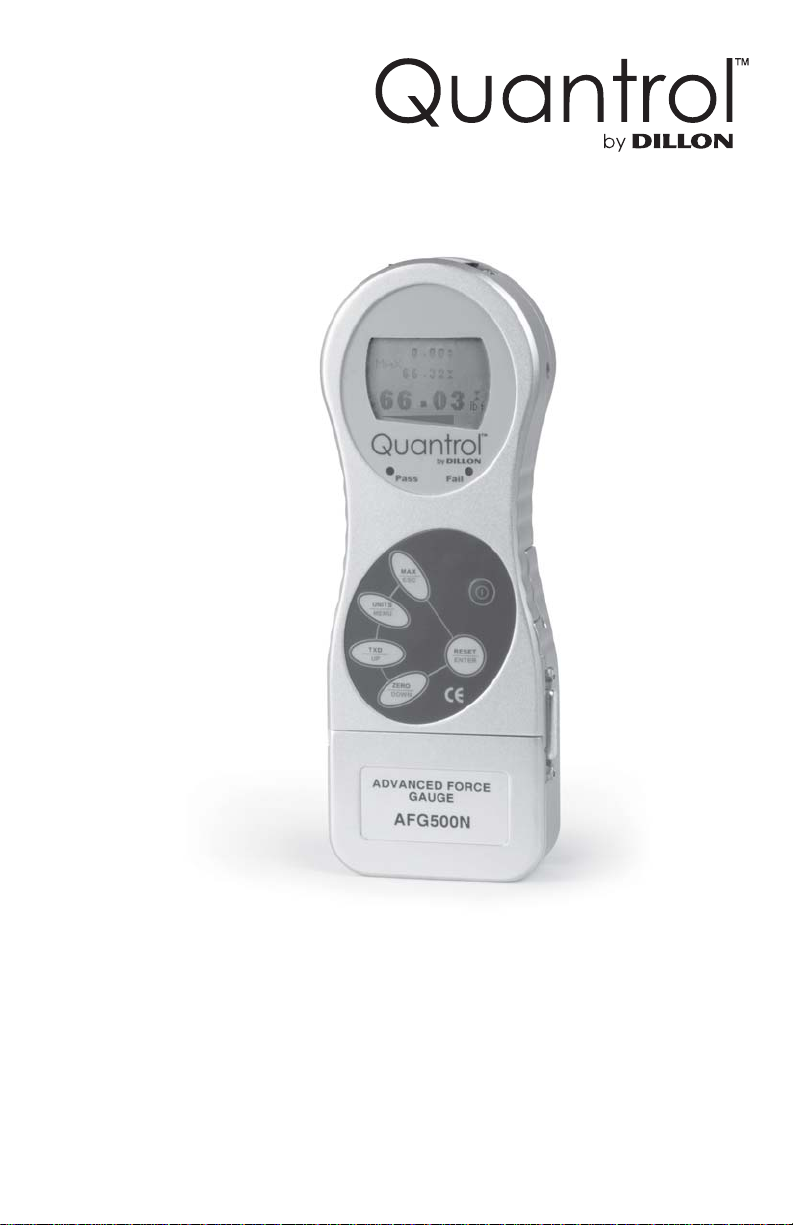

Thank you for choosing the Quantrol Advanced Force

Gauge (AFG) instrument. With correct use and

regular re-calibration it will give many years of

accurate and reliable service.

The AFG uses the latest integrated circuit technology.

It can measure tensile and compressive forces

accurately, while being simple to use by the operator.

Quantrol offers a full range of force measurement

products to complement your force gauge, including

manual and motorized test stands and a large

assortment of grips and attachments. Ask your

Quantrol distributor for additional information.

Upon receiving the unit please check that no physical

damage has occurred to the packaging material,

plastic case or the instrument itself. If any damage is

evident please notify Quantrol immediately.

The most commonly used features (such as display-

ing force, peak hold, zero and changing of displayed

units) can all be done by pressing a single dedicated

key identified on the front panel with grey text – see

the Basic Functions section. For less frequently used

features, a number of menu “hot keys” are provided

so you can press and hold a menu key to access the

gauge configuration – see the Optional Settings

section.

To configure the advanced features of the gauge a full

menu-driven system is available by using the keys

identified on the front panel with red text – see the

Advanced Menu Options section.

The AFG is supplied with a set of 5 Nickel Metal

Hydride AAA rechargeable batteries. For safety

reasons during transportation the batteries are

shipped discharged. To obtain maximum battery life

we recommend that you charge them with the

charger/adaptor supplied for at least 14 -16 hours

when you first receive the AFG.

Important!

Charge the AFG for 14-

16 hours before use.

Advanced Force Gauge User’s Manual

6

Inserting and

Charging the

Batteries

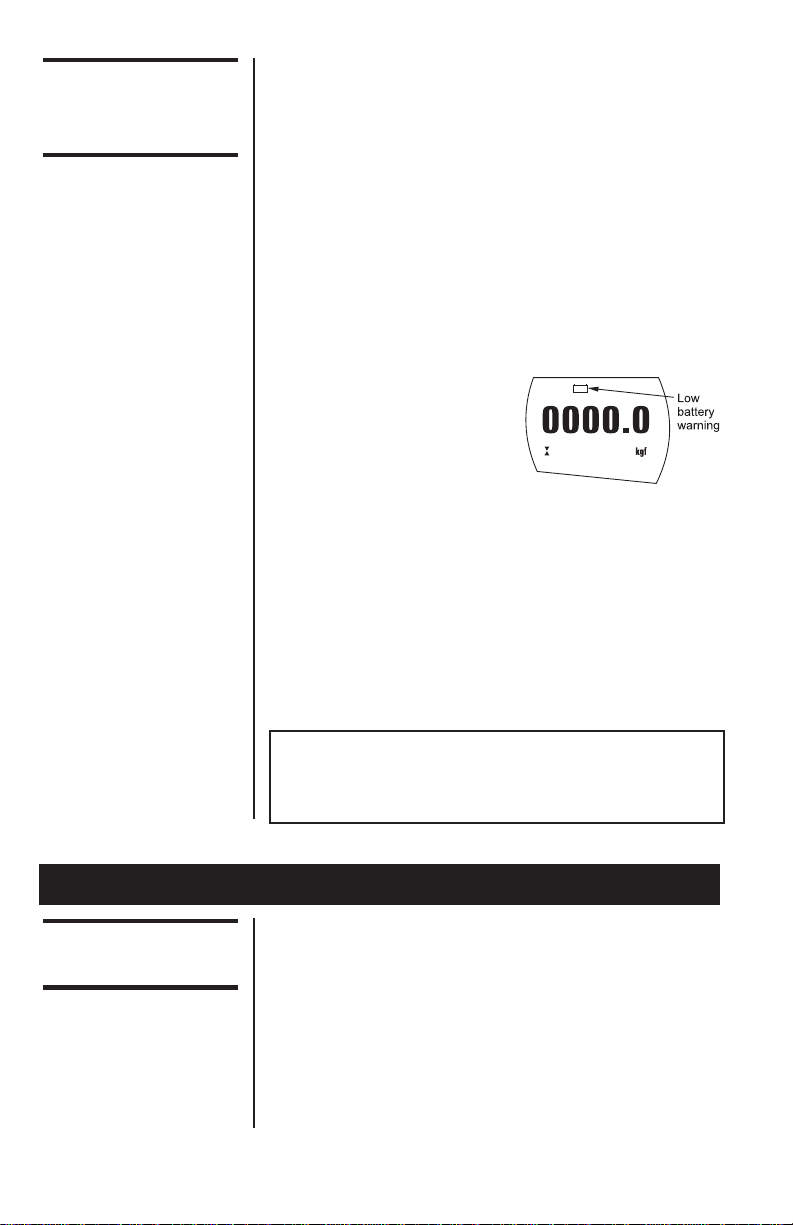

Low Battery Warning

Installing alkaline

batteries

AC operation

Using the AFG

Fitting

Accessories

To insert the batteries, remove the battery cover on

the upper part of the rear of the gauge by undoing the

3 retaining screws. Fit the five batteries in the battery

holder ensuring that you observe polarity and the

batteries are placed on top of the release tag.

To remove the batteries simply pull the release tag.

Refit the battery cover and tighten the 3 retaining

screws. Connect the AC charger to the AFG charger

socket located at the right hand side of the gauge next

to the display and charge the batteries for 14-16

hours. Only use the adaptor/charger supplied.

A low battery symbol will

appear in the display

approximately two minutes

before the gauge powers

down automatically.

The AFG can also be powered directly from

the AC adapter/charger. You can use the adapter

without the batteries present. Connect the AC

adapter/charger to your power supply.

If rechargeable batteries are installed, a trickle charge

will be applied to the batteries.

The AFG can also be powered by five AAA 1.5V

alkaline batteries (not supplied).

Warning: When alkaline batteries are installed, the

AC adaptor/charger must NEVER be connected to the

AFG due to the risk of acid leakage which could

damage the instrument.

The Rotary Coupling is supplied with AFG instruments

between capacities of 10N to 1000N. It allows you to

orientate the gripping accessory without the need for

a locking wheel (as on the extension rod).

We do not recommend it to be used for AFG 2.5N and

5N due to its weight, which would need to be tared

from the measuring range.

Affix the Rotary Coupling to the male thread of either

the short extension rod (1 inch long) or the long

Only use the adaptor/

charger supplied.

Note: When fitting a grip

ensure that it is screwed

finger-tight only.

Excessive torque can

damage the load cell.

Advanced Force Gauge User’s Manual 7

Mounting to a

Test Stand

Note: When fitting a grip

ensure that it is screwed

finger-tight only.

Excessive torque can

damage the load cell.

Powering up

Please note that an AFG

measuring very low

forces may not show

zero if it is moved during

the self test routine.

Once it is properly

mounted and zeroed the

reading will be stable.

extension rod (5 inches long). Affix the extension rod

to the load cell probe in the hole at the bottom of the

gauge by tightening it gently with the fingers.

Your chosen grip or accessory may now be connected

to the rotary coupling.

On the rear of the gauge there are two M5 threaded

holes, which can be used for mounting the gauge to a

Quantrol test stand. Each Quantrol test stand is

supplied with a dedicated dovetailed mounting bracket

and screws for this purpose. If you wish to mount to

another type of stand, ensure that the screws used

are threaded into the gauge to a maximum depth of

0.21 inch. The final thread is peaned but if screws are

fitted beyond this depth, damage to the internal PCB

may occur.

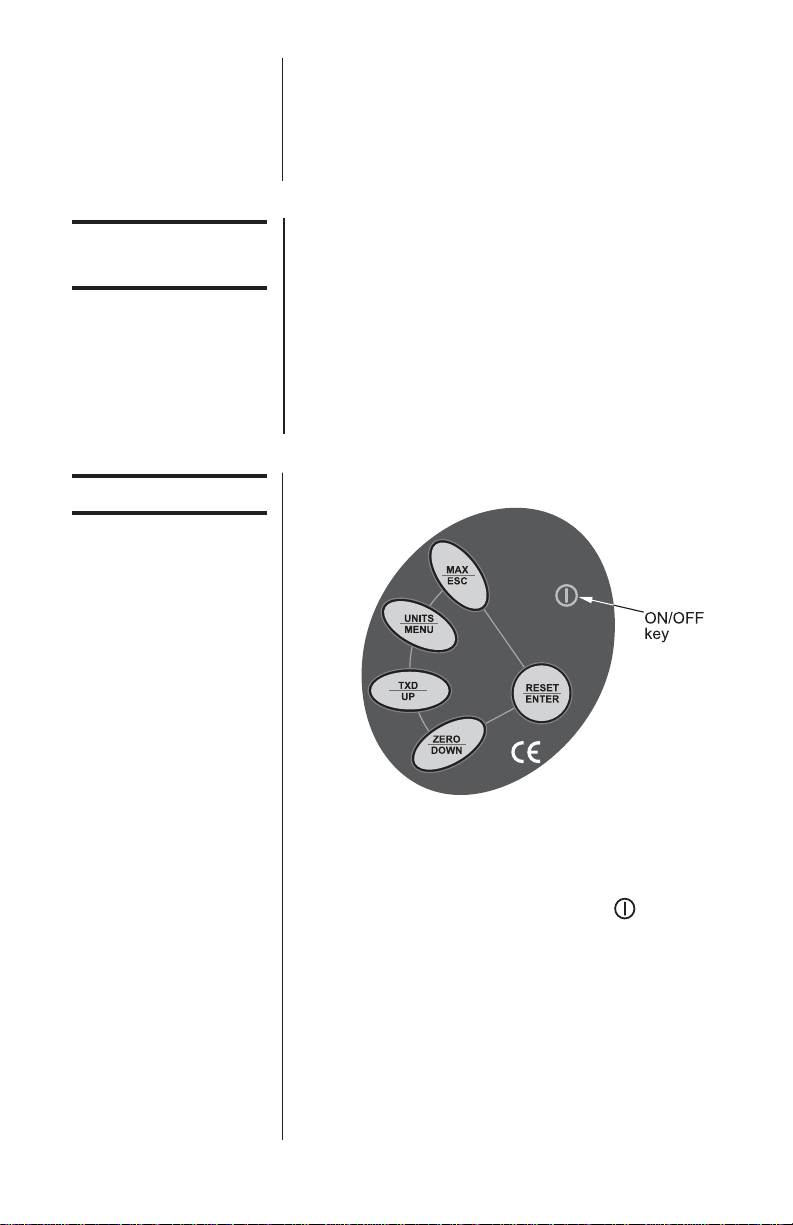

As shown in Figure 1 the control panel has six keys.

Figure 1

AFG control panel

To power up the gauge press the red key. A short

self test runs during which the display will show the

model and capacity in Newtons.

After the self test, providing no load has been applied

to the instrument, the display will show all zeroes.

This is because the gauge rezeroes itself during the

self test routine.

If a force is applied via the load cell probe (hole at

bottom of AFG), the reading on the display will

register the applied force.

Advanced Force Gauge User’s Manual

8

All the current settings

are saved when the

gauge is turned off and

the gauge will function in

the same mode when

powered up again.

Basic Functions

Display of Tension/

Compression

If the AFG has suffered a

serious overload

condition, the load

indicator bar will be

partially displayed even

when no load is present.

This is a warning that the

load cell is damaged and

you should immediately

contact your supplier to

arrange repair.

* Do not overload the load sensor. This will cause

irreparable damage. Forces greater than 120% of full-

scale will produce an audible beep until load is

released and an OL symbol will appear on the display

for 30 seconds.

Forces greater than 150% of full-scale will produce an

audible beep until load is released and an OL symbol

will appear permanently on the display. Consult your

supplier to arrange repair.

To power down the gauge press the red key.

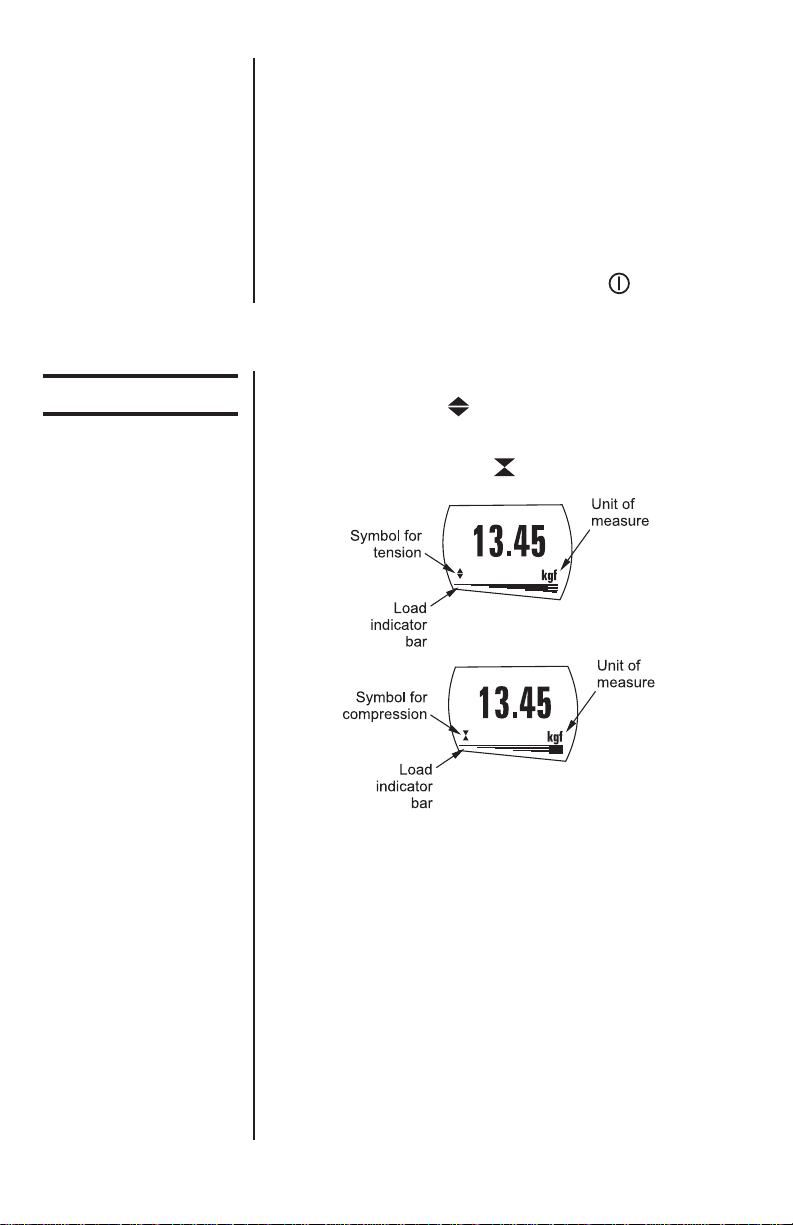

Tensile forces are displayed on the AFG and recog-

nized by the symbol

Compressive forces are displayed on the AFG and

recognised by the symbol

Figure 2

Tension and compression displays

A load indicator bar alerts the operator to how much

load has been applied to the load sensor. As the load

approaches the maximum rating of the load sensor,

the indicator bar changes appearance when above

approx. 80% of the rated capacity. This warns you

that steps should be taken to prevent excessive load

being applied.

For tensile forces the indicator bar is solid then

dotted. For compressive forces the indicator bar is

dotted then solid. See Figure 2.

Advanced Force Gauge User’s Manual 9

Zeroing the Gauge

Changing the Unit

of Measure

Max (peak) Readings

“Max” Mode

During the operation of the gauge it is often necessary

to zero the display – e.g. when you wish to tare out

the weight of a grip, so it does not become part of the

measured reading. Press and release the ZERO key.

The display will blink momentarily as the zero opera-

tion is carried out.

You can choose from the following units of measure

depending on the capacity of your gauge:

milliNewtons, kiloNewtons, Newtons, gram-force,

kilogram-force, ounce-force or pound-force.

To change the display units press and release the

UNITS key. Each successive key press will select the

next available units until the gauge returns to its

original setting. The AFG automatically converts

readings as new units of measure are selected.

The gauge detects and stores maximum (peak) force

in both compressive and tensile directions.

Press the MAX key. The display will show the word

MAX together with the highest tensile force and the

highest compressive force detected during the test.

The current load being applied to the load sensor is

also displayed. See Figure 3a.

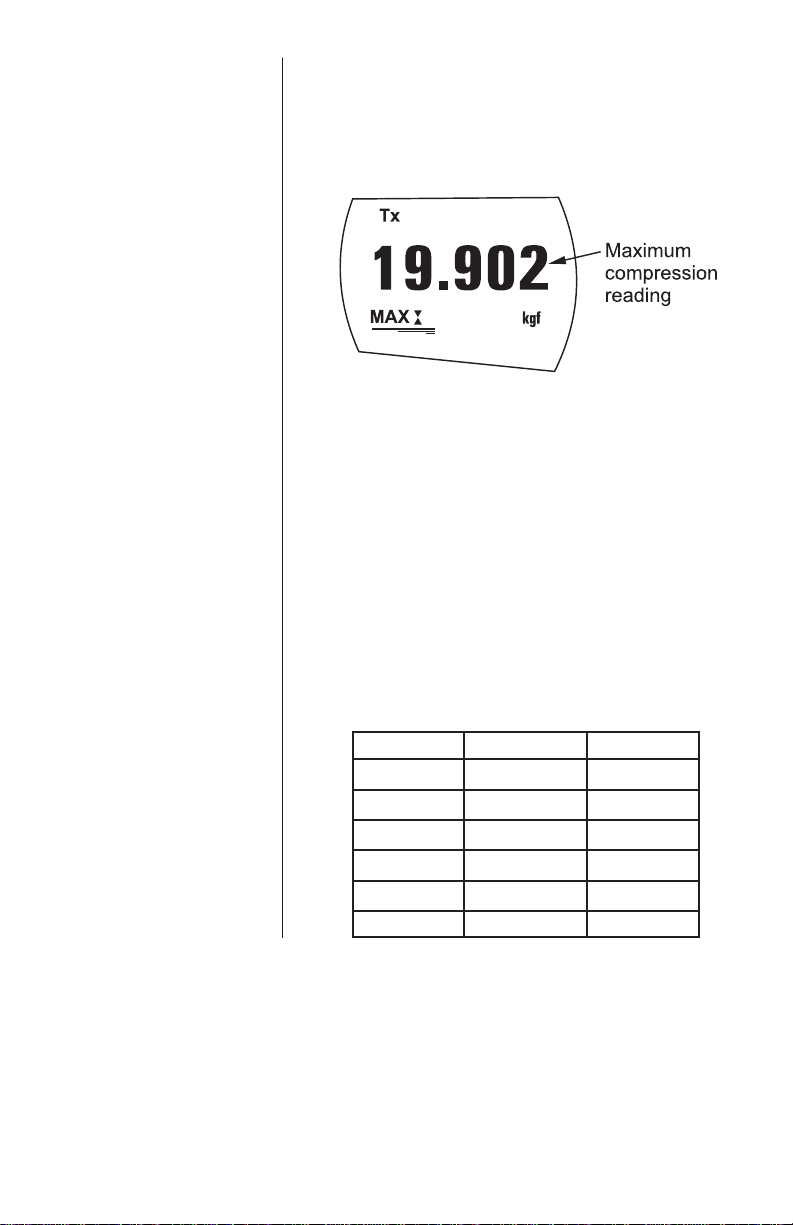

Press the MAX key again and the display will show

the maximum tensile force identified by the symbol

. See Figure 3b. Press the MAX key again and the

display will show the maximum compressive force

identified by the symbol. See Figure 3c.

Figure 3a

Dual Max

Advanced Force Gauge User’s Manual

10

“Normal” mode

Data Output

Analog output

RS232 and Mitutoyo

output signals

Figure 3b

Max Tension

Figure 3c

Max Compression

Press the MAX key again and the word MAX has now

disappeared from the display. The display will now

indicate forces applied in both directions as they are

applied to the load sensor and maintain a live display.

Press the RESET key to clear both maximum regis-

ters and prepare for detecting the next maximum

readings.

(See also COMMS section of Advanced Menu

Options)

A calibrated analog output is available from the top ‘D

type’ connector. See Specifications for details.

It is possible to transmit the displayed reading to

peripheral devices (e.g. PC, printer) by pressing and

releasing the TXD key. Displayed readings can also

be requested individually from a PC via the RS232

interface by sending a”?” (ascii D63 [3fh] character).

Advanced Force Gauge User’s Manual 11

Continuous PC

Communication For sending a continuous data stream to a PC, press

and hold the TXD key for 2 seconds then release. TX

will now appear in the display to indicate that data is

being sent. See Figure 4.To stop sending data, simply

press and release the TXD key, at which point TX will

disappear from the display.

Figure 4

AFG uses 2400, 9600,

57600 or 115200 Baud, 8

data bits, 1 start bit, 1

stop bit and no parity.

(See Advanced Menu

Options for setup details)

A full range of data

cables are available to

connect your gauge to

peripheral devices –

contact your supplier.

Data is output at

approximately 12 Hz.

Only prints large

displayed number in dual

display mode.

Computer Control of

Force Gauge

Key ASCII code Character

TXD 1 <Ctrl> A

UNITS 2 <Ctrl> B

MAX 3 <Ctrl> C

RESET 4 <Ctrl> D

ZERO 5 <Ctrl> E

REQUEST 63 ?

A computer can control the force gauge by sending

RS-232 commands. These commands are interpreted

exactly as if the button on the front of the gauge were

momentarily pressed.

Default baud rate = 9600.

Advanced Force Gauge User’s Manual

12

Factory Default

The AFG has a display backlight that can be turned

on at powerup. Press and hold UNITS while powering

up the AFG with the key. The backlight is now

operating.

Please note that battery consumption is doubled when

using the backlight. For this reason the backlight

setting is not remembered after power down.

An Auto-off feature can be enabled to conserve

battery power where the gauge powers down after 2

minutes since the last key press.

Press and hold ZERO while powering up the AFG with

the key. The symbol Ao will appear in the display

to indicate Auto-off is active. This feature is remem-

bered after power down.

The display may be inverted or “reversed”, so that the

operator can read it more comfortably. Press and hold

the MAX key while powering up the AFG with the

key to invert the display. This feature is remembered

after power down.

The AFG may be returned to its original factory default

settings, shown in the Advanced Menu Options

section of this manual.

Press and hold the RESET key while powering up the

AFG with the key.

Auto-off

Backlit Display

Optional Settings

Invert Display

Advanced Force Gauge User’s Manual 13

Additional Force

& Torque Sensors

Interchangeable

Advanced Loadcell

Cartridges (ALC)’s

Warning! Incorrect

alignment of the ALC

may lead to damage to

the ALC interface pins.

The AFG has an interchangeable loadcell cartridge

(ALC), which allows selection of different capacity

load cells to be fitted to the AFG console.

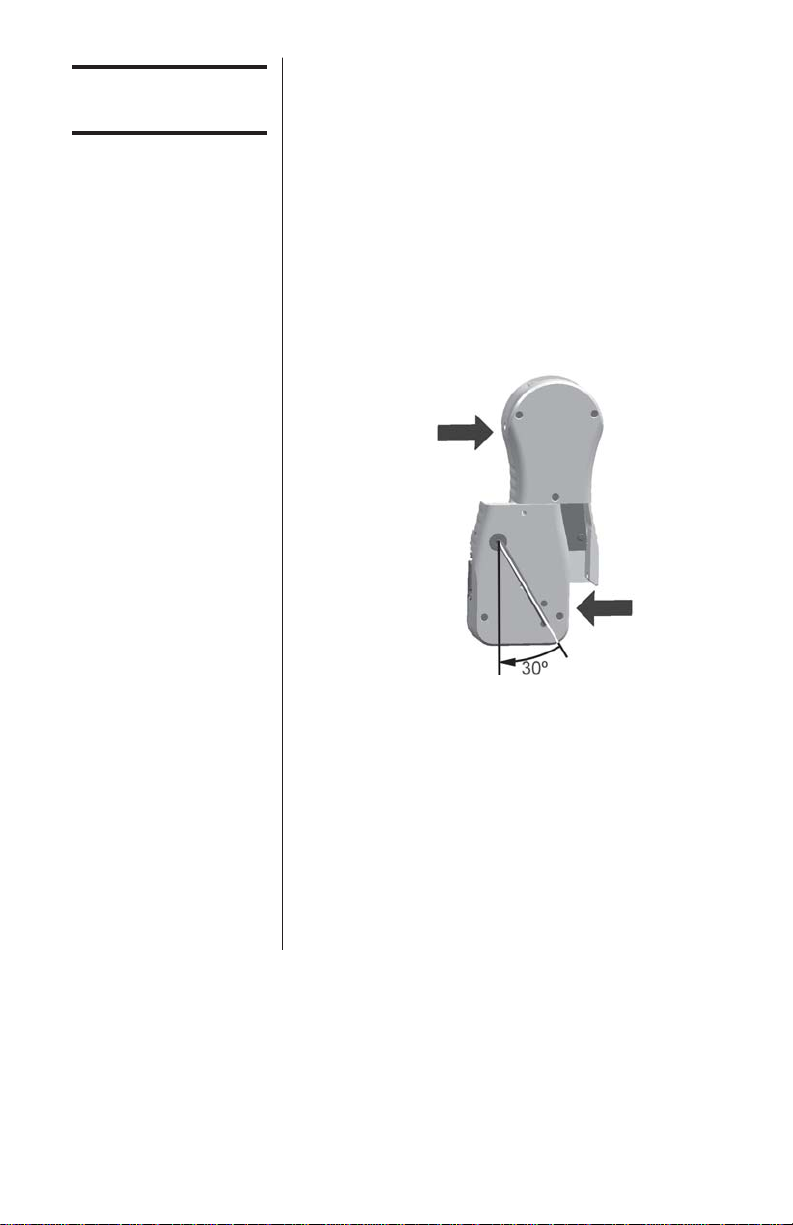

To exchange the cartridge, power down the gauge

and remove it from the test stand if it is fitted to one.

Turn the gauge face down and insert a 3mm Allen key

(supplied) into the boss on the back of the ALC. To

unlock the ALC rotate the boss anti-clockwise with the

Allen key through approximately 30º to release the

spring loaded locking cam. While still holding the

Allen key in position slide the ALC away from the AFG

console to the left. See Figure 5.

Figure 5

Removing ALC

To fit the new ALC, first insert the Allen key into its

boss and rotate the locking cam as above. Slide the

ALC into the AFG console, ensuring that the mating

surfaces are correctly aligned.

Push the ALC firmly home into the AFG console and,

to lock it, tighten the locking cam by rotating the Allen

key clockwise until slight pressure is felt. Take care

not to over tighten the locking cam.

Warning! The AFG must

be powered down when

connecting or discon-

necting smart load

sensors.

Advanced Force Gauge User’s Manual

14

‘Smart’ Sensors

Warning! The AFG must

be powered down when

connecting or discon-

necting smart load

sensors.

Loadcell Diagnostic

Test

Advanced Menu

Options

Navigating the menus

All Advanced Loadcell Cartridges have a 15-pin

‘Smart’ connector port on the right hand side for

interface with Quantrol external ‘Smart’ force and

torque sensors. This allows you to use your existing

AFG console to perform additional tests without the

need for a dedicated instrument.

To connect a ‘Smart’ sensor, power down the gauge

and plug in the ‘Smart’ force or torque sensor to the

15-pin ‘Smart’ port. Power on the AFG. The ‘Smart’

load sensor will be automatically recognized and the

capacity displayed.

If you suspect that your ALC loadcell or ‘Smart’

sensor has sustained an overload it is possible to

check the status of the sensor immediately.

Symptoms of overload may be (a) OL in display (b)

buzzer sound (c) probe not aligned perpendicularly to

gauge (d) load indicator bar present even under zero

load.

See Calibration section of Advanced Menu Options to

check load cell status.

All the features and advanced menu options of the

AFG are also applicable while using the ‘Smart’ range

of peripheral devices.

The AFG Advanced Menus are accessed using the

red text on the keys.

Press and hold the MENU key for approximately 2

seconds to access page 1 of the main menu. To move

between the options listed on the 2 main menu pages,

press UP and DOWN to move the cursor. Press

ENTER to select sub-menus, activate features and

enter values. Within sub-menus UP and DOWN will

also change numerical values. Press ESC to return to

page 1 of the main menu page.

If ALARM is selected in page 1, by pressing ENTER

the status of all the other functions can be seen by

consecutively pressing the MENU key to scroll

through the functions one at a time. Press ESC once

to return to the main menu page and twice to return to

the main display.

An instrument showing

an overload condition

cannot be relied upon to

provide accurate,

repeatable measurement

–consult your Quantrol

distributor.

See the Appendix in the

back of this manual for

flowcharts of all the

menus.

Advanced Force Gauge User’s Manual 15

ALARM

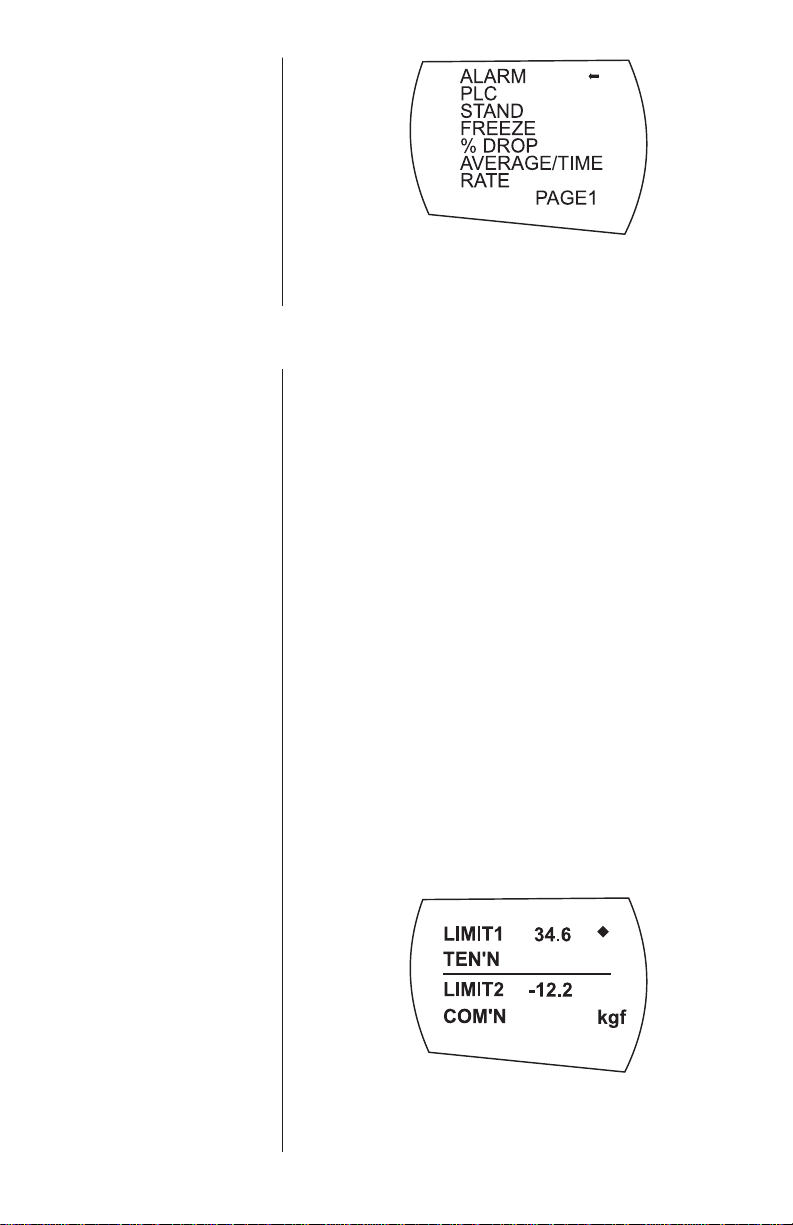

Figure 6

Main Menu

The AFG has an audible and visual alarm feature

which can be set to trigger on pass, fail or sample

break criteria.

To set an alarm, press and hold the MENU key until

page 1 of the main menu appears. The cursor arrow

will point to ALARM. Press the ENTER key.

The display will show ALARM OFF and SET.

Press ENTER to change ALARM OFF to ALARM ON.

Press DOWN to move the arrow cursor to SET and

press ENTER.

The display will now show the two limits LIMIT 1

(lower limit) and LIMIT 2 (upper limit) plus the value

they are set to and whether they are in tension

(TENS’N) or compression (COMP’N). A diamond

cursor will indicate which value is selected. Use UP

and DOWN keys to change the value, press and hold

to scroll values. When the correct value is reached

press ENTER to set LIMIT 1. Repeat procedure for

LIMIT 2.

Figure 7

Menu page 1

ALARM sub-menu 1

ALARM sub-menu 2

The alarm limits are not

active below 1% of the

capacity of the gauge.

Compression limits must

have a negative (-) sign

in front of the number.

Advanced Force Gauge User’s Manual

16

ALARM sub-menu 3 The display shows AUDIBLE, LED and BOTH with the

arrow cursor indicating which feature is selected. This

menu selects how the PASS/FAIL status of a value

will be indicated.

AUDIBLE Only the audible alarm will be activated

when the value is a PASS/FAIL

LED The green and red LED’s will indicate the

PASS /FAIL status.

BOTH Both the LED and the audible alarm will

be activated above.

Use UP and DOWN to move the cursor and press

ENTER to select the desired feature.

The display shows OUT BAND and IN BAND. This

menu selects which values are to be considered.

OUT BAND Any value falling outside the set limits

LIMIT 1 and LIMIT 2

IN BAND Any value falling between the set limits

LIMIT 1 and LIMIT 2

Use UP and DOWN to move the cursor and press

ENTER to select the desired feature.

The display shows PASS and FAIL. This menu sets

the OUT BAND and IN BAND mode.

PASS Values, which fall either OUT BAND (or IN

BAND, if selected), are a PASS

FAIL Values, which fall either OUT BAND (or IN

BAND, if selected), are a FAIL and will

cause an audible beep.

Use UP and DOWN to move the cursor and press

ENTER to select the desired feature.

Display is showing sub-menu 1 again (= ALARM ON

and SET). Press ESC to return to main menu and

again to return to main display. The main display will

now show an alarm ‘bell’ symbol indicating the alarm

is turned on. See Figure 8.

ALARM sub-menu 4

ALARM sub-menu 5

Advanced Force Gauge User’s Manual 17

Figure 8

Alarm symbol

ALARM on break This feature is only activated when the % DROP

feature is used in conjunction with the ALARM

function. The AFG looks for a percentage (of full-

scale) drop from peak load value, set in the % DROP

menu. The alarm can be used to indicate if the break

point falls inside or outside the limits LIMIT 1 and

LIMIT 2 set in the alarm menu (see Examples 1 to 5).

Advanced Force Gauge User’s Manual

18

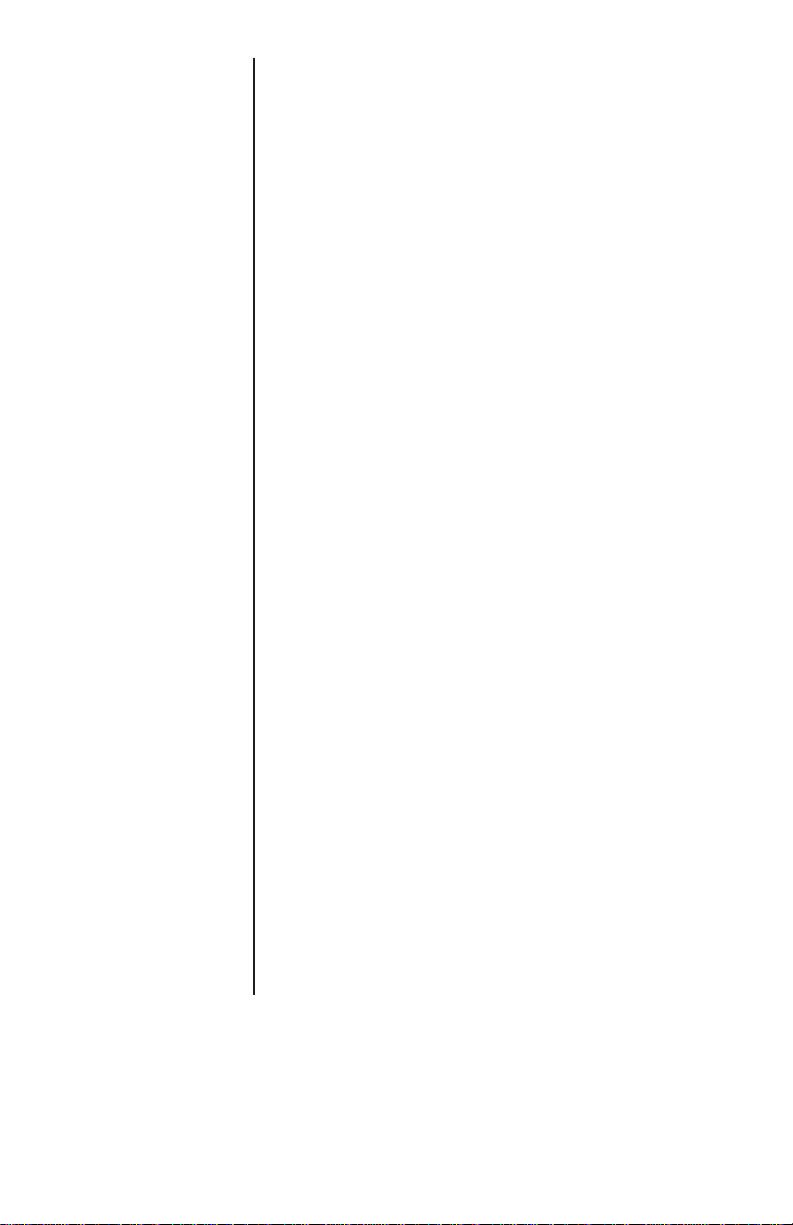

Example 1

Settings: -

- BOTH LED and audio

alarms are active

- Alarm triggers on OUT

BAND

- Alarm is set to FAIL

- % DROP is 10% of

fullscale (e.g. AFG

100N must register

drop of 10N)

Main display is set to

1st peak tension

screen

Example 2

Settings: -

- BOTH LED and audio

alarms are active

- Alarm triggers on OUT

BAND

- Alarm is set to FAIL

- % DROP is 10% of

fullscale (e.g. AFG

100N must register

drop of 10N)

Main display is set to

1st peak tension

screen

Advanced Force Gauge User’s Manual 19

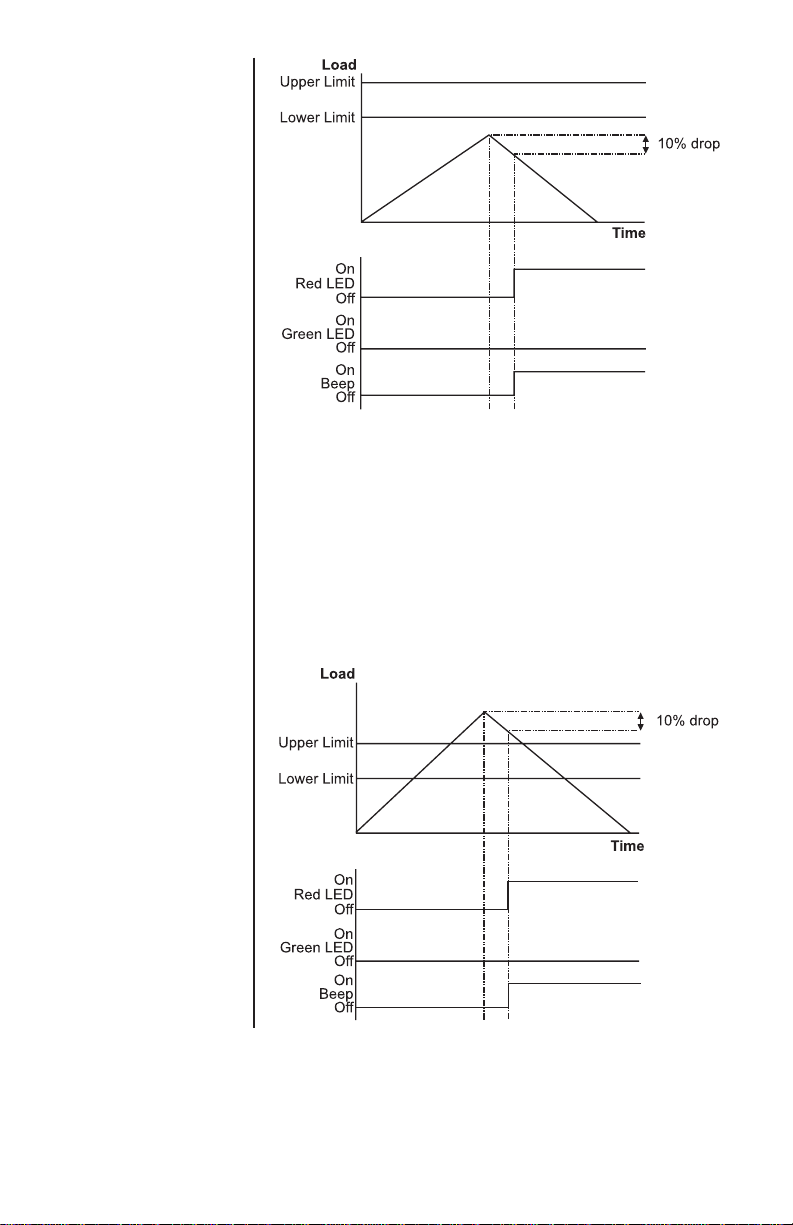

Example 3

Settings: -

- BOTH LED and audio

alarms are active

- Alarm triggers on OUT

BAND

- Alarm is set to FAIL

- % DROP is 10% of

full-scale (e.g. AFG

100N must register

drop of 10N)

Main display is set to

1st peak tension

screen

Example 4

Settings: -

- BOTH LED and audio

alarms are active

- Alarm triggers on OUT

BAND

- Alarm is set to FAIL

- % DROP is 10% of

full-scale (e.g. AFG

100N must register

drop of 10N)

Main display is set to

1st peak tension

screen

Advanced Force Gauge User’s Manual

20

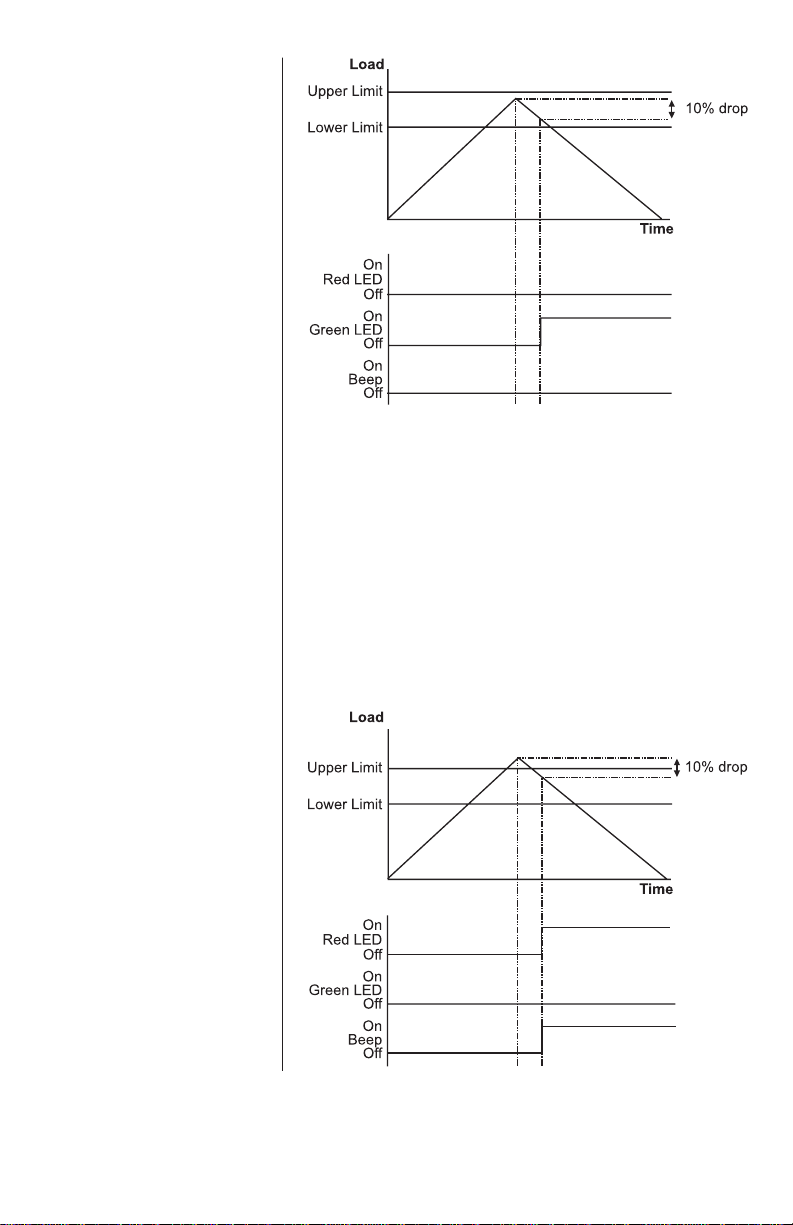

Example 5

Settings: -

- BOTH LED and audio

alarms are active

- Alarm triggers on OUT

BAND

- Alarm is set to FAIL

- % DROP is 10% of

fullscale (e.g. AFG

100N must register

drop of 10N)

Main display is set to

1st peak tension

screen

PLC

(Programmable Limit

Controller)

PLC sub-menu 1

The AFG has a load output signal which may be used

for PLC applications. For PLC applications, this

function requires an external cable with a built-in

solid-state relay – see Specifications for details of the

signal.

To configure the signal output from the AFG, press

and hold the MENU key until page 1 of the main menu

appears. Press DOWN to move the arrow cursor to

PLC and press the ENTER key. The cursor arrow now

points to PLC OFF.

The display will show:

PLC OFF Indicates PLC function status.

RESET When the load limit is reached, the

output signal triggers the relay and

the RESET key must be pressed to

clear the line before starting the next

test.

CONTINUOUS The relay will be activated every time

the load limit is reached and the

output signal will remain on.

PULSE The relay will be activated momen-

tarily when the load limit is reached.

Select the desired function and press the ENTER key.

This manual suits for next models

10

Table of contents

Other Dillon Test Equipment manuals