Page 4

Practical Instrument Electronics

Operating Instructions

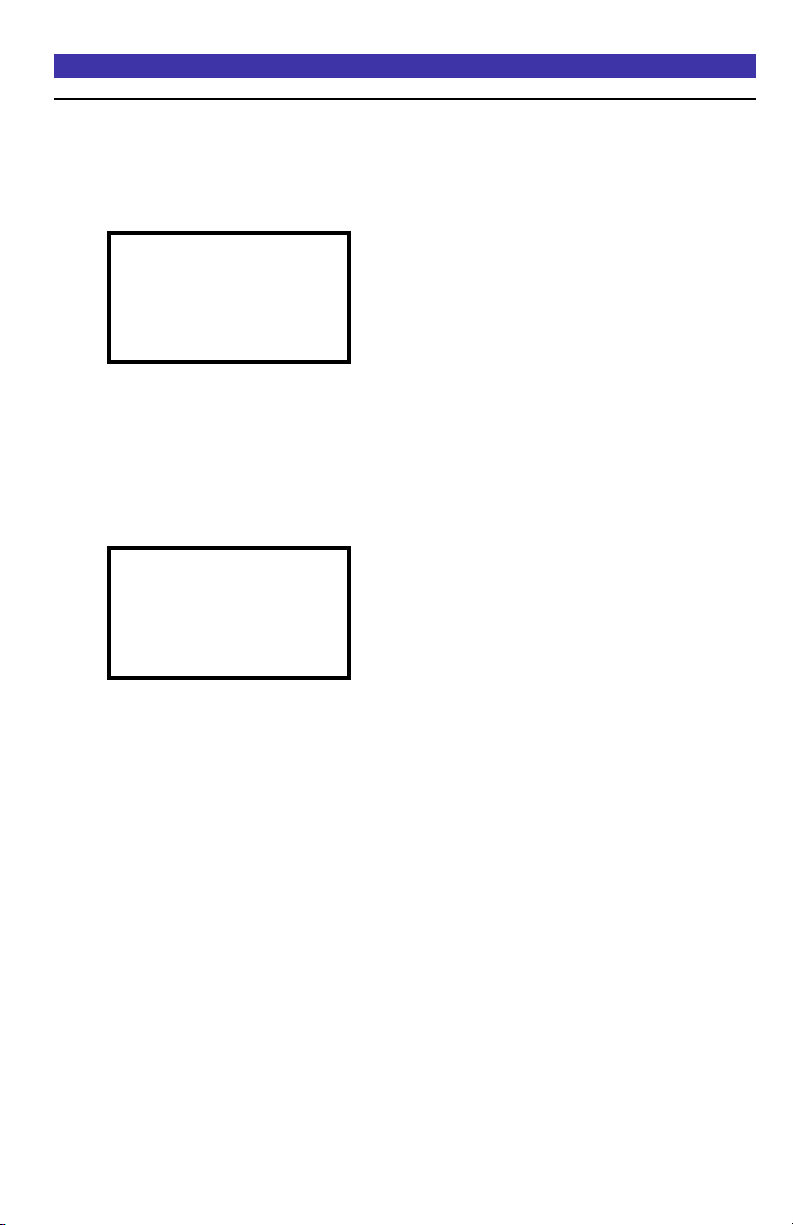

Double Click Menu - STEPPING, AUTO OFF & BACKLIGHT

To change the Automatic Stepping settings

Double click the eDIAL KNOB at any time the

unit is on and the following typical display (will

be different for each FUNCTION) will appear for

15 seconds:

Turn the eDIAL KNOB to move to the second

menu (FEATURES) page.

Turn the eDIAL KNOB to move through the

menu. Press the eDIAL KNOB to toggle

between OFF and ON or to change the STEPS/

RAMP and the STEP/RAMP TIME settings.

These settings are remembered even with the

power off.

EXIT MENU - exits this menu immediately and

saves any changes. Menu will automatically exit

after 15 seconds of inactivity.

AUTO OFF - If AUTO OFF is ON, the unit will

turn off after 30 minutes of inactivity to save

battery life. If AUTO OFF is OFF the unit will stay

on until the POWER SWITCH is moved to the off

position.

BACKLIGHT - If BACKLIGHT is ON the

backlight will light all the time the unit is powered

up. For maximum battery life turn the backlight

off when using the calibrator in areas with

enough ambient light to read the display.

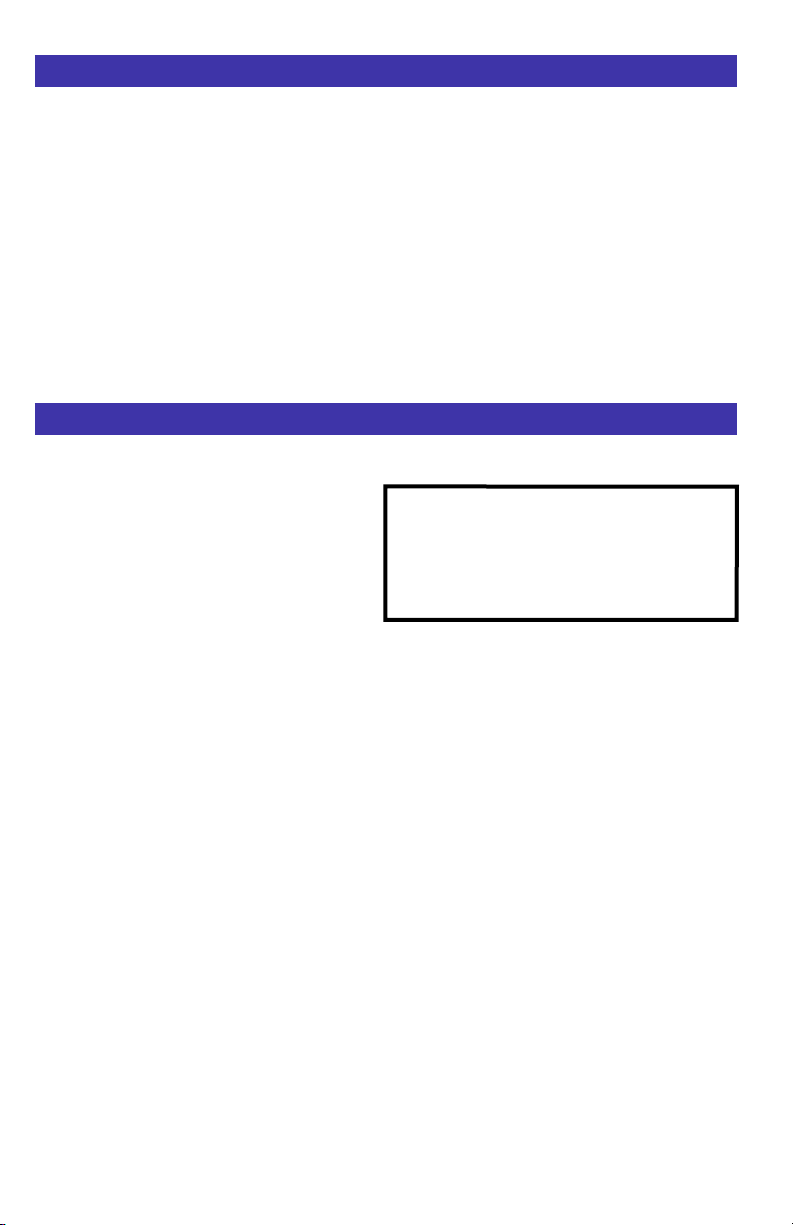

FEATURES

> EXIT (2/2)

AUTO OFF ON

BACKLIGHT ON

STEPS/RAMP 3

STEP/RAMP TIME 5

MAIN

> EXIT (1/2)

FUNCTION mA

MODE SOURCE

UNITS mA

HART 250ΩON

STEPS/RAMP - pressing the knob will cycle

through 2, 3, 5, 11 and RAMP. The endpoints of

the steps or ramp are based on the values

stored in the HI and LO EZ-CHECK outputs.

2 steps will automatically switch between the

values stored in the HI & LO EZ-CHECK (0 &

100%).

3 steps between the HI, Midpoint and LO

EZ-CHECK (0, 50 & 100%).

5 steps between the HI and LO EZ-CHECK

in 25% increments (0, 25, 50, 75 & 100%).

11 steps between the HI and LO EZ-CHECK

in 10% increments (0, 10, 20...80, 90 &100%).

RAMP continuously ramps up and down

between the HI and LO EZ-CHECK outputs.

STEP/RAMP TIME - pressing the knob will cycle

through 5, 6, 7, 8, 9, 10, 15, 20, 25, 30 and 60

seconds.

To start the Automatic Stepping

Start automatic stepping or ramping by placing

the EZ-CHECK Switch into the HI or LO position

then press and hold the eDIAL KNOB for 6

seconds (the word STORE will appear on the

display after 3 seconds and continue to press

the EZ-DIAL KNOB) until the word STEP

appears on the display. The word STEP will

appear on the display anytime the selected

automatic function is running. Stop the stepping

or ramping by again pressing and holding the e

DIAL KNOB for 3 seconds.