Hartridge HK900 User manual

HL030(EN), Issue 1, June 2005

World Leaders in Diesel Fuel Injection Test Equipment

HK900

All Makes Common Rail

Injector Test Kit (AVM2)

Operating Manual

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 1

CONTENTS

FOREWORD.........................................................................................................................................................3

1. INTRODUCTION.........................................................................................................................................7

1.1 SPECIFICATION...............................................................................................................................................7

1.2 RELATED DOCUMENTS...................................................................................................................................7

1.3 DEFINITION OF TERMS AND ABBREVIATIONS.................................................................................................7

2. INSTALLATION..........................................................................................................................................9

2.1 FIXTURE INSTALLATION AND HYDRAULIC CONNECTIONS .............................................................................9

2.2 UPGRADE TO AE31 PUMP CONTROL UNIT...................................................................................................10

2.3 INJECTOR CONTROL UNIT ............................................................................................................................10

2.3.1 Fitting/Installation ...............................................................................................................................10

2.4 ACCESSORY STORAGE..................................................................................................................................14

3. INTRODUCTION TO CR INJECTORS .................................................................................................15

3.1 CR INJECTOR OPERATION............................................................................................................................15

3.2 INJECTOR VALVE TYPES ..............................................................................................................................15

3.2.1 Solenoid Valves....................................................................................................................................15

3.2.2 Piezo Valves.........................................................................................................................................16

3.3 RECOMMENDED TEST SEQUENCE.................................................................................................................16

4. OPERATION ..............................................................................................................................................17

4.1 GUIDELINES FOR SAFE WORKING PRACTICE................................................................................................17

4.2 SOFTWARE OVERVIEW.................................................................................................................................17

4.3 TEST SETUP AND METHOD...........................................................................................................................19

4.3.1 Fit the Surrogate Pump........................................................................................................................19

4.3.2 Load a Testplan....................................................................................................................................19

4.3.3 Measure Injector Coil Resistance ........................................................................................................20

4.3.4 Install Injectors in the Fixture..............................................................................................................20

4.3.5 Run the Test Steps ................................................................................................................................21

4.3.6 End of Test ...........................................................................................................................................22

4.4 INTERPRETATION OF RESULTS .....................................................................................................................22

4.4.1 Response Time......................................................................................................................................22

4.4.2 Delivery................................................................................................................................................23

4.4.3 Backleakage (with HK901) ..................................................................................................................23

4.4.4 Summary...............................................................................................................................................23

4.5 CREATING/EDITING/SAVING TESTPLANS .....................................................................................................23

4.6 VIEWING AND PRINTING SAVED RESULTS....................................................................................................24

5. MAINTENANCE........................................................................................................................................25

5.1 REGULAR MAINTENANCE ............................................................................................................................25

5.2 TROUBLESHOOTING .....................................................................................................................................25

5.2.1 Status Indicator Light...........................................................................................................................25

5.2.2 Other Faults.........................................................................................................................................25

6. SPARES.......................................................................................................................................................26

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

2 HL030(EN), Issue 1, June 2005

This page left deliberately blank

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 3

Foreword

Copyright

Hartridge Ltd. reserves the copyright of all information and illustrations in this publication which is

supplied in confidence and which may not be used for any other purpose other than that for which it

was originally supplied. The publication may not be reproduced in part or in whole without the consent

in writing of this company.

© Hartridge Ltd.

Safety Information

Warnings, Cautions and Notes

The precautionary notes in this publication, indicated by the words WARNING, CAUTION, or NOTE

provide information about potential hazards to personnel or equipment. Ignoring these notes may

lead to serious injury to personnel and/or damage to equipment. These notes appear as follows:

WARNING! INDICATES THAT A SITUATION MAY BE HAZARDOUS TO PERSONNEL.

INSTRUCTIONS ARE PROVIDED FOR AVOIDING PERSONAL INJURY.

CAUTION! Indicates that conditions exist that could result in damage to equipment.

Instructions are provided to prevent equipment damage.

NOTE Indicates additional information for clarification where there may be confusion.

Operational Warnings

WARNING! HIGH PRESSURE FLUID SPRAYS CAN CAUSE SERIOUS INJURY

OR DEATH.

COMMON RAIL SYSTEMS OPERATE AT EXTREMELY HIGH PRESSURES. IF

USED AS INSTRUCTED THE TEST KIT WILL RELIEVE ANY HIGH PRESSURE

WHENEVER THE GUARD DOORS ARE OPENED.

DO NOT ATTEMPT TO BYPASS THE PRESSURE DUMP VALVE OR THE

SAFETY INTERLOCK.

Safety glasses must be worn when working on this equipment for the following

reasons:

1. The test equipment is capable of producing high pressure fluid jets or sprays

which can cause severe eye injury in the event of a malfunction.

2. The test stand uses calibration fluid which is harmful to the eyes.

Always start the system running at a low pressure and visually check for any leaks

before setting higher pressures. This particularly applies having just mounted a

system, or having just replaced a component.

Do not open the guard while the system is running. Wait for the test bench drive to

stop and for the pressure to decay to a lower level before opening the guard.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

4 HL030(EN), Issue 1, June 2005

Impervious gloves and overalls should be worn if regular contact with ISO4113 test

fluid is likely. The pump, high pressure control valve, and delivery lines to the

metering unit will become very hot after running. Wear protective gloves if

handling immediately after use. Refer to the Health & Safety Data Sheets.

General Warnings

Make sure there is adequate ventilation. Oil vapour may be released from hot

fixtures or high pressure leaks. The specific directions in Health & Safety Data

Sheets must be adhered to.

Keep hands and the body away from fluid sprays, especially injectors, leaking high

pressure pipes and seals. High pressure injection through the skin can result in

fatal injury. In the event of injection into the skin, seek urgent medical attention.

Refer to the Health & Safety Data Sheets.

Burns will occur to the hands if certain parts of the test stand or equipment under

test are touched. Keep hands away from the calibration fluid heater element and

injector or high pressure pipes after periods of extended running.

Safety footwear must be worn in the test area at all times. Injury to the feet may be

sustained in the event that equipment under test (during loading or unloading) or

test stand covers are dropped.

Severe injury can be caused by slipping on spilt oils or fluids. All spillages of fluids

in the test area must be dealt with immediately. These can be mopped up and

mineral absorbent material spread over the affected area.

Use calibration fluid and lube oil of the correct specification only. Obtain the

manufacturers Health & Safety Data Sheets and follow the advice given therein.

Prolonged and repeated contact with oil products, ingestion or excessive and

prolonged inhalation of oil mists can be detrimental to health. Use an appropriate

barrier cream.

Ensure that the servicing requirements and intervals as set out in the Maintenance

section are adhered to. Operate and service this equipment only if competent to do

so. Carry out regular inspections to make sure all high pressure connections are

tight and safe.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 5

Remove any tools, cleaning rags or other debris from the test stand before starting

up. Make sure the inching bar is not fitted to the test stand before starting up.

There must be no naked flames. Potentially flammable vapours are present in the

test stand and ignition is possible although unlikely. Smoking whilst operating the

equipment is strictly forbidden.

Accidents can occur to unauthorised personnel during testing. Untrained person(s)

must not be present in the test area when the equipment is operating. Only

qualified personnel are to operate this equipment.

Ensure good levels of lighting for safe, efficient equipment operation.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

6 HL030(EN), Issue 1, June 2005

This page left deliberately blank

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 7

1. Introduction

The HK900 Common Rail Injector Test Kit is designed to be fitted to the AVM2-PC Test Stand to

enable testing of Common Rail injectors. Additional mounting parts are available for testing specific

injector types.

NOTE: The AVM2-PC must be fitted with the following items in order to use the HK900 (all

available separately):

- HB378 Common Rail Base Kit

- HF1130 Common Rail Pump Test Kit

- Version 33 (or later) Magmah PC software

1.1 Specification

Refer to packing list for kit contents. The AE32 Injector Control Unit specification is as follows:

Power Supply

120/240V AC 50/60Hz Single Phase

Control Features

4-channel injector drive circuit, suitable for current Bosch, Delphi and Denso

solenoid injectors, and Siemens piezo injectors.

Measurements

Single channel solenoid resistance measurement.

4-channel response time measurement (via response time unit).

Auxiliary voltage measurement channel.

Miscellaneous

Status reporting.

Interface to HK901 for 4-line backleak flow and temperature measurement.

1.2 Related Documents

This manual describes the general operation of the HK900 kit for testing Common Rail injectors.

Bulletin TIB195/11 (also provided in this kit) outlines the accessories available and which injector

applications they cover.

Please contact Hartridge, or visit www.hartridge.com for the latest availability of accessories and

bulletins.

Users should also be familiar with the HB378 CR Base Kit manual (ref HL024), and HF1130 All

Makes CR Pump Kit manual (ref HL025).

1.3 Definition of Terms and Abbreviations

CR Common Rail

FIE Fuel Injection Equipment

PCV Pressure Control Valve

IMV Inlet Metering Valve

FCV Flow Control Valve

VCV Volume Control Valve

3rd CYL Pump 3rd Cylinder Solenoid (Bosch CP1 pumps)

PWM Pulse Width Modulation

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

8 HL030(EN), Issue 1, June 2005

This page left deliberately blank

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 9

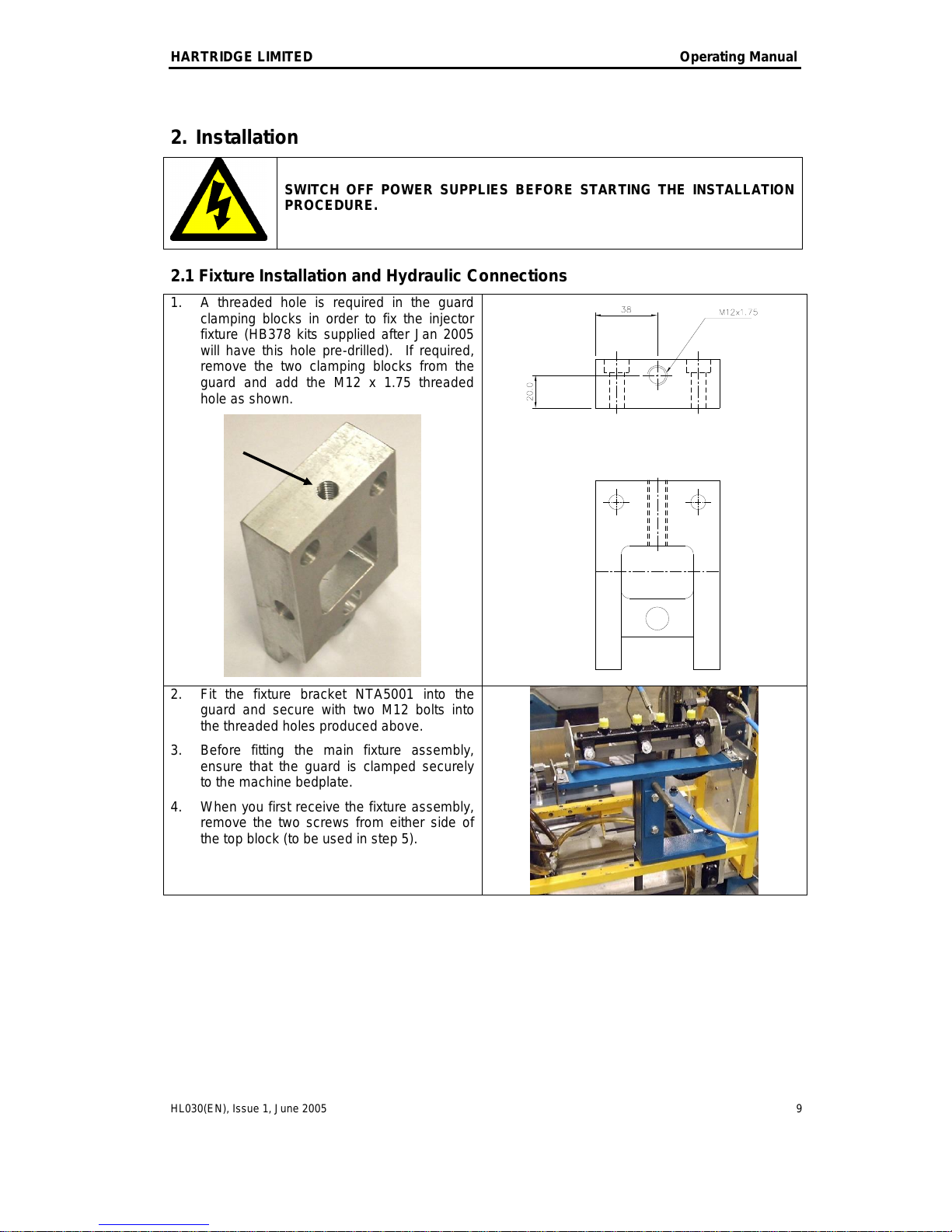

2. Installation

SWITCH OFF POWER SUPPLIES BEFORE STARTING THE INSTALLATION

PROCEDURE.

2.1 Fixture Installation and Hydraulic Connections

1. A threaded hole is required in the guard

clamping blocks in order to fix the injector

fixture (HB378 kits supplied after Jan 2005

will have this hole pre-drilled). If required,

remove the two clamping blocks from the

guard and add the M12 x 1.75 threaded

hole as shown.

2. Fit the fixture bracket NTA5001 into the

guard and secure with two M12 bolts into

the threaded holes produced above.

3. Before fitting the main fixture assembly,

ensure that the guard is clamped securely

to the machine bedplate.

4. When you first receive the fixture assembly,

remove the two screws from either side of

the top block (to be used in step 5).

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

10 HL030(EN), Issue 1, June 2005

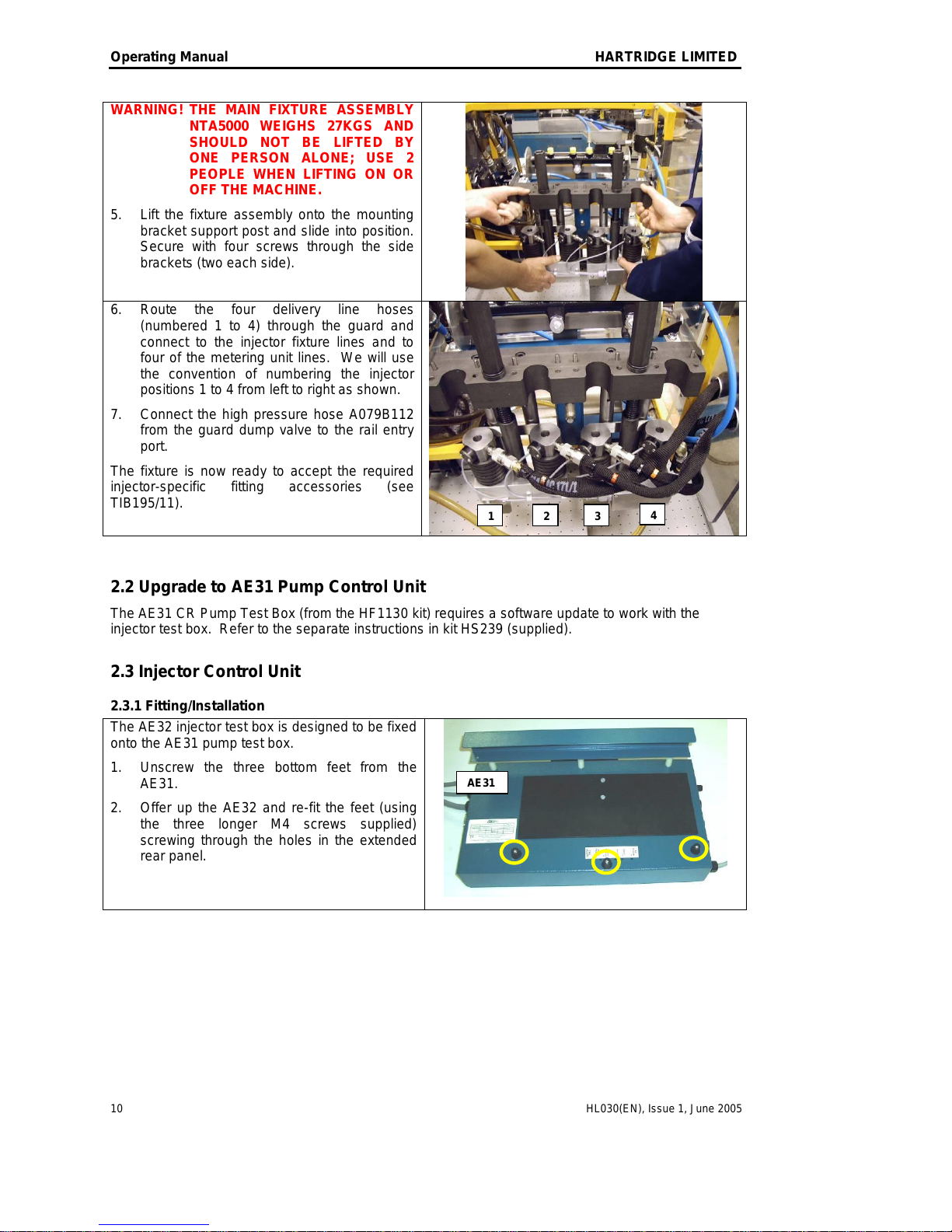

WARNING! THE MAIN FIXTURE ASSEMBLY

NTA5000 WEIGHS 27KGS AND

SHOULD NOT BE LIFTED BY

ONE PERSON ALONE; USE 2

PEOPLE WHEN LIFTING ON OR

OFF THE MACHINE.

5. Lift the fixture assembly onto the mounting

bracket support post and slide into position.

Secure with four screws through the side

brackets (two each side).

6. Route the four delivery line hoses

(numbered 1 to 4) through the guard and

connect to the injector fixture lines and to

four of the metering unit lines. We will use

the convention of numbering the injector

positions 1 to 4 from left to right as shown.

7. Connect the high pressure hose A079B112

from the guard dump valve to the rail entry

port.

The fixture is now ready to accept the required

injector-specific fitting accessories (see

TIB195/11).

2.2 Upgrade to AE31 Pump Control Unit

The AE31 CR Pump Test Box (from the HF1130 kit) requires a software update to work with the

injector test box. Refer to the separate instructions in kit HS239 (supplied).

2.3 Injector Control Unit

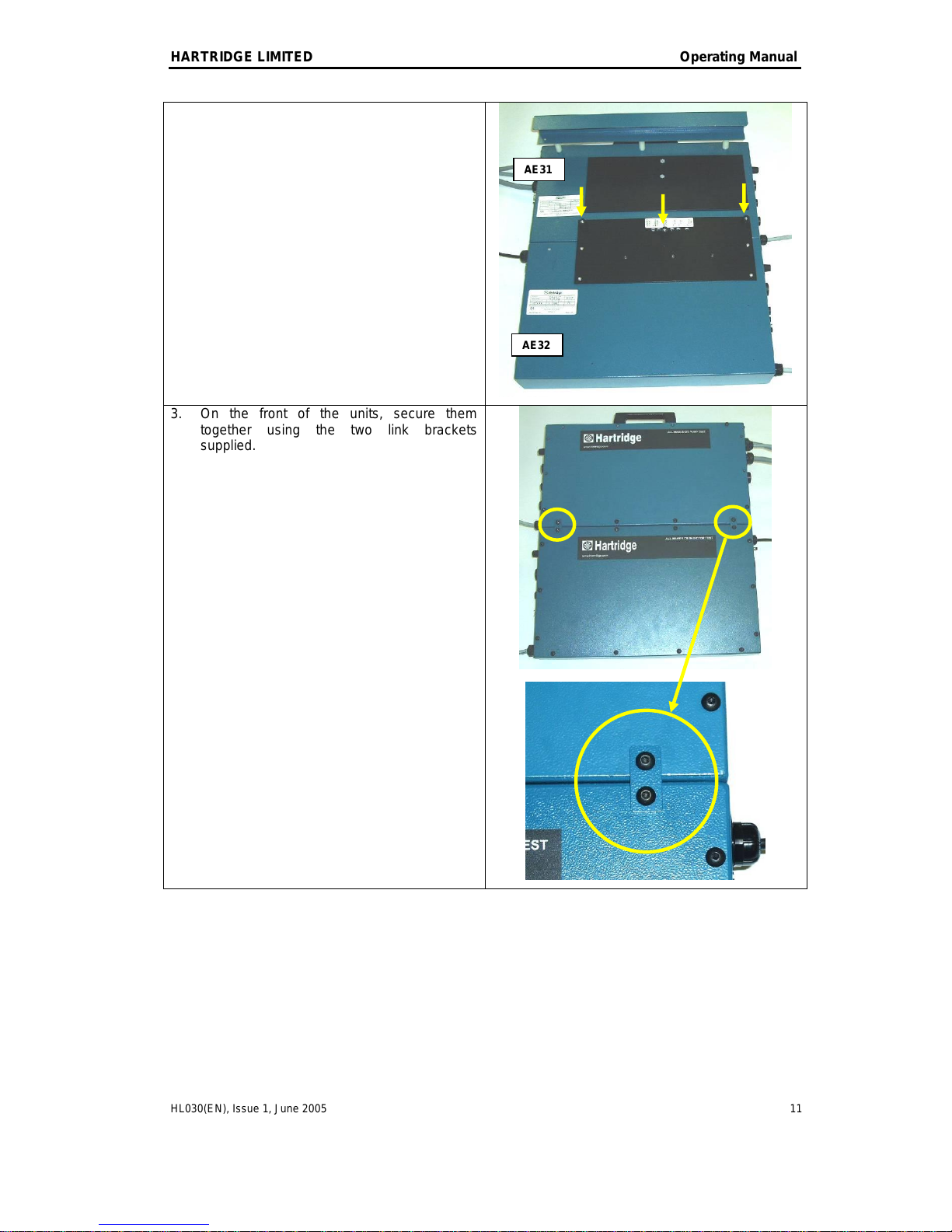

2.3.1 Fitting/Installation

The AE32 injector test box is designed to be fixed

onto the AE31 pump test box.

1. Unscrew the three bottom feet from the

AE31.

2. Offer up the AE32 and re-fit the feet (using

the three longer M4 screws supplied)

screwing through the holes in the extended

rear panel.

1

2

3

4

AE31

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 11

3. On the front of the units, secure them

together using the two link brackets

supplied.

AE31

AE32

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

12 HL030(EN), Issue 1, June 2005

2.3.2 Connections

The features on the left hand side of the box are as follows:

1. Power/status indicator light (see section 5.2.1).

2. Power switch.

3. Connection for Injector cable.

4. Connection for Resistance measurement cable.

5. Connection for HK901 Backleak Unit, and two status

indicator lights (these indicate the backleak unit status and will

be explained in the HK901 manual).

6. Auxiliary 5V output and measurement channel (spare –for

future use).

7. Flying lead for connection to the response time box (on

fixture NTA5000).

Figure 2.2: Box Features (Left)

The features on the right hand side of the box are as follows:

8. Flying lead for connection to AE31.

9. Connection for communications loom A089E956 (to avoid

confusion with the AE31 this loom has a RED D connector)

10. Push button for HK901 Backleak Unit diagnostics.

11. Single Phase power socket with 5A fuse, and voltage

selector switch.

Figure 2.3: Box Features (Right)

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 13

Once the AE31 and AE32 boxes have been fitted together, hang on the right hand side of the test

bench and connect as follows (the numbers in brackets refer to Figures 2.2 and 2.3 above):

CAUTION! The voltage selector switch must be set to the correct setting for your local single

phase voltage (120/240V).

1. Set the voltage selector switch (11) to the correct value then plug in the single phase power lead.

2. Connect flying lead (8) to the spare socket on the right hand side of the AE31 unit.

3. Connect the red D plug on loom A089E956 to socket (9) on the AE32. Plug the other end of this

loom into EXT2 on the rear of the AVM2. Plug the AE31 comms loom A086E913 into the spare

flying socket on this new loom.

4. Connect the flying lead (7) to the response time unit on the fixture.

You are now ready to connect the main injector drive lead to socket (3) and the resistance cable to

socket (4). These cables will depend on the injector type you are testing; see TIB195/11.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

14 HL030(EN), Issue 1, June 2005

2.4 Accessory Storage

The kit includes an accessory panel that can be wall mounted to help store and organise the various

accessory kits. The application/accessory bulletin TIB195/11 can be attached to the board for ease of

reference (using the magnets supplied). Accessory kits will be supplied with the appropriate storage

bins or clips to fit the panel.

Figure 2.4: Accessory Storage Panel

Further panels are available, part number NTA5050.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 15

3. Introduction to CR Injectors

3.1 CR Injector Operation

One of the main differences between Common Rail injectors and traditional mechanical injectors is

the introduction of electrical control; with Common Rail injectors the timing and duration of injection

are controlled using an electrically-operated valve. There are currently two types of valve, described

in section 3.2 below.

In terms of the hydraulic operation, high pressure fuel is supplied to the nozzle body and to a chamber

on top of the control needle. The electrical valve opens/closes a leak off path from this chamber into

the return circuit. When the valve is closed, the high pressure acting on top of the control needle

keeps the injector firmly closed. Opening the valve relieves the high pressure from the top of the

needle, opening the nozzle and starting the injection. Closing the valve re-establishes the high

pressure on top of the control needle, quickly shutting off the injection.

The volume of fuel delivered is proportional to both the duration of the pulse (pulse width), and the

applied pressure, as shown by the graph in Figure 3.1. Typical pulse widths are in the range of 200 to

2000s. There is a minimum pressure below which the injector will not open; this is typically around

200 bars.

s

mm3/stk

b a r

Figure 3.1: Effect of Pressure and Pulse Width on Delivery

3.2 Injector Valve Types

3.2.1 Solenoid Valves

These are electromagnetic coil valves; Figure 3.2 gives a schematic of the drive signal (showing

current against time). There is a higher “pull-in current” (Ip) to initially open the valve, followed by a

lower “hold current” (Ih) to keep the valve open. The overall pulse width (T) is the combined width of

the pull-in and hold phases. There is a maximum limit on the pull-in current to protect the solenoid.

Injectors with solenoid valves are currently manufactured by Bosch, Delphi, and Denso. Each of these

manufacturers uses a different specification for operating voltage and current levels.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

16 HL030(EN), Issue 1, June 2005

Ip

Ih

T

Figure 3.2: Solenoid Injector Drive Signal

3.2.2 Piezo Valves

These use the inherent properties of piezo crystals (that they deflect with applied voltage) to activate

the valve. There is a positive current pulse (I) to switch the valve on, and a negative current pulse to

switch the valve off. The overall pulse width (T) is the time between the positive and negative current

pulses.

I

T

Figure 3.3: Piezo Injector Drive Signal

Siemens were the first manufacturer to introduce piezo injectors, the main advantage over solenoid

valves being that piezo valves have a much faster response time.

3.3 Recommended Test Sequence

The recommended test sequence for Common Rail injectors is as follows:

1. Initial Check Use a Testmaster (HH701) and Signal Unit (HK85x) to check the basic

operation of the injector and the nozzle spray pattern.

2. Cleaning and Repair If required, clean the nozzle in an ultrasonic tank, or dismantle the

injector and replace faulty components. Any dismantling and reassembly

should be done in a clean environment.

3. Re-do initial Check Re-check the injector on a Testmaster after cleaning/repair.

4. Final Test Carry out a full delivery, backleak, and response time test on the

injectors using the HK900 and HK901kits.

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

HARTRIDGE LIMITED Operating Manual

HL030(EN), Issue 1, June 2005 17

4. Operation

WARNING! HIGH PRESSURE FLUID SPRAYS CAN CAUSE SERIOUS

INJURY OR DEATH.

COMMON RAIL SYSTEMS OPERATE AT EXTREMELY HIGH PRESSURES. IF

USED AS INSTRUCTED THE TEST KIT WILL RELIEVE ANY HIGH PRESSURE

WHENEVER THE GUARD DOORS ARE OPENED.

DO NOT ATTEMPT TO BYPASS THE PRESSURE DUMP VALVE OR THE

SAFETY INTERLOCK.

WARNING! THE CONTROLS IN THE HK900 KIT HAVE BEEN DESIGNED TO

WORK WITH ONE OF THE FOLLOWING CR PUMPS:

BOSCH CP1 (WITH PCV) OR SIEMENS

DO NOT ATTEMPT TO USE ANY OTHER TYPE OF PUMP WITH THE KIT.

4.1 Guidelines for Safe Working Practice

Always start the system running at a low pressure and visually check for any leaks

before setting higher pressures. This particularly applies having just mounted a

system, or having just replaced a component.

Do not open the guard while the system is running. Wait for the test bench drive

to stop and for the pressure to decay to a lower level before opening the guard.

The pump, injectors, and delivery lines to the metering unit will become very hot

after running. Wear protective gloves if handling immediately after use.

4.2 Software Overview

The HK900 kit is controlled through the AVM2 PC software; Magmah version 33 or later is required (a

software upgrade kit must be ordered separately if your AVM2 does not have version 33).

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Operating Manual HARTRIDGE LIMITED

18 HL030(EN), Issue 1, June 2005

The software automatically detects when the kit is fitted, and enables the Common Rail injector

control features. Pressing F2 [Metering] from the Main Menu takes you to the new CR Injector Test

screen. This is shown below and explanation of the key areas follows:

Figure 4.1: CR Injector Control Screen

1. Results File Information Shows results file information in results view.

2. Injector Characteristics Shows the injector type loaded and the basic electrical characteristics:

Supply Voltage; Pull-in Current; Hold Current; and Maximum Pulse

Width.

3. Testplan Section Drop-down list of up to 10 test steps. Each step has associated settings

for: Pressure Demand, Speed, Pulse Width, Backleak Pressure, and can

include limits values for Backleak flow, Delivery, and Pressure.

4. Injector Selection Click on the numbered button to turn on metering. Tick the box and

press [Apply Step] to switch on the injector.

5. Resistance Results Injector resistance measurements in Ohms.

6. Response Time Injector response time measurements in microseconds.

7. Metering Line Selection Enter the number in the box for the metering line you are using for that

injector.

8. Delivery Results Bar graph showing delivery metering results.

9. Backleak Results (Only if HK901 fitted). Backleak temperature reading in deg. C. Bar

graph showing backleak flow results. NOTE: the inner grey bar is an

instantaneous reading for indication only; the outer bar and the numerical

value give the accurate result.

10. Speed Readings Pump and Engine Speeds.

11. Rail Pressure Actual rail pressure feedback (from Dump Valve pressure transducer).

THIS IS AN UNCONTROLLED DOCUMENT downloaded by Lukas Matuska on 16 Feb 2016

Any technical intervention requires certified Hartridge training. Contact Hartridge Ltd for details.

Table of contents

Other Hartridge Test Equipment manuals

Popular Test Equipment manuals by other brands

T&R

T&R 200A-3PH Operating and maintenance manual

Tektronix

Tektronix ST112 user manual

Shineway Tech

Shineway Tech GET-100 user manual

Distek

Distek Premiere 5100 Operation manual

Delta

Delta PFM907 user manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 8031 CE instruction manual