FEATURES AND FUNCTIONS

• Allows torque wrenches to be calibrated or tested in accordance with BS EN 26789:2003, ISO 6789-1:2017

and ISO 6789-2:2017.

• Counterbalance reaction is designed to support the weight of the wrench so that the weight does not

become a parasitic force within the calibration system. The floating nature of the support means that the

wrench is able to find its own natural level rather than being constrained as in many other loading devices.

Any such constraint will be a parasitic force within the system. (Patents apply).

• Lightweight alloy construction ensures the TWC is easily transported, making it well suited for mobile

laboratory applications.

• Rotating transducer design ensures that the load is applied 90° to the torque wrench handle. The benefit of

this precise alignment is that forces are applied squarely to the load point of the handle.

• Supplied with a powerful yet simple touchscreen User Interface (UI) (keyboard and mouse also supported if

desired).

• Flexible tool template system; minimises number of templates required to cover a wide range of tools,

aiding efficient use.

• Programmable calibration workflow for each template, can be pre-set to ISO compliant flow for the given

tool for a faster set-up or can also support bespoke workflows.

• Calibration job management; book calibrations, track progress of previous bookings and resume them.

• Automated management of calibration and conformance workflows for non-indicating tools.

• Intelligent rate control system ensures fast cycling of tools while maintaining compliance with 2017

standards.

• Environmental monitoring (humidity/temperature) to ensure compliance with calibration standards.

• Automated management of uncertainty data for ISO 6789-2:2017 calibrations, guiding the user through the

process using dynamically generated instructions based on the current tool’s ISO classification and

workflow.

• Inbuilt data analysis and certification generation seamlessly move from calibration/conformance procedure

to certificate generation, no third-party software required.

• A substantial amount of inbuilt storage allowing for several years' worth of calibration data through normal

use.

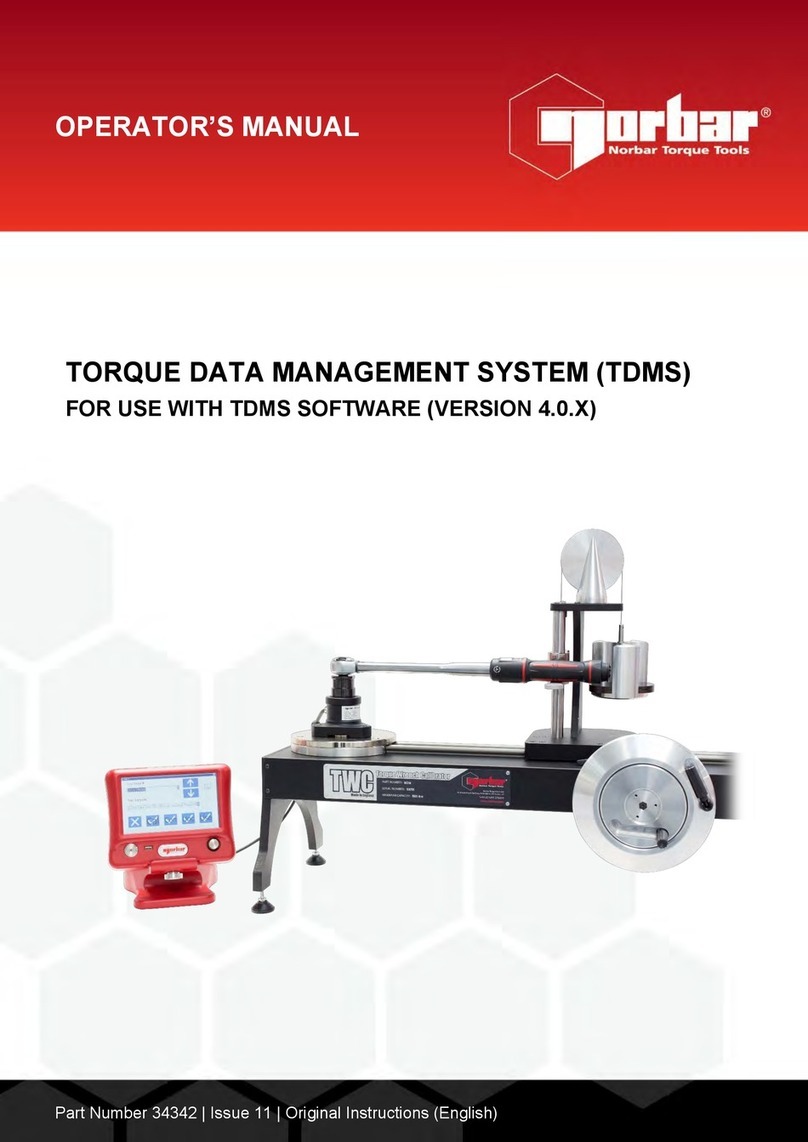

TWC if lifted)

mounting

platform

Counter Balanced

Reaction post assembly

page 7)

Touchscreen

User Interface

Gear input

FIGURE 1 – TWC Auto Features