Dilo SF6 User manual

SF6/ CF4mixing and maintenance unit

Operating Manual (original version)

Type-no.: Z863R01 |Comm-no.: 30000400 |

Year of construction: 2014

Table of contents

www.dilo-gmbh.com |0000.bae

General safety notes 1

Product description 2

Dimension sheet / Technical data

Transport and installation 3

Setting into operation 4

Functional description 5

Mixing of SF6and CF4

Evacuation of air from the gas compartment

Removal and storage of SF6

Filling the gas compartment with SF6 gas

Flooding the gas compartment with ambient air

Special functions for maintenance 6

Purge compressor

Pressure reduction

Recovery of filter

Evacuation of filter

Pressure test compressor

Manual operation

Evacuation of air from the service cart

Filling of external cylinders from the internal storage tank

Options for service cart 7

Fault correction 8

Maintenance and functional test 9

Circuit diagram and spare parts list 10

Operating- and maintenance manuals for integrated components 11

Please read this operating instruction before putting the device into operation. Thus operating faults can be

avoided. In case of nonobservance of the operating instruction the manufacturer cannot assume any liability or

warranty.

The copyright of this documentation remains with DILO Armaturen und Anlagen GmbH, D-87727 Babenhausen.

Any use not permitted by the author (multiplication, leaving to third persons etc.) is subject to penalty and

indemnification.

General safety notes

www.dilo-gmbh.com |0100.bae

Obligation to exercise due care

The device has been designed and constructed bearing in mind the standards to be observed as well as

additional technical specifications.

Safe use of the machine can only be achieved if all the necessary measures are followed.

The operator has to ensure that

the device is only used for the purposes for which it is intended (see chapter 2 product

description).

the device is only operated in accordance with the instructions and in good condition and that the

safety devices are regularly checked.

maintenance and repair personnel are issued with all the required safety and protective clothing,

which shall always be used.

complete and legible operating manuals are available on site.

only qualified personnel operates or repairs the device.

this personnel is regularly instructed in safety procedures and environmental protection and that

this personnel is fully aware of the complete operating manuals and particularly in the safety

notes.

the safety and warning notes mounted on the device are legible and not removed.

all obligatory registrations and tests prescribed by law are carried out on the devices in

accordance with the local regulations (e. g. pressure vessel tests, test for electrical safety etc.)

the safety data sheet on SF6(can be obtained from the SF6 supplier) is available for the operating

personnel. The instructions mentioned in the data sheet and safety precautions must be known

and observed by the operating personnel.

General safety notes

www.dilo-gmbh.com |0100.bae

Specific safety notes and standard symbols

In the following operating manual specific safety warnings are given in order to draw your attention to

residual risks which cannot be avoided during the operation of the device.

These residual risks contain dangers for

Persons

Product and machine

The environment

The symbols used in the operating manual should draw your attention specially to the

safety notes:

This symbol refers to risks for persons (danger to life, danger of injury)

This symbol refers to risks for machines, material and the environment.

This symbol refers to electric shock

The most important aim of the safety notes is to prevent personal injuries.

If the warning sign „Danger“, appears, danger from machines, materials and the environment are

not excluded.

If the warning sign „Warning“, appears, there is no danger for persons.

The corresponding symbol which is used cannot replace the text of the safety note.

Therefore the complete text must always be read.

This symbol is not for safety notes, but for information to understand the

device better.

Danger

Warning

General safety notes

www.dilo-gmbh.com |0100.bae

Basic safety measures during normal operation

The equipment may only be operated throughout the EU by trained and

qualified persons who have been certified in accordance with EC 305/2008

regulations. Transition period until 30th June 2009.

Only trained and authorized persons who are fully aware of the operating manuals should operate the

device and should do so in accordance with the operating manuals.

Before switching on the device ensure that

only authorized persons are present at the device

nobody can be hurt by the operation of the device

Whenever the device is started check for visible damage beforehand and ensure that it is operated in the

correct conditions. Eliminate any damage immediately or inform your supervisor.

Prior to each start check and make sure that the safety features are properly set.

For concentrations of SF6decomposition products of > 100 ppmvwe

recommend using a pre-filter unit to protect the device.

In case of contamination, rinse the device (for at least 10 minutes) with pure

SF6-gas, e. g. by circulation.

All gas compartments and vessels connected to the device via gas connecting

coupling and connecting hose must be equipped with their own safety

equipment against overpressure and vacuum.

The safety equipment integrated in the device only serves for the self-protection

of the device without consideration of the load-bearing capacity of the gas

compartment connected. In case of non-observance there is the danger of

implosion or explosion of the gas compartment if the device is not operated

correctly.

Warning

Danger

General safety notes

www.dilo-gmbh.com |0100.bae

Installation of the device

Position the device on level surface and hard subgrade only. The locking device of the wheels is

not appropriate to put the device on hilly ground.

Only operate the device in sufficiently large and ventilated compartments (room volume > 100 m³)

so that the admissible SF6concentration in ambient air is not exceeded in case of leakages

incurring suddenly.

For operation in smaller compartments SF6warning devices must be available as well as the

possibility to leave the compartment quickly.

In case the device is burning the pressure vessel must be cooled down to prevent an

inadmissible high increase in pressure.

Personal protective equipment for operating personnel

Safety gloves which allow the operation of the electrical operating elements.

Ear protection is recommended for all devices with a sound power level of > 80 dB(A). As from 85

dB(A) the use of ear protection is compulsory.

Safety shoes

Wearing safety goggles is necessary in case hoses and tubes which are under pressure are

opened (e. g. cylinder threads on SF6-gas bottles), as gas or fluid jet could escape.

Basic safety measures during maintenance

Follow inspection and maintenance periods described in the operating manuals.

Follow maintenance and repair instructions for individual components in these operating

manuals.

Prior to carrying out maintenance and repair works turn off the main switch for the power supply

and secure it with a padlock. The key for this lock must be in the hands of the person who carries

out the repair works.

If there is no main switch unplug the power supply cable at the plant and secure against it being

plugged back in.

When exchanging heavy machine parts only use suitable lifting devices in good working

condition. Heavy components are to be secured against falling down by proper facilities.

Prior to carrying out maintenance or repair works ensure that parts which may need to be

handled have cooled down to room temperature.

Dispose of grease, coolant or cleaning material in accordance with environmental regulations.

If a device has been contaminated with SF6decomposition products additional safety measures

are to be taken. Furthermore protective clothing and a dust mask depending on the degree of

contamination is required.

The working protection set is available under the order number: 3-442-R001.

General safety notes

www.dilo-gmbh.com |0100.bae

Work on electrical equipment

Only properly trained electricians should carry out repair works on the device electrical

equipment.

Regularly check the electrical equipment.

Re-tighten loose connections.

Replace damaged lines/cables immediately.

Always keep the control cabinet closed. Only authorized persons with key/tools should

work on the device.

Never clean control cabinets and other electrical equipment housings using a water

hose.

Work on SF6-gas filled equipment

Only specially trained personnel should carry out maintenance and repair works on pressure gas filled

equipment.

Prior to maintenance and repair works depressurize the pressure gas filled equipment of the device.

Replace hose lines for preventive purposes even if no damage is visible. (Follow recommendations of

manufacturer).

After having carried out maintenance and repair works and prior to putting back into service

check that loosened screw connections are properly seated.

ensure that the tank caps, sieves or filters that have been removed have been re-installed.

After having carried out the maintenance and repair works and before operation ensure that

all materials, tools and other equipment which were necessary for the maintenance or repair

works have been removed from the working area of the device.

liquids that may have come out have been removed (wiped away)

all safety devices for the unit are properly set and in working order.

General safety notes

www.dilo-gmbh.com |0100.bae

Observe environmental standards

Whenever working on and with the device please observe legal requirements for waste handling and

disposal.

Particularly during installation, repair and maintenance works substances that cause water pollution such

as:

lubricating greases and oil

hydraulic oils

cooling agents

cleansing liquors containing solvent

must not contaminate the soil or flow into drains.

These substances should be stored in suitable vessels, and removed and disposed of according to local

regulations.

The equipment contains the greenhouse gas SF6 as stipulated in the Kyoto

Protocol, with a global warming potential (GWP) of 22200. SF6 needs to be

recovered and must not be released into the atmosphere.

When using and handling SF6 please observe IEC 62271-4 (High-voltage

switchgear and controlgear – Part 4: Handling procedures for sulphur

hexafluoride (SF6) and its mixtures).

Danger

Product description

www.dilo-gmbh.com |0200.bae

Product description

Correct use

This service cart is designed for the recovery and putting into storage of SF6-gas from gas

compartments. Gas compartments can also be flooded with air, evacuated and filled with SF6-gas.

During each recovery and filling operation the SF6-gas passes through filters, which dry and purify the

gas.

Do not use the cart to exhaust or compress liquids or other gases.

Use of the SF6-gas service cart for any other purpose may not be safe.

The manufacturer will not accept any liability in case of injury and damage

caused by use of the cart for applications for which it was not intended.

We recommend that all persons who are involved in the operation and repair of DILO devices are

properly and specially trained.

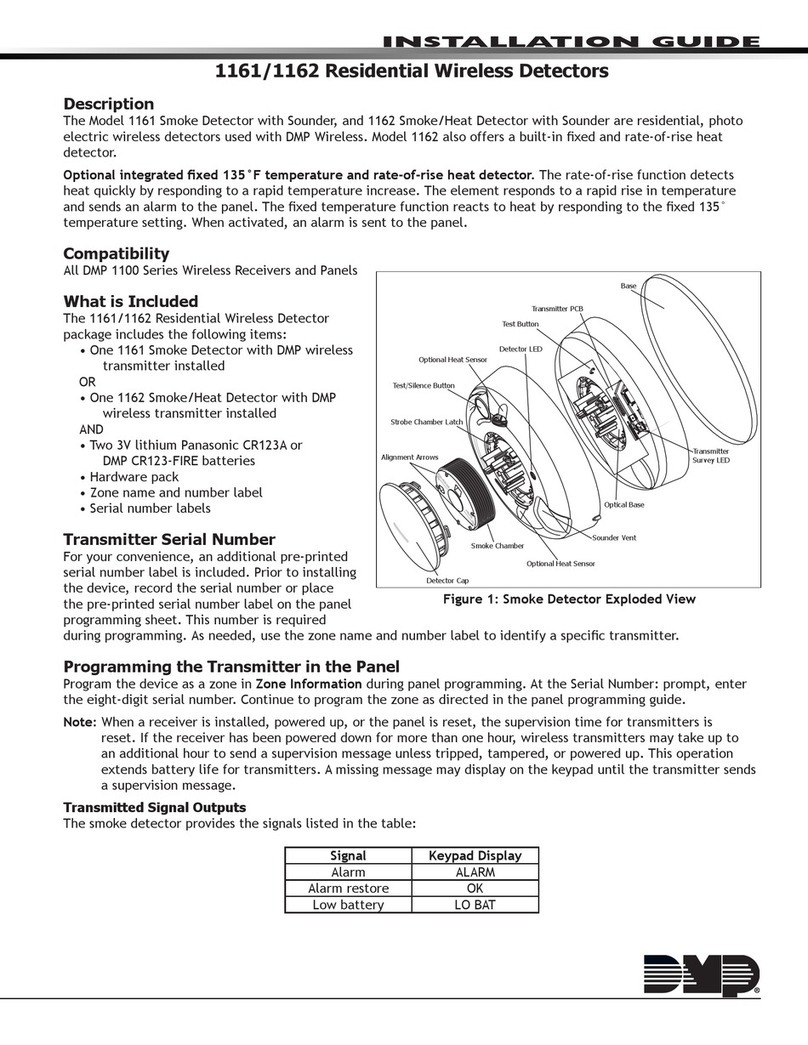

Construction and operation of the service cart

The service cart consists of the following components:

Sheet metal frame evaporator (only for liquid storage)

Compressor storage tank or storage bottles (option)

Vacuum compressor or suction pump particle filter / dry filter

Vacuum pump electric control

Sheet metal frame:

The frame is of sheet metal construction.

It is designed with provisions for fork lift loading and unloading. The standard version is equipped with

fixing- and steerable rollers with brakes.

The wheels on versions with a storage tank or SF6-bottle storage are bolted to the frame. This type of

wheel is not provided on road trailer versions.

Danger

Product description

www.dilo-gmbh.com |0200.bae

Compressor:

The compressor is a dry running type and operates entirely without oil. It is available for different delivery

rates and different final pressures (see technical data).

The compressor housing is absolutely gastight, but the maintenance of the compressor can be carried

out easily. The working overpressure is controlled by a pressure reducer and a contact gauge. The

operating temperature of the motor winding and the cylinder heads are controlled by a thermistor.

(Technical data and description see chapter 11 of the operating manuals for the compressor).

Suction pump: (if included)

The suction pump allows the recovery of gas down to < pa 1 mbar (absolute). The suction pump is a dry-

running type, which operates entirely without oil. It is protected from inadmissible operating conditions by

a pressure switch, pressure sensor, solenoid valves and regulating valve. The suction pump only

switches on automatically at pressures of about pe= 0.1 bar.

The pressure on the output side of the suction pump is controlled by a pressure sensor. The regulating

valve on the suction side prevents a too high output pressure by throttling on the input side.

The output pressure is regulated to about pa 1000- 1050 mbar by the regulating valve on the output of

the suction pump so that the compressor cannot generate any depression on the suction pump and

cause ambient air to be sucked in.

Do not connect any gas compartment with overpressure to the suction side while

the suction pump is running as the suction pump can be damaged by

overpressure.

(Technical data and description see chapter 11 of the operating manuals for the

suction pump).

Vacuum compressor: (if included)

The vacuum compressor allows the recovery of gas down to < pa 50 mbar.

The vacuum compressor is a dry-running type and is protected from inadmissible operating conditions by

manostat, solenoid valve and return valves.

The vacuum compressor switches on automatically during the gas recovery process.

(Technical data and description see chapter 11 of the operating manuals for the vacuum compressor).

Warning

Product description

www.dilo-gmbh.com |0200.bae

Vacuum pump:

The vacuum pump allows the evacuation of air from gas compartments.

To avoid any damage to the vacuum pump it must be protected from overpressure. The solenoid valve

upstream from the vacuum pump only opens if there is no overpressure on the suction side. Reduce the

SF6-overpressure with the compressor and vacuum compressor or suction pump as described under the

operating description “Gas recovery”.

Release air or nitrogen via the venting ball valve.

The vacuum pump only exhausts into the atmosphere.

(Technical data and description see chapter 11 of the operating manuals for vacuum pump).

Evaporator: (only for devices with liquid storage)

The evaporator consists of a special steel housing with electric heating coils inside. It serves to ensure

vaporisation of liquid SF6.

The temperature is regulated via a control unit.

Storage tank:

The SF6-gas is stored in gaseous form or at higher pressure in liquid form. We distinguish between

storage in a pressure tank in gaseous form up to 25 bar and in liquid form up to 50 bar. (Attention! Do

not use these pressure tanks for transport of SF6-gas).

Check the pressure rating of the tank to confirm gaseous or liquid storage. If gas is stored in transport

bottles (in liquid form), please ensure the maximum fill weight stamped on the bottle is not exceeded.

Only use bottles registered for SF6-gas.

For transport of tanks with weight indication the weight must be taken off the

load cell prior to weighing it.

Pressure vessels must not be worked on mechanically, welded or heated.

The type plate must not be removed or made illegible.

Pressure vessels (e. g. SF6-tank, dry filter 64bar) should be approved by the

local technical control organisation.

The pressure vessels are produced and approved in accordance with the

corresponding regulations. (e.g. 97/23 EC).

The operator is responsible for approval and repeating checks.

Particle filter/ Dry filter:

The SF6-gas is purified and dried with the particle filter and dry filter installed in the system. During each

gas handling process the SF6-gas passes through these filters.

(see chapter 9 dry filter or particle filter)

Warning

Product description

www.dilo-gmbh.com |0200.bae

Functional description of the unit:

Electric control:

Power is supplied through the plug mounted on the control cabinet.

The correct phase sequence is checked by a device monitoring the direction of rotation.

The direction of rotation can be modified by means of the integrated reversing switch.

All components are protected by motor protection circuit breakers.

The control circuits are powered at 24V DC.

All other electrical components (e. g. temperature regulation) are supplied at 230V AC.

Both voltages (230 V AC and 24V DC) are generated from the connected supply voltage with a

transformer or a power supply unit.

All important process parameters are displayed on the operating panel.

The device is operated via the operating panel, the knob switch and the start / stop key.

Furthermore, the operating times of the components are indicated on the operating panel. The weight of

the storage tanks (if included) and the weight of the integrated bottle scales are also displayed on the

operating panel.

General information:

All operating elements and control monitoring systems are well arranged on the front panel.

All connecting lines are produced according to the well-proved DILO metal-to-metal sealing principle and

are absolutely tight.

Product description

www.dilo-gmbh.com |0200.bae

Function selection:

The desired functions are to be selected by means of the knob switch.

The following functions are available:

1: Evacuation of air

2: Recovery of SF6

3: Filling of SF6

4: Purge compressor

5: Pressure reduction

6: Recovery of filter

7: Evacuation of filter

8: Pressure test of compressor

9: Manual operation

The selected function is displayed on the operating panel in the upper line.

Double key “1“/ “0“:

This double key serves for starting and stopping the functions.

0: This key has a double function.

When pressing this key the active function is completed. It is also used to confirm the indicated

malfunction message.

1: If there is no malfunction message the function selected by the knob switch can be started.

There is a control lamp between both buttons of the double key which lights up if a function is running.

Operating panel (basic configuration):

Selected function

Storage pressure

Storage weight

Screen selection “Settings“

Screen selection “Manual operation“

Gas compartment pressure

Product description

www.dilo-gmbh.com |0200.bae

Input of values and activation of screen selection

Symbols and digits are input by means of the “F1 – F10” function keys on the operating panel.

Proceed as follows:

1. Select the desired parameter by means of the arrow keys.

2. For modification of the parameter press the <ENTER>- key.

3. Press the corresponding “F1 - F10” key until the desired digit is displayed on the screen.

The desired digit is accepted after one second or immediately after having pressed another key.

4. For navigation between the digits use the arrow keys.

5. Confirm the input by pressing the <ENTER> key.

Product description

www.dilo-gmbh.com |0200.bae

Settings:

When pressing the “Settings“ screen selection key the settings screen can be paged through and

modifications can be carried out.

Note for hysteresis: Input of final vacuum: e. g. 5 Torr

Input of hysteresis: e. g. 4 Torr

The suction pump starts the recovery process after having reached the final vacuum of 1 Torr (difference

final vacuum to hysteresis). Finally a vacuum test is carried out. If the pressure does not exceed the final

vacuum the function is completed automatically.

Note: the entered final vacuum must be higher than the hysteresis entered!

Product description

www.dilo-gmbh.com |0200.bae

The running times of the components are displayed here.

Product description

www.dilo-gmbh.com |0200.bae

Manual operation

In manual operation the components and the valve can be switched separately.

In order to reach the manual operation the basic configuration must be set on the operating panel.

Press the “down arrow” key and turn the knob switch to the position 9.

In case the knob switch is not in position 9 the following page appears:

This page can be left by pressing the “down arrow” key or turn the knob switch to the position 9.

If the manual operation is selected correctly the following page appears:

Now the components indicated on the operating panel can be switched on and off or the valves can be

opened and closed by means of the corresponding function key.

In order to complete the manual operation press the “down arrow“ key and select another function with

the knob switch.

Product description

www.dilo-gmbh.com |0200.bae

Modification of the running times of the components:

This section is only accessible for authorized operators as the switching off

parameters of the scales can be set here.

The running times of the components can only be modified by the supervisor.

For modification press the <F10> key on the basic configuration.

Then enter the password.

After entering the correct password press the <F910> key once again and the page for setting the

running times of the components appears. If the password is incorrect you have to enter the password

again.

Danger

Product description

www.dilo-gmbh.com |0200.bae

The running times of the components can be modified here.

Press the “up arrow” key to leave this page and to reach the storage weight page.

Return to the basic configuration by pressing the “up arrow” key.

Dimension sheet / Technical data

www.dilo-gmbh.com |0202.bae

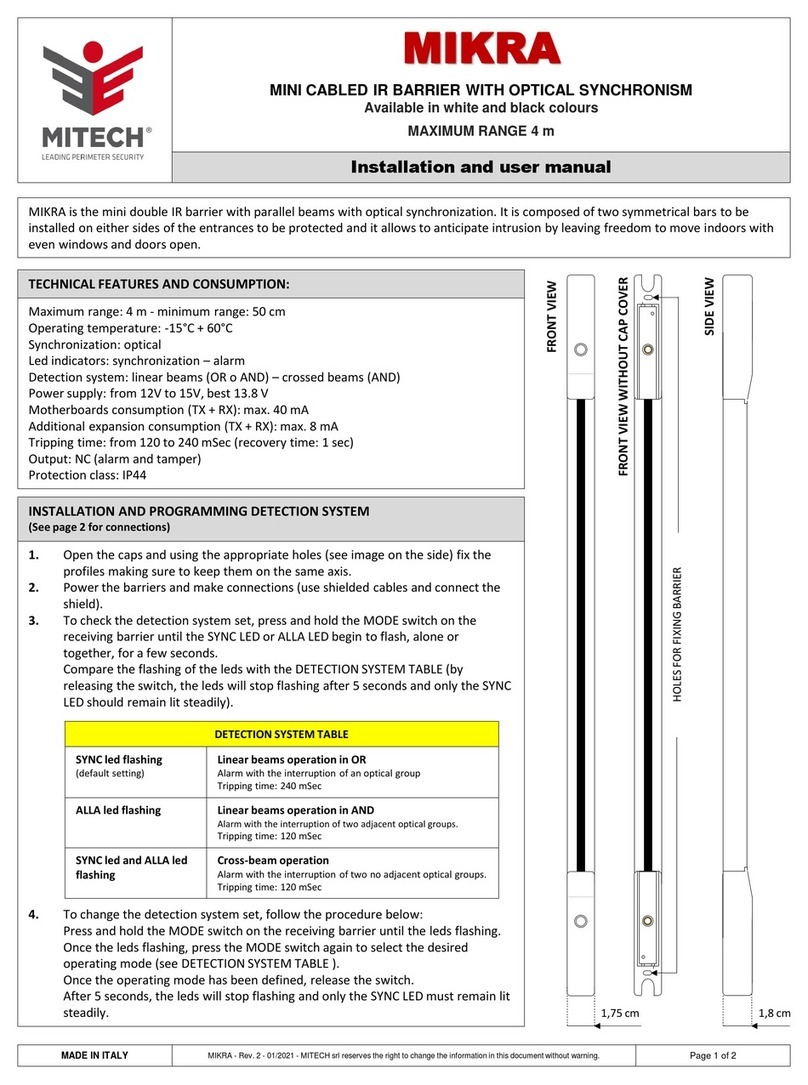

Z863R01

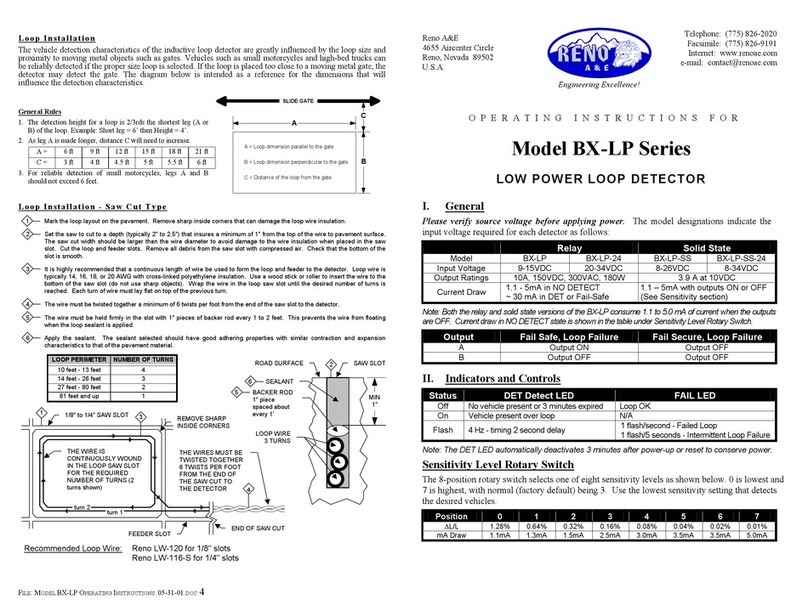

Dimensions Length Width Height Net weight

without storage rack 2300 mm 1200 mm 1000 mm 780 kg

Compressor: Theoretical delivery

rate: Final pressure

max. peDifferential pressure

max.

5.7 m³/h 50 bar 49 bar

Suction pump: Theoretical delivery

rate: Final vacuum:

15 m³/h 1 mbar

Vacuum pump: Theoretical nominal

suction capacity: Final vacuum:

Standard 40 m³/h 1 mbar

Sound level: < 85 dB(A)

Paint: orange RAL 2004

Operating voltage: see type plate

Admissible ambient temperature: 0 to 45°C (Busch vacuum pump)

Electrical connection:

Operating voltage: 208-240V, 50/60 Hz 380-500V, 50/60 Hz

Fuse protection: 32 -50 A time delay 25-32 A time delay

Conductor diameter: ≥10 mm² (AWG 7) ≥6 mm² (AWG 9)

Power plug: 63 A 32 A

Illustration: without storage rack

This manual suits for next models

1

Table of contents

Other Dilo Security Sensor manuals

Popular Security Sensor manuals by other brands

brennenstuhl

brennenstuhl PIR 240 IP44 V2 Directions for use

Honeywell

Honeywell Fire Sentry FS7-2173-2RP Installation guide and operating manual

Xtralis

Xtralis VESDA ECO Product guide

Skil

Skil 0550 instructions

Roaring Forties

Roaring Forties SMA2751 owner's manual

Menlo Systems

Menlo Systems FPD510 operating manual