20

6.5 Transmitter parameter setting

6.5.1 Open the cover. Using selector switch «FREQ» (Pt. 5, Fig Fig 6.8), select the required

frequency of sinusoidal transmission (512/1024/8192 Hz).

6.5.2 Using selector switch «MODE SIN» (Pt. 4, Fig 6.8), select the required type of sinusoidal

transmission («CONT»/« »/»3 FREQ»).

- continuous mode is required for most multi-sensor digital receiving systems;

- pulsed mode – highly economical mode with high legibility against the interference background

for interface with analogue (mainly, one-sensor) receiving systems;

- three-frequency mode provides for selection of optimum frequency at the remote receiver

without changing the transmitter frequency.

6.5.3 Using selector switches «SOURCE» («EXTERN»/»INTERN»), select the required operation

mode.

Set the selector switch (Pt. 3, Fig 6.8) to position «OPER».

Using the internal source voltage selector switch (Pt. 2, Fig.6.8), set the first factor of the

transmission power selection.

Power is selected based on the following principle: «minimum power which is sufficient for

obtaining the output current producing the electromagnetic field allowable for route location».

Follow the below principles when selecting the transmission power and frequency:

- «lower power, lower frequency» – «repeated induction» towards adjacent objects are rarer,

power supply life is longer

- «higher frequency» – receiver sensitivity is higher, lower power is enough, energy saving is

possible, recommended for «high-resistance» utilities, but the degree of signal penetration into

surrounding objects is higher, and due to greater attenuation the signal spreads to a shorter

distance.

- «higher power, lower frequency» – transmission and route detection distance is longer but the

power supply life is shorter.

6.5.4 Switch on power supply setting the power on-key (Pt. 1, Fig 6.8) to the position

corresponding to the second factor of power selection.

6.5.5 Transmission and automatic matching will start with gradual output voltage increase.

Watch the colour of indicator «OUT» (Pt. 7, Fig 6.8). If automatic matching ends with green light, the

preset power has been reached. If automatic matching ends with yellow light, the load resistance

is too high for the preset power while the output power is limited

«by default» at the «safe» level of 24 V.

Here a decision shall be made whether the detection procedure is possible (for example,

through trial route location). If the current in the line is obviously insufficient for producing an

allowable level of the identification field, increase the output voltage higher than the 24 V «safe»

level. After taking the respective safety precautions, the operator can start automatic matching in

«unlimited mode» on his own responsibility.

To start «unlimited» mode, switch on power supply (using the selector switch «START»), with

the red button « » pressed (pos 8, Fig 6.8) and held pressed till the red indicator « »lights up.

Blinking light of this indicator means possible «danger». Continuous light signals about actual

presence of output voltage ≥24 V.

6.5.6 Operation in mode of shock pulses generation «SHOCK»

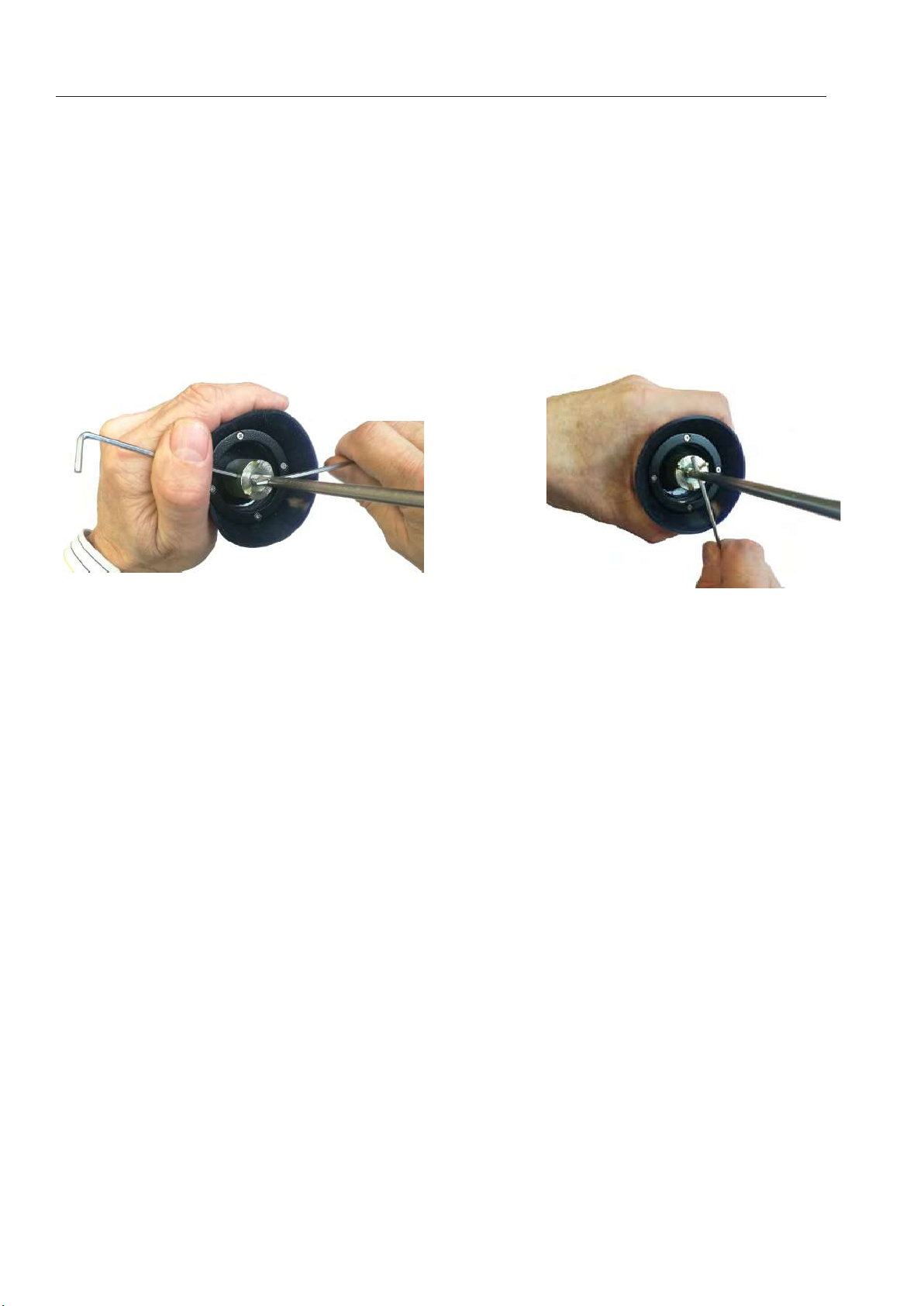

- Fasten the shock device on the facility (pipeline) under examination, using a chain fastener

with a detent lever.

- Connect the shock device to the transmission output connector. When the energy is on, the

instrument switches over to mode «SHOCK» (Pt. 5 Fig 6.8) automatically, where one of the three

repetition rates of shock pulses (30-60-120 shocks per minute) can be selected, and the shock

force is directly proportional to the supply voltage.

- Using the selector switch «SOURCE INTERN» (Pt. 2 Fig 6.8), select the shock force («12 V» –

lower, «24 V» - higher).