DINAMIC OIL SA Series User manual

1

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

December 8, 2021 . Release 01 . English

North America Edition

USERS MANUAL

SAFETY, OPERATION, MAINTENANCE

SA SERIES ANCHOR DRIVE

SA5, SA6, SA6L, SA7, SA8, SA12, SA16, SA20, SA30

Dinamic Oil North America

4725 Entrance Drive, Suite A

Charlotte, NC 28273

dinamicoil.us

© 2021 Dinamic Oil North America All Rights Reserved

SA

SERIES

Printed in the USA.

2SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

PREFACE

This manual contains information for the safe operation and maintenance of your Dinamic Oil attachment. Read the

entire manual before the initial start-up of the attachment. It is important to know the correct operating procedures of the

attachment and all safety precautions to prevent the possibility of property damage and personal injury.

The attachment has been designed and manufactured with quality materials and care in workmanship. The instructions in

this manual have been prepared to ensure that, when followed properly, the attachment will provide ecient and reliable

service. Continuing product development and improvement may have caused changes in the attachment that are not

reected in this manual. If a question arises regarding the attachment, contact a Dinamic Oil dealer for the most current

information available.

INTRODUCTION

Thank you for purchasing your new product! Dinamic Oil attachments are designed for use with specic mounting frames

and linkage to be used with the prime mover. Provided these are used and maintained correctly, the products will provide

a safe and ecient method of use.

Before operating your attachment, please note:

• The planetary drive comes complete, lled with the correct amount of gear oil.

• Hydraulic hoses must be tted and tightened correctly.

• If a case drain hose is required, it must be used and tted correctly.

• The attachment must be broken-in per the recommended procedure.

IMPORTANT

This manual must accompany the attachment at all times and be readily available to the operator. This operating manual

should be used in conjunction with the prime movers operating instructions.

MANUAL REPLACEMENT

Should this manual become damaged, lost or additional copies are required, immediately contact any authorized Dinamic

Oil dealer. You may also download a PDF copy at www.dinamicoil.us.

POSSIBLE VARIATIONS

Dinamic Oil cannot anticipate every possible circumstance that might involve a potential hazard, as

the owner’s requirements and equipment may vary. Therefore, the warnings in this publication and on the product

may not be all- inclusive and you must ensure that the procedure, application, work method and operating technique is

safe for you, and others, before operation.

PUBLIC NOTICE

Dinamic Oil reserves the right to make changes and improvements to it’s products and technical literature at any time,

without public notice or obligation. Dinamic Oil also reserves the right to discontinue manufacturing any product at it’s

discretion, at any time.

WARRANTY

All work or repairs to be considered for warranty reimbursement must be authorized by the Dinamic Oil Service

Department before work is started. Any alterations, modications or repairs performed before authorization by the

Dinamic Oil Service Department will render all warranty reimbursement consideration null and void. Improper operation or

improperly performed maintenance may render any warranty null and void.

3

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

TABLE OF CONTENTS

SAFETY

Preface / Introduction .......................................................................................................................................... 2

Table of Contents .......................................................................................................................................... 3

Declaration of Conformity (CE) ........................................................................................................................... 4

General Safety Precautions ...............................................................................................................................5-9

Safety Decal Info. / Serial Tag Info. .................................................................................................................... 10

PRODUCT SPECIFICATIONS / PERFORMANCE

Part Numbers and Codes ...................................................................................................................................11

Product Specications SA Series ...................................................................................................................... 12

Product Specications SA Series Cont. ............................................................................................................ 13

INSTALLATION

Mounting Kit Installation .................................................................................................................................... 14

Hydraulic Installation / Cold Weather / Break-In ................................................................................................ 15

OPERATION / MAINTENANCE

Lubrication Information ...................................................................................................................................... 16

Operating Temperature Guidelines .................................................................................................................... 17

Oil Check and Filling / Service Schedule .......................................................................................................... 18

Torque Chart For Common Bolt Sizes ............................................................................................................... 19

WARRANTY

Warranty Information .......................................................................................................................................... 20

4SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

I, the undersigned:

Ich, der Unterzeiche:

Je soussigné:

El abajo rman:

lo sottoscritto:

hereby declare that the equipment specied hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especica a continuación:

Dichiaro che le apparecchiature specicate di seguito:

Philip Joyce, President - North America

Category/Kategorie/Catégorie/Categoria/Categoria:

Make/Marke/Marque/Marca/Marca

Type/Typ/Type/Tipo/Tipo:

Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Directive/Standards

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

Representative in the Union:

Vertreter in der Union

Représentant dans l’union

Representante en la Union

Rappresentante presso l’Unione

Position/Position/Fonction/Cargo/Posizione

Planetary Anchor Drive Attachment

Dinamic Oil

SA and TA Series

All

EN 12100-1:2010 - Safety of Machinery

EN 16228-1:2014 - Drilling and Foundation Equipment. Common req.

EN 16228-4:2014 - Drilling and Foundation Equipment. Fnd Equip.

EN 16228-7:2014 - Drilling and Foundation Equippment. Aux Equip.

2006/42/EC - Machinery Directive

2000/14/EC - Noise Emission

Eris Lanciotti

Dinamic Oil S.p.A. con Socio Unico

Via Togliatti, 15

41030 Bomporto - MO - Italy

Technical Manager

5

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

SAFETY STATEMENTS

Your safety and the safety of others is a direct result of how you operate and maintain your equipment. Read and

understand this manual and other safety information provided with the base machine and be sure that you understand all

controls and operating instructions before attempting to operate this equipment. Failure to follow the safety precautions

can result in personal injury, death or property damage.

Dinamic Oil cannot foresee all hazardous circumstances, the precautions listed in this manual and on the equipment are

not all-inclusive. If a procedure, method, tool or part is not specically recommended by Dinamic Oil, determine whether

it is safe for you and others, and that the equipment will not be damaged or made unsafe as a result of your decision to

implement it. The basic rules are summarized in this section of the manual. They also appear throughout the manual

along with additional specic rules for safety and operation.

Carefully read all safety messages in this manual and on your equipment safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

SAFETY ALERT SYMBOLS AND SIGNAGE

Never compromise on safety! It can cause serious injury or death! All operators must read and fully understand all of

the safety instructions and alert symbols.

DANGER

WARNING

CAUTION

NOTICE

Indicates an imminently hazardous situation

which will result in death or serious injury.

The Safety Alert Symbol alerts you to potential personal injury

hazards. Obey all safety messages.

Indicates a potential hazardous situation which

could result in death or serious injury.

Indicates hazards that could result in damage

to the equipment or personal injury.

Indicates important procedures.

6SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

READ MANUAL PRIOR TO INSTALLATION

Improper installation, operation, or maintenance of

this equipment could result in serious injury or death.

Operators and maintenance personnel should read this

manual,as well as all manuals related to this equipment

and the prime mover thoroughly before beginning

installation, operation, or maintenance.

READ AND UNDERSTAND ALL SAFETY

STATEMENTS

Read all safety decals and safety statements in all

manuals prior to operating or working on this equipment.

Know and obey all regulations, local laws, and other

professional guidelines for your operation.

Know and follow good work practices when assembling,

maintaining, repairing, mounting, removing, or operating

this equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions, and

operations before operating.

Visually inspect your equipment before you start, and

never operate equipment that Is not in proper working

order with all safety devices intact.

Check all hardware to ensure it is tight. Make certain that

all locking pins, latches, and connection devices

are properly installed and secured.

Remove and replace any damaged, fatigued, or

excessively worn parts.

Make certain all safety decals are in place and are

legible.

Keep decals clean, and replace them if they become

worn or hard to read.

PRIME MOVER LIFT CAPACITY

Alert yourself to the weight of the Drive attachment. DO

NOT exceed the recommended lift capacity of the prime

mover. Refer to your prime mover’s owners manual for

suggested lift capacity and lift considerations.

NOTICE

DO NOT MODIFY EQUIPMENT / PRODUCT

Modications may weaken the integrity of the attachment

and may impair the function,safety, life, and performance

of the attachment.

When making repairs, use only the manufacturer’s

genuine parts, following authorized instructions. Other

parts may be substandard in t and quality.

Never modify any ROPS (Roll Over Protective Structure)

or FOPS (Falling Object Protective Structure) equipment

or device. Any modications must be authorized in

writing by the manufacturer.

RAISED EQUIPMENT CAUTION

DO NOT work under raised booms without supporting

them.

Never place any body part between the prime mover

chassis and the attachment.

Do not use support materials made of concrete blocks,

logs, buckets, barrels, or any other material that could

suddenly collapse or shift positions. Make sure support

material is solid, not decayed,warped, twisted, or tapered.

Lower booms and attachments to the ground before

leaving the cab or operator’s station.

Whenever the boom structure must be raised for

attachment installation or servicing ensure the boom

locking devices (if equipped) are deployed to prevent the

accidental lowering of boom structures.

CALIFORNIA PROPOSITION 65 WARNING

This product may contain a chemical known to the

state of California to cause cancer, or birth defects or

other reproductive harm. www.P65Warnings.ca.gov

For Customers in California, pursuant to California Health

and Safety Code Section 25249.5 et seq., commonly

referred to as Proposition 65 (“Prop 65”), DONA hereby

noties Buyer that the Goods sold contain shale oils,

mineral oils, and tetrachloroethylene, which are known to

the State of California to cause cancer.

WARNING

WARNING

7

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

OPERATOR SAFETY

Safety equipment should be worn at all times when

viewing, operating or maintaining the attachment.

Safety equipment includes eye protection, hard hat, steel

toe shoes, gloves and hearing protection.

Wear protective clothing and equipment appropriate for

the job. Avoid loose tting clothing.

Prolonged exposure to excessive noise can cause

hearing loss. Wear suitable hearing protection such as

ear plugs.

Operating equipment safely requires the full attention of

the operator. Avoid distractions.

Operate only from the operator’s cab/station.

Reduce speed when driving over rough terrain, on a

slope, or turning, to avoid overturning the vehicle.

Travel only with the attachment in a safe transport

position to prevent uncontrolled movement.

Drive slowly over rough ground and on slopes.

Before exiting the machine, lower the attachment to

the ground, apply the parking brakes, turn o the prime

mover’s engine and remove the key.

Flow and pressure gauges, ttings, and hoses must

have a continuous operating pressure rating of at least

25% higher than highest pressures of the system.

Do not operate the unit when you are tired, ill or under the

inuence of alcohol, drugs or medication.

Never let a minor or inexperienced person operate the

unit.

Keep all body parts away from rotating objects.

Inspect the ground area before operation. Remove

objects which can be thrown or become entangled.

DO NOT operate the attachment in areas where carbon

monoxide fumes can accumulate.

Be alert when operating in locations where any type of

landscaping fabric/mat may be present. The material

can be rapidly drawn into the point of operation, possibly

causing injury or death to anyone standing on or near the

fabric.

PRODUCT SAFETY

NEVER suspend the attachment over people or

equipment. Maintain a safe distance of at least 30 feet

(10 meters).

Inspect the entire product before operation.

Replace parts that are cracked, chipped or damaged in

any way before operation.

Keep others away when making any adjustments to the

unit.

If the attachment is not functioning properly, shut down the

machine, follow proper Lock-out / Tag-out procedures.

NEVER approach power lines with any part of the

machine. Keep clear at a minimum of 15 feet (5 meters).

Avoid working on unstable or slippery areas and position

the prime mover on rm, level ground.

Tether any anchor or extensions connected to the

Anchor Drive with a chain if necessary, to prevent

uncontrolled swinging of the attachments when moving

from position to position.

Side loading is NOT recommended. Excessive side

loading can cause output shaft deection and or failure.

Avoid excessive side loading to prevent possible

instantaneous output shaft failure. Such a failure could

result in injury from disconnected parts and or being hit by

the Drive attachment causing serious injury or death.

Anchor Drive attachments shall be used only for

their designed intent and shall not be loaded beyond

their rated capacity. Overloading or exceeding the

manufacturers specications will void all warranty.

UNDERGROUND HAZARDS

It is the responsibility of the operator to know where buried

power, gas, telephone, and other utilities are at in the work

area.

This may lead to shock or an explosion. Have the work

area marked for buried lines and do not dig in marked areas

set by your local municipals.

WARNING

8SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

BE ALERT ON THE JOB SITE

Tragic accidents can occur if the operator is not alert to the

presence of bystanders.

Children in particular are often attracted to machinery

and work activity. Never assume that children will

remain where you last saw them.

BE ALERT and turn the equipment o if children enter the

work area. Keep children out of the work area and under

supervision of another responsible adult.

SILICA DUST CAUTION

Exposure to respirable crystalline silica dust along

with other hazardous dusts may cause serious or

fatal respiratory disease.

Concrete and masonry products contain silica sand.

Quartz, which is a form of silica and the most common

mineral in the earths crust, is associated with many types

of rock. Some activities that silica dust may be present

in the air include demolition, sweeping, loading, sawing,

hammering, drilling, or planing of rock, concrete or

masonry.

It is recommended to use dust suppression, dust

collection or personal protective equipment during the

operation of any attachment that may cause high levels of

silica dust.

The NIOSH recommended exposure limit for respirable

crystalline silica is 0.05 mg/m3 as a time-weighted

average for up to 10 hours/day during a 40-hour work

week [NIOSH 1974].

PRACTICE SAFE MAINTENANCE

Use proper tools and equipment when conducting

maintenance. Work in a clean dry area.

Inspect all parts. Be sure parts are in good working

condition and installed properly. Remove build up of

grease, oil or any debris.

Remove all tools and unused parts from equipment before

beginning operation.

CAUTION

REMOVE PAINT BEFORE WELDING OR

HEATING

Hazardous fumes/dust can be generated when paint is

heated by welding, soldering or using a torch. Do all work

outside or in a well ventilated area and dispose of paint

and solvent properly. Remove paint before welding or

heating.

When sanding or grinding paint, avoid breathing the

dust. Wear an approved respirator.

If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or paint

stripper containers and other ammable material from

area. Allow fumes to disperse at least 15 minutes before

welding or heating.

SOUND AND VIBRATION

Sound pressure levels and vibration data for this

attachment are inuenced by many dierent

parameters: some items are listed below (not inclusive):

Prime mover type, age, condition, with or without cab

enclosure and conguration

Operator training, behavior, stress level.

Job site organization, working material condition,

environment

Based on the uncertainty of the prime mover, operator,

and job site, it is not possible to get precise machine and

operator sound pressure levels or vibration levels for this

attachment.

END OF LIFE DISPOSAL

At the completion of the useful life of the unit, drain all

uids and dismantle by separating the dierent materials

(rubber, steel, plastic, etc.). Follow all governmental and

local regulations for recycling and disposal of the uid and

components.

CAUTION

WARNING

9

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

TRANSPORTING THE DRIVE ATTACHMENT

Travel only with the Drive attachment in a safe transport

position to prevent uncontrolled swinging. Tether the

Drive attachment with a chain, if necessary, to prevent

uncontrolled swinging of the attachment when moving

from hole to hole.

Remove the earth auger or helical pile from the Drive

attachment before transporting to and from the job site.

Use extreme care during transport to prevent contact

between the Drive attachment and bystanders or

solid objects. Contact with the Drive attachment

could cause serious damage, injury or death.

Never operate the Drive attachment while

transporting.

Drive slowly over rough ground and on slopes. Position

the Drive attachment as low to the ground as possible

maintaining a low center of gravity.

Verify that all tie down accessories (chains, slings, ropes,

shackles and etc.) are capable of maintaining attachment

stability during transporting and are attached in such a

way to prevent unintended disengagement or shifting of

the unit. Failure to do so could result in serious personal

injury or death.

HYDRAULIC FLUID PRESSURE

Hydraulic uid under pressure can penetrate the skin and

cause serious injury or death.

Hydraulic leaks under pressure may not be visible. Before

connecting or disconnecting hydraulic hoses, read your

prime mover’s operator’s manual for detailed instructions

on connecting and disconnecting hydraulic hoses or

ttings.

Keep unprotected body parts, such as face, eyes, and

arms as far away as possible from a suspected leak.

Flesh injected with hydraulic uid may develop

gangrene or other permanent disabilities.

Hydraulic oil becomes hot during operation. DO NOT

come in contact with hot hydraulic oil as it could

cause severe burns. Wear adequate protective

clothing and safety equipment.

DO NOT tamper with hydraulic lines or components

while they are pressurized. Escaping uid under

pressure can penetrate the skin, causing serious

injury. Keep hands and body away from pinholes and

nozzles which eject uids under high pressure.

Wear safety glasses, protective clothing, and use a piece

of cardboard or wood when searching for hydraulic leaks.

DO NOT USE YOUR HANDS! SEE ILLUSTRATION.

WARNING

NOTICE

WARNING

Safety equipment should be worn at all times when

working with hydraulics.

Safety equipment includes eye protection, hard hat,

steel toe shoes, gloves and hearing protection. Wear

protective clothing and equipment appropriate for the

job. Avoid loose tting clothing.

10 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

SERIAL TAG INFORMATION

Its important to make the correct reference to the serial number of the

unit when making repairs or ordering parts. The serial number plate will

be located near the top of the Drive attachment.

SAFETY DECALS

The Drive attachment comes equipped with all safety decals in place. They are designed to help you safely operate your unit.

Read and follow all safety decals.

Keep all safety decals clean and legible at all times.

Replace safety decals that are missing or have become illegible.

Safety decals are available from your distributor or manufacture.

Some parts installed during repair may require safety decals to be axed to the replacement part. When ordering the

replacement part(s) be sure the correct safety decal(s) are included in your order.

INSTALLING SAFETY DECALS

Clean the desired area with warm soapy

water.

Decide on exact position before you remove

the backing paper.

Peel backing paper from decal. Press rmly

on the surface.

Remove all air pockets. Air pockets can be

pierced with a pin and smoothed.

NOTICE

Dinamic Oil North America

4725 Entrance Drive, Suite A

Charlotte, NC 28273

dinamicoil.us I 704.587.4600

Assembled

in the USA

Part Number Model

TD FLANGE

Serial Number

32521345

521250108 029813261

Nov-2021Serial Number

NASA012501 SA12-BE

WARNING

CALIFORNIA PROPOSITION 65

CANCER AND REPRODUCTIVE HARM

www.P65warnings.ca.gov

DR50785

WARNING

PINCH POINT

HAZARD

KEEP CLEAR

DR50791

UNDERGROUND

HAZARD

READ MANUAL

HIGH-PRESSURE

FLUID HAZARD

FLUID OR THROWN

OBJECT HAZARD

STAY 20 FEET (6m) AWAY FROM

ATTACHMENT DURING OPERATION.

DO NOT WORK

UNDER EQUIPMENT

AVOID INJURY OR DEATH

ENTANGLEMENT

HAZARD

DR50792

CAUTION

KEEP ALL HYDRAULIC HOSES,

FITTINGS AND COUPLERS TIGHT

AND FREE OF CONTAMINATION

AND LEAKS.

MAX PRESSURE

3000 PSI (207 BAR)

DR50808

NADCL00106 - SA20-B DECAL MASTER SHEET

Decal Kit Example

11

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

PART NUMBERS AND CODES (TA MODELS)

The list below outlines all TA series Anchor Drive models and congurations.

SA5

Part Number Description

NASA005100 Anchor Drive SA5-A

NASA005600 Anchor Drive SA5-AE

NASA005200 Anchor Drive SA5-C

NASA005400 Anchor Drive SA5-CE

NASA005300 Anchor Drive SA5-B

NASA005500 Anchor Drive SA5-BE

SA6

Part Number Description

NASA006100 Anchor Drive SA6-A

NASA006600 Anchor Drive SA6-AE

NASA006200 Anchor Drive SA6-C

NASA006400 Anchor Drive SA6-CE

NASA006300 Anchor Drive SA6-B

NASA006500 Anchor Drive SA6-BE

SA6L

Part Number Description

NASA06L100 Anchor Drive SA6L-A

SA7

Part Number Description

NASA007100 Anchor Drive SA7-A

NASA007600 Anchor Drive SA7-AE

NASA007200 Anchor Drive SA7-C

NASA007400 Anchor Drive SA7-CE

NASA007300 Anchor Drive SA7-B

NASA007500 Anchor Drive SA7-BE

SA8

Part Number Description

NASA008200 Anchor Drive SA8-C

NASA008400 Anchor Drive SA8-CE

NASA008300 Anchor Drive SA8-B

NASA008500 Anchor Drive SA8-BE

SA12

Part Number Description

NASA012200 Anchor Drive SA12-C

NASA012400 Anchor Drive SA12-CE

NASA012300 Anchor Drive SA12-B

NASA012500 Anchor Drive SA12-BE

SA16

Part Number Description

NASA016200 Anchor Drive SA16-C

NASA016400 Anchor Drive SA16-CE

NASA016300 Anchor Drive SA16-B

NASA016500 Anchor Drive SA16-BE

SA30-BE

Series

“SA”

Model

5, 6, 6L, 7, 8, 12, 16, 20, 30

Conguration

A = Motor & Gearbox

AE = Motor, Gearbox, Energi

C = Crown

B = Bail

CE = Crown Energi

BE = Bail Energi

Model Code Example

SA20

Part Number Description

NASA020300 Anchor Drive SA20-B

NASA020500 Anchor Drive SA20-BE

SA30

Part Number Description

NASA030300 Anchor Drive SA30-B

NASA030500 Anchor Drive SA30-BE

12 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

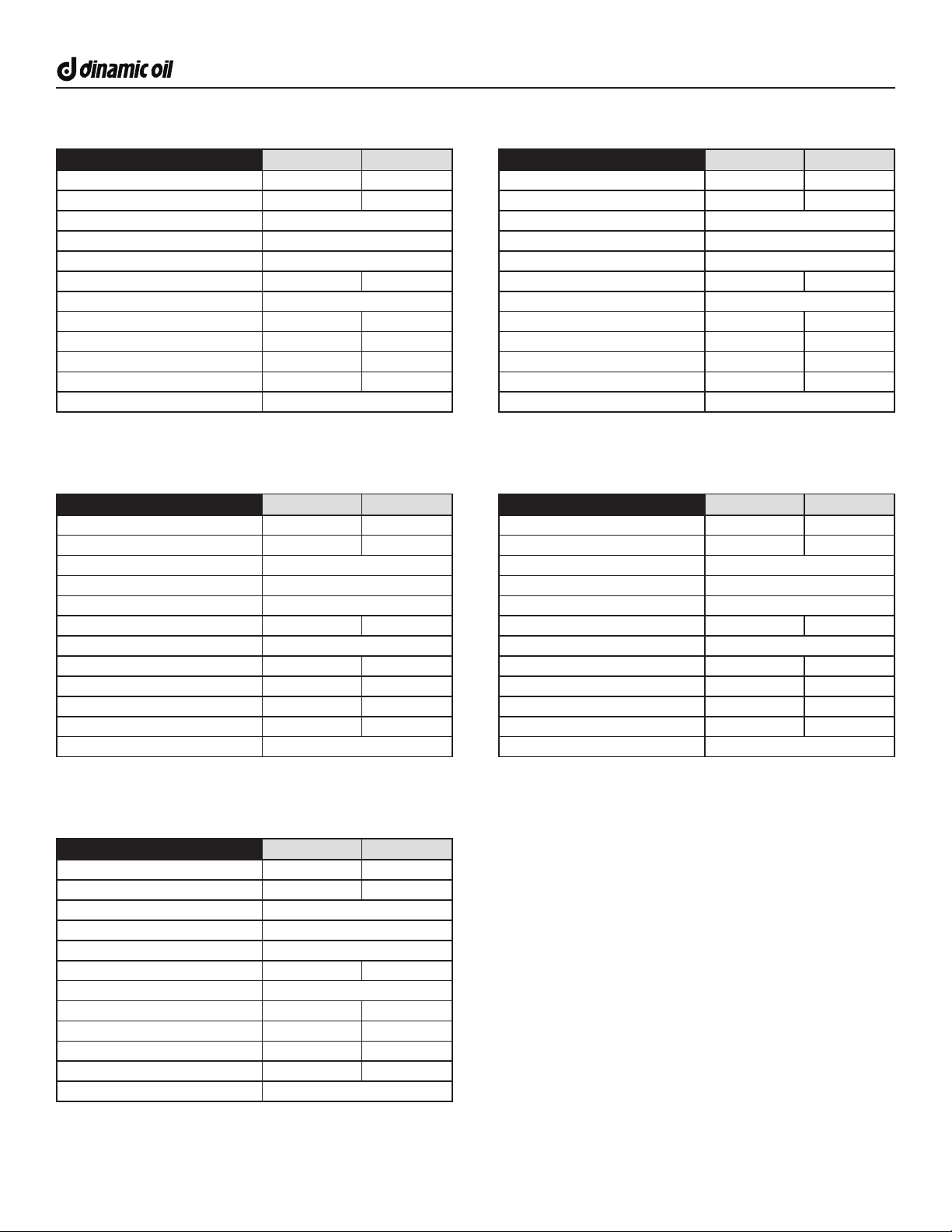

PRODUCT SPECIFICATIONS (SA SERIES)

Dinamic Oil publishes both Theoretical and Actual performance values for comparative purposes. Mechanical and

volumetric eciencies are applied to the Actual torque and speed values. Product performance is dependent on the prime

mover’s hydraulic system. Dinamic Oil has made every eort to present accurate information at the time of publication.

The performance values should be used for information and comparative purposes only. Contact DInamic Oil for specic

application information.

Dinamic Oil reserves the right to make changes and improvements to its products and technical literature at any time,

without public notice or obligation.

SA5SA5 Imperial Metric

Max Hydraulic Pressure 2500 PSI 172 Bar

Max Hydraulic Flow 25 GPM 94 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2” Hex

Oil Capacity .3 Gallons 1.4 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 12,900 LBS 5,851 Kg

SA5-C Weight (Center Mnt) - LBS - Kg

SA5-B Weight (Bail) 212 LBS 96 Kg

Actual Torque @ 2500 PSI 5,104 FT-LBS 6,919 Nm

Actual Speed @ 25 GPM 30 RPM

SA6SA6 Imperial Metric

Max Hydraulic Pressure 2500 PSI 172 Bar

Max Hydraulic Flow 25 GPM 94 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2” Hex

Oil Capacity .3 Gallons 1.4 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 12,900 LBS 5,851 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 212 LBS 96 Kg

Actual Torque @ 2500 PSI 6,253 FT-LBS 28,477 Nm

Actual Speed @ 25 GPM 25 RPM

SA6LSA6L Imperial Metric

Max Hydraulic Pressure 2500 PSI 172 Bar

Max Hydraulic Flow 25 GPM 94 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2” Hex

Oil Capacity .25 Gallons 1 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 5,700 LBS 2,585 Kg

SA6L-C Weight (Center Mnt) - LBS - Kg

SA6L-A Weight 212 LBS 96 Kg

Actual Torque @ 2500 PSI 6,631 FT-LBS 8,960 Nm

Actual Speed @ 25 GPM 23 RPM

SA7SA7 Imperial Metric

Max Hydraulic Pressure 2500 PSI 172 Bar

Max Hydraulic Flow 25 GPM 94 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2” Hex

Oil Capacity .4 Gallons 1.6 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 12,900 LBS 5,851 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 228 LBS 103 Kg

Actual Torque @ 2500 PSI 7,381 FT-LBS 10,007 Nm

Actual Speed @ 25 GPM 25 RPM

13

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

PRODUCT SPECIFICATIONS (SA SERIES) CONTINUED

SA8SA8 Imperial Metric

Max Hydraulic Pressure 2500 PSI 172 Bar

Max Hydraulic Flow 25 GPM 94 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2-1/2” Hex

Oil Capacity - Gallons - Liters

Oil Type SAE 80W90

Shaft Pullout Rating - LBS - Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) - LBS - Kg

Actual Torque @ 2500 PSI - FT-LBS - Nm

Actual Speed @ 25 GPM - RPM

SA12SA12 Imperial Metric

Max Hydraulic Pressure 3000 PSI 207 Bar

Max Hydraulic Flow 35 GPM 133 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2” Hex

Oil Capacity 1.2 Gallons 4.5 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 13,600 LBS 6,168 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 455 LBS 207 Kg

Actual Torque @ 3000 PSI 12,879 FT-LBS 17,461 Nm

Actual Speed @ 35 GPM 20 RPM

FUTURE MODEL

SA16SA16 Imperial Metric

Max Hydraulic Pressure 3000 PSI 207 Bar

Max Hydraulic Flow 35 GPM 133 LPM

Motor Type Single Speed

Motor Ports -12 JIC

Output Shaft 2-1/2” Hex

Oil Capacity 1.7 Gallons 6.5 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 16,500 LBS 7,484 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 550 LBS 249 Kg

Actual Torque @ 3000 PSI 17,190 FT-LBS 23,306 Nm

Actual Speed @ 35 GPM 15 RPM

SA20SA20 Imperial Metric

Max Hydraulic Pressure 3000 PSI 207 Bar

Max Hydraulic Flow 40 GPM 151 LPM

Motor Type Single Speed

Motor Ports -16 JIC

Output Shaft 3” Hex

Oil Capacity 1.8 Gallons 7 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 13,600 LBS 6,168 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 590 LBS 267 Kg

Actual Torque @ 3000 PSI 22,517 FT-LBS 30,529 Nm

Actual Speed @ 35 GPM 13 RPM

SA30SA30 Imperial Metric

Max Hydraulic Pressure 3000 PSI 207 Bar

Max Hydraulic Flow 40 GPM 151 LPM

Motor Type Single Speed

Motor Ports -16 JIC

Output Shaft 4” Square

Oil Capacity 2.9 Gallons 11 Liters

Oil Type SAE 80W90

Shaft Pullout Rating 25,300 LBS 11,475 Kg

SA6-C Weight (Center Mnt) - LBS - Kg

SA6-B Weight (Bail) 830 LBS 376 Kg

Actual Torque @ 3000 PSI 30,885 FT-LBS 41,875 Nm

Actual Speed @ 35 GPM 10 RPM

14 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

INSTALLATION - MOUNTING KIT

Before connecting the Drive attachment to the prime

mover, ensure all mounting surfaces, attachment plates,

and quick couplers are free of dirt and debris. Conrm all

attaching pins, fasteners, and latches are appropriately

secured. Ensure the mounting plate or bracket is secure

to the prime mover. Improper installation can result in

product damage, personal injury, and death.

Never place any part of your body between the

attachment mount and the prime mover.

ALWAYS work in pairs (2 skilled operatives)

whenever the Drive attachment is being assembled or

disassembled from the prime mover.

Always check the weight of the Drive attachment and

verify you have the correct equipment for safe operation.

Ensure all connection pins, fasteners and latches are

properly secured.

Ensure that the mounting frame / attachment

mounting plate is rigidly secured to the prime mover.

Improper installation can result in product damage,

personal injury and death.

Ensure all hydraulic hose assemblies are of adequate

length and have enough slack for full Drive attachment

movement. Failure to provide adequate length hydraulic

hoses can result in hose rupturing. A hydraulic hose

rupture can result in product damage, personal injury and

death.

Follow all standard safety practices and the

instructions for installing an attachment as shown in

your prime movers manual.

General instructions for Skid Steer Loaders, Excavators

and Telehandler prime movers.

1. Remove the bucket or other attachment from the

prime mover quick attach platform.

2. Attach the Drive mounting bracket to the prime mover,

as per manufacturer’s recommendations.

CAUTION

Note: The link arm is only used with Skid Steer Loaders

and Excavators that utilize a quick coupler. The link

arm will not be used with Excavators that DO NOT use

a quick coupler. In this situation the Drive mount will

connect directly to the Excavator boom (bucket linkage).

3. Attach the link arm to the Drive mounting bracket

with the pin provided. Secure the pin in place with the

provided end keepers.

4. Install the Drive Attachment to the link arm using the

pin provided. Secure the pin in place with the provided

end keepers.

INSPECT BEFORE USE

Before rst use. Inspect the Drive attachment for shipping

damage. If damage does exist, do not operate until the

damaged parts have been replaced or repaired.

Ensure all fasteners are in place and properly tightened.

Make sure that all hydraulic ttings are tightened and that

there are no leaks in any ttings or hoses.

Check the gearbox oil level before each operation

to ensure the planetary is suciently lubricated.

The lubricating oil level plug is located on the “top”

section of the gearbox, to ensure the upper bearing

is lubricated.

Visually inspect the oil level before each use.

Make sure that all safety signs are in place, are clean, and

are legible.

NOTICE

DANGER NOTICE

15

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

INSTALLATION - HYDRAULIC KIT

The Drive attachment receives its hydraulic oil ow and

pressure from the prime mover through the auxiliary

hydraulic circuit via two quick-release couplers. All Drive

attachments require pressure and return lines of hydraulic

oil from the parent machine’s auxiliary hydraulic power

supply to operate. All Drive attachments are bi-directional

and require the host machine to be tted with a two-way

ow auxiliary circuit.

Understand the Drive attachment maximum ow

and pressure ratings. Ensure your prime mover

ow and pressure settings are suitable to the Drive

attachment. Never exceed the maximum ow and

pressure ratings of the Drive attachment.

Follow the steps below to complete the hydraulic hook-up

between your prime mover and Drive attachment.

1. Locate the auxiliary hydraulic connection ports on the

prime mover.

2. Determine the length of hydraulic hose necessary

to connect the auxiliary hydraulic circuit to the Drive

attachment. Be sure to allow sucient “slack” in the hose

length to enable the Drive attachment to perform its full

range of operation.

3. Ensure that the hydraulic hose couplers are compatible

with the hydraulic quick couplers on the prime mover.

4. Relieve any pressure from the auxiliary hydraulic

system and after ensuring no foreign matter on the

hydraulic couplers, connect the power, return and case

drain hoses to the auxiliary hydraulic system of your

machine.

5. When all of the hydraulic connections have been made

and checked for leaks, the Drive attachment is ready for

operation.

If a hydraulic leak develops, correct it immediately.

Escaping hydraulic uid can have extremely high

pressure. It is imperative that the connections are

tight and that all hoses are in good working condition.

Hydraulic hoses and ttings used on the prime mover

and Drive attachment must have a continuous operating

pressure rating of at least 25% higher than the maximum

pressure of the hydraulic system.

NOTICE

COLD WEATHER WARM-UP AND

OPERATION

The information listed on this page will provide overall

guidelines for warm-up and operation of your Dinamic Oil

Drive attachment in cold weather conditions. Prepare the

prime mover for cold weather conditions as instructed in

the machines operator manuals.

Read and follow the information for selecting the correct

gear oils for use in cold weather.

PROCEDURE FOR STARTUP IN COLD WEATHER

For temperatures below 5°C (48°F) it is recommended

to slowly start the Drive attachment under no load, at

minimum speed. Allow warm hydraulic oil from the prime

mover to circulate through the hydraulic motor and

slowly bring it to the minimum recommended operating

temperature of 5°C (48°F).

When the minimum operating temperature has been

achieved the Drive attachment is ready for full operation.

Note as the Drive attachment is operated under load the

gearbox oil will increase in temperature.

Follow the same warm-up procedure after each period

of down time in cold weather conditions. The prime

mover will retain internal component heat longer than

the Drive attachment. It is critical that the same warm-

up procedure is followed the ensure full operating

temperatures. Operating the Drive attachment without

a proper warm-up procedure can cause issues such

as high back pressure reading and potential shaft seal

issues.

BREAK IN OPERATION

To maximize the life of the unit, it must be broke-in or

commissioned. Suspend the drive unit in it’s vertical,

working position.

For the duration of the break-in procedure, ensure

that no bystanders (including animals) can get within 6

meters of the work area.

Operate the attachment at 50% of rated pressure for

10 minutes in each direction before application of full

operating load.

To further ensure best motor life and maintain warranty,

refer to page 16 for lubrication temperature instructions.

16 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

LUBRICATION INFORMATION

In order for the Drive attachment to operate at peak performance the following guidelines must be followed to avoid damage

to the main components.

All Dinamic Oil Anchor Drive gearboxes are supplied with lubricating oil.

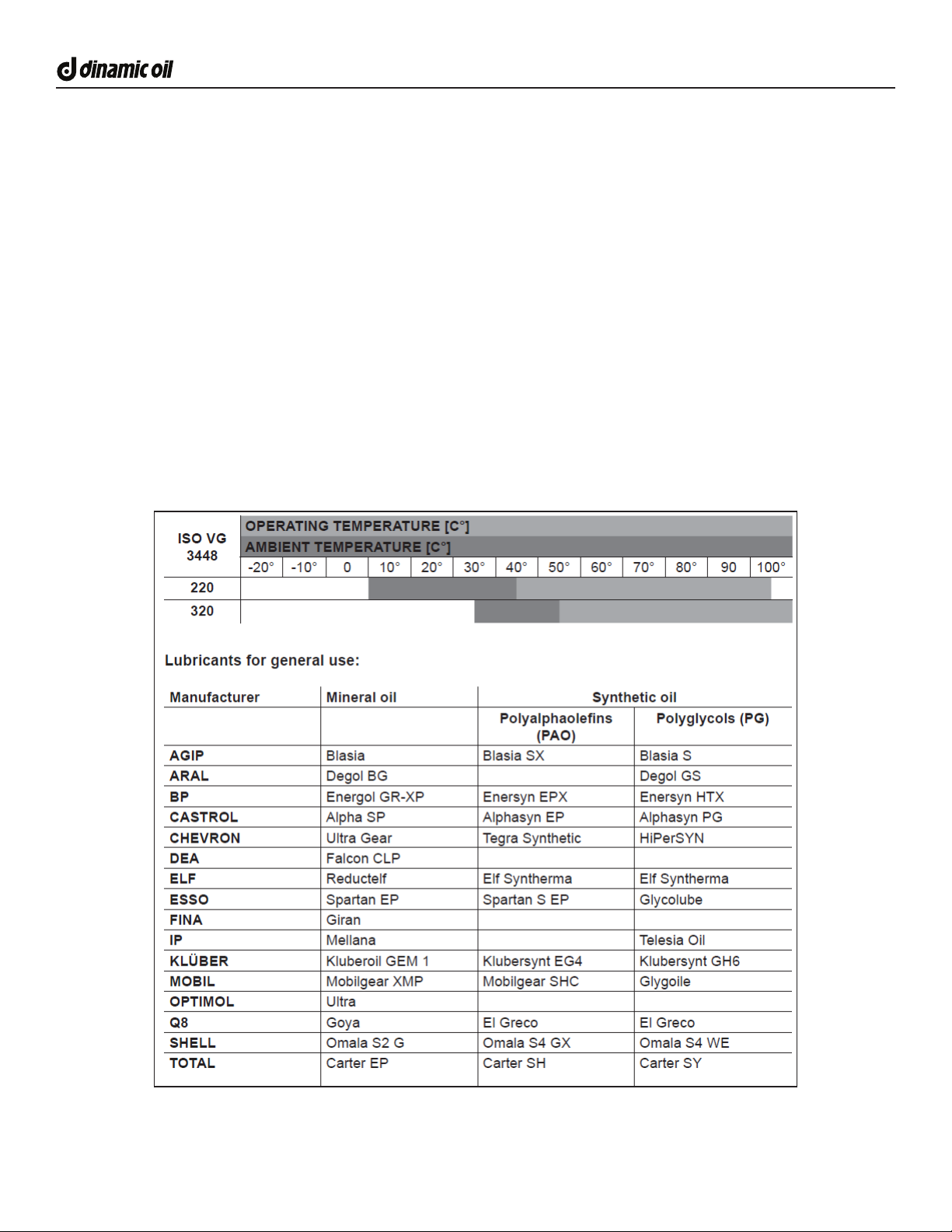

TYPE OF LUBRICATION

Gearboxes are oil bath lubricated. Before putting the gearbox to use, ll it with oil, looking through the level cap to see if it

is at the correct level. This operation requires special attention, and the level must be checked again after a few minutes of

operation.

SELECTING AN OIL

Any mechanical transmission oil with EP additives in viscosity classes ISO VG220 to ISO VG320 under ISO 3448 can be

used. In special cases oils with dierent viscosities may be used. In this case, contact DInamic Oil technical assistance

service. The oil viscosity must be chosen to suit the room temperature and the gearbox’s real operating temperature. If

the gearboxes must operate at very high ambient temperatures or with very large temperature excursions, synthetic oil is

recommended.

RECOMMENDED VISCOSITY

17

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

DO NOT Exceed Maximum Oil Temperatures. Hydraulic Fluid and Gearbox Oil should not exceed:

Min Temperature = -4 F (-20 C)

Min Temperature = 194 F (90 C)

Exceeding these temperatures lowers the oil viscosity, which will lead to premature wear in the gears and seals in the

hydraulic motor and gearbox.

OPERATING TEMPERATURE PARAMETERS

In order for the Drive attachment to operate at peak performance the following guidelines must be followed to avoid damage

to the main components.

DO NOT exceed the advertise maximum hydraulic pressure.

DO NOT exceed the published maximum hydraulic ow.

Approved Operating Temperature Ranges F (C):

Hydraulic Motor/Manifold: -20 to 194 F (xx to 90 C)

Pressure Transducers: -40 to 250 F (-40 to 125 C)

TD Flange (Energi models): -4 to 194 F (-20 to 90 C)

WiFi Module (Energi models): -4 to 140 F (-20 to 60 C)

Gearbox: -4 to 194 F (-20 to 90 C)

F(C) -40 (-40) -20 (-29) 0(-17) 20 (-6) 40 (4) 60 (15) 80 (26) 100 (38) 120 (49) 140 (60)

Gearbox

CAUTION

Approved Temperature Ranges

Pressure Transducers

TD Flange

WiFi Module

Hydraulic Motor

18 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

OIL FILLING AND LEVEL CHECKING

Every gearbox is equipped with level, vent, lling and

draining caps for gear oil. The lubricating oil level is

located on the “top” section of the gearbox, to ensure the

upper bearing is lubricated.

OIL REPLACEMENT AND FILLING PROCEDURE

• Ensure the power supply is disconnected when

lling.

• Unscrew and remove the loading and level plugs.

• Place a receptacle of sucient size underneath the

draining cap.

• Unscrew the gearbox’s loading and draining caps

and allow the oil to completely drain.

• Replace the oil drain plug.

• Feed the oil through the lling port at the top of the

gearbox until it ows out of the level port.

• Ret the plugs using the appropriate tightening

torques.

• Unscrew the plug adjacent the lling port, located

on the upper part of the gearbox, to prevent an air

bubble from forming at the upper rotary seal.

AMOUNT OF OIL

Gear oil amounts are given on pages 12 and 13 of

this manual. The data sheets show the quantities of oil

required for lling. However, these values should be

used for reference purposes only and exact lubrication

should be veried by means of visual checks.

SUPPORT AND SERVICING

Servicing must be performed by authorized personnel

adhering to the work and environmental safety

standards. Servicing on the gearbox must be

performed with the power supply disconnected and

the gearbox taken “out of service” to prevent an

accident. The oil temperature must be at a safe level

so as not to burn the operators. The instructions given

in this paragraph must be followed, ensuring the gearbox

is operational and that required levels of safety are met:

• Only use original spare parts.

• Use lubricants that are recommended by the

manufacturer.

• After any servicing work, always replace the seal

washers and any lubricating oil.

• Use additional lighting if carrying out servicing work

in dimly lit areas, to ensure that it is performed

safely.

• Take relevant precautions if carrying out servicing

work in enclosed spaces, to ensure that it is

performed safely.

ROUTINE SERVICING

Proper servicing improves performance, longevity and

safety.

Check the gearbox oil level before each operation to

ensure the planetary is suciently lubricated.

After the rst 50 hours of operation:

• Check the gearbox oil level. Check for leaks.

• Change the gearbox oil - this is required as the rst

50 hours are considered the break-in period.

Important! If the rst oil change is not performed

after the rst 50 hours excessive gearbox wear can

occur and cause failure.

After the rst 150 hours of operation:

• Check the gearbox oil level. Check for leaks.

• Check there are no metal residues of abnormal size

in the magnetic caps on the gearboxes.

• Clean the surfaces of the hydraulic motor and

gearbox body and the air ventilation pathways.

• Change the lubricating oil.

• Check the screws are all tight, and tighten them

where required.

After every 3 months of operation and for the entire

service life of the gearbox, it is necessary to check:

• Check the gearbox oil level. Check for leaks.

• Check for contamination from dirt, metal residues

and other contaminants and deposits of water or

other contaminating liquids in the areas of the input

or output shafts, in particular close to the seals.

• Absence of oxidation on the input and output shafts

and near the sealing areas.

• Absence of abnormal clearance on the output/input

shafts, pinions, joints and other accessories.

• Absence of contact wear on input/output shafts,

joints, and other accessories; absence of cracks and

damage on supports, shaft anges, and other parts

of the gearbox.

• No breakage or extension of the ange and bolts.

• Check for any damage and vibrations or abnormal

noise.

• Be aware of any abnormal heating or abnormal

temperatures.

After every 2000 hours of operation or at least every

12 months:

• Clean the surfaces of the gearbox body and the

air ventilation pathways to ensure correct heat

dispersal.

• Check the screws are all tight, and tighten them

where required.

19

Gearboxes - Hoists - Winches - Construction Attachments

SA Series Users Manual . Release 01 . English

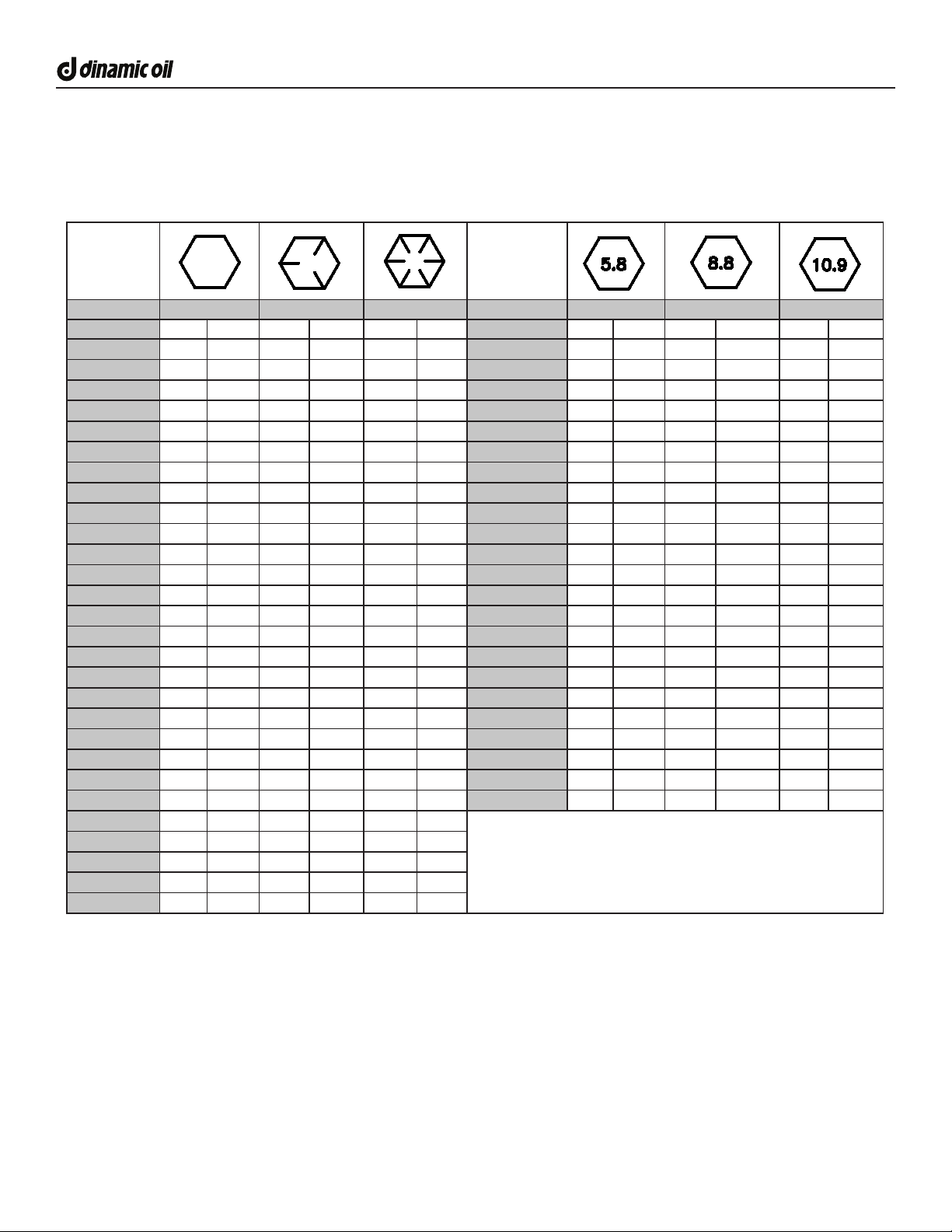

TORQUE CHART FOR COMMON FASTENERS

The chart below lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this

chart to determine the grade of the bolt and the proper torque. Except when specic torque values are list in a particular

application.

tpi = Nominal thread diameter in inches per inch.

Nm = Newton Meters.

Ft-Lbs = Foot Pounds

mm x = Nominal thread diameter in millimeters x thread pitch.

Bolt Size (In) Grade 2 Grade 5 Grade 8 Bolt Size (mm) Class 5.8 Class 8.8 Class 10.9

tpi Nm Ft-Lbs Nm Ft-Lbs Nm Ft-Lbs mm x Nm Ft-Lbs Nm Ft-Lbs Nm Ft-Lbs

1/4”-20 7.4 5.6 11 8 16 12 M5 X 0.8 4 3 6 5 9 7

1/4”-28 8.5 6 13 10 18 14 M6 X 1 7 5 11 8 15 11

5/16”-18 15 11 24 17 33 25 M8 X 1.25 17 12 26 19 36 27

5/16”-24 17 13 26 19 37 27 M8 X 1 18 13 28 21 39 29

3/8”-16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8”-24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16”-14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16”-20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2”-13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2”-20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16”-12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16”-18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8”-11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8”-18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4”-10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4”-16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8”-9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8”-14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1”-8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1”-12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8”-7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1-1/8”-12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1-1/4”-7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1-1/4”-12 750 555 1680 1240 2730 2010

1-3/8”-6 890 655 1990 1470 3230 2380

1-3/8”-12 1010 745 2270 1670 3680 2710

1-1/2”-6 1180 870 2640 1950 4290 3160

1-1/2”-12 1330 980 2970 2190 4820 3560

20 SA Series Users Manual . Release 01 . English

Gearboxes - Hoists - Winches - Construction Attachments

WARRANTY INFORMATION

Dinamic Oil North America (DONA) warrants its gearbox for a period of twenty-four (24) months and twelve (12) months on

the hydraulic motor months from invoice date to the original user.

DONA warranty covers faulty workmanship and defective parts manufactured by DONA. The warranty does not extend

to transportation cost of parts, nor does it cover consequential loss or damage to prime mover equipment. Dinamic Oil

Construction Attachments must be operated in accordance with the recommended procedures and within the specied

operating parameters, both on the unit and contained in the operating manual. DONA will not be responsible for or accept

any charges for work carried out by any repairs, or for any charges for any spare parts tted to any DONA products without

written approval from DONA. This warranty is void if eld repairs have been made to the hydraulic motors, gearboxes and

controls without written approval. The complete unit must be available for inspection in its original but alleged failed condition.

Dinamic Oil North America reserves the right to make design, specication and price changes without notice, and obligations

to the eect of such changes.

LIMITATION OF LIABILITY - DONA takes no responsibility for Goods selection, operation, and use, regardless of any

recommendations or suggestions made by the DONA. Buyer shall make selections based upon its own analysis with regard

to function, material compatibility, tness for use or intended purpose, and Goods ratings. Any such analysis, including

testing, shall be the sole responsibility of Buyer. Proper installation, operation, and maintenance are solely the responsibility

of Buyer or its customer. Any specications listed in DONA’s datasheets, catalog, and website are for reference only and are

subject to change without notice.

RETURNED GOODS (RGA)

Dinamic Oil reserves the right to determine whether products claimed to be defective shall be inspected by our personnel

in the eld or returned to the factory. If determined to be defective in material or workmanship, the product will be

replaced or a credit issued at the option of Dinamic Oil North America.

All returns for replacement or credit MUST be accompanied by a RGA number. Products returned without an RGA

number will be rejected and returned to the sender freight collect. All returns must be shipped “prepaid”. Products

shipped “collect” will be refused. Proof of purchase such as invoice number must accompany returns. All RGA’s must be

returned within 30 days of the request.

PARTS / SERVICE

Minimize downtime and maintain peak performance by choosing genuine Dinamic Oil parts and maintenance kits for your

gear products. For assistance, please contact us:

EMAIL: [email protected]

PHONE: 1.704.587.4600

This manual suits for next models

9

Table of contents

Other DINAMIC OIL DC Drive manuals

Popular DC Drive manuals by other brands

HAUTAU

HAUTAU SM 101 Installation and operating instructions

easydriver

easydriver basic 1.8 Installation and instruction manual

Ingersoll-Rand

Ingersoll-Rand TRANE AFDJ Installation, operation and maintenance

Raymarine

Raymarine E12026 installation guide

YASKAWA

YASKAWA SI-P1/ V7 instructions

Becker

Becker M installation manual