Dinamica Generale AgriNIR W User manual

General Information AgriNIR™ Analyzer Rev. A11

ENGLISH

1

INTRODUCTION

Some images included in this manual may differ from the real ones due a recent product updates. The

methods of use described are equally correct.

AgriNIR™ by is a portable

optical analyzer for fresh forages based on NIR

technology in order to measure humidity (dry

matter), crude protein, starch, ash, ADF and NDF of

the analyzed materials. Thanks to AgriNIR™ the

analysis of most relevant and variable ingredients

(forages!) used in your ratios can be performed just

in a few seconds on site, allowing to know in real

time its actual nutritional values.

AgriNIR™ is based on NIR (Near Infra-Red) techno-

logy: it scans the sample with light and reads the

spectra absorbed by the sample in the NIR region.

Thanks to chemometrics techniques and

mathematical algorithms based on multivariate

analysis, the AgriNIR™ is able to provide

predictions on actual nutrients of the sample in a

real time.

This instrument structure is composed by :

•a microcomputer that manages the data, carries out mathematical operations applying complex

algorithms, providing the final results and the user interface devices: screen, keyboard and printer;

•an optical group: the sample scanner and the NIR sensor, a transducer able to transform the optical

signal in an electrical one.

During the process of analysis there are the following main steps:

1. the light source emits light investing the sample inserted into the sample cup;

2. the sample absorb part of the light accordingly to its actual nutritional values;

3. the thermo-controlled NIR sensor collects spectra and measures the absorbance transforming the

optical in an electrical signal, then in numerical data;

4. the data are transferred to the microcomputer able to apply all mathematical algorithms in order

to predict the actual nutritional values for the sample.

General Information AgriNIR™ Analyzer Rev. A11

2

LICENCE AGREEMENT

IMPORTANT NOTICE: Acceptance and use of the enclosed NIR system (hereinafter

referred to as “Purchased Product”) constitutes your agreement to the following terms

and conditions. Please carefully read the following terms and conditions before using or

reselling the Purchased Product.

1. Limited License

. Dinamica generale, an Italian company (“Owner”) is the owner of

the following Patents related to NIR solutions EP 2 377 392 / US 8 651 730 (“Patents”).

Owner hereby grants to the customer(“Customer”) a non-exclusive, non-transferable,

revocable, limited license to use the technology described in the Patents to use the

Purchased Product in the process covered by the Patents (“Licensed Product”), and to

sell and offer for sale other Licensed Product in accordance with the terms and

conditions set forth herein. Alternatively, Customer may resell the Purchased Product to

another entity for the purpose of that entity assembling the Licensed Product under a

permitted sublicense from the Customer with the same terms as this Agreement.

2. Acceptance of Terms and Conditions

. Customer warrants that it has the authority

to enter into this binding agreement. If Customer does not accept the terms and

conditions, Customer shall not use the Purchased Product. Customer understands and

agrees that if it uses the Purchased Product as permitted herein, it will be deemed to

have accepted these terms and conditions and they shall become a binding agreement.

3. Limitations on Use

or otherwise transfer its rights under this Agreement to a third party, other than to resell

the Purchased Product to another entity for the purpose of that entity assembling the

Licensed Product; (ii)

. Customer agrees that it will use the Licensed Product only as

expressly authorized in this Agreement, and that any use not expressly authorized in

this Agreement is prohibited. Customer agrees that it will not: (i) loan, rent, lease,

assign, sublicense, distribute

copy or reproduce the Licensed Product; or (iii) grant any sublicenses other than to an

end user of the Licensed Product, or to another entity for the purpose of that entity

assembling the unit of a Licensed Product. Customer agrees to use reasonable efforts

to prevent any unauthorized

use or copying of the Licensed Product and will notify Owner immediately upon learning

of any such unauthorized use or copying.

Customer’s obligations under this section shall survive any termination of this

Agreement or the license granted hereunder. Any unauthorized use of the Licensed

Product will result in, among other things, the immediate termination of this license.

4. Ownership of Proprietary Rights

. Customer acknowledges that the Licensed

Product is covered intellectual and/or proprietary rights, and that all such intellectual and

proprietary rights are owned by Owner. Customer hereby acknowledges that it has no

rights in the foregoing except as expressly granted herein.

5. NO WARRANTY

liability for the Purchased Product or the Licensed Product. The Purchased Product is

furnished to Customer “AS IS.” Except as otherwise provided by separate

documentation, OWNER

. Customer agrees to fully test and evaluate the Purchased Product

and Customer acknowledges and agrees that Owner will not assume any product

liability or any other

MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO

THE PURCHASED

General Information AgriNIR™ Analyzer Rev. A11

ENGLISH

3

PRODUCT.

damages for loss of profit, good will or otherwise. Customer shall indemnify and hold

Owner harmless from any and all losses, expenses, damages, costs or expenses of any

kind,

Customer agrees that Owner shall have no liability resulting from

Customer’s use of the Purchased Product for any indirect damages including

consequential, incidental or special

including but not limited to reasonable attorneys’ fees, incurred by Owner resulting from

Customer’s use of the Purchased Product. NO ORAL OR WRITTEN STATEMENTS

MADE BY OWNER OR ITS EMPLOYEES INCLUDING BUT NOT LIMITED TO

STATEMENTS REGARDING CAPACITY,

SUITABILITY FOR USE, OR PERFORMANCE OF THE PURCHASED PRODUCT

SHALL BE DEEMED A WARRANTY OR REPRESENTATION BY OWNER FOR ANY

PURPOSE NOR GIVE RISE TO ANY LIABILITY OR OBLIGATION OF OWNER.

6. Remedies for Violations

Licensed Product.

. Owner reserves the right to seek all remedies available at

law and in equity for violations of this Agreement, including but not limited to the right to

recover the

7. Fees

. In consideration for the rights granted under this Agreement, Customer has

paid a license fee that was included in the amount invoiced to the Customer for the sale

of the Purchased Product.

8. Entire Agreement

. Except as expressly stated herein to the contrary, this Agreement

constitutes the entire agreement between the parties regarding the subject matter

hereof, and no verbal or written prior statements or representations of any sort made by

any party shall be effective or valid for any purpose whatsoever. This Agreement may

be amended only upon the mutual consent of all parties in writing.

9. Severability

. If any provision of this Agreement shall be held to be invalid, illegal or

unenforceable, the validity, legality and enforceability of the remaining provisions shall

not in any way be affected or impaired thereby. The failure of any party to enforce any

provision of this Agreement shall not be considered a waiver thereof, nor shall such

failure prevent the future enforcement of any such provision.

10. Governing Law.

This Agreement and the relationship between the parties shall be

governed in all respects by the laws of Italy. The parties consent to the jurisdiction and

venue of the Italian court of Bologna for resolution of any dispute under to this

Agreement.

Use or sale of the Licensed Product or of Purchased Product shall bind Customer

to all terms and conditions herein without the necessity of signatures on this

Agreement.

General Information AgriNIR™ Analyzer Rev. A11

4

BEFORE USING

1.

For a correct functioning of the device, it will be necessary to put the AgriNIR™ on a

horizontal surface allowing the user to move easily the fodder box containing the

sample to analyze.

2.

The AgriNIR™ device must be supplied with a tension between 9,5 –

32 VDC

through the suitable connector put on the upper of the case. That can be done

through:

•Power Supply (output at 12 VDC) provided with the device;

•Supply cable (optional) with plug for car lighter supply.

In case other supply sources were used,

is not responsible for

damages to people or the AgriNIR™ device.

3.

For a correct functioning verify:

•In case of supplying through a 12 VDC supplier, that the cable for the supplier is

connected to a tension between 100-240 VAC;

•In case of supplying through the plug for car lighter, that the battery has a tension

always higher then 9,5 Volts.

4.

During delivery of the AgriNIR™ it is important:

•Not to put mobile and/or sharpened objects inside the case preventing the

electronic/optoelectronic (graphical display, printer, communication cable, optical

fiber protected by a black sheath put at the bottom of the case) device from

being broken or wrongly hurt.

•To fasten the accessories (fodder box, accessories for the fodder box, power

supplier, supply cable, supply cable with plug for car lighter, clearing accessories)

to prevent them from moving inside the case or the electronic/optoelectronic

device from being broken.

If it is not the case, is not responsible for damages to the AgriNIR™.

5.

DO NOT POWER the AgriNIR™ device (by supply power cable for car lighter) during

transporting by car.

If it is not the case, is not responsible for damages to the AgriNIR™.

6.

Disconnect the supply cable from the device before servicing and/or

clearing the

AgriNIR™.

If it is not the case, is not responsible for damages to people or to

the AgriNIR™.

7.

To clean the AgriNIR™ correctly:

•for the upper part (display, keyboard, printer, reading glass) use a so

ft and

slightly wet cloth;

•For the bottom (metal chassis of the fodder box and reading window of the Read

NIR) use pressurized air or a soft and slightly wet cloth.

DO NOT use neither alcohol nor other solvents!

DO NOT wet with water!

If it is not the case, is not responsible for damages to the AgriNIR™.

8.

For a correct functioning of the sampling fodder box, use a soft cloth or pressurized

air or flowing water. DO use neither alcohol nor other solvents!

If it is not the case, is not responsible for damages to the device.

General Information AgriNIR™ Analyzer Rev. A11

ENGLISH

5

NOTES FOR THE USER

1.

After switching ON the AgriNIR™, recommends strongly to wait

at least 15 minutes before executing the analysis. That will allow the optimization of

the exercise temperature of the optoelectronic device.

2.

For a correct functioning of the optoelectronic device contained in the AgriNIR™, it’s

better to monitor the temperature of the place where it is

used. While working the

device mustn’t exceed the temperature range between 0°C and +40°C.

If it is not the case, is not responsible for damages to the AgriNIR™.

3.

If ambient temperature is 35°C or upper, DO NOT keep the AgriNIR™ device turned

on for more than 2 hours time (IMPORTANT!

If it is not the case,

for machines HW rev. B3 or previous).

is not responsible for damages to the AgriNIR™.

4.

In case of use of the device outside, it SHOULD NOT

be exposed directly to climatic agents such as rain,

snow, hail ...

If it is not the case, is not responsible for damages to the AgriNIR™.

5.

In case AgriNIR™ were supplied through the suitable supply cable (optional) with

plug for car lighter, disconnect this cable when the vehicle’s battery is being charged.

If it is not the case, is not responsible for damages to people or to

the AgriNIR™.

6.

Disconnect the supply cable from the device before servicing and/or clearing the

AgriNIR™.

If it is not the case, is not responsible for damages to people or to

the AgriNIR™.

7.

For a correct functioning verify:

•In case of supplying through a 12 VDC supplier, that the cable for the supplier is

connected to a tension between 100-240 VAC;

•In case of supplying through the plug for car lighter, that the battery has a tension

always higher then 9,5 Volts.

8.

DO NOT use USB extension cables LONGER than 1 meter to connect the USB

memory key to the USB connector available on the front unit of AgriNIR™ device.

9.

CANNOT be considered responsible for damages to people or

things because of a misuse of the device.

10.

DOES NOT assume the responsibility for the result provided by

AgriNIR™ in case there were not correspondence between the material analyzed and

the one declared by the system.

11. This marking on the product or on its packaging illustrates that

this product may not be disposed of with normal household

waste. You are responsible for disposal of this equipment in a

correct way and in according to local regulations.

General Information AgriNIR™ Analyzer Rev. A11

6

1 CONTENTS

INTRODUCTION ...................................................................................................................1

LICENCE AGREEMENT........................................................................................................2

BEFORE USING....................................................................................................................4

NOTES FOR THE USER.......................................................................................................5

1CONTENTS ..................................................................................................................6

2TECHNICAL DATA & CONFIGURATION .....................................................................7

3ACCESSORIES SUPPLIED..........................................................................................9

4ELECTRIC CONNECTIONS.......................................................................................11

4.1 Supplying AgriNIR™ with the provided power supply .....................................................11

4.2 Supplying AgriNIR™ with the power cable for car lighter plug........................................12

5Description of the portable Analyzer AgriNIR™...........................................................13

6Use of the Portable AgriNIR™ Analysis System..........................................................16

6.1 NIR Parameters and NIR Families...................................................................................16

6.2 Correct Use of the Fodder Box for the Samples to Analyze............................................18

6.3 Turning on the AgriNIR™ system....................................................................................21

6.4 States & Messaging of NIR analyzer internal system......................................................23

6.5 Error Messaging of NIR analyzer internal system ...........................................................25

6.6 Initial Optical Checking of the AgriNIR™ system.............................................................27

6.7 Analysis Samples Identifying...........................................................................................31

6.8 Analysis Execution with AgriNIR™ System.....................................................................34

6.9 Case of incorrect analysis................................................................................................39

6.10 Analysis printing on tickets...............................................................................................40

6.11 Analysis saving on USB pen drive...................................................................................42

6.12 Analysis History – available only for AgriNIR W..............................................................44

6.13 Other Settings of AgriNIR™ System................................................................................46

6.14 Calibration Updating of AgriNIR™ System......................................................................47

6.14.1 Update Calibrations for AgriNIR W....................................................................................... 48

6.15 LOADING OF NEW NIR DATA STRUCTURE (NIRDATA.BIN file)................................50

6.16 Deleting Analysis on internal memory .............................................................................52

6.17 Deleting the initial message of FULL MEMORY..............................................................53

6.18 Printer Header Settings....................................................................................................55

7CLEANING THE DEVICE............................................................................................57

8DEVICE SERVICING..................................................................................................58

8.1 Verification and Servicing of the Optical Group...............................................................58

8.2 Replacement of the Printer’s Paper.................................................................................59

9RESPONSIBILITIES ...................................................................................................60

10 CE CONFORMITY DECLARATION............................................................................61

11 WARRANTY................................................................................................................62

General Information AgriNIR™ Analyzer Rev. A11

ENGLISH

7

2 TECHNICAL DATA & CONFIGURATION

AgriNIR™ configurations

Code Machine Features

999-0228 AgriNIR Analyzer standard machine

999-0565 AgriNIR W Analyzer Worldwide version

999-0347 AgriNIR Analyzer with GSM/GPRS with GSM/GPRS Quad-Band internal modem

Accuracy

[Note 2. at next page] [ see the tables at next page ]

Working Temperature

[Note 1. at next page] 0° ÷ +40°C

Power 12 ÷ 18 VDC

60W max

Display LCD monochromatic

¼ VGA

Dimensions 50 x 31 x 46 cm

Weight 20 Kg

Box ABS plastic

Protection Grade n. a.

GMS / GPRS

internal modem

[only cod. 999-0347]

Quad-Band GSM release 99

850/900/1800/1900 MHz

GPRS multi-slot class 12

Output power :

•Class 4 (2 W) for EGSM850

•Class 4 (2 W) for EGSM900

•Class 1 (1 W) for GSM1800

•Class 1 (1 W) for GSM1900

Paper Type Thermal paper roll

(thermal side outside of the roll)

Paper width 57 mm ±0.5 mm

Paper Type suggested from 55 g/m² to 70 g/m²

Roll diameter inner core 13 mm

Outer roll diameter max. Ø44mm

Soul type Cardboard or plastic

General Information AgriNIR™ Analyzer Rev. A11

8

1.

NOTES.

If AgriNIR™ machine has Hardware revision B3 or previous (the HW rev. is showed on yellow

label together machine S/N), the maximum working temperature recommended is 35°C.

For Hardware revision B4 or newer the maximum working temperature is 40°C.

Please DO NOT exceed the limits of temperature, according to

NOTES FOR THE USER points N°

2 and 3 at page 3.

2.

The percentage of Accuracy DOES NOT express the mathematical percentage of the error on

analysis result, but it represents the maximum error in percentage points between the analysis

result (just expressed in percentage points) provided by AgriNIR™ and the real analysis value, that

you can obtain by chemical analysis on the material in question.

Please see below the specific AgriNIR™ Accuracy values for each NIR family / parameters :

AgriNIR™

accuracy for

DG standard

calibrations package

NIR Chemical Parameters

Moisture

( Humidity ) Starch Crude

Protein ADF NDF Ash

Crude Fat

( Ether

Extract )

NIR Families

CORN SILAGE ±2,0% ±2,0% ±1,0% ±1,0% ±1,5% ±0,5% ±0,5%

HAY ±1,0% n.a. ±1,0% ±2,0% ±2,5% ±1,5% ±0,5%

HIGH

MOISTURE

CORN

±2,0% ±3,0% ±1,0% ±1,5% ±2,5% ±0,5% ±0,5%

ALFALFA HAY ±1,0% n.a. ±1,5% ±3,0% ±3,0% ±1,0% ±0,5%

GRASS SILAGE ±2,0% n.a. ±1,5% ±2,0% ±2,5% ±1,5% ±0,5%

T.M.R. ±2,0% ±2,0% ±1,0% ±1,5% ±2,0% ±0,5% ±0,5%

SOYBEAN

FLOUR ±1,0% n.a. ±1,5% n.a. ±1,5% ±1,0% ±1,0%

AgriNIR™

accuracy for

DG grains

calibrations package

[ optional ]

NIR Chemical Parameters

Moisture

( Humidity ) Starch Crude

Protein ADF NDF Ash

Crude Fat

( Ether

Extract )

NIR

Families

CORN GRAIN ±1,0% ±1,0% ±1,0% n.a. ±1,0% ±1,0% ±1,0%

WHEAT GRAIN ±1,0% ±1,0% ±1,0% n.a. ±1,0% ±1,0% ±1,0%

General Information AgriNIR™ Analyzer Rev. A11

ENGLISH

9

3 ACCESSORIES SUPPLIED

Accessory Description

FODDER BOX

Tray with glass for fodder samples

and its pressure plate.

Also it presents special housing for

Check-Cell.

PRESSOR

The pressor with sponge is used for

grains or dry and chopped matter.

The pressor without sponge is used

for forages of wet and voluminous

type.

General Information AgriNIR™ Analyzer Rev. A11

10

CHECK CELL

Special sample cell

acetyl resin for the

optics testing of

the machine.

POWER SUPPLY

AC input :

100-240V~2A, 50-60Hz

DC output :

12V, max 8A

and

AC power cable with SCHUKO plug

IEC320 connector.

Power cable for car lighter

plug

USB memory pen-drive

Roll of thermal paper for

printer

AgriNIR™ User Manual

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

11

4 ELECTRIC CONNECTIONS

4.1 Supplying AgriNIR™ with the provided power supply

Power Connector

Power Supply

IN : 100-240VAC –2A

OUT : 12VDC –max 8A

AgriNIR™ Analyzer

Configuration AgriNIR™ Analyzer Rev. A11

12

4.2 Supplying AgriNIR™ with the power cable for car lighter plug

Power cable for car lighter plug

Power Connector

AgriNIR™ Analyzer

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

13

5 Description of the portable Analyzer

AgriNIR™

In the following pictures it is explained how the system AgriNIR™ is composed:

FODDER BOX

for inserting the sample to analyze

NIR OPTICAL UNIT

Knob and security

hinge of NIR Unit

Communication

cable of NIR Unit

Printer

USB plug

for memory

pen drive

PROG / DATA connector for

downloading data and

programming AgriNIR™

[ DG assistance only ]

Screen and keypad

ELECTRONIC UNIT

GSM/GPRS

modem led

available only for

AgriNIR 999-0347

ON / OFF

Configuration AgriNIR™ Analyzer Rev. A11

14

The portable Analyzer AgriNIR™ is composed by:

FODDER BOX →sampling box with screwed handles on presser, for the collection of the forage samples

that has to be analyzed with AgriNIR™.

NIR OPTICAL UNIT →optical unit for acquisition of light produced by the sample to be analyzed.

This unit consists of:

•Read NIR →Optical reading head that senses the light spectra produced by the feed component

present in the fodder box inside AgriNIR™ system.

•Optical Fiber →transmits the light sensed by Read NIR head to NIR optical sensor.

•NIR sensor →optoelectronic device that receives the light spectra sensed by Read NIR head

on the feed component and transforms them in electrical signals.

ELECTRONIC UNIT →processing and control unit of the AgriNIR™ system. With this unit the operator

can start the analysis on the feed components put in the fodder box, and get the analysis results shown

on display. These results can be printed on a paper or stored on a USB Pen Drive.

USB MEMORY PEN DRIVE →Memory unit that allows to store the results of the performed analysis and

to transfer them to PC through the management software DGNirManager.

Please see NOTES FOR THE USER point N° 8 at page 3.

The conceptual model that defines the functioning of the portable analysis system AgriNIR™ is explained

in the following scheme :

USB

key Data saving for :

analysis results;

optical spectra.

Sample of forage

Measured Light

Spectra

Setting of :

NIR Families;

Chemical Parameters;

Calibration Curves.

Optical Spectra Archive

NIR Families and

Chemical Parameters

NIR Calibrations

DGNirManager

AgriNIR™ Analyzer

Configuration AgriNIR™ Analyzer Rev. A11

ENGLISH

15

For the setting of the feed components to analyze and the storage of the performed analysis on PC it is

used the management program DGNirManager produced by .

This software product on PC allows the user to:

•set the Chemical Parameters for the analysis to be performed with the AgriNIR™ system;

•mark the feed components that will be analyzed with the AgriNIR™ system, by means of NIR

Families components giving them proper theoretical reference values for the chemical

parameters that characterize them; after having completed its own set of feed components, this is

transferred to AgriNIR™ system through the USB memory key;

•store all the analysis performed with AgriNIR™ system and relevant optical spectra sensed on

the analyzed components, previously stored on USB memory key; after having completed its own

set of analysis, new Calibration Curves can be performed, i.e. new setting curves to be

transferred to the AgriNIR™ system through the USB memory key, in order to make AgriNIR™

analysis even more accurate.

Use AgriNIR™ Analyzer Rev. A11

16

6 Use of the Portable AgriNIR™ Analysis

System

6.1 NIR Parameters and NIR Families

In case of standard calibrations package, the portable analysis system AgriNIR™

can analyze till to a max of 7chemical parameters for a max of 7feed components categories of most

common use in cattle breeding.

In all NIR analysis systems produced by and therefore also for AgriNIR™ it is

defined:

NIR Parameters

all chemical parameters analyzable by an optical NIR analysis system

NIR Families

the categories or families of feed components analyzable by an optical NIR

analysis system

For cattle feeding, the list of all chemical NIR parameters that can be analyzed for each NIR family is

expressed in the following table:

NIR chemical

parameters that

can be analyzed in

every NIR Family

DG standard

calibrations package

NIR Chemical Parameters

Moisture

( Humidity ) Starch Crude

Protein ADF NDF Ash

Crude Fat

( Ether

Extract )

NIR Families

CORN SILAGE YES YES YES YES YES YES YES

HAY YES NO YES YES YES YES YES

HIGH

MOISTURE

CORN

YES YES YES YES YES YES YES

ALFALFA HAY YES NO YES YES YES YES YES

GRASS SILAGE YES NO YES YES YES YES YES

T.M.R. YES YES YES YES YES YES YES

SOYBEAN

FLOUR YES NO YES NO YES YES YES

It is necessary to keep this table in mind while defining with DGNirManager the feed components to

analyze.

•The a.m. definition of the NIR families and therefore of the feed components categories

analyzable by NIR systems, is subjected to market requests and intends to include all feed

components mostly used in cattle breeding. Moreover, depending on the usage of the AgriNIR™

system (according to the NIR Calibrations carried out by specialized laboratories) it is possible to

create NIR Families that are completely different from those mentioned here (e.g. NIR family for

Olive Husk).

Use AgriNIR™ Analyzer Rev. A11

ENGLISH

17

•For every NIR family it is necessary to set the suitable Theoretical Reference Values for each

NIR chemical parameter that can be analyzed (see table above). These reference values are

normally the result of laboratory chemical analysis performed on different samples of the NIR

family and allow to the AgriNIR™ system to make a “selection” of the optical analysis that result

incorrect (ex. due to a bad optical reading, to a false position of the sample under the reading

head Read NIR, to a too much damaged component, to external rests present, etc...).

In case of grains calibrations package (optional calibrations for grains), the

portable analysis system AgriNIR™ can analyze following NIR grain families and allows these chemical

NIR parameters :

NIR chemical

parameters that

can be analyzed in

every NIR Family

DG grains

calibrations package

[ optional ]

NIR Chemical Parameters

Moisture

( Humidity ) Starch Crude

Protein ADF NDF Ash

Crude Fat

( Ether

Extract )

NIR

Families

CORN GRAIN YES YES YES NO YES YES YES

WHEAT GRAIN YES YES YES NO YES YES YES

The of grains calibrations package

is an Optional Calibration

package that the final customer can add, when he orders a new AgriNIR™ machine.

Use AgriNIR™ Analyzer Rev. A11

18

6.2 Correct Use of the Fodder Box for the Samples to Analyze

Before going on with the real use of the Portable AgriNIR™ Analysis System, it is important to understand

the correct use of the fodder box containing the sample to analyze.

This fodder box (provided with the AgriNIR™) is composed by :

•an upper side with glass, to allow the optical scanning of the sample;

•a metallic frame able to maintain the sample properly (with the right pressure!) in front of the

scanning window glass.

To fill in the fodder box with the food sample to analyze, it is very IMPORTANT to put in practice the

following simple rules:

•make sure the fodder box GLASS IS CLEAN, without residues of other samples;

•in case of very soft materials with long pieces, as hay, alfalfa, or grass silage, it is NECESSARY :

sampling material using a special Corer (strongly suggested!) and then cut the sample in

order to have parts with length equal to 2/3 cm;

press the sample in order to reduce its volume up to 1/2 or 1/3 of the original one;

•the sample must be put into the fodder in order to cover completely the scanning window (glass)

without open spaces. Below you can see 2 different pictures reporting how the sample has to be

putted inside the fodder: quantity, pressure…

•in the first picture below, you can see a sample well prepared and ready for analysis

OK!

good pressure without

air spaces.

•in the second picture below, a sample prepared in a wrong way: sample quantity is wrong and its

pressure on the glass is too low

NO!

low pressure with air

spaces.

This manual suits for next models

1

Table of contents

Other Dinamica Generale Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Gossen MetraWatt

Gossen MetraWatt DIGISIX 2 operating instructions

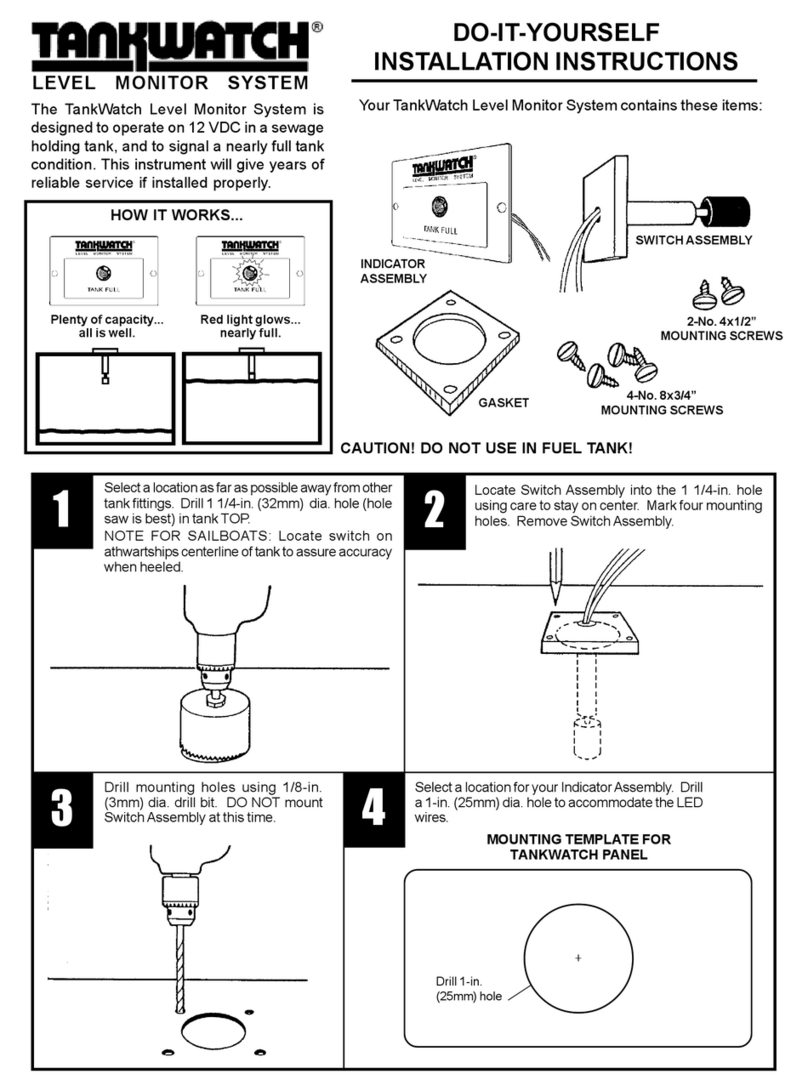

SeaLand

SeaLand TankWatch Level Monitor System installation instructions

Agilent Technologies

Agilent Technologies FieldFox N9912A Service note

Xylem

Xylem Sensus Domo R Instructions for installation, use and maintenance

Teledyne

Teledyne WORKHORSE Deployment guide

HYDAC International

HYDAC International AquaSensor AS 8000 Series operating manual