Dinel PCU-100 Series User manual

Before the rst use of the unit, read the instructions in this manual and keep it

carefully. The manufacturer reserves the right to do alteration without prior notice.

PROGRAMMABLE CONTROL UNIT

PCU–100

USER MANUAL

Firmware version 2.0.2. or higher

1 . Basic description ................................................................................................................... 4

2 . Range of application .............................................................................................................. 5

3 . Variants of sensors ................................................................................................................ 5

4 . Dimensional drawings ........................................................................................................... 5

5 . The front panel and terminal block ........................................................................................ 6

6 . Installation and putting into operation ................................................................................... 6

7 . Mechanical mounting ............................................................................................................ 6

8 . Electrical connection ............................................................................................................. 7

9 . Settings ................................................................................................................................ 10

9.1. Setting of the input channel in the unit .......................................................................... 11

9.2. Display conguration .................................................................................................... 16

9.3. Conversion Rules ......................................................................................................... 19

9.4. Output Relay .................................................................................................................25

9.5. The archiving and data export conguration ............................................................... 27

9.6. Parametrization of connected measuring devices using the HART® protocol .............. 28

9.7. Other settings of the control unit .................................................................................... 37

9.8. Menu Structure ............................................................................................................. 40

10 . Functions of the device ......................................................................................................44

10.1. Description of the front panel ......................................................................................44

10.2. Signalling functions ....................................................................................................45

10.3. Export of data .............................................................................................................45

10.4. Displaying Functions of the User Menu .....................................................................46

10.5. Unit rmware updates ................................................................................................. 47

11 . Order code .........................................................................................................................48

12 . Correct specication examples ......................................................................................... 49

13 . Safety, protection and compatibility ................................................................................... 49

14 . Use, manipulation and maintenance ................................................................................. 49

15 . General, conditions and warranty ..................................................................................... 50

16 . Marking of labels ................................................................................................................ 50

17 . Technical specications ..................................................................................................... 51

18 . Packing, shipping and storage ........................................................................................... 52

CONTENT

PCU–100 © Dinel, s.r.o.

4

Programmable control unit PCU–100 is used for measurement, displaying and archiving of the

physical value (liquid level, pressure, ow, temperature, etc.). One transducer of physical magni-

tude with an analogue 4-20 mA output can be connected to the unit.

Dierent types of conversion (converting) characteristics (linear, square, root and user dened),

may be selected, also the tank dimensions for conversion to the volume of the media may be speci-

ed. The unit is also available in the version without graphic LCD display that is replaced with the

status LEDs. The unit has a battery backed real-time circuit. Archiving with user-dened period

takes place on the internal ash memory with a capacity sucient for more than 500,000 samples.

Data can be exported to a micro SD card for additional processing.

User conguration is possible through a regular desktop application after connecting a PC via

a micro USB connector located on the front panel of the unit. For the version tted with an LCD

display the conguration is also possible using the graphical menu and four membrane keys.

The unit is equipped with one input settings in the hardware conguration according to the type of

unit. One relay output is fully user-congurable, including the possibility of two-state control. The

functionality of the unit is expandable with optional modules. The units are built into the ABS / PC

instrument boxes intended for wall mounting. Connection terminal is located inside the device.

All the operations described in these operating instructions must be made only by trained

personnel or by an authorised person. Warranty and post-warranty repairs must be carried

out exclusively at the manufacturer. Incorrect sensor use, assembly or conguration may

cause accidents in the application (tank overlling or damage to the system components).

The manufacturer is not responsible for the improper use, working losses incurred by

either direct or indirect damage and the expenditure incurred during the installation or

the use of the sensor.

In order to ensure maximum safety of control processes, we have dened the following safety and infor-

mation instructions. Each instruction is marked with a corresponding pictogram.

Caution, warning, danger

This symbol informs about particularly important instructions for the installation and opera-

tion of the device or dangerous situations that may occur during installation and operation.

Ignoring these instructions may be the cause of the fault, damage to or destruction of the

device or may cause damage to health.

Information

This symbol indicates particularly important device characteristics and recommendations.

Note

This symbol indicates the useful additional information.

5

© Dinel, s.r.o. PCU–100

Programmable control unit can be used as a universal industrial data logger for monitoring of

a measured value. Thanks to a relay output, it is also possible to use the unit for the control of

the process of measured value using two-state control.

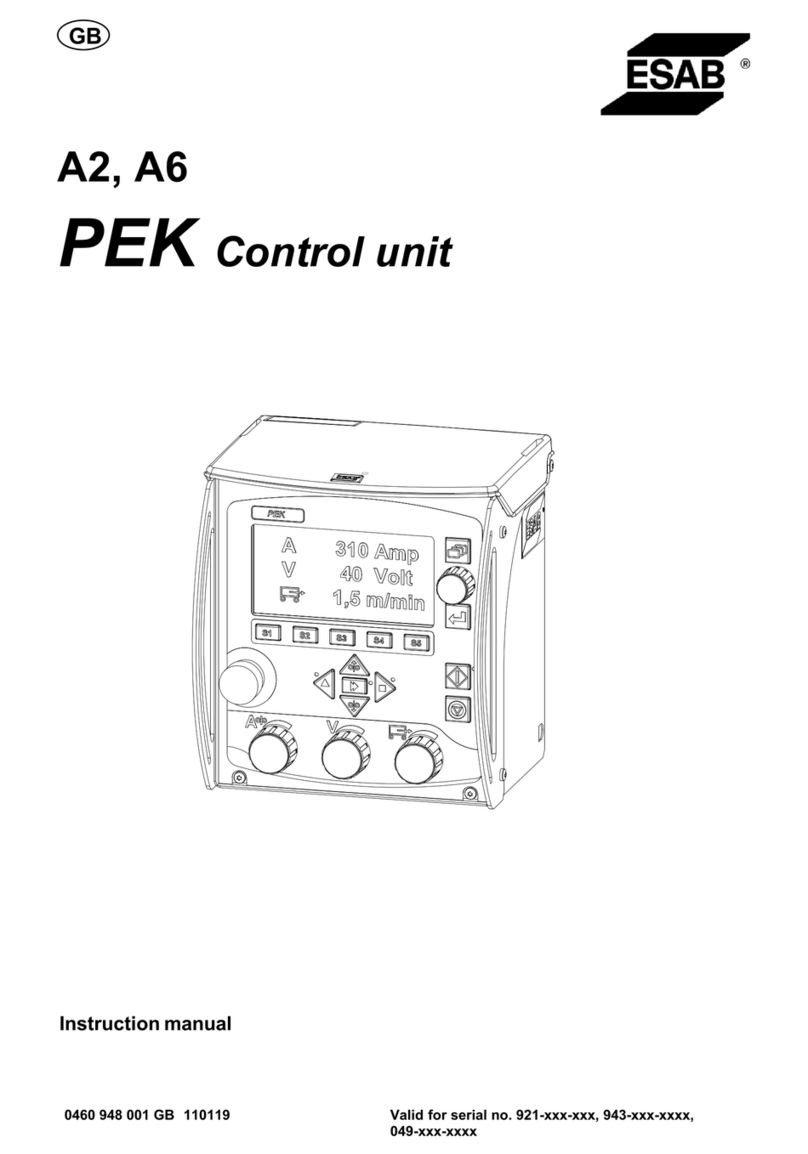

• PCU–100–D Front panel with a graphic LCD display and a membrane keypad. The en-

try depending on conguration (for connecting one sensor), one relay output.

The unit is available in two versions. The makes are dierent by the front panel appearance.

Both versions have a micro USB connector to connect a computer to congure the unit via the

conguration application and micro SD card slot for the purposes of exports of the recorded data.

• PCU–100–L The front panel without an LCD display with status LEDs. The entry

depending on conguration (for connecting one sensor), one relay output

the earthing contact

PCU–100 © Dinel, s.r.o.

6

• A number of evaluation units PCU-100-_ is designed to be installed on a wall using four mounting

screws or bolts (hereinafter referred to as “the screws”).

• When installing the device, it is rst necessary to withdraw the transparent polycarbonate hous-

ing of the front panel that is held in place by 4 plastic screws. The mounting holes designed for

screws for attaching to the wall are located under the plastic screws. Using the screws, the unit is

xed in the required position on the wall. Now, it is possible to connect the cables to the terminals.

• Then, return the transparent cover to the place on the front panel and its plastic screws are suf-

ciently tightened to achieve full coverage.

• The prescribed tightening torque is 3 Nm.

No. of terminal

1L (85 - 253 VAC)

2N (85 - 253 VAC)

3 Functional earthing

4Current input +

5Current input -

20 RE 1 (100 mA / 250 VAC)

21 RE 1 (100 mA / 250 VAC)

SCHÉMA ŠTÍTKU (ČERVENĚ JSOU VYZNAČENY OTVORY)

Poznámka: šedé orámování tlačítek bude ještě v rovině fólie

www.dinel.cz

Programmable Control Unit PCU-100

ESC OK

1234

PIN 1

PIN 1

1234

MAR SR 191

Transparent

PANT 320

vývod

z rubové

strany

PIN 1

14,5

15

SCHÉMA ŠTÍTKU (ČERVENĚ JSOU VYZNAČENY OTVORY)

MAR SR 191

PANT 320

www.dinel.cz

Programmable Control Unit

PCU-100

POWER

POWER

SD CARD

LOGGING

OUTPUT

POWER

PCU–100–D PCU–100–L

Terminal Block: PCU–100–_–I:

This procedure has the following three steps:

•

•

•

Be extremely careful when placing the cover in place. It is not possible to settle the front

cover arbitrarily, there are located protrusions on the bottom of the housing and on the body

of the boxes. At bad settlement, these protrusions may prevent the full engagement of the

seal and the achievement of full coverage.

7

© Dinel, s.r.o. PCU–100

Electrical connection can only be made in a voltage-free state!

The temperature of the internal components of the unit may under specic conditions exceed

a temperature of 60°C after a longer period of time in service. Take care when handling.

• The device may only be connected to the power supply via an easy to reach switch with

marked turned o/on positions and must be protected by a fuse or circuit breaker with a value

of max. 16 A!

• The used connecting cables must be of circular cross-section of the prescribed diameter (2.5 - 6.5

mm). The connection cable must be according to the specications of the manufacturer rated to

the operating voltage (85 - 253 VAC) and the current load corresponding to the rated wattage (6

VA) at this voltage. The insulation material must comply with the operating voltage and endure the

ambient temperatures of up to 70 °C. In the case, there is no cable in the penetration, the penetra-

tion must be tted with a plug. Cable grommets must be tightened to the specied torque (3 Nm).

The switch or circuit breaker used as the disconnect device must be in accordance with the

IEC60947-1 and IEC60947-3, must be marked and must not be in the network inlet.

The external power supply is not connected

Power supply inlet power supply AC lead “L” to the terminal No.1 and lead “N” to the

terminal No.2.

Connections of input device current loop “+” to terminal No. 4 and “-” to No. 5

Relay output (galvanically sepa-

rated solid state relay - SSR) the connection to the terminals No.6 and No.7.

The electrical connection is made to the terminal block of the device. For an access to the terminal

block, it is required:

1. Remove the transparent front polycarbonate housing (see chapter Mechanical assembly)

2. Grip the front panel on the sides by the grips intended for this purpose (see gure below)

3. Pull evenly on both sides to eject the front panel from the connector.

PCU–100 © Dinel, s.r.o.

8

The grounding wire is always attached only in one place by using the method 1 or 2. It is

never attached in both places at the same time.

Grounding wire connected to the unit serves always as the functional ground to improve the as-

sembly resistance against EM interference and does not full the protective function. Connection

of a functional earth to the unit is possible in one of the two ways while we are choosing the way

that allows connection the ground wire on a shorter route:

1. We will connect the grounding wire inside the unit to the terminal number three where it is as-

sumed to bring the earthing wire to the unit within the power cable.

2. The grounding wire will be connected to the external earth terminal of the device, which is

located on the bottom of the box together with outlets.

*

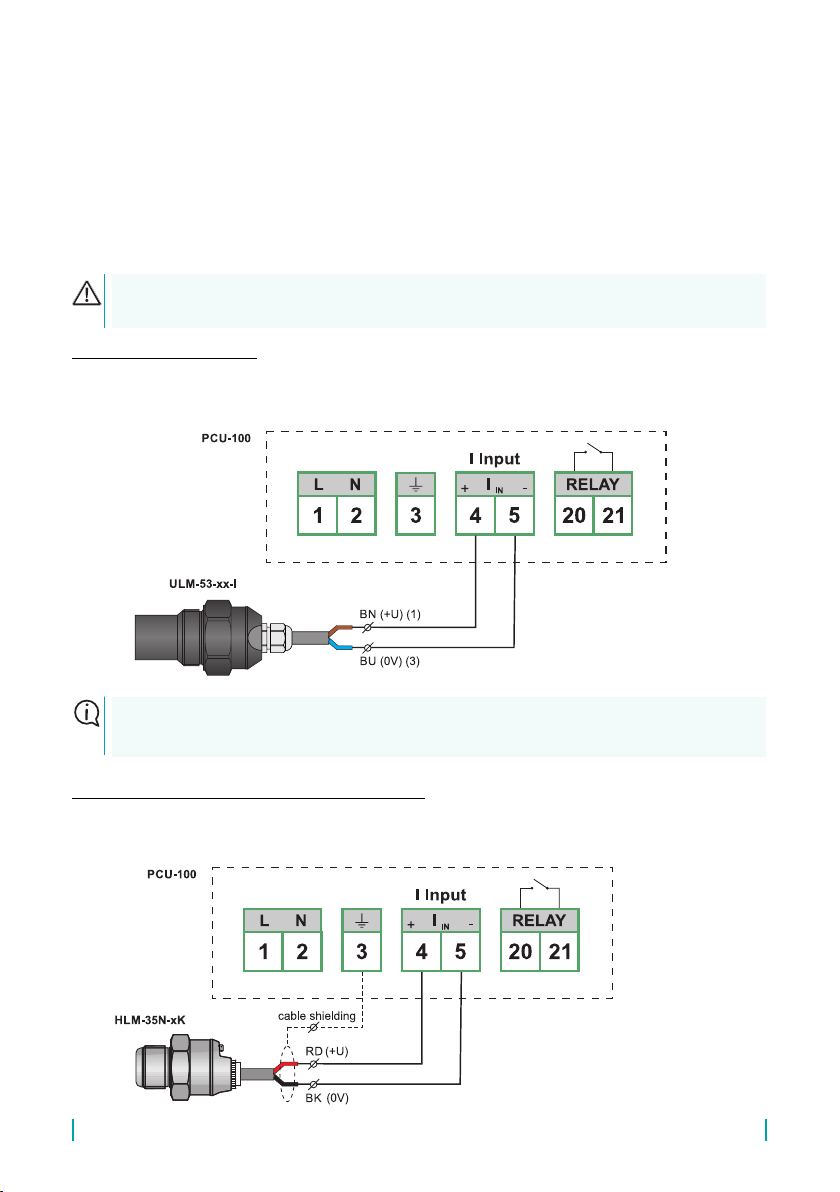

Example connection:

A n ex am pl e of the PCU –10 0 - _- I uni t c on ne ct io n w it h t he leve l s en so r U LM - 53 - _ _ - I is shown here.

Legend:

BN – brown

BU – blue

The level transmitter ULM-53-__-I may be replaced by any other measuring device

with current output.

(RD (+U)(1))

(BK (0V)(3))

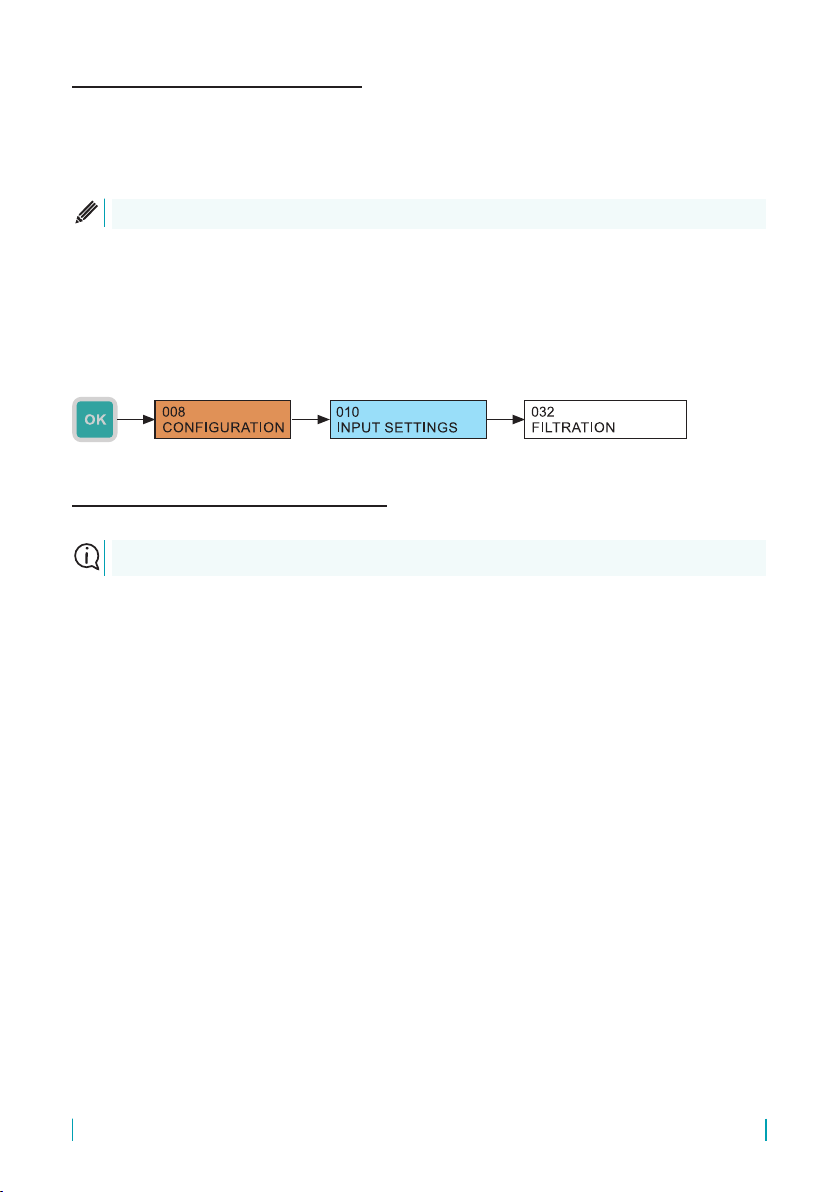

Legend:

RD – red

BK – black

---- – shielding

Example of a circuit with shielded cable:

A n ex am p le of t he PC U –1 0 0 - _ - I u ni t c o nn ec t io n w it h t h e l ev el se ns o r - H LM - 3 5 N - _ K is sh ow n h er e.

9

© Dinel, s.r.o. PCU–100

The example of several level meters connection with the HART®protocol support:

The example of the PCU-100-_-H unit connection with several ULM-70-N-_ _-_-I level meters is

shown here.

It is important that the measuring devices are in the so-called multi drop mode. For level meters from

Dinel s.r.o., this mode is set by changing the HART® polling address to other than 0. Regardless of

the measured value, a constant current of 4 mA ows through the level meter and communication

then proceeds only via the HART® protocol.

The ULM-70N-_ _-_-I level meter can be replaced by any other mesuring device with current output

and the HART®protocol support (such as GRLM-70 or CLM-70 from Dinel s.r.o.). The devices can

also be combined and do not have to be of the same type.

For correct functionality it is also necessary that all connected devices have different polling

addresses (see chapter [reference to chapters 9.1.1 and 9.6.1]).

I Input

Legend:

BN – brown

BU – blue

(1...) – numbers of the

connector terminals

PCU–100 © Dinel, s.r.o.

10

Be extremely careful when placing the cover back in place. It is not possible to settle the

front cover arbitrarily, there are located protrusions on the bottom of the housing and on the

body of the boxes. At bad settlement, these protrusions may prevent the full engagement of

the seal and the achievement of full coverage.

The symbol used in the manual: [ESC]

Functionality:

• The procedure in the menu one level up

• Change cancelling when editing

The symbol used in the manual: [↕]

Functionality:

• The shift in the menu

• Increase of the highlighted character value on the screen for entering the values

The symbol used in the manual: [↔]

Functionality:

• The shift in the menu

• Shift between the characters on the screen for entering the values

• Change the value of the check mark at the menu item

• Change the value on the screen with the values selection

The symbol used in the manual: [OK]

Functionality:

• Entering the main menu

• Entering the sub-menu

• Conrming changes when editing

If no key is pressed within 5 minutes in the menu, the unit automatically switches back to the

display mode.

The basic functions of buttons and their symbols

The units in the version PCU–100-D with LCD display can be set using the graphical menu con-

trolled by four membrane keys. For access to the control buttons and USB connector, it is necessary

to withdraw rst the transparent polycarbonate housing of the front panel that is held in place by

4 plastic screws. (see Chapter Mechanical mounting).

11

© Dinel, s.r.o. PCU–100

The application is free to download at www.dinel.cz/download-1

Entry to the menu and scrolling through the menus

The entry to the menu is performed by pressing the [OK] button. By pressing briey the button [↕]

we are moving in the sub-menu, we get to the next level by pressing [OK]. The edited data can be

changed using the arrows [↕] [↔]. The changes are saved with the [OK] button, back to the main

menu, we get by pressing the button [ESC].

The unit can also be fully set up using a PC conguration application. To connect the unit to your

computer, a micro USB connector on the front panel of the unit is used. PCU-100-L units that are

not equipped with a display can only be parametrized using this application.

The layout of the application is intuitive and respects the layout of the graphical menu of the unit

(user manual). A more detailed description can be found in the user manual for the application.

The Micro USB cable must be connected to the unit on the y; it must not be connected

before connecting the unit to the power supply.

For a correct display of bar graph and for the purpose of the transfer characteristics conguration

it is necessary to specify the limits of the measuring range of the unit, thus, minimum value of the

input magnitude (corresponds to 0 %) and its maximum value (corresponds to 100 %).

The measuring range can be also congured inversely, when minimum of the range corresponds

to a greater level of the input value than the maximum of the range.

Deviation of values outside the measuring range is indicated on the display of the unit by the text

“Below the range”/”Above the range”. However, the conversion of the value for display and archiv-

ing takes place also within the limits of the extended measuring range, if congured. Outside the

extended measuring range is logged and displayed the value -N/A (below the minimum) or +N/A

(above the maximum).

The extended measuring range can be congured identically as the measuring range. In this way

the unit behaves even if the limits of the extended measuring range of the congured senselessly

(in the area of the measuring range or inverted).

PCU–100 © Dinel, s.r.o.

12

By factory default settings, HART®communication units (PCU-100-_-H-_-_) operate with an

analogue current value in the loop in mA (see chapter 9.1.3.). When the input is changed to a digital

value, the measuring range limits are entered in the relevant physical units. Which were set on the

measuring device.

Example:The levelmeter GRLM-70N-10-_-I-_-_-E2000 isconnected to theunit PCU-100-_-H-_-_.

In case that we want to read the distance digitally to the level in millimetres, we set the MIN RANGE

= 100 and MAX RANGE = 2000.

Range Minimum Range Maximum

0 % 100 %

-N/A Measuring range +N/A

Extended measuring range

Minimum of the Extended Range Maximum of the Extended Range

<0 % = Indication

“Below the range“

>100 % = Indication

“Above the range”

Type of unit

inlet

Measuring

range mini-

mum

Measuring

range maxi-

mum

Extended

measuring

range mini-

mum

Extended

measuring

range

maximum

Limits of the

user congu-

ration

Menu ID 028 029 030 031 –

Current 4 mA 20 mA 3.85 mA 20.55 mA 0 – 24 mA

HART®4 mA / [-] 20 mA / [-] 3,85 mA / [-] 20,55 mA / [-] neomezený

13

© Dinel, s.r.o. PCU–100

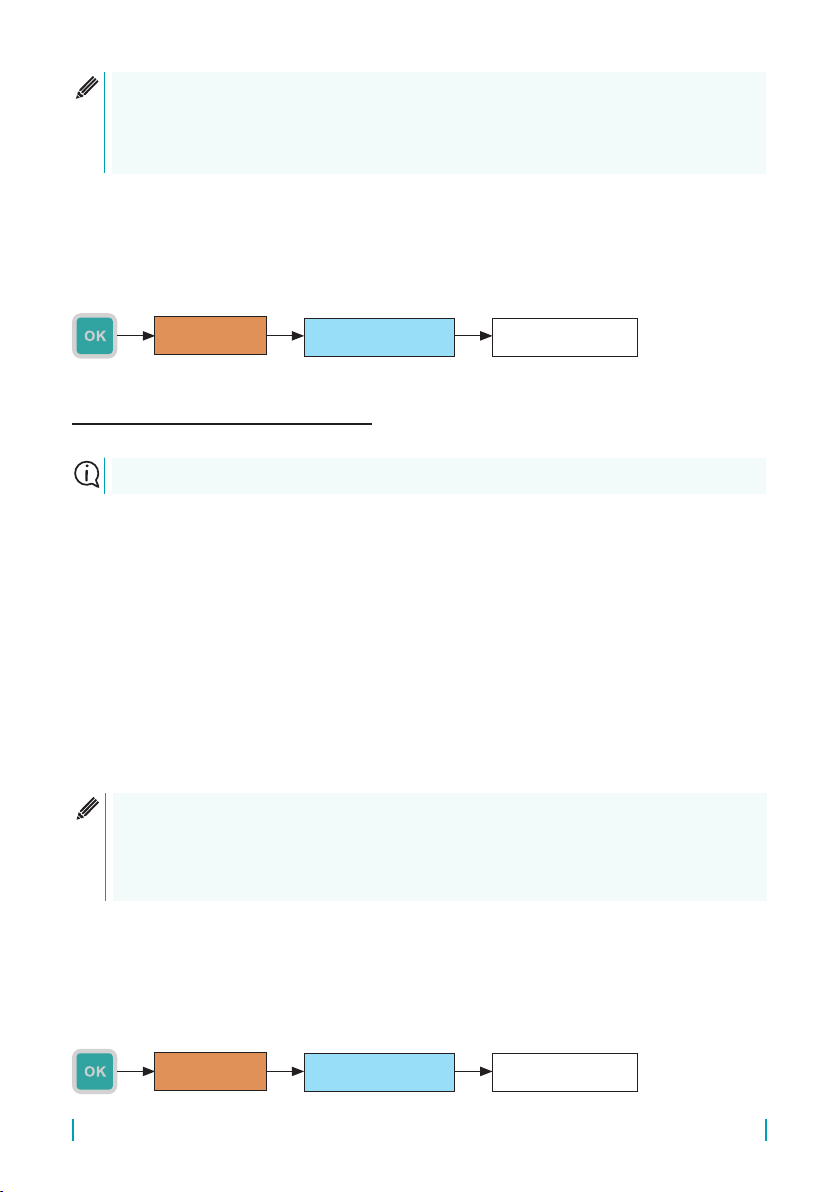

It is suitable to use the ltration function for suppression of the uctuations in view at fast or jump

changes of the input value. The subsequent speed of change of the input value will be depend-

ent on an exponential course. Filtration with dened delay in seconds indicates the time that the

exponential curve reaches 2/3 of its maximum value.

Control units with the HART® communication input (PCU-100-_-H-_-_) make it possible to work

with a current value in the loop measured analogously or a digital value of the measured quantity

read out using the HART® protocol. This communication is described in chapter (see chapter 9.6).

The following types of the input channel can be set for this unit:

• Menu:

• Default value: 20 sec

• Conguration range: 0-999 sec

• [↔] - Movement between the characters [↕] - Change of Value

• Analogue

The measured magnitude is read from the value of current in the current loop.

• HART®– primary variable

The measured magnitude is determined by the primary variable received

from the measuring device.

• HART®– secondary variable

The measured magnitude is determined by the secondary variable received

from the measuring device.

• HART®– tertiary variable

The measured magnitude is determined by the tertiary variable received

from the measuring device.

• HART®– quaternary variable

The measured magnitude the quaternary variable received

from the measuring device.

This setting is only available for units with the HART®input (PCU-100-_-H-_-_).

To turn off the ltration, it is necessary to congure the value to 0 seconds.

PCU–100 © Dinel, s.r.o.

14

If the control unit is required to read the input magnitude digitally using the HART® protocol, it

is necessary to check the conguration in which the PCU-100-H is connected to the other con-

nected devices. The following 2 states can occur:

1. The unit is connected only to measuring devices (ow meters, level meters, etc.)

and no other HART®communicator is connected to the network.

In this case, the unit should be set as the primary master.

2. The unit is connected to measuring devices (ow meters, level meters, etc.) and

another HART®communicator is connected to the network as well.

In this case, it is necessary to set the PCU to the opposite master type than the HART®

communicator. This means that if the connected HART® communicator is set as the prima-

ry master, the PCU must be set as the secondary master and vice versa.

Primary and secondary masters are terms dened in the HART®protocol standard. These are the

devices that initiate communication with measuring devices. They actively query by commands

and process the responses from measuring devices. The PCU-100-H unit is always in the master

(primary or secondary) position, while the measuring devices are always in the slave position.

• Menu: (

• Default: Primary

• [↔] - The type selection of the master

008

CONFIGURATION

010

INPUT SETTINGS

055

MASTER TYPE

Primary, secondary, tertiary and quaternary variables are terms dened in the HART®protocol

standard. Their values depend on the type of connected level meter. For ULM-54, ULM-70,

GRLM-70, and CLM-70 level meters from Dinel s.r.o., the individual variables are described in

chapter.

• Menu: (

• Default: Analogue

• [↔] - Selection of the measurement input source

008

CONFIGURATION

010

INPUT SETTINGS

054

INPUT TYPE

This setting is only available for units with the HART®input (PCU-100-_-H-_-_).

®

15

© Dinel, s.r.o. PCU–100

By factory default settings, the polling address of the sensor with the HART® protocol support

is set to 0. This setting is intended for the operation of the only sensor connected to the input of

the unit (or any other master device in general). All digital communication then proceeds with this

only sensor and the sensor also sets the loop current to its full extent depending on the measured

quantity.

If several sensors are required to be connected to the unit (or any other master device in general),

then these sensors must have polling addresses set in the range 1–15. In this setting, the sensor

communicates just at this address, the current in the loop is xed to 4 mA and the measured value

is read only digitally using the HART® protocol.

By setting the device’s polling address to the unit, you specify the sensor with which the device

should communicate. The sensor with the relevant polling address can then be parametrized

(procedure in chapter 9.6.) or the digitally measured value can be read from it, see chapter 9.1.3.

This setting is only available for units with the HART®input (PCU-100-_-H-_-_).

Each of the connected devices must have a unique polling address

• Menu: (

• Default: 0

• Conguration range: 0-15

• [↕] - Value change

008

CONFIGURATION

010

INPUT SETTINGS

056

DEVICE ADDRESS

PCU–100 © Dinel, s.r.o.

16

The conguration of the main screen graphical style showing the measured value according to the

user conguration. The conguration will aect the size of the digits, possible display of the bar

graph, date and time. Detailed view is intended more as a diagnostic and, therefore, it shows the

value of the input as well as user value with a xed number of decimals.

• Menu: Main screen type (ID 020)

• Default: Basic 32 px

• [↔] - Change the display type

Basic 32 px With bar graph 24 px

Detailed 8 px

The conguration of a preferred number of decimal places on the main screen. The display takes

place with a specied number of decimal places, if the amount of the value of the to display allows

it with regard to the number of positions on the display. If there is not enough positions available

for display, automatic reduction of the number of decimal places takes place.

The detailed display mode works with a xed number of decimals and this conguration is not

reected.

• Menu: DECIMAL PLACES ID (021)

• Default value: 2

• Conguration range: 0-5

• [↕] - Change of value

17

© Dinel, s.r.o. PCU–100

unit

The physical unit for display on the main screen, the unit is not stored into the memory, to the head

of the le with the exported data, there is given only the unit congured at the time of export. It can

be selected out of seventeen predened units + user-dened units.

Dimensionless [-] Decimetres dm Cubic metres m3

Milliamperes mA Metres mGallons gal

Volts VInches in Barrels bbl

Percentage %Feet ft Centigrades °C

Millimetres mm Litres lDegree Fahrenheit °F

Centimetres cm Hectolitres hl User-dened unit ????

Causes displaying of zeros in free positions in front of the displayed value on the main screen.

• Menu:

• Default value: prohibited

•

• Menu:

• Default: Percentage

• [↔] - Changing the unit

It is possible to enter any 4 characters. The here dened unit is then oered the selection of dis-

played physical units.

• Menu:

• [↔] - Movement between characters [↕] - Change of the character

PCU–100 © Dinel, s.r.o.

18

The control unit allows to select a language mutations of the menu. Czech or English are

available.

• Menu:

• Default: English

• [↔] - Change of value

Conguration of the LCD backlight level. It is possible to select from nine levels backlight and its

full turn-o (0 value).

• Menu:

• Default value: 3

• Conguration range: 0 - 9

• [↕] - Change of value

Conguration of LCD display contrast:. Control electronics of the display uses automatic contrast

correction according to the ambient temperature, therefore, in most cases there is no need of

adjusting this conguration. However, in extreme cases, it is possible for the user to increase

(positive values conguration) or decrease the contrast (negative value settings). The value can

be congured in the range from -9 to +9.

• Menu:

• Default value: 0

• Conguration range: -9 to 9

• [↕] - Change of value

19

© Dinel, s.r.o. PCU–100

The control unit can convert the input value according to a mathematical curve, to a mathematical

model of the tank with the specied dimensions or to a user-dened table. There are 3 types of

curves and 8 types of tanks.

All types of transfer characteristics work with the value of the input magnitude as a percentage ac-

cording to the settings of the input channel of the unit (see section 9.1. Setting of the input channel

at the unit). The resulting value given by the conversion rules according to user conguration is

displayed on the display and stored with the congured period in the internal memory.

Transfer characteristics Name in the menu Parameter menu

Linear curve LINEAR CURVE

CURVE PARAMETERS (ID 034)Quadratic curve QUADRATIC CURVE

Square root curve SQUARE ROOT CURVE

Vertical rectangular tank with a

hopper VERT. RECT. TANK

TANK DIMENSIONS (ID0 35)

Vertical cylindrical tank with a

tapered termination

VERT. CYL. TANK TA-

PERED

Vertical cylindrical tank with spheri-

cal terminations

VERT. CYL. TANK

SPHER.

Vertical cylindrical tank with el-

lipsoidal terminations VERT. CYL. TANK ELLIP.

Horizontal cylindrical tank with at

terminations HOR. CYL. TANK FLAT

Horizontal cylindrical tank with

ASME type terminations HOR. CYL. TANK ASME

Horizontal cylindrical tank with

ellipsoidal terminations 2:1 HOR. CYL. TANK E2:1

Horizontal cylindrical tank with half

spheric type terminations HOR. CYL. TANK K1/2

User dened table USER TABLE USER TABLE (ID 036)

If the extended measuring range is congured, conversion takes place also for the negative

percentage value entry and values greater than 100 %.

The rst step is to congure the desired conversion type and then the parameters of the selected

transfer characteristics that are involved in the following sections.

• Menu:

• Default: Linear curve

• [↔] - Change of value

PCU–100 © Dinel, s.r.o.

20

If linear, square or square root characteristics is selected as the conversion type, the resulting

value of the conversion is the given by two points. The zero value of input magnitude (In) cor-

responds to the value of the “User minimum” (U min) and the value of 100% input value (In) corre-

sponds to the value of the '”User maximum” (U max). The resulting user value “W” is throughout the

extended user range given by the mathematical dependence given below at the graphical display

depending on the input value.

The value of the parameter “User minimum” may be greater than the value of the parameter “User

maximum”. When you increase the input values then the displayed and logged value decreases.

User minimum (Umin)

• Menu:

User maximum (U max)

• Menu:

• [↔] - movement between characters [↕] - The increase of value of the marked digits

(at marked decimal comma, a shift by an order occurs)

=[%]

100 ×ýšá

=[%]

100 ×()+

=[%]

100 ×()+

=[%]

100 ×()+

=[%]()

()()×[()()]+()

=[%]

100 ×

Other manuals for PCU-100 Series

1

This manual suits for next models

2

Table of contents

Other Dinel Control Unit manuals

Popular Control Unit manuals by other brands

Graco

Graco 236864 instructions

Sierra Wireless

Sierra Wireless AirPrime SL8080 Hardware integration guide

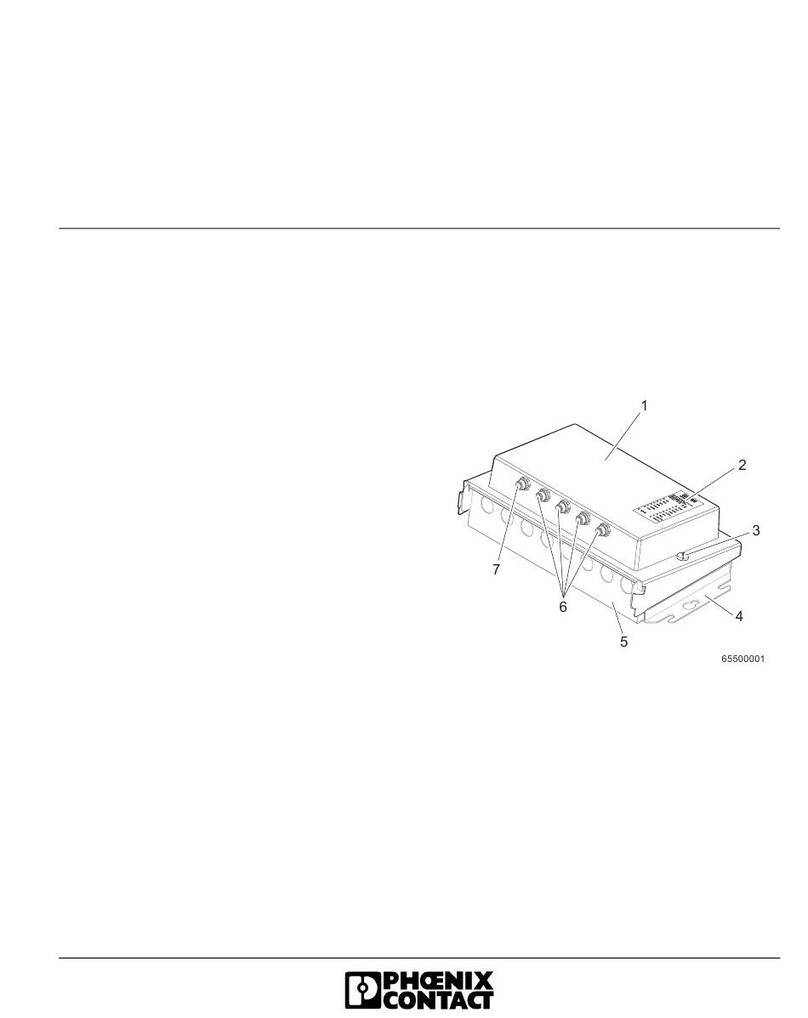

Phoenix Contact

Phoenix Contact IBS IP 400 ME-ELR R-3A FO manual

Lenz Elektronik

Lenz Elektronik Digital plus BM1 Information

GE

GE MiCOM P40 Agile Technical manual

O&O

O&O LOG-BC Installation and operation manual