Convection Heated Plate and Base Dispenser | 5

If either Temperature Sensor is “open” or not plugged in, the

Audio Alert will sound, the corresponding heater output will be

turned OFF, the Display will show “Opn”, and the LED indicator

for the heater will turn On. The Audio Alert can be cancelled by

pressing any of the buttons. If this alarm occurs during a timing

cycle, the timer will be cancelled; when probe is corrected the

timing cycle will restart.

If either Temperature Sensor is “shorted”, the Audio Alert will

sound, the corresponding heater output will be turned OFF, the

Display will show “Err”, and the LED indicator for the heater will

turn On. The Audio Alert can be cancelled by pressing any of

the buttons. If this occurs during a timing cycle, the timer will be

cancelled; when probe is corrected the timing cycle will restart.

If the internal memory has been damaged, the Display will show

“dft” on power up and the default Timer and Temperature values

will be used.

!

NOTE:

CLEANING

!CAUTION: Make sure unit is unplugged and cool before attempting

to clean.

The following procedures should be followed during the regular

cleaning routine on all of the plate & base heaters.

1. Turn the unit off, disconnect the plug from the outlet, and

allow the cabinet to cool. Remove plug by pulling it straight

out. Never pull on cord.

2. Pull the elevator mechanisms up and out, place them on a

work surface. You can wipe down the mechanisms with a

damp cloth to clean them.

3. Place the elevator mechanisms back inside the cabinet and

clean the outside of the cabinet with a mild, non-abrasive

soap or detergent in a warm water solution. A commercial

stainless steel cleaner can also be used for this procedure.

!NOTE: Do not use abrasives, harsh chemicals, or cholorine

products for cleaning.

!WARNING: Do not steam or pressure clean or hose down the

cabinet. This could damage the equipment and possibly cause an

electrical shock to the operator.

MAINTENANCE

ALARMS

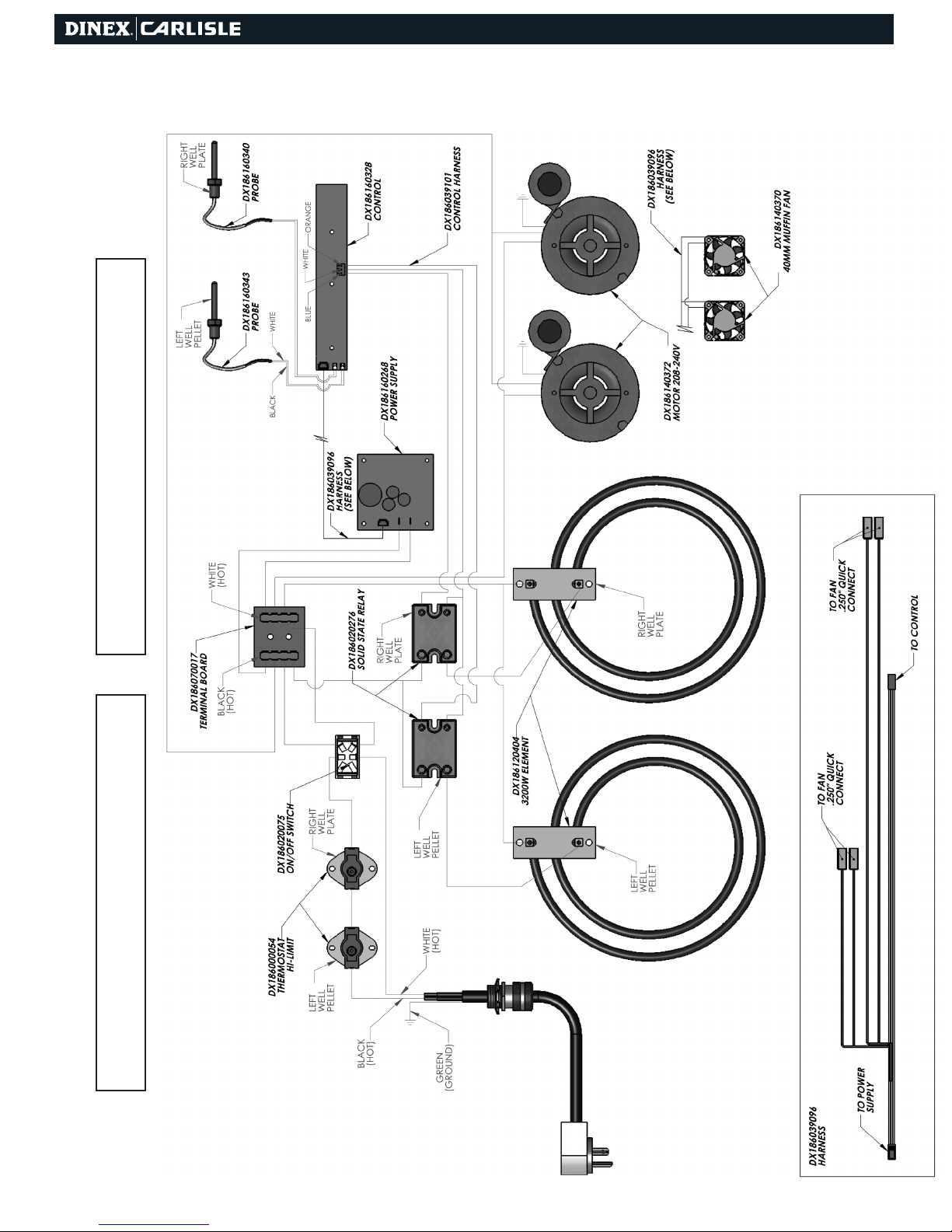

Cabinet does not roll easily. 1. Debris on wheel or axle.

2. No lubrication.

1. Clean out debris.

2. Lubricate axles with load

bear

ing grease. Lubricate

swivel bearings with

30-weight oil.

Dispenser binds. 1. Improper springs

2. Debris on guide rods.

1. Depending on contents, use

correct number of springs,

make sure identical number

& size of springs are on each

dispenser.

2. Clean off debris.

Unit heats, but fan does not

blow.

1. Defective motor.

2. Jammed or loose fan blade

3. Loose wiring.

1. Replace motor.

2. Replace or tighten blade.

3. Determine fault & correct.

Unit does not operate and

power indicator light does not

come on.

1. No power.

2. Open Hi Limit.

3. Defective power switch

4. Loose wiring

1. Make sure plug is connected

& switch is ON.

2. Check for power to receptacle.

3. Replace power switch.

4. Check and secure wiring.

Base/plate temperature is too

low, but fan is operating.

1. Thermostat set too low.

2. Fan blade is jammed or loose

3. Cover is open.

1. Readjust thermostat on

plate side. Replace

Thermostat on base side.

2. Replace or tighten blade.

3. Close cover.

Unit does not operate & light

does not come on.

1. No power.

2. Bad power switch.

3. Loose wiring.

1. Make sure plug is connected

& switch is ON. Check for

power to receptacle.

2. Replace power switch.

3. Check and secure wiring.

PROBLEM REMEDYPOSSIBLE

Base/ plate temperature is

too high, and fan is operating.

1. Thermostat is set too high.

2. Closed control.

3. Closed high limit switch.

1. Readjust thermostat on

china plate side. Replace

Thermostat on base side.

2. Replace control.

3. Replace high limit switch.

Casters

1. Check casters for freedom of movement and proper brake

operation.

2. Maintain casters free of debris. (mop strings, paper, plastic,

hair nets, etc.)

3. Clean or replace as required.

Cord and Plug

1. Inspect plug blades for distortion and replace if any blades

are missing, bent or broken.

2. Inspect cord wiring for integrity at termination points by

having qualified service person remove the back panel from

the cabinet. Make sure the cord sheathing extends into the

cabinet interior. If wires are showing on the outside of the

cabinet, remove the unit from use and have repairs made

before turning on power to the unit.

Dispensing Mechanism

Periodically check springs for proper dispensing by filling each

cavity with bases

/plates

and checking to see that it indexes as they

are removed. If bases

/plates

do not index properly, and unit is not

overloaded, adjust or replace springs.

Unit does not heat, but fan is

operating.

1. Loose wiring

2. Defective heating element.

1. Check & secure wiring.

2. Replace heating element.

TROUBLESHOOTING

!CAUTION: Thermostat adjustment should only be made by qualied

personnel. Thermostat adjustment not covered under warranty.

Lower Heater Base Cavity: 330°F

Upper Heater Base Cavity: 330°F

Lower Heater Plate Cavity: 210°F

Upper Heater Plate Cavity: 180°F

Default Temperature Setpoints: