Dini Argeo HLD Series User manual

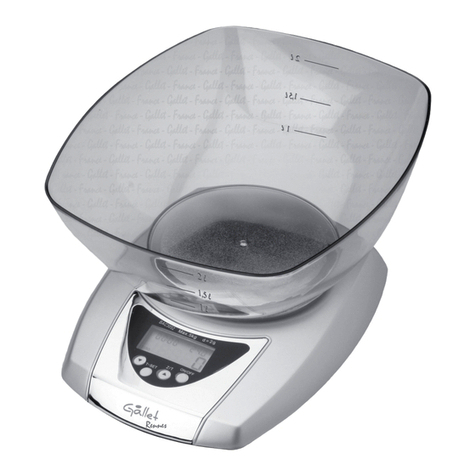

LABORATORY SCALE

LABORWAAGE

BALANCE POUR LABORATOIRES

BILANCIA DA LABORATORIO

HLD

OPERATING MANUAL

Industrial Weighing Systems

9 Richmond St, Picton, Ontario, Canada, K0K 2T0

www.iwsystems.ca e-mail info@iwsystems.ca

HLD_V1.003_11.06_EN_DE_FR_IT

3

ENGLISH

INDEX

1. INTRODUCTION ................................................................................................................................................................. 4

2. MAIN TECHNICAL SPECIFICATIONS ............................................................................................................................... 4

3. INSTALLATION ................................................................................................................................................................... 5

3.1 POWER SUPPLY AND START-UP ............................................................................................................................ 5

3.2 BATTERY POWERED ............................................................................................................................................... 5

4. FRONT PANEL KEYS AND INDICATORS ......................................................................................................................... 6

5. SYMBOLS ON THE LCD DISPLAY .................................................................................................................................... 7

6. OPERATION ....................................................................................................................................................................... 7

6.1 AUTOMATIC ZERO UPON START-UP ...................................................................................................................... 7

6.2 SCALE ZERO FUNCTION ......................................................................................................................................... 7

6.3 TARE FUNCTION ...................................................................................................................................................... 7

6.4 OVERLOAD MESSA E ............................................................................................................................................ 7

6.5 TOTALISATION OF THE WEI HT ............................................................................................................................ 8

6.5.1 MANUAL OR AUTOMATIC TOTALIZATION .................................................................................................... 8

6.6 COUNTIN PIECES .................................................................................................................................................. 8

6.7 SAMPLE WEI HT PERCENTILE .............................................................................................................................. 9

6.8 UNIT OF MEASURE CONVERSION ......................................................................................................................... 9

6.8.1 SECONDARY UNITS OF MEASURE ............................................................................................................. 9

7. SET-UP ENVIRONMENT .................................................................................................................................................... 9

7.1 SET-UP ENVIRONMENT BLOCK DIA RAM .......................................................................................................... 10

7.2 F1 Unt CONFI URATION OF SECONDARY UNITS OF MEASURE ...................................................................... 10

7.3 F2 bL DISPLAY BACKLI HTIN ............................................................................................................................ 10

7.4 F3 CoM TRANSMISSION MODE ............................................................................................................................ 11

7.5 “tEcH” - SCALE CONFI URATION ......................................................................................................................... 11

8. SERIAL OUTPUT .............................................................................................................................................................. 13

8.1 TRANSMISSION MODES ........................................................................................................................................ 13

. ERROR MESSAGES ........................................................................................................................................................ 14

RECYCLING INSTRUCTION ................................................................................................................................................ 14

DECLARATION OF CONFORMITY ...................................................................................................................................... 15

WARRANTY .......................................................................................................................................................................... 15

4

1. INTRODUCTION

This manual was created to help you install and learn all about the functional possibilities of the HLD scale.

WARNINGS

The scales should be sited in a location that will not degrade the accuracy.

Avoid extremes of temperature. Do not place in direct sunlight or near air conditioning vents.

Avoid unsuitable tables. The tables or floor must be rigid and not vibrate. Do not place near vibrating machinery.

Avoid unstable power sources. Do not use near large users of electricity such as welding equipment or large motors.

Avoid high humidity that might cause condensation. Avoid direct contact with water. Do not spray or immerse the scales in

water.

Avoid air movement such as from fans or opening doors. Do not place near open windows.

Keep the scales clean.

Do not stack material on the scales when they are not in use.

2. MAIN TECHNICAL SPECIFICATIONS

Model

Plate

dimensions

mm

Capacity

g

Standard

Division

g (*)

HR

Division

g (*)

Linearity

g +/-

Internal

sensitivity

g

Min.

APW

recommended

g

HLD150

Φ

80mm

150

0,02

0,002

0,004

0,0002

0,002

HLD300

Φ

120mm

300

0,05

0,005

0,01

0,0005

0,005

HLD600

Φ

120mm

600

0,1

0,01

0,02

0,001

0,01

HLD1500

140x150mm

1500

0,2

0,02

0,04

0,002

0,02

HLD3000

140x150mm

3000

0,5

0,05

0,1

0,005

0,05

HLD6000

140x150mm

6000

1

0,1

0,2

0,01

0,1

(*) Standard and HR division selectable in weighing phase, through the unit of measure conversion function, see section

6.8.

Stabilisation Time

2

Seconds typical.

Operative Temperature:

0°C

-

40°C / 32°F

-

104°F.

Power supply:

with fitted 240 Vac mains power adapter or with fitted battery

Battery life:

up to

3

0 hours of continuous use.

Recharge time:

12 hours.

Parameter Setup:

Calibration fully digital and programmable from the keyboard

.

Display :

LCD backlit with 6 ½ digits 1

6

m

m high

.

Case:

ABS Plastic.

Zero range:

+/

-

2% of max load capacity.

Auto ze

ro at start

-

up:

+/

-

1

0

%

of max load capacity.

5

3. INSTALLATION

a) Unpack then product.

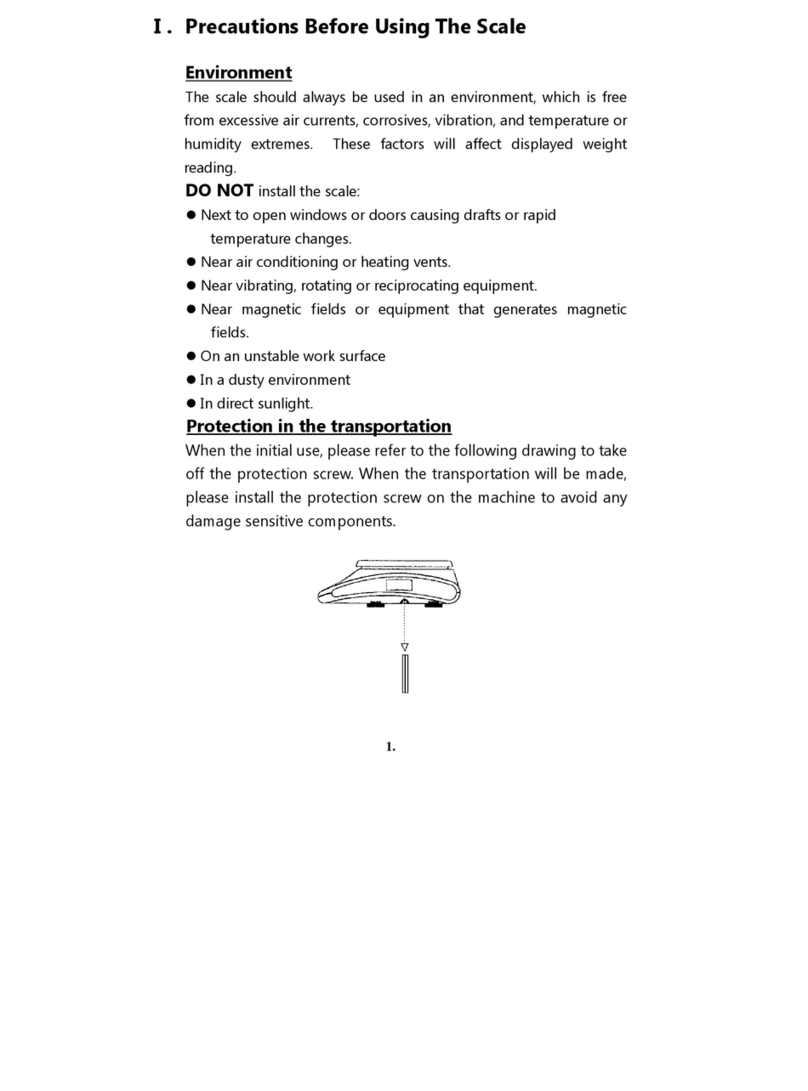

b) If present (depending on the model), it is necessary to unscrew and remove the locking screw for the transportation

placed under the scale, as shown in the figure below:

c) Level the platform by adjusting the adjustable feet until the bubble is in the centre of the level. The stability of the

platform is very important.

ALL THE CORNERS MUST REST IN A UNIFORM WAY. Carefully check that all feet fully rest on the ground and that the

platform, loaded on the corner, is not unstable (if a corner is not resting on the ground its relative foot is easier to turn).

3.1 POWER SUPPLY AND START-UP

The indicator can be powered with a fitted 240 Vac external power adapter or just with the fitted battery.

NOTE: it is advisable to completely recharge the battery (12 hours) with the first installation of the instrument.

TO POWER the instrument through the 240 Vac mains put the AC/DC power plug in the appropriate socket under the

scale and the power adapter in the 240 Vac mains socket.

TO TURN ON/TURN OFF the instrument press the ON/OFF key.

3.2 BATTERY POWERED

The weighing indicator can be operated from the battery if desired.

When the battery needs charging the

symbol on the weight display will be empty. The battery should be charged

when the symbol is on. The scale will still operate for about 10 minutes after which it will automatically switch off to protect

the battery.

To charge the battery simply plug into the mains power. The scale does not need to be turned on.

The battery should be charged for 12 hours for full capacity.

You can find the

symbol on the display to indicate the status of battery charging. When the scale is plugged into

6

the mains power the internal battery will be charged. If the symbol is full the battery has a full charge. If it is half the

battery is nearly discharged and empty indicates the battery should be charged.

As the battery is used it may fail to hold a full charge. If the battery life becomes unacceptable then contact your distributor

4. FRONT PANEL KEYS AND INDICATORS

FUNCTION OF THE KEYS

- It turns on/off the scale.

- Clears the displayed gross weight if it’s within +/- 2% of the total capacity.

- A secondary function of "Enter" key when setting parameters or other functions.

- If pressed for an instant it executes the semiautomatic tare.

- A secondary function of incrementing the active digit or selecting a value or

parameter when in setting mode.

- If pressed for an instant it allows linking a weight to the 100 percentile (see section

6.7).

- In the numeric input, it selects the digit to be modified, from left to right.

- If pressed for an instant it allows to execute the reference operation (see section

6.6)

- In the numeric input, it selects the digit to be modified, from right to left.

- It allows to convert in the configured secondary units of measure (see section 6.8).

- In the numeric input phase, it quickly clears the present value.

- If pressed for an instant it adds the value to the accumulation memory if the

accumulation function is not automatic.

- Secondary function (ESC) is to return to normal operation when the scale is in a

parameter setting mode.

7

5. SYMBOLS ON THE LCD DISPLAY

The LCD display has symbols which show the indicator’s functioning status; you will find the description for each symbol

below.

6. OPERATION

6.1 AUTOMATIC ZERO UPON START-UP

The indicator has an “auto zero at start-up” function: in other words it means that if at start-up a weight within +/- 10%

of the capacity is detected, it will be zeroed; if the weight is not within this tolerance, the display shows “Err 4” and the

present weight after a few instants.

6.2 SCALE ZERO FUNCTION

You can press the ZERO key at any time to set the zero point from which all other weighing and counting is measured,

within +/- 2% of power up zero. This will usually only be necessary when the platform is empty. When the zero point is

obtained the display will show the indicator for zero.

The scale has an automatic rezeroing function to account for minor drifting or accumulation of material on the platform

(see step “P4 AZn”, section 7.5). However you may need to press the ZERO key to rezero the scale if small amounts

of weight are shown when the platform is empty.

6.3 TARE FUNCTION

Zero the scale by pressing the ZERO key if necessary. The zero symbol will be on.

Place a container on the platform, a value for its weight will be displayed.

Press the TARE key to tare the scale when the “stable” is light. The weight that was displayed is stored as the tare

value and that value is subtracted from the display, leaving zero on the display. The "T" indicator will be on. As

product is added only the weight of the product will be shown. The scale could be tared a second time if another type

of product was to be added to the first one. Again only the weight that is added after taring will be displayed.

When the container is removed a negative value will be shown.

To remove the tare, unload the scale and press again TARE.

6.4 OVERLOAD MESSAGE

Please do not add item that is over the maximum capacity. When reading “- - - - - -“ and hear beeping sound, remove

the item on the platter to avoid damage to the load cell.

SYMBOL

FUNCTION

Indicates the status of battery charging (see section 3.2)

Indicates that the weight is stable.

NET

Indicates that the displayed weight is a net weight.

0

Indicates that the weight detected on the weighing system is near zero.

T

Indicates that a tare is enabled.

g

Indicates the unit of measure in use (gram).

Pcs

Indicat

es that the number of sampled pieces is being displayed (see section

6.6).

%

Indicates that the weight is displayed in percentile of the sample weight (see section 6.7).

kg, g, ct, lb, oz,

d, oz t, dwt,

mom, tLh, tLc,

tL t, t, bt, n

Indicate the unit of measure in use (see section 6.8).

8

6.5 TOTALISATION OF THE WEIGHT

The scale can be set to accumulate manually the weight on the scale by pressing the PRINT/M+ key (see step “AU”,

chapter 7.1).

The weight displayed will be stored in memory when the PRINT/M+ key is pressed and the weight is stable.

The display will show "ACC 1" while the weight will be printed, then the total in memory for 2 seconds before returning

to normal.

Remove the weight, allowing the scale to return to zero and put a second weight on. Press the PRINT/M+ key, the

display will show " ACC 2" and then the new total.

Continue until all weights have been added.

To view and print the totals in memory press PRINT/M+ key when current scale in zero status (Zero indicator on)

To clear the accumulated total weight, press the PCS key when show total values.

Scale automatically exit form the visualization of the total values after few seconds.

NOTE:

- The totalisation functions with a minimum weight of 20d.

- The maximum number of totalisations is 999 while the maximum total value which may be accumulated is

999999.

Once reached these limits, one should clear the total; by pressing PRINT/M+ the message “AdErr” will appear on

the display.

- The total values will be cleared when it’s turned off.

6.5.1 MANUAL OR AUTOMATIC TOTALIZATION

The operation of accumulation, normally done manually with key PRINT/M+, can be done automatically when the

weight is stable. In regards to the choice of the totalisation execution mode, see step “AU”, section 7.1.

6.6 COUNTING PIECES

Through the reference function it’s possible to use the scale as a piece counter.

COUNTING PROCEDURE

The operations to be carried out are the following:

1) Place the empty container on the scale and press TARE to tare it.

2) Check that the zero is on the display and put the quantity of pieces chosen for the SAMPLE on the scale and

press PCS key

.

3) The display suggests a REFERENCE QUANTITY. The possible options are: 10, 20, 50, 100, and 200.

4) Press TARE the number of times needed to reach the desired sample size.

5) Press ZERO; the display will indicate "- - - - - -" and the indicator will calculate the Average Piece Weight (APW).

After a few instants the display will indicate the quantity selected put on the platform.

6) Add the rest of the items to count in the container and whose value will appear on the display.

7) Unload the scale, the APW will remain stored in memory for the next counting of similar pieces, without having to

repeat the REFERENCE operation.

8) By pressing the MODE

key one switches from the display of the number of pieces to the display of the average

piece weight and of the net weight.

) Per cancel or to carry out a new reference operation, press the PCS key and repeat the operations as

describe in point 1).

9

6.7 SAMPLE WEIGHT PERCENTILE

In this functioning mode, the display shows the weight expressed as a percentile, comparing it with a reference weight

for which the 100 percentile has been already linked.

MATCHING PROCEDURE

-Put the reference weight on the scale

.

-Press the % key when the “stable” indicator is on.

-The scale has executed the percentile matching and displays the percentile of the weight on the scale.

-Unload the scale: the following weighs will be expressed as a percentage in reference to the reference weight.

-To cancel or execute a new matching operation, press the % key and repeat the operations described above.

6.8 UNIT OF MEASURE CONVERSION

By pressing various times the MODE key the conversion into the secondary units of measure takes place; the relative

symbol will turn on in the display (see section 5).

NOTE: The function is not available if the counting function or the percentile function is enabled.

6.8.1 SECONDARY UNITS OF MEASURE

No

Unit mark

Unit name

Conversion

(g)

1

g

gram

2

g

gram

(

weight

x 10

,

high resolution

)

3

ct

net carat

=0.2g

4

lb

lb

=453.59237g

5

oz

ounce

=28.349523125g

6

d

dram

=1.7718451g

7

ozt

troy ounce

=31

.1034768g

8

dwt

penny weight

=1.55517384g

9

mom

momme

=3.749996g

10

tl.h

tael twn

=37.49995g

11

tl.c

tael chn

=37.799375g

12

Tl.t

troy tael

=37.4290018g

13

t

tola

=11.6638039g

14

Bt

Bangladeshi tola

1bt=11.6638039g

15

n

newton

NOTE: It is possible to enable or disable the unit of measure in the “F1 Unt” step, see section 7.2.

7. SET-UP ENVIRONMENT

The scale has various parameters that can be configured in the SET-UP environment.

To enter in the SET-UP environment press during the start-up the MODE key during the countdown.

- The display will show the first function, which is "F1 Unt":

- Pressing the MODE will cycle through the other functions.

- Pressing ZERO will allow you to set the function.

- Use MODE to select the value, or set a value using the % key and the PCS key to move the active digit and then using

the TARE key to increment a digit

- Press the ZERO key to confirm the modification and pass to the following step or use the PRINT/M+ key to leave a

parameter unchanged or to escape set-up environment.

10

7.1 SET-UP ENVIRONMENT BLOCK DIAGRAM

SETUP

ENVIRONMENT

F2 bL

F1 unt

XXXXXX

tEch Pin

P3 Cnt

P4 Azn

P6 CAP

150, 300,

600, 1500,

3000, 6000

0.5d, 1d,

2d, 4d

n

g Ut on, Ut oFF

Ut on, Ut oFF

... Ut on, Ut oFF

EL on, EL AU,

EL oFF,

baud b600, b1200,

b2400, b4800,

b9600

F3 CoM Printer port 232, USB

Transmission

mode

P Prt, P Cont,

P AUto,

WirELE

Printer type tP, LP-50

P1 Lin

P2 CAL

P5 GRA X.XXXXX

7.2 F1 Unt CONFIGURATION OF SECONDARY UNITS OF MEASURE

By pressing ZERO it’s possible to choose the units of measure for the conversion function (see section 6.8), enabling

(on) or disabling (oFF) the suggested secondary units of measure:

1) The display proposes the first secondary unit of measure to be enabled or disabled.

2) Press MODE to change the options and confirm with ZERO, or press PRINT/M+ to exit without confirming and

pass to the following unit.

3) The display proposes the 2nd secondary unit to be enabled or disabled.

4) Proceed as described in point 2 up until the last proposed unit of measure.

7.3 F2 bL DISPLAY BACKLIGHTING

EL oFF backlighting always off

EL on backlighting always on.

EL AU backlighting on only when the weight is greater than 20d or when a key is pressed. When a key is pressed,

if the weight is less than 20d, the backlighting remains active for 5 seconds.

11

7.4 F3 CoM TRANSMISSION MODE

PRINTER PORT

One will be asked to select the port to be used, press MODE to select one of the suggested values:

S 232 RS232 port

S USB Not used in this application.

Select S 232 and press ZERO to confirm.

TRANSMISSION MODE

One will be asked to select the transmission mode, press MODE to select one of the suggested values:

P Prt Manual transmission through the PRINT/M+ key.

P Cont continuous transmission with P Cont. protocol

P Auto Automatic transmission upon weight stability (when in totalisation mode).

WirELE Not used in this application.

Press ZERO to confirm.

BAUD RATE

One will be asked to select the baud rate, press MODE to select one of the suggested values: 600, 1200, 2400 4800,

9600. Press ZERO to confirm.

PRINTER TYPE

One will be asked to select the printer type, press MODE to select one of the suggested values:

tP enables the printing with ASCII printer (for example TPR).

LP-50 Non used in this application.

Select tP and press ZERO to confirm.

7.5 “tEcH” - SCALE CONFIGURATION

By pressing ZERO it’s possible to access the scale configuration menu. One is asked to enter the password.

To enter the menu press the PCS, M+, and TARE keys, one after the other.

The display shows the first parameter, “P1 Lin”.

IN CASE THE ZONE OF USE IS DIFFERENT FROM THE CALIBRATION ZONE ONE SHOULD:

1) Set the gravity acceleration value for the ZONE OF CALIBRATION, see P5 step.

2) Carry out the calibration as following described (P1 or P2 step).

3) Set the gravity acceleration value for the ZONE OF USER, see P5 step.

P1 Lin CALIBRATION WITH DEFINED SAMPLE WEIGHTS

By pressing ZERO it’s possible to access the calibration with defined sample weights. One is asked to enter the

password.To enter the menu press the M+, PCS, and % keys, one after the other.

-The display shows “UNLOAD”;

-Empty the platter, after Stable indicator on the weight will be acquired automatically;

-The display shows “L XXX”;

-Put the first sample weight, defined in the table below, on the scale and the stability indicator is on the weight will

be acquired automatically;

-The display shows “L XXX”;

-Put the second sample weight, defined in the table below, on the scale and when the stability indicator is on the

weight will be acquired automatically;

-The display shows “L XXX”;

-Put the thirdsample weight, defined in the table below, on the scale and when the stability indicator is on the

weight will be acquired automatically;

-The indicator returns to weighing.

12

CALIBRATION WEIGHTS

MODEL

HLD150

HLD300

HLD600

HLD1500

HLD3000

HLD6000

1° SAMPLE WEIGHT

50g

100g

200g

500g

1000g

2000g

2° SAMPLE WEIGHT

100g

200g

400g

1000g

2000g

4000g

3° SAMPLE WEIGHT

150g

300g

600g

1500g

3000g

6000g

P2 CAL CALIBRATION WITH FREE SAMPLE WEIGHT

By pressing ZERO it’s possible to access the calibration with free sample weight.

-The display shows “UNLOAD”;

-Empty the platter, after Stable indicator on the weight will be acquired automatically;

-Set the value of the mass weight by using the MODE key to clear the value, the TARE key to increase the value

of the digit, the PCS key to go on the previous digit and the % key to go on the following digit.

-Confirm the entered value with ZERO; the display shows “LOAD”;

-Put the mass on platter, after stable indicator on the weight will be acquired automatically.

-The indicator returns to weighing.

P3 Cnt A/D CONVERTER POINTS

By pressing ZERO the instrument shows the A/D converter points relative to the weight on the scale.

Press PRINT/M+ to exit the step.

P4 AZ ZERO TRACKING

By pressing ZERO one sets the divisions' number for the zero tracking, in other words, scale’s thermal drift

compensation parameter; the set value corresponds to the number of divisions which is cleared.

Press MODE to select one of the suggested divisions: oFF, 0.5d, 1d, 2d, 4d.

P5 GrA GRAVITY COEFFICIENT

Trough this step one access the acceleration value setting of instrument calibration and use zone.

Manual entry of the g value: Set the value by using the MODE key to clear the value, the TARE key to increase the

value of the digit, the PCS key to go on the previous digit and the % key to go on the following digit; one must modify

all the 6 digits of the gravitational acceleration. Confirm the entered value with ZERO or press PRINT/M+ to exit

the step.

P6 CAP SCALE CAPACITY

By pressing ZERO one selects the total capacity of the scale.

Press MODE to select one of the suggested divisions: 150, 300, 600, 1500, 3000, 6000 g.

13

8. SERIAL OUTPUT

Specifications

RS-232 output for the transmission of the weight data

ASCII code

Baud 4800 (selectable from 600 - 9600)

Connector: 9 pin (female)

Pin 2: RECEPTION

Pin 3: TRANSMISSION

Pin 5: ND

8.1 TRANSMISSION MODES

The transmitted data format varies depending on the selected transmission mode (see section 7.4).

P Prt and P Auto

Totalisation Mode

In the normal weighing operations when one is accumulating the weight the data format is the following:

When the totals are recalled from the storage the data format is the following:

Counting Mode

In the counting operations when the PRINT/M+ key is pressed the data format is the following:

Percentage Mode

In the percentage operations when the PRINT/M+ key is pressed the data format is the following:

Progressive of totalisations

Total net weight

<CR><LF>

<CR><LF>

Percentage of weight

<CR><LF>

Progressive of totalisations

S for gross weight, NT for net weight

<CR><LF>

<CR><LF>

Number of pieces

Average piece weight

S for gross weight, NT for net weight

<CR><LF>

<CR><LF>

14

P CONT

In this transmission mode the instrument transmits continuously the following data format depending on the functioning

mode:

Totalisation Mode

Counting Mode

Percentage Mode

. ERROR MESSAGES

ERROR

MESSA ES

DESCRIPTION

RESOLUTION

-

-

-

-

-

-

Over range

Remove weight from the scale

.

Err 4

Zero Setting Error

Upon start

-

up or when the

ZERO

key is pressed, the weight on the

scale exceeds the percentage programmed on the max. capacity.

Remove the excess weight and retry.

Err 5

Keyboard Error.

The keyboard could be damaged

.

Err 6

Input signal greater

than 3mV/V

Indicates that the A/D converter value is greater than the maxim

um

value:

- Remove the weight from the scale if it’s exceeding.

- The load cell or the electronics could be damaged.

RECYCLING INSTRUCTION

The crossed-out wheeled bin on the product means that at the product end of life, it must be taken to

separate collection or to the reseller when a new equivalent type of equipment is purchased. The

adequate differentiated refuse collection in having the product recycled, helps to avoid possible

negative effects on the environment and health and supports the recycling of the materials of which

the equipment is made. The unlawful disposal of the product by the user will entail fines foreseen by

the current regulations.

ST, S,XXX.XXXXkg

<CR><LF>

<CR><LF>

S for gross weight, NT for net weight, XXX.XXXX is the weight

PCS:XXXXXXXXpcs

<CR><LF>

<CR><LF>

XXX.XXXX is the Number of pieces

PERC:XXXXX.XX

%

<CR><LF>

<CR><LF>

XXXXX.XX is the Percentage of weight

This manual suits for next models

6

Table of contents

Other Dini Argeo Scale manuals

Dini Argeo

Dini Argeo TPW Series Operating instructions

Dini Argeo

Dini Argeo T Series User manual

Dini Argeo

Dini Argeo MCW Guide

Dini Argeo

Dini Argeo TPW E-FORCE Instruction Manual

Dini Argeo

Dini Argeo ALP User manual

Dini Argeo

Dini Argeo APM User manual

Dini Argeo

Dini Argeo MCW PROFESSIONAL User manual

Dini Argeo

Dini Argeo DGT100 User manual

Dini Argeo

Dini Argeo MCWN Series Operating instructions