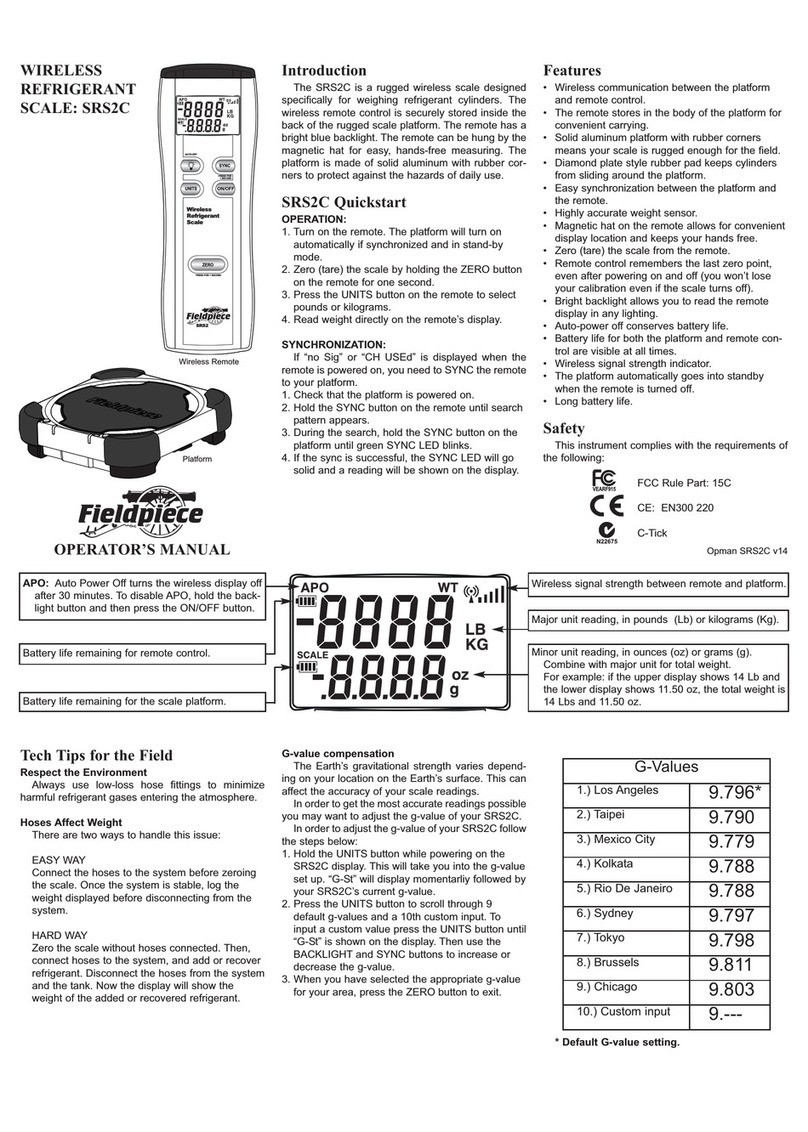

Dini Argeo MCWN Series Operating instructions

www.diniargeo.com

MCWN

Professional electronic suspended crane scale

ENGLISH

USER, INSTALLATION, MAINTENANCE INSTRUCTIONS

MCWN 3

Index

IDENTIFICATION 8

Identification of the Manufacturer 8

Machine identification 8

Identification plate 8

EC Declaration of Conformity 9

Reference directives 10

Documentation supplied 10

PRELIMINARY INFORMATION 11

Recipients 11

Supply and storage 11

Updates 11

Language 12

Operators 12

Symbols used in the manual 12

Personal protective equipment 13

Warranty 14

SAFETY DEVICES 15

Noise 15

Vibrations 15

Residual risks 15

Safety pictograms applied to the machine 16

DESCRIPTION 17

Intended use (correct) 17

Reasonably foreseeable misuse 17

Obligations and prohibitions 18

Operator obligations 18

Operator prohibitions 18

Technical data 19

Permitted environmental conditions 20

USER_MAN_ENG_MCWN

Contents

MCWN 4

Main components 21

Battery 22

Optional components 23

PACKAGING AND HANDLING 24

Packaging and handling warnings 24

Packaging 25

Packaging handling (case) 25

ASSEMBLY 26

Assembly warnings 26

Assembly procedure 27

COMMANDS 28

Display 28

Keyboard 29

Remote control 30

USE 31

General warnings for correct use 31

Suspended crane scale conditions 32

Checks before use 33

Load lifting and weight reading 33

BASIC SCALE FUNCTIONS 34

Start-up - On 34

Shutdown - O 34

Zero 34

Display brightness adjustment 35

Automatic tare 35

Tare deletion 36

Set a known tare value (PT) 36

Metrics 38

USER_MAN_ENG_MCWN

Contents

MCWN 5

ADVANCED SCALE FUNCTIONS 39

How to access the function menu 39

Exchange between net weight and gross weight 40

Unit of measurement conversion 41

Weight remains displayed on the screen 43

Weight peak 44

METROLOGICAL SCALE INFORMATION 45

MAINTENANCE 46

TROUBLESHOOTING CASES 47

Error messages 48

USER_MAN_ENG_MCWN

Contents

MCWN 6

USER_MAN_ENG_MCWN

Contents

MCWN 7

i

Introduction

USER_MAN_ENG_MCWN

Dear Customer, Thank you for choosing a DINI ARGEO product.

The suspended crane scale you have purchased is ideal for weighing in industrial environments.

It is equipped with high performance weighing electronics, precise and durable, and features a multifunctional

program that can help you perform your daily tasks. Before using the instrument, please read this instruction manual

carefully in order to be able to use it in complete safety and to learn about all of the functions it oers.

Safety information - Warnings

• Read this manual carefully before carrying out any handling operations or lifting any loads.

• NEVER load the suspended crane scale beyond the maximum capacity stated on the plate of the weight

readout instrument.

IT IS forbidden to use the scale in environments where there is the danger of fire or explosion

• Apply the load to the hook only when the load is resting on the ground.

• Before using the suspended crane scale, ensure it is in perfect working order.

• To achieve a correct weighing result, the load must be raised by at least 5-10 cm from the ground (Para-

graph “Load lifting and weight reading” ref.).

• Do not expose the suspended crane scale to atmospheric agents (sun, rain, etc.).

• Use the suspended crane scale in non-condensing environments with moderate temperature and humid-

ity levels.

• Use the suspended crane scale where there are no vibrations.

• Carefully read and apply the aforementioned description of the weight indicator.

• To clean the suspended crane scale, avoid the use of solvents or aggressive substances.

• It is forbidden to make any modifications to the structural work if not authorised by the manufacturer.

• It is forbidden to use the suspended crane scale when it no longer fulfils the safety criteria.

• It is forbidden to use flammable products to clean the instrument.

• It is forbidden to wash the suspended crane scale with direct water jets.

• Do not pour liquids on the indicator.

• Anything not specifically described in this manual is considered improper use of the equipment.

• The crossed out wheelie bin symbol on the product shows that it must be brought to appropriate

separate waste collection centres at the end of its life cycle or returned to the dealer when pur-

chasing a new equivalent product.

• Proper separate collection to send the product on to recycling helps prevent possible negative

effects on the environment and to health, and promotes the recycling of the materials. Users who

dispose of the product illegally shall face administrative sanctions as provided for by law.

The safety precautions described in this manual, marked with the symbol, must be followed during all installation,

use, maintenance or repair stages of the weighing system.

Any use other than that reported in this manual, as well as not following the safety precautions, relieves the

manufacturer from any responsibility and will void the product warranty.

MCWN 8

Mod.

Sn

DFWL

9876543210

Dini Argeo - v. Fisica, 20 - 41042 Fiorano (MO) Italy

GB-1461

6 V DC

Max

Min

e =

B1W1 B1W2 B1W3

300 kg 600 kg 1500 kg

2 kg 4 kg 10 kg

0.1 kg 0.2 kg 0.5 kg

Art. MCWNT1-3 UK 2931

Identification

USER_MAN_ENG_MCWN

IDENTIFICATION

Identification of the Manufacturer

Manufacturer DINI ARGEO s.r.l.

Address Via della Fisica, 20

41042 Spezzano di Fiorano Mod.se (MO) - Italy

Tel. +39 0536 843418 Fax +39 0536 843521

Machine identification

Machine DIGITAL SUSPENDED CRANE SCALE

Model MCWNXX

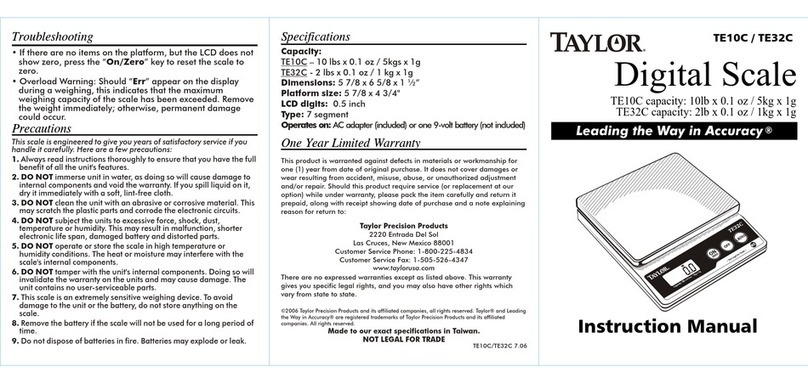

Identification plate

The machine is equipped with an identification plate positioned on its right side.

The identification details of the machine, to be cited to the Support Centre if required, are provided on the plate.

WARNING!

It is strictly forbidden to remove the CE identification plate and/or replace it with other plates.

If, for accidental reasons, the plate is damaged or removed, the customer must inform the Manufacturer.

MCWN 9

EU DECLARATION OF CONFORMITY

EU-KONFORMITÄTSERKLÄRUNG, DÉCLARATION UE DE CONFORMITÉ, DECLARACIÓN DE CONFORMIDAD, DICHIARAZIONE DI

CONFORMITA’ UE, DECLARAÇÃO UE DE CONFORMIDADE, DECLARAȚIA UE DE CONFORMITATE, ES - IZJAVA O SKLADNOSTI, ES

ATITIKTIES DEKLARACIJA , ES VYHLÁSENIE O ZHODE

English

We declare under our sole responsibility that the products to which this declaration refers to, conform with the following

standard(s) or other regulations document(s).

Deutsch

Wir erklären unter unserer alleinigen Verantwortung, dass die Produkte auf die sich diese Erklärung bezieht, den

folgenden Normen und Regulierungsbestimmungen entsprechen.

Français

Nous déclarons sous notre responsabilité que les produits auxquels se rapporte la présente déclaration, sont conformes à

la/aux norme/s suivante/s ou au/aux document/s normatif/s suivant/s.

Español

Nosotros declaramos bajo nuestra responsabilidad que los productos a los que se refiere la presente declaración, están

en conformidad con la/s siguiente/s norma/s o documento/s normativo/s.

Italiano

Noi dichiariamo sotto nostra unica responsabilità che i prodotti ai quali si riferisce la presente dichiarazione, sono

conformi alla/e seguente/i norma/e o documento/i normativo/i.

Portugues

Declaramos sob nossa exclusiva responsabilidade que os produtos que se referem a esta declaração, são conformes ao

seguinte padrão eo documento de regulamentação

Romana

Declaram pe propria raspundere ca produsele la care se refera aceasta declaratie sunt conforme cu urmatoarele

standarde sau alte documente normative.

Slovene

S polno odgovornostjo izjavljamo, da so izdelki, na katere se nanaša ta izjava o skladnosti, skladni s sledečim/imi

standardom/i ali normativom/i dokumentom/i.

Lietuvių

esame visiškai atsakingi už tai, kad produktai, kurie nurodyti šioje deklaracijoje, atitinka šiuos standartus ar kitus

reglamentavimo dokumentus.

Slovak

Na svoju vlastnú zodpovednosť vyhlasujeme, že výrobky na ktoré sa toto vyhlásenie vzťahuje sú v súlade s

nasledujúcim/i štandardom/mi alebo inými smernicami.

Fabbricante/Manufacturer/Fabricant/Hersteller/Proizvajalec:/Gamintojas:

DINI ARGEO S.r.l. Via della Fisica,20 Fiorano Modenese (MO) Italy

Tipo/Type/Typ/Vrsta/Tipas/Typ:

DFWL

Numero di serie/Serial number/Numéro di série/Seriennummer/Serijska Stevilka/

Serijinis numeris/Sériové číslo:

0100746560

N° CE del Tipo/ EC type Examination certificate/ CE de type/ EU-Baumusterprüfbescheinigung/

EC Certifikat o tipskem pregledu/EB tipo patvirtinimo sertifikatas/ES certifikát typu:

NMO-0126 /

UK 2931

Certificato di prova / Parts (Test) Certificate / Certificat (d’essai) de partie / Teilegutachten (Prüfschein)/

Testni certifikat/Bandymų sertifikatas/Test certifikát:

GB-1461

EU Directive

Standards

2014/30/EU EMC

EN 61000-6-2:2005, EN 61000-6-4: 2007+A1:2011, EN 61326-1 : 2013, EN55011:2009+A1:2010

2014/35/EU LVD

EN 61010-1 : 2010

2006/42/EU

UNI EN 13155 / 2009 ; UNI EN 13889

La persona autorizzata a costituire il fascicolo tecnico presso la sede del fabbricante è la Direzione Tecnica./The person authorised to compose the

technical file at the premises of the manufacturer is the Technical Management. / Die autorisierte Person, die die technischen Dokumente im

Firmensitz des Herstellers verwaltet, ist das technische Management. / La personne autorisée à constituer le dossier technique chez la siége du

fabricant est le directeur technique. / La persona autorizada a constituir el expediente técnico en la sede del fabricante es la Dirección

Técnica./Oseba, pooblaščena za sestavljanje tehnične dokumentacije v prostorih proizvajalca, je tehnični direktor./Asmuo, įgaliotas sudaryti

techninę bylą gamintojo patalpose, yra technikos tvarkytojas./ Autorizovaná osoba, ktorá má oprávnenie spravovať technickú dokumentáciu

výrobcu je technický manažment.

Fiorano Modenese (MO) Italy,

23/01/2019

Signature

Marco Bertoni

President

1

Identification

USER_MAN_ENG_MCWN

EC Declaration of Conformity

The EC Declaration of Conformity is available on: www.diniargeo.com

FAC-SIMILE

MCWN 10

Identification

USER_MAN_ENG_MCWN

Reference directives

The machine supplied by DINI ARGEO s.r.l. does not fall within one of the categories of machines listed in Annex

IV of the Directive; therefore, for the purposes of certifying conformity of the machinery with the provisions of this

Directive, DINI ARGEO s.r.l. shall apply the conformity assessment procedure with internal check on the manufacture

of the machinery, as set out in Annex VIII.

To certify the conformity of the machine with the provisions of the Directive, before placing it on the market DINI ARGEO

has carried out the risk assessment in order to verify compliance with the essential health and safety requirements of

the Directive as well as the tests and checks required by the applied reference standards.

The technical construction file has been prepared in compliance with the provisions of Annex VII of Directive

2006/42/EC and is available for inspection by supervisory authorities upon a reasoned request, as required by the

laws in force on the matter.

DINI ARGEO s.r.l. then places the machine on the market, along with:

• CE Marking

• EC Declaration of Conformity

• Instruction manual for use, installation and maintenance (Documentation drawn up according to section 1.7.4 of

Machinery Directive 2006/42/EC)

please note that the machine has been designed according to the following Directives:

• 2006/42/EC Machinery Directive

• 2014/30/EU Electromagnetic Compatibility Directive

And that the following harmonised standards have been applied:

• EN 61000-6-2 : 2005

• EN 61000-6-4 : 2007 + A1 : 2011

• EN 61326-1 : 2013

• EN 55011 : 2009 + A1 : 2010

• EN 61010-1 : 2010

• UNI EN 13155 / 2009

• UNI EN 13889

Documentation supplied

• EU Declaration of Conformity available on the diniargeo.com site in the documents area

• Testing certificate available on the diniargeo.com site in the documents area

• User manual available on the diniargeo.com site in the product DOWNLOAD area

• Safety and maintenance manual supplied with the suspended crane scale

MCWN 11

Preliminary information

USER_MAN_ENG_MCWN

PRELIMINARY INFORMATION

Recipients

The manual is intended for operators appointed to using and managing the machine throughout all its technical

lifespan stages. It contains the topics referring to the correct use of the machine, in order to maintain its functional

and qualitative characteristics unchanged over time. All information and warnings for correct use in complete safety

are also provided.

The manual, similarly to the EC compliance certificate, is an integral part of the machine and must always accompany

it if moved or resold. It is the responsibility of the user to keep this documentation intact so that it can be consulted

throughout the lifespan of the machine itself.

Supply and storage

The manual is available in electronic format on: www.diniargeo.com

Store this manual supplied with the machine, in order for it to be easily consulted by the operator.

The manual is an integral part for safety purposes, therefore:

• it must be kept intact (in all its parts). Should it be lost or damaged, it is necessary to request a copy immediately.

• it must follow the machine until demolition (even in case of relocation, sale, lease, rental, etc....);

DINI ARGEO declines any liability for improper use of the machine and/or damage caused as a result of operations

not covered by the technical documentation.

Updates

Should the machine require functional modifications or replacements, the revision or update of the manual is the

responsibility of the Manufacturer. The Manufacturer is responsible for delivering the update of the manual.

The user is also responsible for ensuring that, if the present document is modified by the Manufacturer, only the

updated versions of the manual are actually kept at the points of use.

MCWN 12

Preliminary information

USER_MAN_ENG_MCWN

Language

The original manual has been drawn up in Italian.

Any translations into additional languages must be carried out starting from the original instructions.

The Manufacturer considers himself responsible for the information contained in the original instructions; translations

in dierent languages cannot be fully verified, therefore if an incongruity is detected, it is necessary to follow the

original text or contact the Support Centre.

Operators

In order to establish with certainty the skills and qualifications of the operators involved in the various tasks

(commissioning, cleaning, scheduled maintenance), refer to the following table:

Qualification Description

OPERATOR Personnel of the user, trained and qualified to use and run the machine for production purposes for

the activities it was built and supplied for.

They must be able to perform all the operations required for proper functioning of the machine

and for the safety of themselves or of any collaborators. They must have proven experience in the

correct use of these types of machines and be trained, informed and instructed in this regard. In

case of doubt, they must report any anomaly to their superior.

Note: they are not authorised to carry out any maintenance operation.

MECHANICAL

MAINTENANCE

TECHNICIAN

Qualified technician able to perform preventive/corrective maintenance on all mechanical parts of

the machine subject to maintenance or repair.

Qualified technician able to access all machine parts for visual analysis, checking the equipment

status, adjustments and calibrations.

Note: they are not authorised to operate on live electrical systems (if any).

MANUFACTURER’S

TECHNICIAN

Technician qualified by the Manufacturer and/or their distributor for complex operations, as they

are knowledgeable of the machine’s production cycle.

This person operates according to the user's requests.

Symbols used in the manual

Symbol Description

Symbol used to identify important warnings for the safety of the operator and/or machine.

Symbol used to identify information of particular importance in the manual. The information also

concerns the safety of personnel involved in using the machine.

MCWN 13

Preliminary information

USER_MAN_ENG_MCWN

Personal protective equipment

When working near the machine, both for assembly operations and for maintenance and/or adjustment, it is strictly

required to comply with the general accident-prevention regulations, therefore it will be important to use the personal

protective equipment (PPE) required for each individual operation.

The complete list of personal protective equipment (PPE) that may be required for the dierent procedures is

provided below:

Symbol Description

Obligation to use safety or insulating gloves.

Indicates a requirement for personnel to use safety or insulating gloves.

Obligation to use safety goggles.

Indicates a requirement for personnel to use safety goggles.

Obligation to use safety footwear.

Indicates a requirement for personnel to use safety footwear.

Obligation to use noise protection devices.

Indicates a requirement for personnel to use earplugs or earmus for hearing protection.

Obligation to use safety clothing.

Indicates a requirement for personnel to wear the specific safety clothing.

The clothing of those operating or maintaining the line must comply with the essential safety requirements defined

by EU Reg.2016/425 and with the laws in force in the country where the line is installed.

MCWN 14

Preliminary information

USER_MAN_ENG_MCWN

Warranty

IMPORTANT!

The complete warranty terms are set out in the sales contract.

The conditions foreseen in the commercial contract (if different) have priority over what is provided in

this section.

The warranty is subject to the following general conditions:

• the machine must be used within the limits stated in the contract and provided in the technical documentation.

• maintenance must be carried out within the time-frames and in the ways required by the manual, using DINI ARGEO

original spare parts and assigning the operations to qualified personnel.

The warranty is void in case of:

• failure to comply with the safety regulations;

• removal of or tampering with control and safety devices;

• improper use of the machine;

• use of the machine by untrained and/or unauthorised personnel or failure to comply with the skills of the various

operators, as indicated in the manual;

• modifications or repairs made by the user without the Manufacturer's written authorisation;

• partial or total failure to comply with the instructions;

• lack of maintenance;

• use of non-original spare parts;

• exceptional events such as flooding, fires (if not caused by the machines).

MCWN 15

Safety devices

USER_MAN_ENG_MCWN

SAFETY DEVICES

Noise

Noise measurements have been carried out in accordance with the provisions of standards UNI EN 11200 and UNI

EN ISO 3746.

During the operating cycles, under conditions of perfect operation and maintenance, the noise exposure of

personnel is less than 70 dB.

It is the user's responsibility to apply the resulting preventive and protective measures, in compliance with the

legislation of the country where the machine is installed and used.

Vibrations

The vibrations produced by the machine, according to its operating mode, are not dangerous to the health of the

operators.

WARNING!

Excessive vibration can only be caused by a mechanical fault that must be immediately reported and

eliminated, in order not to compromise the safety of the line and of the operators.

Residual risks

The machine has been designed to assure the essential safety requirements for the operator.

Safety has been integrated into the design and construction of the machine as much as possible; however, risks

remain that operators must be protected against.

For each residual risk, a description of the risk and of the zone or part of the machine subject to the residual risk is

provided (unless it is a risk valid for the entire machine). Procedural information on how to avoid the risk and on the

correct use of the personal protection devices provided and required by the Manufacturer is also given.

Risk Description and procedural information

Risk of crushing The risk of crushing lower limbs under the load during its descent remains.

Risk of load

falling The risk of the load falling and crushing during lifting operations remains.

MCWN 16

1

2

3

4

Safety devices

USER_MAN_ENG_MCWN

Safety pictograms applied to the machine

Stickers and safety plates are applied to the machine, as shown in the following table. Refer to the image for positioning.

Pos. Pictogram Description

1

Mod.

Sn

DFWL

9876543210

Dini Argeo - v. Fisica, 20 - 41042 Fiorano (MO) Italy

GB-1461

6 V DC

Max

Min

e =

B1W1 B1W2 B1W3

300 kg 600 kg 1500 kg

2 kg 4 kg 10 kg

0.1 kg 0.2 kg 0.5 kg

Art. MCWNT1-3 UK 2931

CE IDENTIFICATION PLATES

2

IT IS FORBIDDEN TO HALT OR TRANSIT UNDER SUSPENDED LOAD

DER AUFENTHALT UNTER HÄNGENDEN LASTEN IST VERBOTEN

IL EST INTERDIT DE S’ARRETER OUPASSER SOUS LA CHARGE SUSPENDUE

VIETATO SOSTARE O TRANSITARE SOTTO IL CARICO SOSPESO

PROHIBIDO DETENERSE O TRANSITAR POR DEBAJO DE UNACARGA SUSPENDIDA

WARNING DO NOT TRANSIT UNDER THE LOAD

3MANUFACTURER DATA STICKER

4CAPACITY STICKER

MCWN 17

Description

USER_MAN_ENG_MCWN

DESCRIPTION

Intended use (correct)

The machine in question is intended for industrial use for:

• weighing objects.

Max capacity permitted:

MODELS RESPECTIVE CAPACITY

MCWN Not approved: MCWNT1, MCWNT3, MCWNT6, MCWNT9 1500 kg, 3000 kg, 6000 kg, 9500 kg

Approved: MCWNT1M, MCWNT3M, MCWNT6M, MCWNT9M 1500 kg, 3000 kg, 6000 kg, 9000 kg

The machine has been designed to:

• meet the specific needs mentioned in the sales contract;

• be used according to the instructions and limits of use provided in this manual.

The machine has been designed and built to operate safely if:

• it is used within the limits stated on the contract and in this manual;

• the user manual procedures are followed;

• scheduled maintenance is carried out in the times and in the ways indicated;

• unscheduled maintenance is promptly carried out if required.

Reasonably foreseeable misuse

The reasonably foreseeable misuses, which are intended as strictly forbidden, are listed below:

• transporting people;

• transporting unstable loads or fluids;

• using the machine in poorly lit areas;

• using the machine to move the load;

• using the machine in order to obtain production values above the required limits;

• using the machine dierently than described in paragraph “Intended use (correct)”.

Any other use of the machine than intended must be previously authorised in writing by the Manufacturer. In the

absence of said written authorisation, the use is considered “improper”; therefore the Manufacturer declines any

responsibility in regards to damage caused to property or people and deems any type of warranty on the machine

as void.

IMPORTANT!

Improper use of the machine relieves the Manufacturer from any responsibility.

MCWN 18

Description

USER_MAN_ENG_MCWN

Obligations and prohibitions

Operator obligations

The operator must:

• Always perform maintenance operations with the machine switched o.

• Operators with long hair must tie it up in order to prevent it from getting caught.

• Use the protective devices made available by the employer in an appropriate manner.

• Immediately report any deficiencies of the safety devices to the employer, the manager or the person in charge.

Operator prohibitions

Specifically, operators must not:

• use the machine improperly, i.e. for uses other than those indicated in the paragraph “Intended use (correct)”;

• remove or modify safety or warning devices without authorisation;

• carry out operations or manoeuvres that are not within their competence or that may compromise their own

safety or that of other workers of their own initiative;

• wear bracelets, rings or chains that can dangle and be dragged by moving parts, creating a hazard for the

operator;

• replace or modify the speed of the components of the machine without being authorised by a manager;

• use the machine if it has not been installed according to the regulations in force;

• use the machine to move loads even if it is not running (otherwise there is the risk of falling and/or damaging the

machine);

• use the machine outside of the permitted environmental conditions (consult the paragraph “Permitted

environmental conditions”).

WARNING!

DINI ARGEO is not liable for damage to property or people if it is ascertained that the machine has been

used in a non-permitted environment.

MCWN 19

Description

USER_MAN_ENG_MCWN

Technical data

MCWN

Material PAINTED AND ABS STEEL

Case dimensions 175 x 480 x 390 mm

Weight without packaging with packaging

MCWNT1 8 kg 11 kg

MCWNT3 10 kg 14 kg

MCWNT6 11 kg 15 kg

MCWNT9 15 kg 18 kg

Max capacity respective capacity

Not approved MCWNT1, MCWNT3,

MCWNT6, MCWNT9

1500 kg, 3000 kg, 6000 kg,

9500 kg

Approved MCWNT1M, MCWNT3M,

MCWNT6M, MCWNT9M

1500 kg, 3000 kg, 6000 kg,

9000 kg

Power supply BATTERY, 4 “AA”

Keyboard 5 KEYS

Remote control • infrared with 17 buttons (standard)

• Radio with display with 5 buttons (optional)

Operating life 40 hrs (without radiofrequency module)

MCWN 20

Description

USER_MAN_ENG_MCWN

Permitted environmental conditions

The facility where the machine must be used is an indoor environment protected from weather such as rain, hail,

snow, fog, suspended dust, combustible dust and it must not be a classified environment, it must be protected from

aggressive agents such as corrosive vapours or excessive heat sources.

The machine has been designed and built to operate safely in the following environmental conditions:

Room temperature -10°C ~+ 40°C

Maximum relative humidity 85 % non-condensing

Room lighting min. 50 lux - non-glare light

WARNING!

Environmental conditions other than those specified may cause serious damage to the machine and void

the warranty.

IMPORTANT!

The work surface must be sufficiently illuminated.

In the event of dark areas in the workplace, it is the user's responsibility to provide suitable lighting

devices.

This manual suits for next models

8

Table of contents

Other Dini Argeo Scale manuals

Dini Argeo

Dini Argeo HLD Series User manual

Dini Argeo

Dini Argeo APM User manual

Dini Argeo

Dini Argeo MCW PROFESSIONAL User manual

Dini Argeo

Dini Argeo MCW Guide

Dini Argeo

Dini Argeo DGT100 User manual

Dini Argeo

Dini Argeo ALP User manual

Dini Argeo

Dini Argeo T Series User manual

Dini Argeo

Dini Argeo TPW Series Operating instructions

Dini Argeo

Dini Argeo TPW E-FORCE Instruction Manual