Dini Argeo T Series User manual

0

Modules for electronic weighing

ELECTRONIC PLATFORMS

T and TE SERIES

Installation and operating manual

T_TE_SERIE_14.07_EN

1

INDEX

IMPORTANT WARNINGS ............................................................................... page 2

1 - INTRODUCTION......................................................................................... page 3

1.1 –TECHNICAL SPECIFICATIONS ..............................................................page 3

2 - INSTALLATION .......................................................................................... page 4

2.1 –INSTALLING THE TCA COLUMN............................................................page 8

2.2 –INSTALLING THE TCB COLUMN............................................................page 9

3 –MAINTENANCE AND REPAIRS................................................................ page 10

4 –TRANSPORTING THE PLATFORM .......................................................... page 10

5 –SHIELDED CABLE .................................................................................... page 10

INDICATOR JUNCTION BOX CABLE...............................................................page 10

WARRANTY AND AUTHORIZED SERVICE CENTRE.................................... page 11

2

IMPORTANT WARNINGS

Put the platform in a place in which the following conditions are respected:

-Flat, level, stable support surface

- Stable and absent of vibrations,

-Absence of dust or aggressive vapours,

- Absence of air currents,

- Moderate temperature and humidity (not exposed to direct sunlight or near heat sources).

Make sure to level the platform by adjusting the feel and checking air bubble level (see INSTALLATION

instructions).

Do not weld, perforate or modify the structure without consulting the reseller. If it is damaged or tampered

with the warranty conditions will be annulled.

If the place of use is a humid or wet environment, the installation must be carried out in such a way so

that water stagnation and/or scraps under the structure are avoided.

The platform must be connected to a weigh indicator. Refer to weigh indicator owner’s manual for

connection instruction.

Do not step, crush or expose to sunlight the connecting screen cable.

DO NOT INSTALL IN HAZARDOUS ENVIRONMENTS.

(unless specifically made for this use)

Do not use solvents when cleaning.

3

1 –INTRODUCTION

All weighing modules are built with high quality materials and are calibrated in such a way, which

guarantees full reliability and weighing accuracy that lasts in time. The measuring elements are load cells,

produced in conformance to the OIML R60 standards.

The T and TE platforms have load cells connected to the indicator with a 6-pin shielded cable, 3 meters of

length.

Every weighing module is built and engineered to guarantee a uniform detection of the load on the load

cell weighing modules, even in adverse environment conditions.

The electronic weighing platform T and TE series, are suitable for creating weighing systems or small and

medium, capacity, piece counter. The weigh capacity goes from 0,6 kg to 600 kg.

The Tseries platform have a structure made of tubular steel, oven fire painted black, and satined AISI 304

stainless steel loading surface. The measuring element consists of an approved aluminium “single point”

load cell according to OIML R60 standards with protection against dust and moisture according to IP65

standards.

The TE series platform have a structure made with tubulars, mechanics, trinkets and satined steel loading

surface in AISI304 stainless steel. The measuring element consists of an approved “single point”

STAINLESS STEEL load cell according to OIML R60 standards with protection against dust and moisture

according to IP68 standards (for the TSNE and TTNE version the protection is IP67).

1.1 - TECHNICAL SPECIFICATIONS

Load cell off-center direct load

Power supply 15 Vcc

Nominal output (max. load) 2 mV/V ±10% (platform related)

Operating temperature range -10 / + 50 °C

ACCESSORIES

Indicator holder column (integral with platform).

Floor-mounted indicator column.

Various types of conveyor carriages.

Junction box IP67.

4

2 - INSTALLATION

Refer to Figure 1, Figure 2 and Figure 3.

NOTE: The weighing module must be connected to its appropriate weight indicator with the cable

coming from the load cell. The indicator, connected to the platforms, can not be calibrated if not

powered.

It is the customer’s responsibility to prepare and calibrate the indicator.

For any further detail, refer to the technical and operational manual, supplied with the indicator.

a) Unpack then product. Pick up and remove plate (1).

b) Remove the locking strips (2).

Keep and reuse the wooden strips, in the event the platform needs to be moved again

c) Take off the bands which keep fixed the underplate (see fig.2 and fig.3)

d) Level the platform by adjusting the adjustable feet (3) until the bubble (4) is in the centre of the level.

The stability of the platform is very important.

ALL THE CORNERS MUST REST IN A UNIFORM WAY. Carefully check that all feet fully rest on the

ground and that the platform, loaded on the corner, is not unstable (if a corner is not resting on the

ground its relative foot is easier to turn).

e) Never remove the red painted bolts and nuts.

f) Reposition plate (1).

g) Connect the shielded cable from the load cell (5) to the weigh indicator (refer to the indicator manual).

The cable must be free, so that the resistances are not energised, which could alter the measurement.

h) You need to ground the metallic structure of the platform using the appropriate plug, which has this

symbol , especially if you need to weigh materials that, while handled, can cause electrical

discharges (dust, plastic materials, etc.). If there are any doubts, consult the reseller.

i) Make sure to follow the warnings at page 2.

5

Fig.1

SHIELD CABLE

INDICATOR

2 WOODEN STRIP USED FOR

TRANSPORT TO BE REMOVED LIKE

SHOWN

GROUND

PLUG

6

Fig.2

Remove the band

Remove the band

7

Fig.3

Remove the band

Remove the band

8

2.1 –INSTALLING THE TCA COLUMN

n.

q.ty

description

1

1

DFWL, DFWLI, CPWET e TRI

Indicators

2

1

Stainless steel column

3

1

DFWL holder

4

1

Foot

5

2

M6x1 hexagonal nut

6

1

Platform series T or TE

7

4

M6x12 screws

8

2

6.4x18 washer

9

2

M4x6 screw

10

2

M6x12 screw

9

2.2 –INSTALLING THE TCB COLUMN

Components:

1. DFWLI indicator

2. n.2 M6 exagonal nuts

3. n.1 column TCBI350-1, TCBI500-1 or TCBI700-1

4. n.4 VTC M6X16 inox (screw)

5. Platform

Please note that the M6 hex nuts (part 2) are supplied with the DFWLI. Remove the DFWLI wall brackets

and use nuts for connection to the column.

10

3 - MAINTENANCE AND REPAIRS

To obtain the best performance

-One should keep the platform clean. If dirt and dust accumulate on the platform one should clean it

with a damp cloth or with the common cleaning products (do not use SOLVENTS and ACIDS)

-Avoid platform collisions because this could cause serious damages..

Breakdowns and overloads

If you think the platform is broken or damaged disconnect it in a permanent way. Do this if the platform:

-appears to be damaged.

-does not work.

-has been loaded more than its tolerable limits (which could happen during the transportation or at time

of storage).

4 –TRANSPORTING THE PLATFORM

To pack the platform follow the procedure below:

a) turn off the instrument.

b) disconnect the platform’s instrument.

c) Put into the locking strips as shown on drawing 3.

5 - SHIELDED CABLE

See test certificate of the platform, located on "Documents" section of the website www.diniargeo.com or

the plate located under the plate.

INDICATOR JUNCTION BOX (JBOX) CABLE

EXCITATION + Brown

SENSE + Green

EXCITATION - Grey

SENSE - White

SIGNAL + Pink

SIGNAL - Yellow

EARTH BRAIDING Orange

11

WARRANTY

The ONE-YEAR warranty period begins on the day the instrument is

delivered and covers spare parts and labour if the INSTRUMENTS are

returned with prepaid shipping to the DEALER and if the breakdowns

are not caused by the customer (so are not included in the warranty,

failures resulting from improper use) or during the transport.

If on site service is requested (or is necessary) the customer will be

responsible for all of the service technician’s costs: travel time and

expenses plus room and board (if any).

The customer pays for the shipping costs (both ways), if the instrument

is shipped to DEALER or manufacturer for repair.

The WARRANTY IS VOIDED if breakdowns happen because repairs

have been made by unauthorised personnel or due to connections to

equipment installed by others or incorrect connection to the power

supply.

This warranty DOES NOT PROVIDE for any compensation for damages

(indirect or direct) which may cause partial or complete failure of the

instruments or systems sold, even if still in the warranty period.

AUTHORIZED SERVICE CENTRE STAMP

This manual suits for next models

1

Table of contents

Other Dini Argeo Scale manuals

Dini Argeo

Dini Argeo MCW PROFESSIONAL User manual

Dini Argeo

Dini Argeo TPW E-FORCE Instruction Manual

Dini Argeo

Dini Argeo ALP User manual

Dini Argeo

Dini Argeo APM User manual

Dini Argeo

Dini Argeo HLD Series User manual

Dini Argeo

Dini Argeo MCW Guide

Dini Argeo

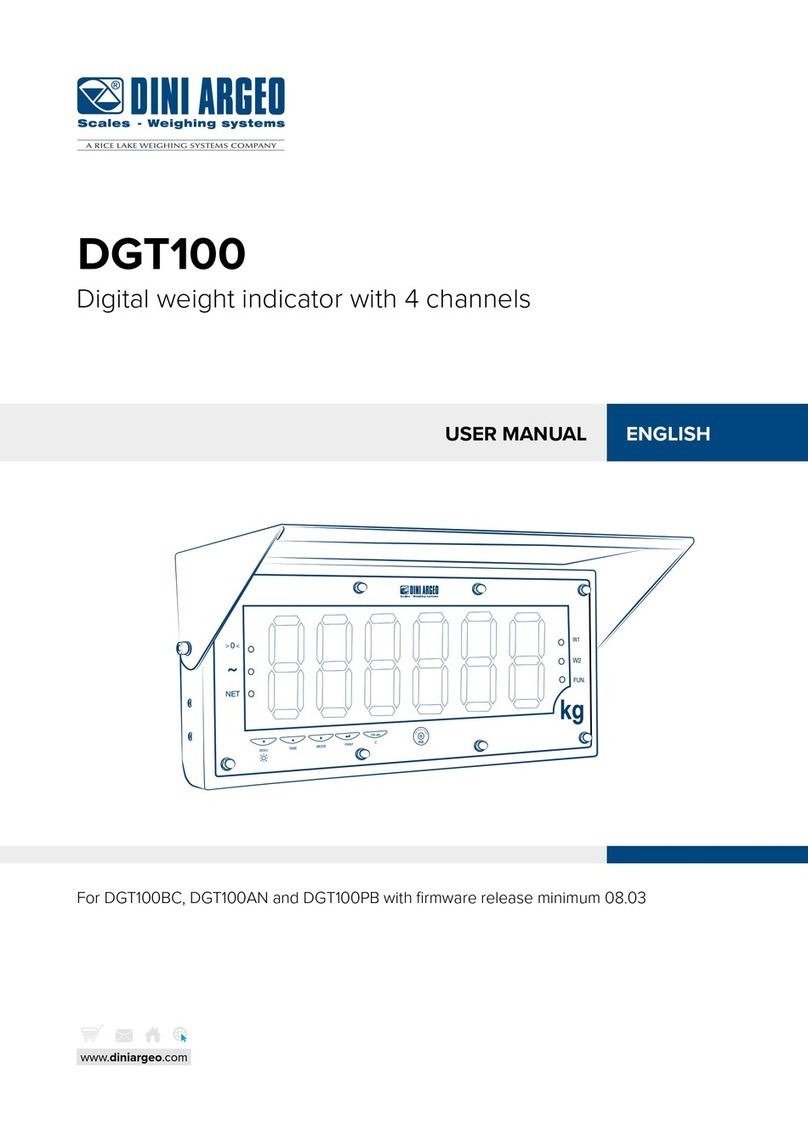

Dini Argeo DGT100 User manual

Dini Argeo

Dini Argeo TPW Series Operating instructions

Dini Argeo

Dini Argeo MCWN Series Operating instructions