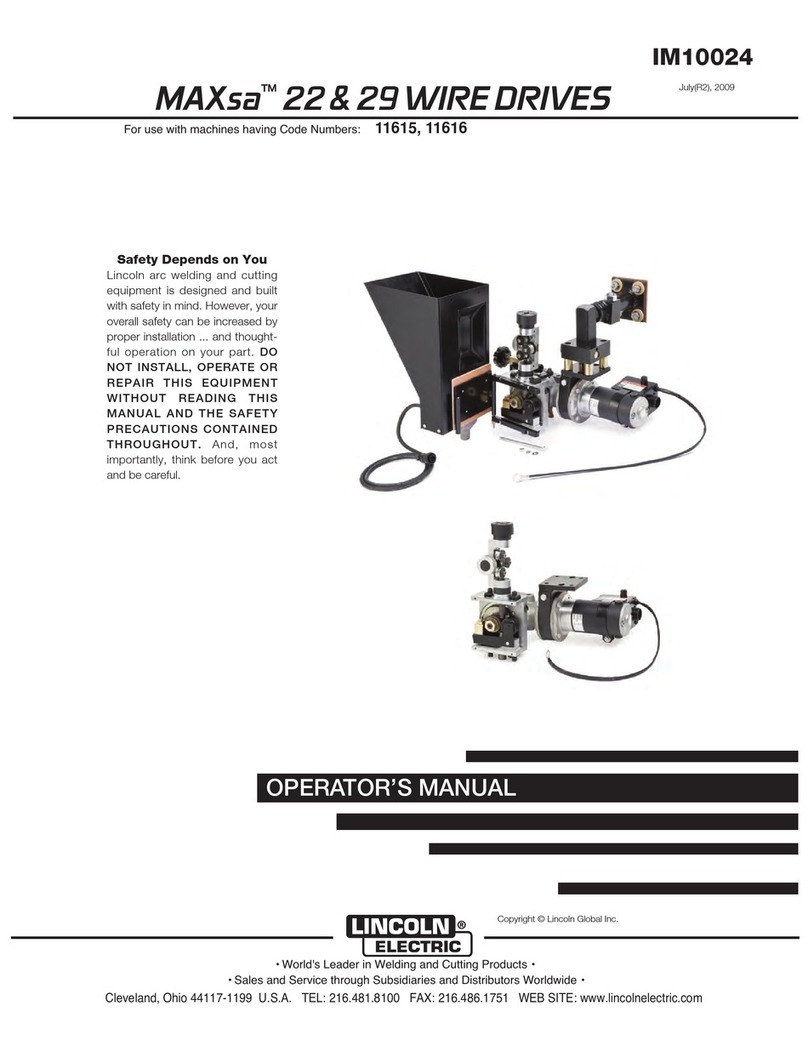

PIPELINER®200D K6090-11

RECOMMENDED GENERAL OPTIONS

Spark Arrestor Kit K903-1

Medium Welder Trailer with Duo- itch™: 2" Ball/Lunette Eye itch K2636-1

- Fender & Light Kit K2639-1

- Cable Rack K2640-1

Service Indicator Kit K1858-1

Stainless Steel Sheet Metal Kit K2423-1

RECOMMENDED STICK OPTIONS

Accessory Kit, 400 amp K704

Accessory Kit, 150 amp K875

Remote Control K924-5

RECOMMENDED WIRE FEEDER OPTIONS

Wire Feed Module K623-1

Remote Control Kit (Stick &Wire) K2464-1

LN-25 PRO Wire Feeder K2613-1

Magnum®350 Innershield®Welding Gun K126-2

Drive Roll and Guide Tube Kit, .068"-.072" (for LN-25 PRO) KP1697-068

Drive Roll and Guide Tube Kit, 5/64" (for LN-25 PRO) KP1697-5/64

TOTAL:

THE LINCOLN ELECTRIC COMPANY®

22801 St. Clair Ave., Cleveland, O 44117-1199 • 216.481.8100 • www.lincolnelectric.com

PIPELINER®200D ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

RECOMMENDED OPTIONS

Accessory Kit

For stick welding. Includes 20 ft. (6.1 m)

#6 electrode cable with lug, 15 ft. (4.6 m)

#6 work cable with lugs, headshield, filter

plate, work clamp, electrode holder and

sample pack of mild steel electrode. 150

amp capacity.

Order K875

Remote Control

Remote control rheostat permits machine

output changes up to 100 ft. (30.5m) from

the machine. Plugs into receptacle on

control panel.

Order K924-5

WIRE FEEDER OPTIONS

Wire Feed Module

Provides constant voltage (CV) output

with improved arc stability for Innershield®

welding. Recommended wire feeder is

LN-25.

Order K623-1

Remote Control Kit (Stick & Wire)

For Classic®& Pipeliner®machines that

have the wire feed module. Contains

a rheostat for stick output, a

potentiometer for wire output and

100 ft. (30.5m) of control cable.

Order K2464-1

LN-25 PRO Wire Feeder

Portable CC/CV unit for flux-cored and

MIG welding with MAXTRAC®wire drive

system. Includes Gas Solenoid & Internal

Contactor. Requires Wire Feed Module.

Order K2613-1

Magnum®350 Innershield®Gun

( or LN-25 PRO)

For self-shielded wire with 15 ft. (4.5m)

cable. For .062"-3/32"

(1.6-2.4 mm) wire.

Order K126-2

Drive Roll and Guide Tube Kit

( or LN-25 PRO,)

For cored or solid steel wire.

Order KP1697-068

for .068"-.072" (1.8 mm)

KP1697-5/64

for 5/64" (2.0 mm)

GENERAL OPTIONS

Spark Arrestor Kit

Attaches to muffler exhust tube. Virtually

eliminates spark emissions.

Order K903-1

Medium Welder Trailer

For heavy-duty road, off-road, plant and

yard use. Includes pivoting jack stand,

safety chains, and 13" wheels. Stiff .120"

welded rectangular steel tube frame

construction is phosphate etched and

powder coat painted for superior rust and

corrosion resistance. Low sway

suspension gives out-standing stability

with manageable tongue weight. Wheel

bearings are packed with high viscosity,

high pressure, low washout Lubriplate®

grease. Includes a Duo- itch™:a 2"

Ball/Lunette Eye combination hitch.

Overall width: 60".

Order:

K2636-1 Trailer

K2639-1 Fender & Light Kit

K2640-1 Cable Rack

Service Indicator Kit

Provides a GO/NO-GO visual indication

of air cleaner element useful service life.

Filter service based on restriction

readings allows the longest life possible

from the filter and best engine protection.

Order K1858-1

Stainless Steel Sheet Metal Kit

Stainless steel roof and doors. Also

includes decals (mounted), door latches,

door hooks, bumpers and all required

mounting hardware. Fits K6090-9 and -10

Pipeliner®200D and K1643-1 thru -10

Classic®300D

Order K2423-1

STICK OPTIONS

Accessory Kit

For stick welding. Includes 35 ft. (10.7 m)

2/0 electrode cable with lug, 30 ft. (9.1 m)

2/0 work cable with lugs, headshield, filter

plate, work clamp and electrode holder.

400 amp capacity.

Order K704