Operating Manual MSA 160

MSA 160 Ver. 1.00

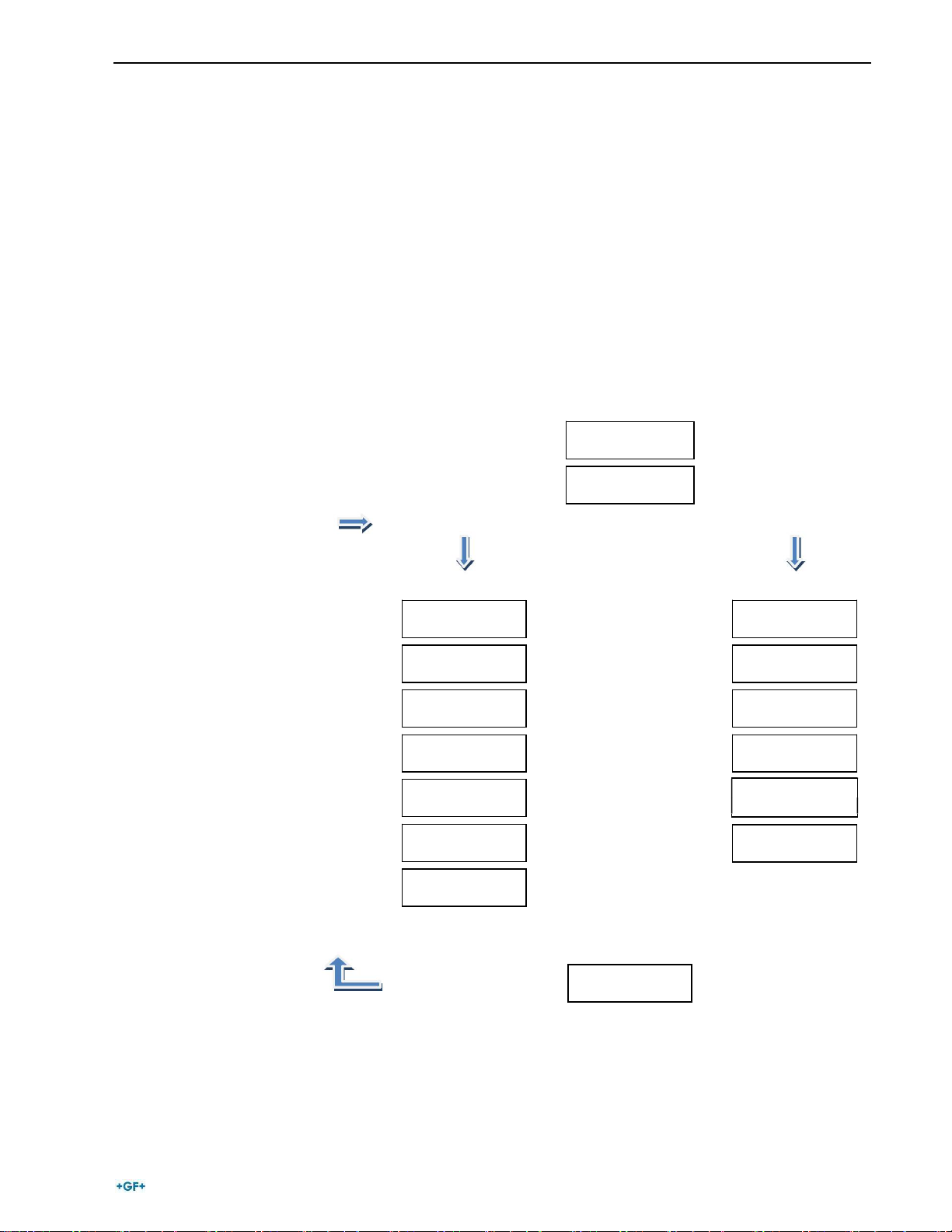

SN: S182Z6605010

230V 50Hz

01/04/17 12:12

2.2 Power On

Connect the machine to the power mains or power generator, already

started, and switch on the machine. The display shows the information

concerning the installed software and the serial number of the

machine.

Then it shows the input voltage and frequency

At this time you may change some settings of the unit: date/time,

language or brightness of the display itself (see “Settings” paragraph).

Make sure that the frequency value is in the range 50 – 60 Hz and the

voltage is between 205 – 255 V. Then press START to go ahead.

PEEL & CLEAN?

YES=START

Advise

ENTER FUSION

DATA

GF I 110 mm

40 V 210 sec

2.3 Fusion data entry

The MSA 160 allows the manual insertion of the parameters or the

automatic acquisition, if the scanner is used, by reading the barcode

data of the fitting.

If the scanner is available and connected to the USB port, the MSA 160

will switch to barcode mode.

If not, it will allow the input of values manually (see next paragraphs for

the detailed explaination).

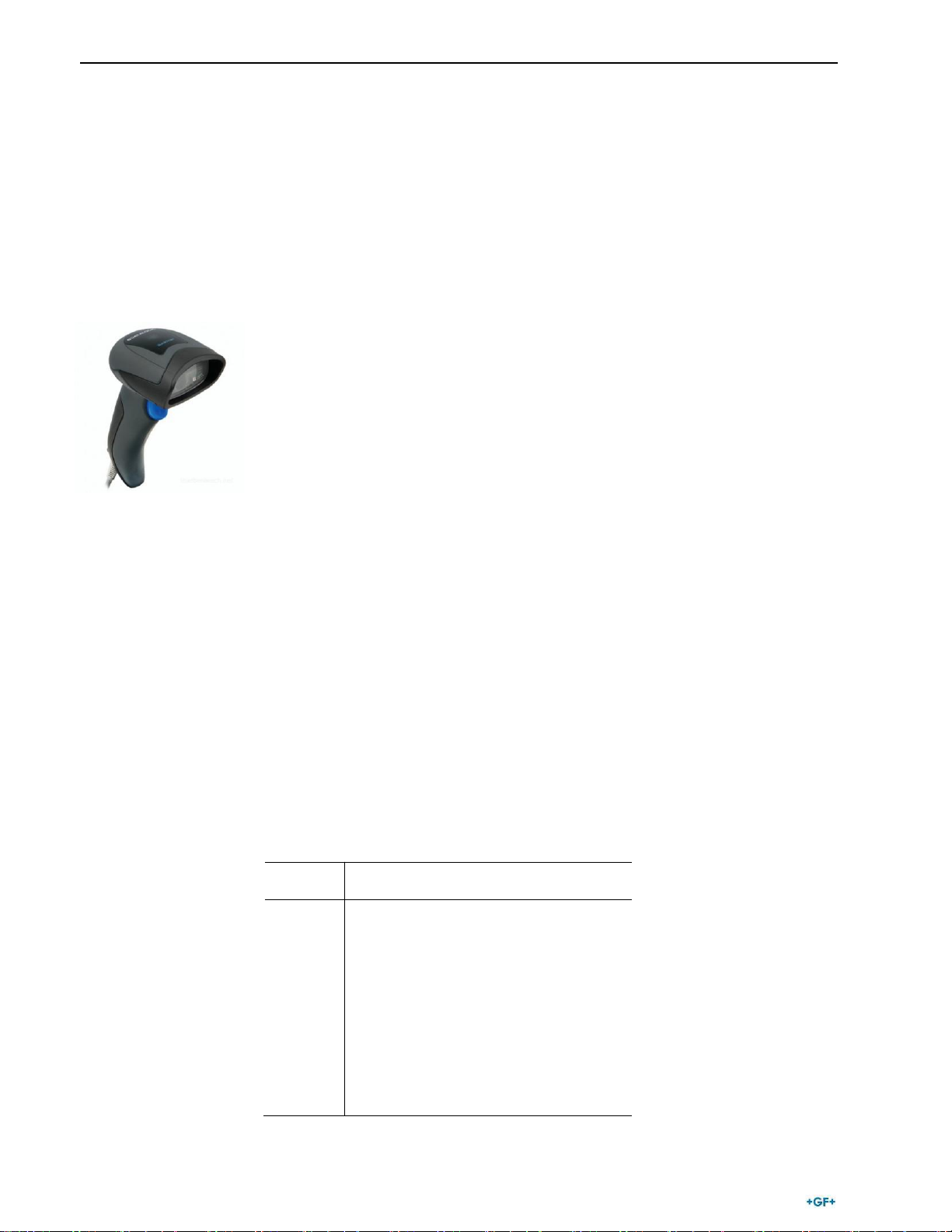

2.3.1 Bar code data input (optional)

Pipes preparation

If the pipes are scraped and cleaned press START; otherwise get

back and do the fusion preparations.

The preparation of the pipes according to guidelines (scraping, cleaning,

alignment) is essential to ensure the quality of the welding.

Data entry

If the scanner is connected, the next message will ask to ENTER FUSION

DATA, coded on the sticker of the connected fitting.

Only fittings with a diameter ≤ 160 will be accepted by the MSA160. For

larger diameters a message will pop up on the display, alerting the user.

When the data are captured, the display will switch automatically to a

different view, summarizing the parameters printed in the barcode.

If the barcode is not read, try once again, taking care of the

suggestions mentioned in the previous chapter.

8