5 OF 6 IG102918-6.0

HYDROLUME®INSTALLATION GUIDE

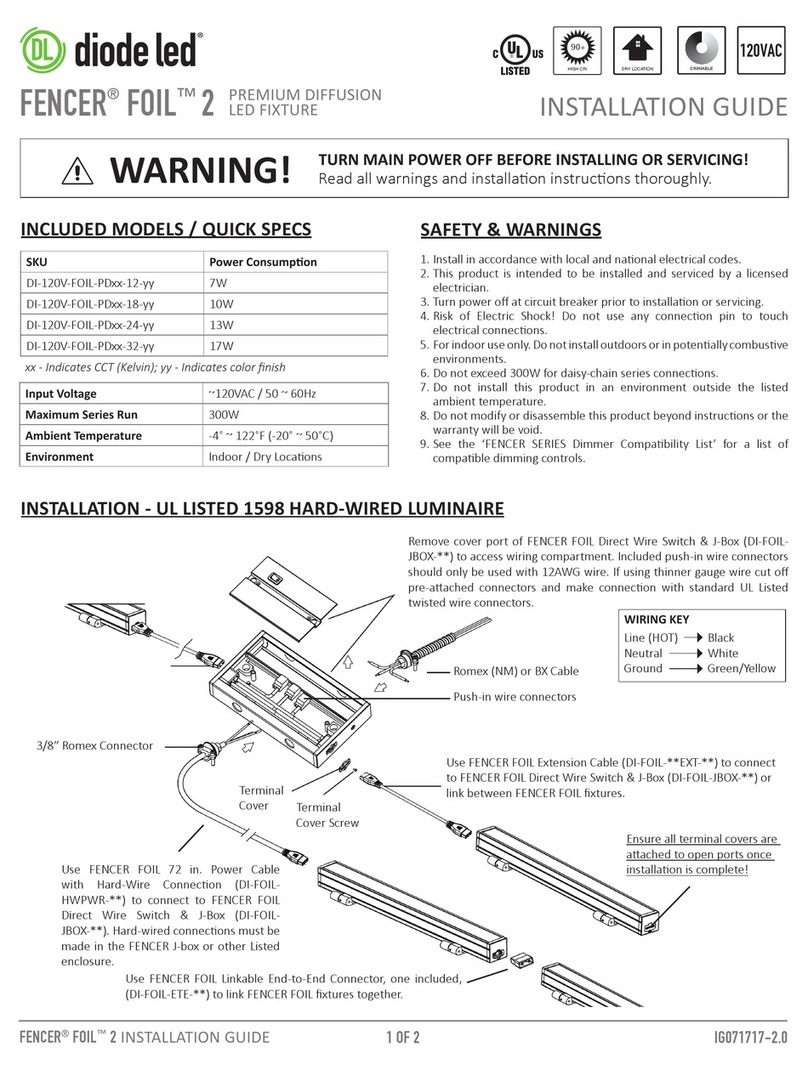

SYSTEM DIAGRAMS

The following diagrams are provided as example system designs. For information regarding larger systems or systems not pictured below, please see

our web page or contact technical support. Always review each component installation guide for detailed and up-to-date wiring instructions. Install in

accordance with national and local electrical codes.

L

N

G*

N

LV+

V−

120VAC On/Off Switch Class 2 Low Voltage Driver2

Installed in Junction Box7

V+

V-

8

Install appropriate wire gauge / type

V+

V-

AC Power

50/60Hz

INPUT

OUTPUT

Tradional ON/OFF Switch System

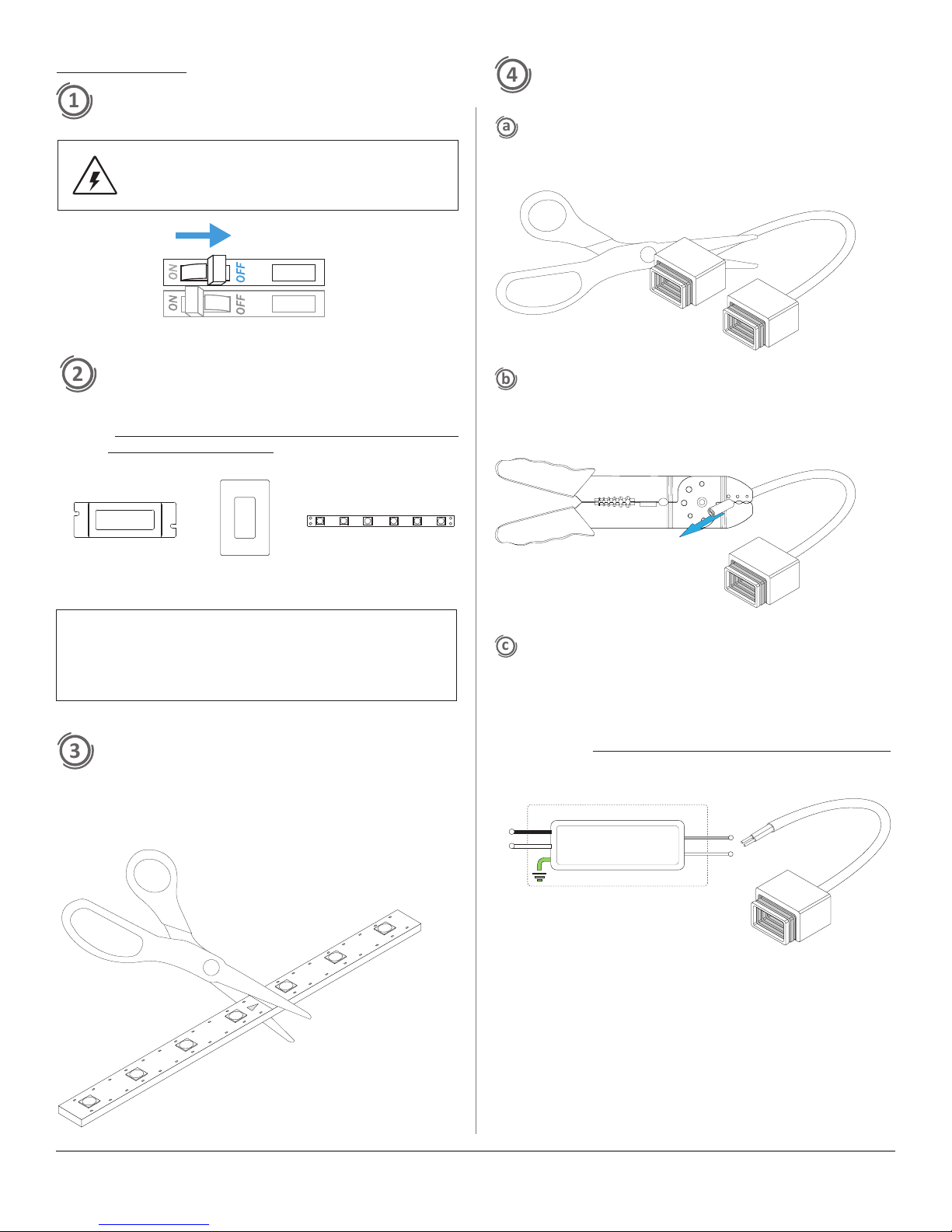

AC Power

50/60Hz

Compatible Dimming Control

or On/Off Switch5

LED Tape Light / Fixture8

L

Install appropriate wire gauge / type

OMNIDRIVE®Dimmable Driver6

Some dimmers may require an

additional neutral wire connection.

NNGND*

N

LV+

V−

V−

INPUT

OUTPUT

Class 2 Low Voltage Driver2

Installed in Junction Box7

REIGN® 12-24V Dimmer System

OMNIDRIVE® Electronic Dimmable Driver System

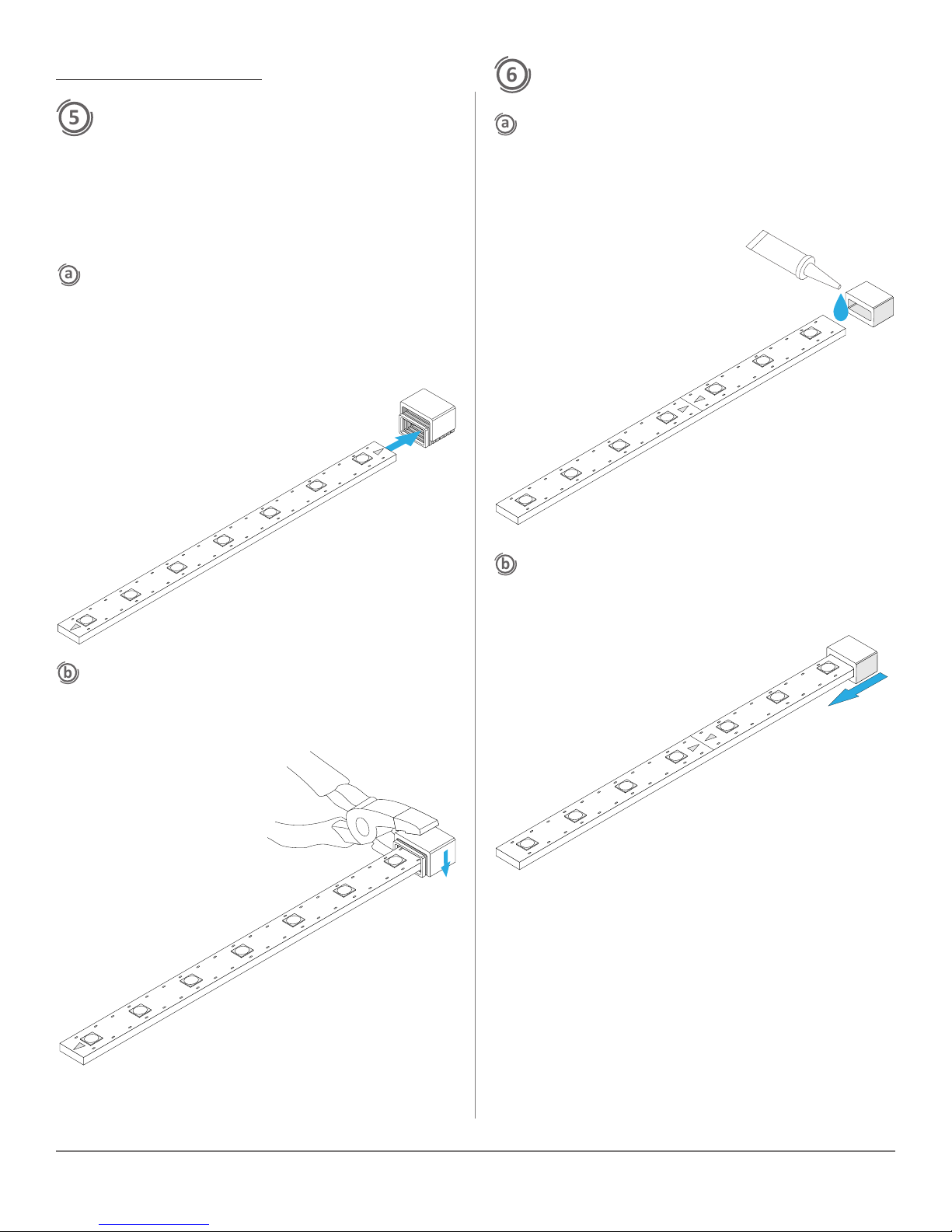

SWITCHEX® Dimmer/Driver System

G*

N

LV+

V−

Class 2 Low Voltage Driver3

Installed in Junction Box7

V- (Black)

Input Output

V+ (Red)

Install appropriate wire gauge / type

V+

V-

LED Tape Light / Fixture8

REIGN 12-24V Dimmer4

V-

L

N

AC Power

50/60Hz

INPUT

OUTPUT

* Driver may not require a fault ground connection. Refer to driver specications for additional information.

** Install a compatible Class 2 constant voltage driver. Refer to each driver specication sheet for full power ratings & load deratings.

*** Install a Class 2 constant voltage driver compatible with a low voltage PWM controller/dimmer switch. Refer to each driver specication sheet for full power ratings & load deratings.

**** Determine the number of low voltage outputs of the driver when installing multiple PWM controllers/dimmer switches. No more than one PWM controller/dimmer switch can be attached

to a single output of the driver.

^ Install a compatible dimming control or switch. See the ‘Electronic Dimmable Driver / Dimmer Compatibility List’ for compatible dimming controls. See the dimming control manufacturer

installation guide for complete wiring instructions.

^^ Ensure to load the driver at least 60% the labeled load for proper dimming performance (required for dimmable installations only).

‡ Refer to driver or controller specications for a compatible junction box.

‡‡ See xture specications for maximum series run limits.

N (WHT)

120 VAC

~ 60Hz

V+ (RED)

V−(BLUE)

+

−

+

−

L (BLK)

(Dimmer + Driver)

LED ARRAY / FIXTURE

Install applicable wire gauge / type

Install applicable wire gauge / type