Dion-Ag Scorpion 2430 User manual

Operator’s Manual

FORAGE HARVESTER

Manual no. F6918E998E

v1.5

2

3

FOREWORD

We thank you for your confidence towards DION-Ag Inc. agricultural equipment. We have prepared this manual with care

and attention and have designed it as an essential tool that will allow you to use and maintain your machine adequately

and safely. By following the instructions that it contains, you will obtain optimal performance and durability of the

harvester for years to come.

Carefully read this manual in order to familiarize yourself with the adjustment procedures and operation, before

attempting to use the machine. Keep in mind this machine has been designed and tested to perform in most conditions.

However, its performance is tightly linked to the maintenance it receives.

Any equipment requires a minimum amount of service and repair to be kept in good working condition. We have

attempted to cover most of the required adjustments for the different possible field conditions. However, some unique

cases might require special adjustments. Contact your dealership for any support or information. They will assist you with

the purchase of replacement parts and will be able to provide qualified technicians to repair, maintain and adjust your

machine.

This manual has been prepared with the latest available information at the time of publishing. The company reserves the

right to make any changes without prior notice.

SAFETY

The Safety section of your Operator’s manual is intended to point out some of the basic safety situations which may be

encountered during normal operation and maintenance of your Forage Harvester, and to suggest possible ways of dealing

with these situations. This section is NOT a replacement for other safety practices featured in other sections of this

manual.

The safety of the operator is one of the main concerns in designing and developing a new Forage Harvester. Designers

build in as many safety features as possible. However, every year accidents may occur which could have been avoided by

a few seconds thought and a more careful approach to handling farm machinery and implements.

Read and implement the safety instructions detailed within and share them with other operators.

WARRANTY INFORMATION

You will find the warranty information for this machine at the beginning of this manual. The warranty information shall

be filled out and signed by all parties and the appropriate copies sent to the 3 parties as indicated at the bottom of

each page. Failure to submit this information to DION-Ag Inc. may affect the warranty duration.

IMPORTANT: THIS MANUAL MUST REMAIN WITH THE MACHINE IF SOLD.

4

DION-AG INC. LIMITED WARRANTY

TERMS AND CONDITIONS

Covered by Warranty – Under the warranty, DION-Ag Inc. guarantees its new machinery and/or equipment to be free of

defects, both in workmanship and material, for a period of one (1) year from the time of delivery by the dealer to the

owner. DION-Ag Inc. will repair or replace, at its discretion and without charge for service parts or labour, any defective

part of the equipment on condition that the machinery and/or equipment has been operated in accordance with the

instructions contained in the DION-Ag Inc. Operator’s Manual provided the warranty form is submitted to DION-Ag Inc.,

in full, as mentioned in the afore Warranty Information section.

Not covered by Warranty – This warranty does not cover: (1) service parts and labour needed to maintain the unit; and

(2) the replacement of parts due to normal wear and tear. The owner is responsible for these items. Some examples of

maintenance and normal wear parts are: oil, lubricants & other fluids, belts, knives, clutch and clutch discs, roller chain,

paddles, etc. DION-Ag Inc. is not responsible for depreciation or damage caused by normal wear, lack of reasonable and

proper maintenance, failure to follow operating instructions, misuse, lack of proper protection during storage, vandalism,

the elements, collision or accident. (3) Using the forage harvester with a header from another manufacturer will void

warranty on all driveline components. Any other damage caused to the harvester by this header will not be covered.

Securing Warranty Service – To secure warranty service, the owner must report the machinery and/or equipment defect

to an authorized dealer and request warranty service within the applicable warranty term.

Owner’s Obligation – It is the responsibility of the Owner to transport the equipment to the service shop of an authorized

DION-Ag Inc. Dealer or to reimburse the dealer for any travel or transportation expense involved in fulfilling this warranty.

This warranty does NOT cover rental of replacement equipment during the repair period, loss of profits, or other

commercial loss, and any or all incidental or consequential damages, overtime labour charges and/or freight charges for

replacement parts.

Limitations of This Warranty – No agent, employee or representative of DION-Ag Inc. has the authority to amend, or

modify, in any manner whatsoever, the terms of the present warranty. The express warranties herein contained exclude

all other express, implied or statutory warranties. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR ANY PARTICULAR PURPOSE.

Right to Inspect – DION-Ag Inc. and its authorized agents reserve the right to inspect the owner’s DION-Ag Inc. product

to determine if a defect in material or workmanship exists prior the commencement of any covered repairs. It is the

owner’s responsibility to ensure availability and/or delivery of the product to DION-Ag Inc. for the purpose of inspection.

Right to Make Design Changes – DION-Ag Inc. reserves the right to make changes in the design and other changes in its

products at any time and from time to time without notice and without incurring any obligation of its part to modify,

improve or add to products previously ordered from DION-Ag Inc. And sold or shipped by DION-Ag Inc.

Liability – DION-Ag Inc. shall not be liable, if, during the use of the machinery and/or attachment, the security guards

have been removed, modified, or have not been properly maintained.

Metal Detector Warranty – Due to its limitations, the metal detector cannot and should not be considered as an infallible

system. THE WARRANTY DOES NOT COVER INCIDENTAL OR INDIRECT DAMAGES.

The Warranty shall not apply if the instructions mentioned in this manual have not been followed completely and

correctly. Nor will the warranty apply if the owner or any third party modifies the machine without DION-Ag Inc.’s

knowledge and/or authorization. Every owner, when buying a DION-Ag Inc. machine, agrees and undertakes to use and

operate the machinery and its component parts safely, and in accordance with all applicable laws, and in accordance with

the Operator’s Manual. Furthermore, the owner agrees and accepts to indemnify and hold harmless DION-Ag Inc. for all

losses and damages to any person or property resulting from the owner’s non-compliance with the terms and conditions

of this warranty. Each owner further agrees to bring the warranty to the attention of any subsequent owner, and to obtain

agreement therein as a condition of resale or transfer.

5

January 1st 2019

TABLE OF CONTENTS

FOREWORD ................................................................................................................................................................................................ 3

SAFETY ....................................................................................................................................................................................................... 3

WARRANTY INFORMATION ....................................................................................................................................................................... 3

DION-AG INC. LIMITED WARRANTY ........................................................................................................................................................... 4

SPECIFICATIONS ......................................................................................................................................................................................... 9

DIMENSIONS .......................................................................................................................................................................................... 9

WEIGHT ................................................................................................................................................................................................. 9

TRANSMISSIONS .................................................................................................................................................................................... 9

CUTTER HEAD ........................................................................................................................................................................................ 9

TIRES AND WHEELS .............................................................................................................................................................................. 10

FEATURES ............................................................................................................................................................................................ 10

SERIAL NUMBER LOCATION ................................................................................................................................................................. 11

SAFETY RULES .......................................................................................................................................................................................... 12

A WORD TO THE OPERATOR ................................................................................................................................................................ 12

CODES AND SYMBOLS .......................................................................................................................................................................... 12

FOLLOW A SAFETY PROGRAM.............................................................................................................................................................. 12

GENERAL SAFETY RULES ...................................................................................................................................................................... 13

PTO OPERATION .................................................................................................................................................................................. 13

PREPARATION AND OPERATION .......................................................................................................................................................... 14

MANDATORY STOPPING PROCEDURE ................................................................................................................................................. 14

INSPECTION, MAINTENANCE AND ADJUSTMENTS .............................................................................................................................. 15

TRANSPORT AND STORAGE ................................................................................................................................................................. 15

GUARDS AND SHIELDS ......................................................................................................................................................................... 16

SAFEY SIGN LOCATION ......................................................................................................................................................................... 17

SETUP ....................................................................................................................................................................................................... 22

BOLT TORQUE SPECIFICATIONS ........................................................................................................................................................... 22

MANUAL JACK ...................................................................................................................................................................................... 23

12V POWER CONNECTION ................................................................................................................................................................... 23

CONTROL BOX INSTALLATION.............................................................................................................................................................. 24

HYDRAULIC CONNECTION ................................................................................................................................................................... 24

CONNECTING THE HARVESTER TO THE TRACTOR ................................................................................................................................ 26

DRAW BAR EXTENSION ........................................................................................................................................................................ 27

CONFIGURING FOR CORN HARVEST SETUP ......................................................................................................................................... 30

CONFIGURING THE HARVESTER FOR WINDROW (HAY) HARVESTING ................................................................................................. 37

SETTING THE LENGTH OF CUT .............................................................................................................................................................. 44

PROCEDURE TO MODIFY THE LENGTH OF CUT .................................................................................................................................... 45

SPOUT EXTENSION REMOVAL .............................................................................................................................................................. 46

HEADER INSTALLATION........................................................................................................................................................................ 48

HEADER SUSPENSION .......................................................................................................................................................................... 51

HEADER HEIGHT ADJUSTMENT ............................................................................................................................................................ 52

STARTING UP AND BREAK-IN ............................................................................................................................................................... 52

KNIVES AND SHEAR BAR ...................................................................................................................................................................... 52

SHEAR BAR DESIGN .............................................................................................................................................................................. 53

KNIFE SHARPENING ............................................................................................................................................................................. 54

DAILY SHEAR BAR ADJUSTEMENT ........................................................................................................................................................ 55

CONTROL BOX FUNCTIONS .................................................................................................................................................................. 56

METAL DETECTOR GENERAL INFORMATION ....................................................................................................................................... 57

DAILY CHECKS ON THE METAL DETECTOR............................................................................................................................................ 58

METAL DETECTOR SENSITIVITY AJUSTEMENT ...................................................................................................................................... 59

DISABLING THE METAL DETECTOR ....................................................................................................................................................... 60

DRIVE FAILURE DETECTOR ................................................................................................................................................................... 61

7

DISABLING THE DRIVE FAILURE DETECTOR .......................................................................................................................................... 62

LIQUID INCORPORATION SYSTEM........................................................................................................................................................ 63

PRESSURE ADJUSTEMENT .......................................................................................................................................................... 63

FLOW CALIBRATION PROCEDURE .............................................................................................................................................. 64

TRANSPORT LIGHTS ............................................................................................................................................................................. 65

SET TRACK WIDTH ................................................................................................................................................................................ 66

GROUND CLEARANCE .......................................................................................................................................................................... 66

OPERATION PRACTICAL ADVICE........................................................................................................................................................... 67

HARVESTER DRAW BAR POSITION ............................................................................................................................................. 67

STOPPING THE MACHINE ..................................................................................................................................................................... 67

FIELD WORK ......................................................................................................................................................................................... 67

F-N-R TRANSMISSION SHIFTING .......................................................................................................................................................... 69

WITHOUT METAL DETECTOR, OR DEACTIVATED ....................................................................................................................... 69

WITH METAL DETECTOR ............................................................................................................................................................ 69

INITIALIZING THE METAL DETECTOR .................................................................................................................................................... 70

STARTING UP ....................................................................................................................................................................................... 70

STOPPING THE HARVESTER .................................................................................................................................................................. 70

METAL DETECTION PROCEDURE .......................................................................................................................................................... 71

PROCESSOR ROLL PRESSURE AND SPACING ........................................................................................................................................ 71

PROCESSOR ROLL CLEARANCE ADJUSTMENT PROCEDURE ................................................................................................................. 72

HEADER OR FEED ROLL OVERLOAD ...................................................................................................................................................... 72

SHEAR BOLT FAILURE ........................................................................................................................................................................... 73

FRICTION CLUTCH (OPTIONAL) ............................................................................................................................................................ 74

CLEANING THE PROCESSOR ROLLS ...................................................................................................................................................... 74

TRANSPORT ......................................................................................................................................................................................... 75

HYDRAULIC CIRCUITS ........................................................................................................................................................................... 77

POWER TAKE OFF (PTO) ....................................................................................................................................................................... 77

DRIVE CHAINS ...................................................................................................................................................................................... 77

LUBRICATION CHART ........................................................................................................................................................................... 78

GEARBOXES LUBRICATION ................................................................................................................................................................... 78

PROCESSOR ROLL LUBRICATION .......................................................................................................................................................... 85

SMOOTH FEED ROLL SCRAPER ADJUSTMENT ...................................................................................................................................... 88

KNIFE ADJUSTMENT ............................................................................................................................................................................. 89

KNIFE REPLACEMENT ........................................................................................................................................................................... 90

SHEAR BAR REPLACEMENT .................................................................................................................................................................. 91

SHEAR BAR INITIAL ADJUSTMENT ........................................................................................................................................................ 93

SHEAR BAR CLAMPING ADJUSTMENT .................................................................................................................................................. 94

CUTTERHEAD LINER REPLACEMENT .................................................................................................................................................... 97

PROCESSOR LINER ADJUSTMENT ......................................................................................................................................................... 98

PROCESSOR MINIMUM GAP ADJUSTMENT ....................................................................................................................................... 100

ACCELERATOR LINER REPLACEMENT ................................................................................................................................................. 101

ACCELERATOR ADJUSTMENT ............................................................................................................................................................. 102

ACCELERATOR PADDLE REPLACEMENT AND BALANCING ................................................................................................................. 103

SPOUT ROTATION MOTOR AND GEAR ADJUSTMENT ........................................................................................................................ 104

SPOUT CYLINDER TRAVEL SENSOR ADJUSTMENT .............................................................................................................................. 105

SPOUT LINER REPLACEMENT ............................................................................................................................................................. 106

FEED ROLL SPRING TENSION .............................................................................................................................................................. 107

HARVESTING UNDER SPECIAL CONDITIONS....................................................................................................................................... 107

FEED ROLLS CHAIN TENSION .............................................................................................................................................................. 108

TRANSMISSION BELT TENSION .......................................................................................................................................................... 109

ACCELERATOR BELT TENSION ............................................................................................................................................................ 110

PROCESSOR BELTS TENSION .............................................................................................................................................................. 110

HEADER LIFT CYLINDER ADJUSTMENT ............................................................................................................................................... 111

STONE CARRIAGE ADJUSTMENT ........................................................................................................................................................ 112

SHARPENING STONE REPLACEMENT ................................................................................................................................................. 113

8

SHARPENER FRAME ADJUSTMENT .................................................................................................................................................... 113

F-N-R TRANSMISSION SHIFTER ARM ADJUSTMENT ........................................................................................................................... 114

F-N-R TRANSMISSION SENSOR ADJUSTMENT .................................................................................................................................... 115

FEED ROLL STOPPING MECHANISM ADJUSTMENT ............................................................................................................................ 116

SPEED SENSOR ADJUSTMENT ............................................................................................................................................................ 117

ELECTRONIC CONTROL UNIT & CONNECTOR CLEANLINESS ............................................................................................................... 118

WELDING ON THE HARVESTER ........................................................................................................................................................... 118

STORAGE PROCEDURE ....................................................................................................................................................................... 119

DIAGNOSTICS & TROUBLESHOOTING .................................................................................................................................................... 121

CONTROLLER ALARMS AND LOGIC .................................................................................................................................................... 121

TRANSMISSION SHIFTER LOGIC ......................................................................................................................................................... 122

CONTROL BOX, TRANSMISSION AND METAL DETECTOR ................................................................................................................... 123

EJECTION ........................................................................................................................................................................................... 126

FEEDING ............................................................................................................................................................................................. 127

LIQUID INCORPORATION SYSTEM...................................................................................................................................................... 127

CUTTING ............................................................................................................................................................................................ 128

PROCESSOR ROLLS ............................................................................................................................................................................. 128

DRIVE ................................................................................................................................................................................................. 129

ELECTRO-HYDRAULIC FUNCTIONS ..................................................................................................................................................... 130

CHECKLIST .............................................................................................................................................................................................. 140

SPECIFICATIONS

Specification and design are subject to change without notice and responsibility from the manufacturer.

DIMENSIONS

OVERALL width (narrow axle position)

With tires 31x13.50 - 15 TerraRib…….…………………………………….3.30 m (142”)

With tires 31x15.50 - 15 TerraGrip…..…………………………………….3.50 m (150”)

LENGTH (Spout in transport position) …................………...............................6.22 m (244”)

HEIGHT min / max – (Wheels in standard position)

Standard spout – lowered/lifted…………………….………………………2,79 m / 3.44 m (110”/140”)

‘Stinger’ spout – lowered/lifted……….…………………………………....2,79 m / 5.38 m (110”/212”)

WEIGHT

Standard equipment – tandem axle, Metal detector, short spout …………..2860 kg (6300 lb)

Processor rolls……….……….........................................................+300 kg (660 lb)

‘Stinger’ spout……….……….........................................................+110 kg (230 lb)

TRANSMISSIONS

ANGLE DRIVE CONFIGURATIONS

1000/800: 1000 rpm PTO - 815 rpm at the cutter head - 90 to 180 hp

1000/1000: 1000 rpm PTO - 1033 rpm at the cutter head - 160 to 300 hp

OIL CAPACITY

8 litres – Synthetic 80W140

MAIN GEARBOX FEATURES

Reverse, Neutral, Forward position (R-N-F)

Electro-hydraulic shifter

Torque limiter

2 length of cut ranges (LOC pulley - factory installed)

3 length of cut (cut sprockets)

OIL CAPACITY

4 litres – Synthetic 80W140

CUTTER HEAD

Width:………........................610mm (24”)

Diameter:………...................560mm (22”)

Rotation speed:………….......810, 815 or 1033 rpm

SPECIFICATIONS

10

TIRES AND WHEELS

SINGLES

31, 13.5-15 TerraRib

31 x 15.5 TerraTrac

TANDEM

31, 13.5-15 TerraRib

31 x 15.5 TerraTrac

FEATURES

STANDARD

Angle drive 1000/1000

Cutter head with 24 (8x3) tungsten carbide Duradrumtm knives

Built-in grinder

One-side sharpening and shear bar adjustment (Performed on the ground)

Fully electro-hydraulic functions

Three length of cut sprockets 17T, 26T, 34T

Height adjustable spout with 310° rotation

Feed roll grain pan

Adjustable drawbar Cat. II to IV

OPTIONAL

Angle drive 1000/800

12 knife cutter head (12 knife cutter head (LOC from 4 to 24 mm possible)

Spout extensions

o Vertical extension 600 mm (24")

o Horizontal extension 1.50 m (60")

o ‘Stinger’ Extension 4.0m (157") – Includes LED spout light and wireless camera

Single or tandem axles

Quick trailer disconnect

Metal detector and emergency stop via ultra-fast logic control

Liquid incorporation system

o Single or double supplementary tanks

Corn processor rolls

Drawbar extension

Two length of cut ranges « LOC L » and « LOC H »

SPECIFICATIONS

11

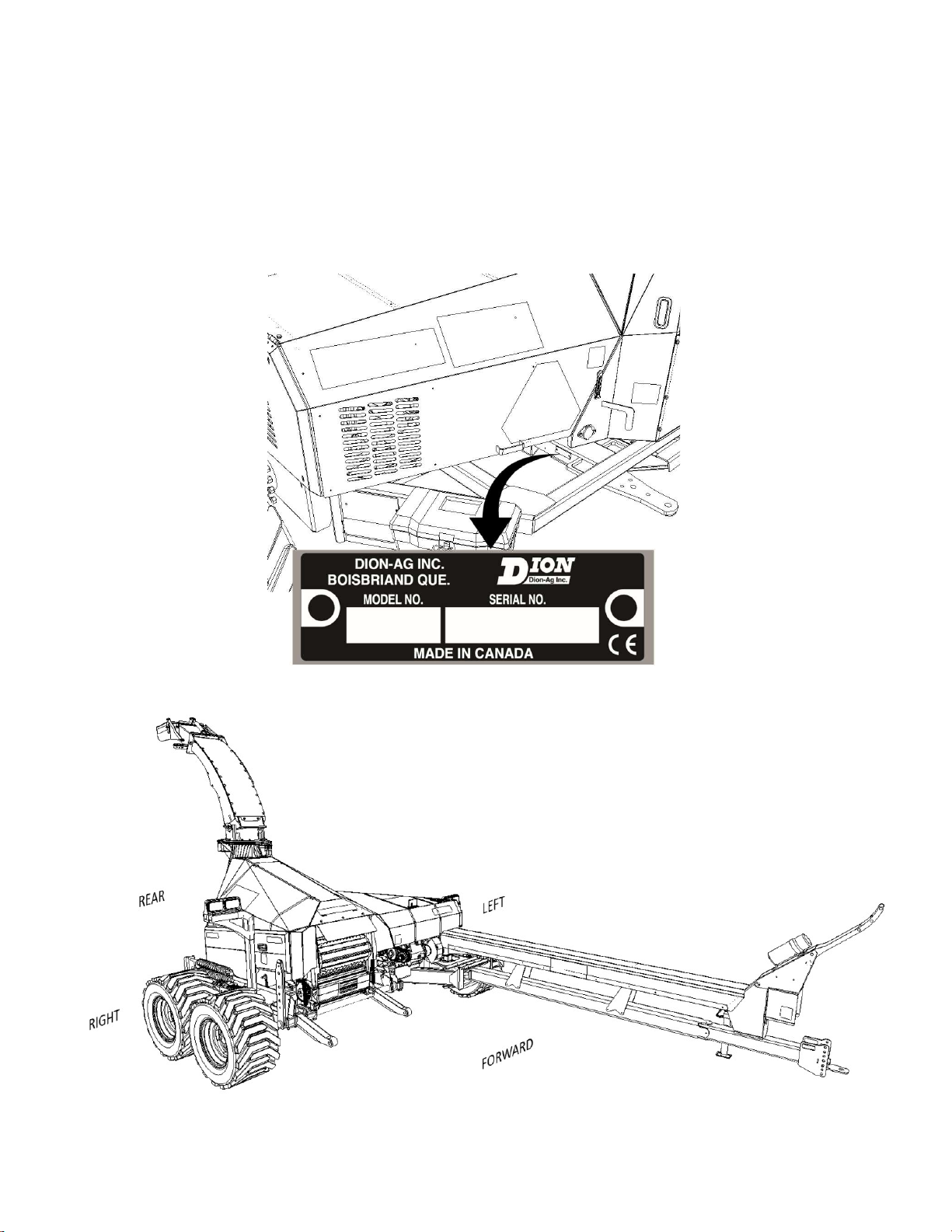

SERIAL NUMBER LOCATION

For your convenience, write down the full model and serial number of your machine in this manual, as shown on the

name plate illustrated below. Always mention both the model and the serial number when ordering parts or regarding

any other correspondence with your machine.

Write down your number here:

MODEL NO.: ___________________________ SERIAL NUMBER: ___________________________

Figure 1 Serial number

Figure 2 Machine orientation

SAFETY RULES

A WORD TO THE OPERATOR

It is the responsibility of the OWNER to read and fully understand the safety section in this manual before operating your

tractor. You must follow these safety instructions that will assist you step by step throughout your workday.

After reading this section, you will note that illustrations have been used to highlight certain situations. Each illustration

is numbered and the same number appears in the text in parenthesis.

Remember that YOU are the key to safety. Good safety practices not only protect you, but also the people around you.

Study the features in this manual and make them a working part of your safety program.

Think SAFETY! Work SAFELY!

CODES AND SYMBOLS

The symbol below calls attention to instructions concerning your personal safety. It is found throughout the manual as

well as on the machine to point out specific hazards and ways to avoid these hazards. Always follow the instructions to

minimize the risk of personal injury or death.

SAFETY SYMBOL

DANGER, WARNING AND CAUTION

Whenever you see the words and symbols shown below or used in this manual and on decals, you MUST take note of

their instructions as they relate to personal safety.

DANGER: This symbol together with the word DANGER indicates an imminently hazardous situation that, if not

avoided, will result in DEATH OR VERY SERIOUS INJURY.

WARNING: This symbol together with the word WARNING indicates a potentially hazardous situation that, if not

avoided, could result in DEATH OR SERIOUS INJURY.

CAUTION: This symbol together with the word CAUTION is used to indicate a potentially hazardous situation

that, if not avoided, may result in MINOR INJURY.

IMPORTANT: The word IMPORTANT is used to identify special instructions or procedure which, if not strictly observed,

could result in damage to, or destruction of the machine, process or its surroundings.

NOTE: The word NOTE is used to indicate points of particular interest for a more efficient and convenient service and

operation of the machine.

FOLLOW A SAFETY PROGRAM

For safe operation of a Forage Harvester, you must be a qualified and authorized operator. To be qualified, you must read

and understand the written instructions supplied in this Operator’s Manual, have training, and know the safety rules and

regulations for the job.

Some regulations specify that no one under the age of 16 years, for example, may operate power machinery. This includes

tractors. It is your responsibility to know what these regulations are, and obey them, in the operating area or situation.

These will include, but are not limited to, the following instructions for proper operation.

SAFETY RULES

13

GENERAL SAFETY RULES

CAUTION: In some of the illustrations used in this Operator’s Manual, panels or guards may have been removed

for clarity. Never operate the machine without these components in place.

CAUTION: An operator should not be under the influence of alcohol or drugs which can alter alertness or

coordination. An operator on prescription or “over the counter” drugs needs medical advice on whether or not

he or she can operate machines.

CAUTION: DO NOT remove or obscure Danger, Warning, Caution or Instruction Decals that are not legible or

are missing. Replacement decals are available from your Dealer in the event of loss or damage. The actual

location of these Safety Decals is illustrated on page SAFEY SIGN LOCATION, See SAFEY SIGN LOCATION.

Wear appropriate clothing, safety boots or shoes.

Keep children away from the machine at all time.

Do not operate the machine when visibility is bad, or during night, in poor lighting.

Do not allow anyone to ride on the machine at any time.

The tractor ignition key must be removed every time the operator leaves the tractor.

Keep hands and body out of hitch area when attaching towing vehicle.

Carefully read the safety decals on the machine. If any are damaged, replace them immediately.

PTO OPERATION

Before starting the tractor engine, make sure that the PTO driveline locking device is properly engaged onto both

the tractor and equipment drive shafts. Secure the safety chain to the tractor frame.

Never proceed to start the machine before making sure all driveline, machine and tractor shields are properly

installed in place.

Never wear loose clothing and keep people, especially children away from the driveline.

The PTO driveline shields should turn freely, be well connected and be maintained in good condition.

Do not connect a tractor with a PTO speed of 1000 RPM on a machine equipped with a 540 RPM drive.

Do not connect a tractor with a PTO speed of 540 RPM on a machine equipped with a 1000 RPM drive.

Keep a good distance away from a rotating driveline (approximately the distance greater to your height).

Never step across any PTO driveline.

Never use the PTO driveline as a step.

SAFETY RULES

14

PREPARATION AND OPERATION

Before starting the tractor engine, make sure all guards, shields, and doors are in place and properly secured and

check the machine thoroughly for possible loose parts or bolts. Make any necessary adjustments.

Use a lift system with a minimum lifting capacity of 2500 lbs (1150 kg) to install a header on the forage harvester.

Refer to the header specifications.

Never operate a Forage Harvester without first having installed a header.

If a feeding or throwing mechanism should become jammed, never attempt to unblock it or remove any material

when the machine is in motion or while the tractor engine is running.

Make sure all rotating parts are stopped and the tractor engine is turned OFF before cleaning the machine throat.

Never stand underneath the forage harvester deflector or forage path when the machine is running. Keep the

discharge spout toward the forage box.

MANDATORY STOPPING PROCEDURE

No matter what type of machine is being used, it is extremely hazardous to perform any kind of maintenance work while

the machine is running. It could lead to serious injuries or even death. Before cleaning, adjusting or greasing the machine,

the following procedure should be followed to stop the Forage Harvester:

1. Place the transmission in neutral.

2. Disengage the PTO from the tractor.

3. Switch off the forage harvester control box.

4. Switch off the oil flow (distribution valve).

5. Switch off the tractor engine.

6. Apply the tractor's safety brake.

7. Wait until all rotating parts have completely stopped.

8. Disconnect the PTO input shaft from the tractor's PTO.

9. Block all wheels.

DANGER: Rotating driveline contact may cause serious injury or death.

SAFETY RULES

15

INSPECTION, MAINTENANCE AND ADJUSTMENTS

WARNING: Hydraulic fluid under pressure can penetrate the skin or eyes and cause serious personal injury,

blindness or death. Fluid leaks, under pressure, may not be visible. Use a piece of cardboard or wood to find

leaks. DO NOT use your bare hand. Wear gloves and safety goggles for eye protection.

CAUTION: Hydraulic lines and components can become very hot in operation and cause burns. Wear gloves and

safety goggles for eye protection.

Never proceed to start the machine before making sure all driveline, machine and tractor shields are well installed

and in place.

Never lubricate or clean any part while the machine or tractor engine is running.

Never attempt to check or adjust chains while the machine is running.

Disengage the PTO and shut off engine before leaving the operator’s seat for refueling, lubricating or adjusting

the machine.

When performing a metal detection test, stop the PTO, wait until all moving parts are stopped, then disconnect

the PTO from the tractor.

Securely block the wheels from moving before working on or under the machine.

If necessary, to work under or close to moving parts that may crush or hit you, block their movement to make the

working environment safe.

Make sure that all wheel bolts are properly torqued.

When knives are being readjusted, a piece of wood should be used to immobilize the cutting head.

Always pick-up tools after performing any adjustment.

TRANSPORT AND STORAGE

Maximum traveling speed of a forage harvester should not exceed 32 km/h (20 mph).

Never pull a loaded wagon behind the harvester on the road.

Always use a draw pin of sufficient capacity, with a safety clip, to connect the harvester to the tractor and the

trailer to the harvester, for every trip on the road or in the field.

Attach a safety chain of at least 20,000 lbs (9071 Kg) capacity for transportation.

Always deactivate the hydraulic circuit of the harvester and turn off the control box before traveling on public

roads.

Ensure the spout is in lock position before traveling on the road.

When driving on a public road, or on hilly land, make sure the ‘Hitch Disconnect’ red safety cap is covering the

switch and install the locking pin in the stop pawl of the quick-disconnect hitch to prevent unlocking. This locking

pin should also be used for the manual quick-disconnect hitch.

Never disconnect a trailer on hilly land.

Make sure to meet local regulations for excessive width on public roads.

When storing or parking the harvester, always lower the header down to the ground.

SAFETY RULES

16

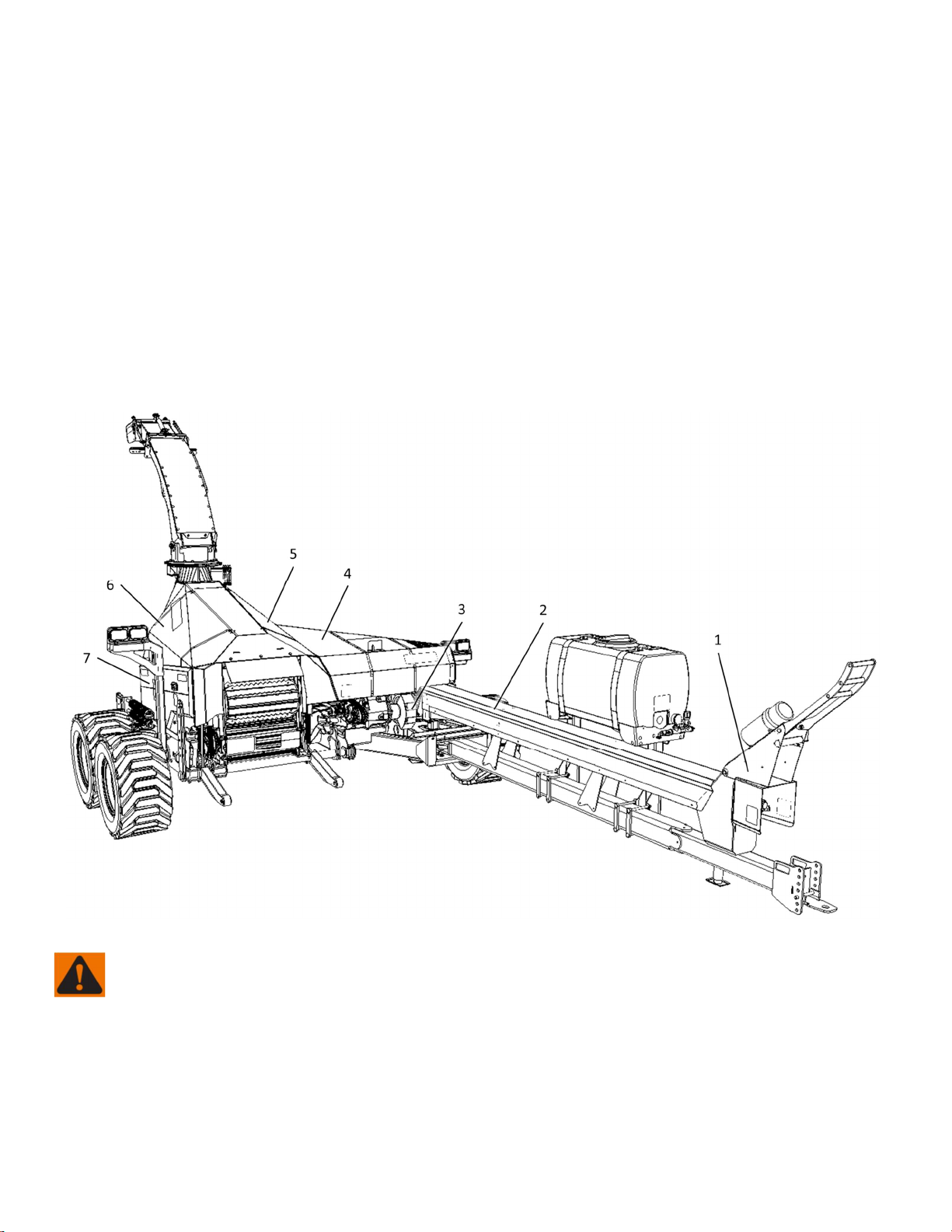

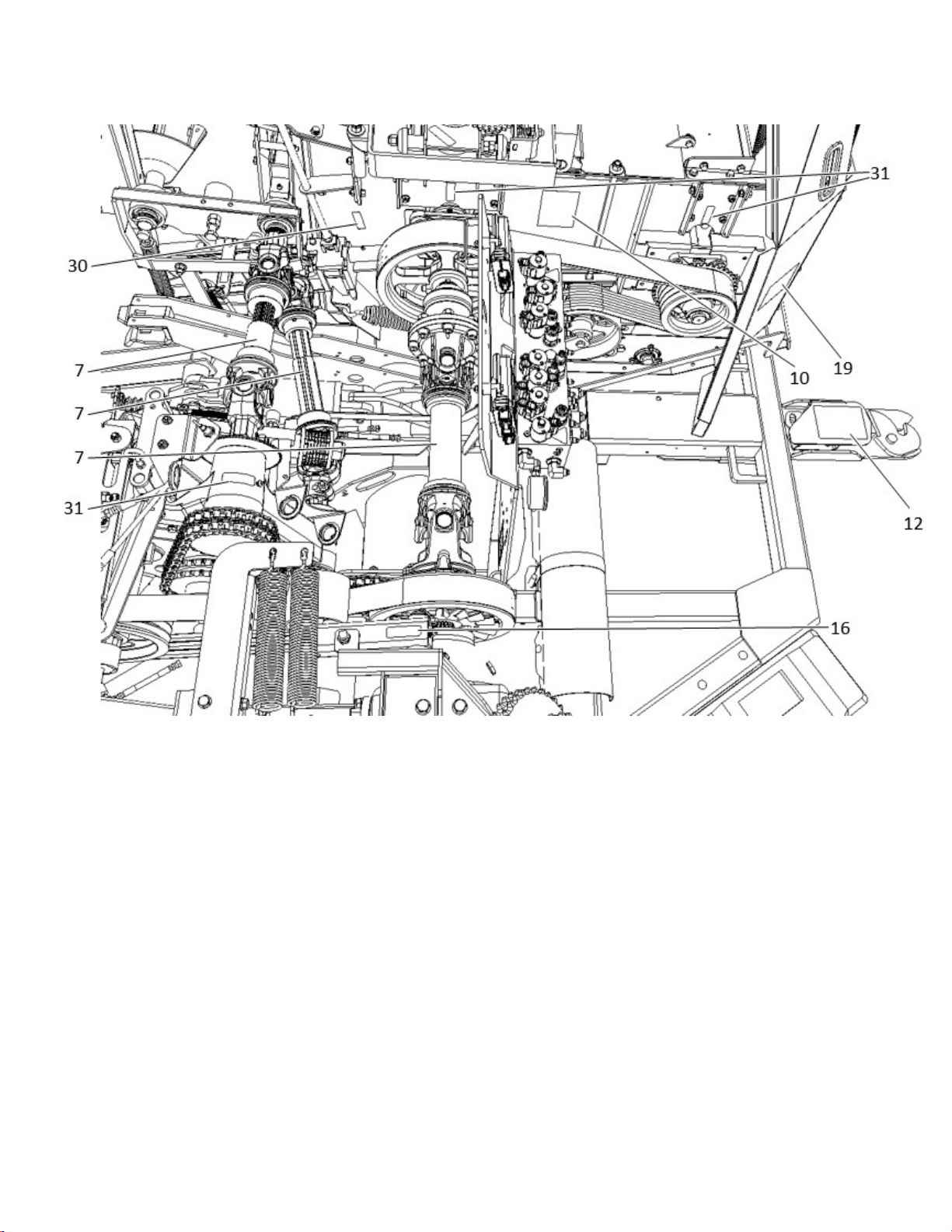

GUARDS AND SHIELDS

The Forage Harvester is equipped with guards and shields wherever accidents can occur. These guards and shields do not

affect the performance of the machine. Refer to Figure 3 to identify these guards and their location to make sure they

remain in place for a safe operation.

1. PTO shaft, cables and hose shield.

2. Transmission shaft guard.

3. Feed roll transmission pulley guard.

4. Main guard covering the power transmission components.

5. Left « Butterfly guard » covering the processing element drive.

6. Right « Butterfly guard » covering the processing and sharpening elements.

7. Side guard covering the feed rolls and processor roll drive elements.

Figure 3 Location of the main guards

WARNING: All factory installed guards and shields should be in place and maintained in good condition.

SAFETY RULES

17

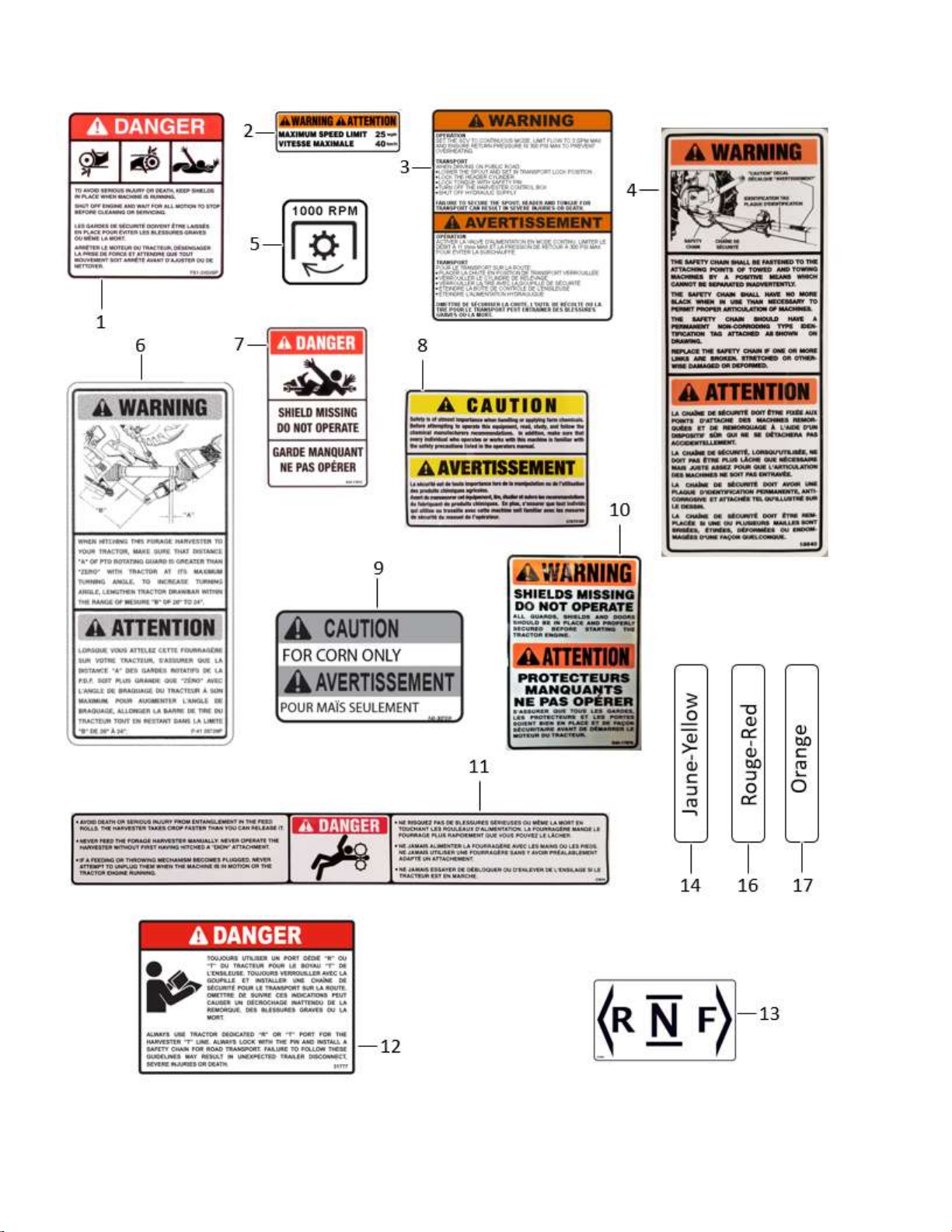

SAFEY SIGN LOCATION

Several decals located around the hazard areas indicate the potential dangers.

IMPORTANT: Decals must be kept clean to allow for visibility at all times.

Figure 4 Safety Decals

Figure 5 Safety Decals

SAFETY RULES

18

Figure 6 Safety Decals

Figure 7 Safety Decals

SAFETY RULES

19

Figure 8 Safety Decals

SAFETY RULES

20

Figure 9 Safety Decals

Table of contents

Other Dion-Ag Farm Equipment manuals