Dion-Ag F41 User manual

Operator’s Manual

Forage Harvester

Manual No. F4117E987E V1.1

2

DION-AG INC. LIMITED WARRANTY TERMS AND CONDITIONS

Covered by Warranty – Under the warranty, Dion-Ag guarantees its new machinery and/or equipment to be free

of defects, both in workmanship and material, for a period of one (1) year from the time of delivery by the dealer.

Dion-Ag Inc. will repair or replace, at its discretion and without charge for service parts or labour, any defective part

of the equipment on condition that the machinery and/or equipment has been operated in accordance with the in-

structions contained in the Dion-Ag Inc. Operator’s Manual.

Not covered by Warranty – This warranty does not cover: (1) service parts and labour needed to maintain the

unit; and (2) the replacement of parts due to normal wear and tear. The owner is responsible for these items. Some

examples of maintenance and normal wear parts are: oil, lubricants & other uids, belts, knives, clutch and clutch

discs, roller chain, paddles, etc. Dion-Ag Inc. is not responsible for depreciation or damage caused by normal wear,

lack of reasonable and proper maintenance, failure to follow operating instructions, misuse, lack of proper protec-

tion during storage, vandalism, the elements, collision or accident.

Securing Warranty Service – To secure warranty service, the purchaser must report the machinery and/or equip-

ment defect to an authorized dealer and request warranty service within the applicable warranty terms.

Owner’s Obligation – It is the responsibility of the Owner to transport the equipment to the service shop of an au-

thorized Dion-Ag Dealer or to reimburse the dealer for any travel or transportation expense involved in fullling this

warranty. This warranty does NOT cover rental of replacement equipment during the repair period, loss of prots,

or other coercial loss, and any or all incidental or consequential damages, overtime labour charges and/or freight

charges for replacement parts.

Limitations of This Warranty – No agent, employee or representative of Dion-Ag Inc. has the authority to amend,

or modify, in any manner whatsoever, the terms of the present warranty. The express warranties herein contained

exclude all other express, implied or statutory warranties. THIS WARRANTY IS IN LIEU OF ALL OTHER WAR-

RANTIES INCLUDING THE WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR ANY PARTICULAR

PURPOSE.

Right to Inspect – Dion-Ag and its authorized agents reserve the right to inspect the purchaser’s Dion-Ag product

to determine if a defect in material or workmanship exists prior the coencement of any covered repairs. It is the pur-

chaser’s responsibility to ensure availability and/or delivery of the product to Dion-Ag for the purpose of inspection.

Right to Make Design Changes – Dion-ag reserves the right to make changes in the design and other changes in

its products at any time and from time to time without notice and without incurring any obligation of its part to modify,

improve or add to products previously ordered from Dion-Ag and sold or shipped by Dion-Ag.

Liability – Dion-Ag Inc. shall not be liable, if, during the use of the machinery and/or attachment, the security guards

have been removed, modied, or have not been properly maintained.

The Warranty shall not apply if the instructions mentioned in this manual have not been followed completely and

correctly. Nor will the warranty apply if the owner or any third party modies the machine without Dion-AG’s know-

ledge and/or authorization. Every purchaser, when buying a Dion-Ag machine, agrees and undertakes to use and

operate the machinery and its component parts safely, and in accordance with all applicable laws, and in accord-

ance with the Operator’s Manual. Furthermore, the purchaser agrees and accepts to indemnify and hold harmless

Dion-Ag for all losses and damages to any person or property resulting from the purchaser’s non-compliance with

the terms and conditions of this warranty. Each purchaser further agrees to bring the warranty to the attention of any

subsequent purchaser, and to obtain agreement therein as a condition of resale or transfer.

Manual No. F4117E987E V1.1

3

Forage Harvester F41 & F41 Stinger

TO OUR CUSTOMER

We appreciate your condence in Dion Farm Equipment and thank you for your trust. In preparing this

manual, we hope we have furnished you with a valuable tool for operating and maintaining this ne ma-

chine. Use this manual as your guide. Practicing the instructions given here will result in many years of

dependable service from your machine.

Your dealer can give you assistance with parts and specially trained personnel to assist you in repair and

maintenance.

Call your dealer if you need any assistance or information.

Manual No. F4117E987E V1.1

4

SPECIFICATIONS.....................................................................................................................8

SERIAL NUMBER LOCATION ................................................................................................. 9

CHECK LIST............................................................................................................................. 10

PRE-SEASON CHECKS.....................................................................................................................10

DAILY CHECKS ..................................................................................................................................11

FOREWORD .............................................................................................................................12

TO OUR CUSTOMER.........................................................................................................................12

THIS MANUAL SHOULD REMAIN WITH THE MACHINE WHEN SOLD...........................................12

WARRANTY INFORMATION..............................................................................................................12

WARRANTY ON THE METAL DETECTOR ........................................................................................12

SAFETY ..............................................................................................................................................12

SAFETY RULES .......................................................................................................................13

SAFETY ALERT SYMBOL ..................................................................................................................13

DANGER, WARNING AND CAUTION ................................................................................................13

DECALS:.............................................................................................................................................13

FOLLOW A SAFETY PROGRAM........................................................................................................13

A WORD TO THE OPERATOR...........................................................................................................13

PTO OPERATION ...............................................................................................................................15

MANDATORY STOPPING PROCEDURE ..........................................................................................15

GUARDS AND SHIELDS ....................................................................................................................16

SAFETY SIGN LOCATION ....................................................................................................... 17

SAFETY SIGN APPLICATION PROCEDURE ...................................................................................21

MATERIAL SUPPLIED SEPARATELY WITH THE MACHINE: ...........................................................22

HARVESTERS ARE SHIPPED TO OPERATE AS FOLLOWS:..........................................................22

OPTIONAL EQUIPMENT CHOICES:..................................................................................................22

DELIVERY.................................................................................................................................22

MANUAL JACK ...................................................................................................................................23

RECEIVING YOUR FORAGE HARVESTER ......................................................................................23

PREPARING THE FORAGE HARVESTER ........................................................................................23

ASSEMBLING INSTRUCTIONS............................................................................................... 23

INSTALLING THE CONTROL BOX ....................................................................................................24

INSTALLING THE CONTROL BOX (F41 STINGER MODEL ONLY)..................................................24

CONNECTING THE POWER-TAKE-OFF (PTO) ...............................................................................26

INSTALLING THE FOLDABLE SPOUT (F41 MODEL ONLY).............................................................27

INSTALLING THE 12” (30 cm) SPOUT EXTENSION (F41 MODEL ONLY) FIGURE 12....................28

INSTALLING THE 24” (60 CM) SPOUT EXTENSION (F41 MODEL ONLY) ......................................29

HOW TO MAKE THE ELECTRICAL CONNECTIONS ON THE SPOUT (F41 MODEL ONLY)..........31

INSTALLING THE CLOSING PLATE ON THE SPOUT ......................................................................32

INSTALLING MUDGUARDS OVER TANDEM WHEELS ...................................................................32

INSTALLING AN ATTACHMENT ON THE FORAGE HARVESTER ..................................................33

INSTALLING THE RECUTTER BAR ASSEMBLY FOR CORN CROP ..............................................35

INSTALLING THE GRAIN PAN AND FRONT RUBBER PAD ASSEMBLY FOR CORN CROP..........35

INSTALLING A LIGHT ON THE SPOUT DEFLECTOR (F41 MODEL ONLY) ....................................36

INSTALLING THE INSPECTION LIGHT ............................................................................................37

ASSEMBLING INSTRUCTIONS - LIQUID INCORPORATION SYSTEM ................................ 38

INSTALLING A SECOND TANK..........................................................................................................47

ASSEMBLING INSTRUCTIONS - MANUAL QUICK-DISCONNECT HITCH .......................... 50

ASSEMBLING INSTRUCTIONS - ELECTRIC QUICK-DISCONNECT HITCH (UP TO 2017) 52

ASSEMBLING INSTRUCTIONS - ELECTRIC QUICK-DISCONNECT HITCH (2017+) .......... 54

ASSEMBLING INSTRUCTIONS - DRAW BAR EXTENSION.................................................. 58

ASSEMBLING INSTRUCTIONS - TRANSPORT LIGHTS....................................................... 60

TABLE OF CONTENTS

Manual No. F4117E987E V1.1

5

CORN CRACKER INSTALLATION INSTRUCTIONS .............................................................. 61

PARTIAL DISMANTLING OF THE CORN CRACKER FOR HAY CROP ................................ 76

PARTIAL REASSEMBLING OF THE CORN CRACKER FOR CORN CROP......................... 83

HYDRAULIC SPOUT CONVERSION ...................................................................................... 88

BREAK-IN SPEED ..............................................................................................................................88

BOLT TORQUE SPECIFICATIONS ....................................................................................................88

METAL DETECTOR............................................................................................................................88

STOPPING THE MACHINE ................................................................................................................88

TRANSPORTATION ON PUBLIC ROADS .........................................................................................88

OPERATING INSTRUCTIONS ................................................................................................. 90

TRANSPORT POSITION - F41 STINGER..........................................................................................91

PREPARING FOR FIELD OPERATION..............................................................................................92

HITCHING THE FORAGE HARVESTER TO THE TRACTOR .........................................................92

ADJUSTING THE ATTACHMENT GROUND CLEARANCE..............................................................93

STARTING UP.....................................................................................................................................93

INFORMATION ON THE METAL DETECTOR....................................................................................94

DAILY CHECKS ON THE METAL DETECTOR ..................................................................................94

INITIALIZING THE METAL DETECTOR

(STARTING UP THE MACHINE WITH METAL DETECTOR) ............................................................95

STOPPING THE MACHINE ................................................................................................................95

STARTING OPERATION.....................................................................................................................96

THE CONTROL BOX .........................................................................................................................96

EMERGENCY STOP ..........................................................................................................................96

OPERATING INSTRUCTION FOR THE F41 STINGER SPOUT .......................................................96

WHAT TO DO WHEN THE MACHINE DETECTS A FERROUS METAL............................................97

WHAT TO DO IF MATERIAL ACCUMULATION OCCURS (CLOGGING) ..........................................98

HOW TO BY-PASS THE METAL DETECTOR ...................................................................................99

SHEAR BOLT .....................................................................................................................................100

PRESSURE AND FLOW CHARTS FOR STANDARD NOZZLE.........................................................101

STANDARD NOZZLE FOR WATER SPRAYING TEEJET XR8004VS ...............................................101

HOW TO OPERATE THE LIQUID INCORPORATION SYSTEM........................................................101

CALIBRATION PROCEDURES .........................................................................................................101

PRESSURE ADJUSTMENT ...............................................................................................................101

DETECTION SYSTEM FOR SAFETY BOLT BREAKAGE OR

FRICTION CLUTCH SLIPPAGE ON THE CUTTER HEAD TRANSMISSION SHAFT. ......................102

TRANSPORT LIGHT ..........................................................................................................................103

HYDRAULIC CIRCUIT........................................................................................................................104

POWER-TAKE-OFF (PTO) .................................................................................................................104

LUBRICATION CHART .......................................................................................................................104

CHAINS LUBRICATION......................................................................................................................104

GEAR BOX LUBRICATION.................................................................................................................104

LUBRICATION .......................................................................................................................... 104

CORN CRACKER LUBRICATION ......................................................................................................111

ADJUSTMENTS - MAINTENANCE.......................................................................................... 113

WHEEL POSITIONING ......................................................................................................................113

GROUND CLEARANCE .....................................................................................................................114

DISMANTLING AND REASSEMBLY OF THE POWER-TAKE-OFF (PTO) ROTATING GUARDS.....114

FORAGE HARVESTER DRAW BAR..................................................................................................115

FEED ROLL BALANCING SPRINGS ................................................................................................115

UPPER FEED ROLL CHAIN TENSION .............................................................................................116

LOWER FEED ROLL CHAIN TENSION ............................................................................................116

STRAW CHOPPING ...........................................................................................................................116

BALANCING SPRINGS 2 ...................................................................................................................117

UPPER ROLL ADJUSTING BOLTS ...................................................................................................118

TABLE OF CONTENTS

Manual No. F4117E987E V1.1

6

MAGNETIC DRAIN PLUGS................................................................................................................118

SPOUT WEAR PLATE (F41) ..............................................................................................................119

SPOUT WEAR PLATE (F41

STINGER

) .............................................................................................119

HYDRAULIC SPOUT CYLINDER STROKE ADJUSTMENT (F41 STINGER) ...................................120

ADJUSTING THE FREE ROTATION OF THE SPOUT ......................................................................121

ROTATION MOTOR ADJUSTMENT (F41 STINGER) .......................................................................122

FEED ROLL STOPPING SYSTEM ....................................................................................................123

FAN BELT TENSION .........................................................................................................................124

FAN AND TRANSMISSION BELT REPLACEMENT ..........................................................................124

CORN CRACKER BELT TENSION ....................................................................................................125

CORN CRACKER BELT REPLACEMENT .........................................................................................126

TRANSMISSION BOX BELTS ............................................................................................................127

REVERSE, NEUTRAL AND FORWARD SPEEDS POSITIONS ........................................................127

ANGLE DRIVE TRANSMISSION BOX SHEAVE ...............................................................................128

FAN ADJUSTMENT ...........................................................................................................................129

KNIFE ADJUSTMENT ........................................................................................................................131

KNIFE GRINDING ..............................................................................................................................132

KNIFE REPLACEMENT .....................................................................................................................134

KNIVES & SHEAR BAR GENERAL INFORMATION..........................................................................134

SHEAR BAR ADJUSTMENT ..............................................................................................................135

DAILY ADJUSTMENT (AFTER KNIVES HAVE BEEN GROUND)......................................................135

REPLACEMENT AND INITIAL ADJUSTMENT OF THE SHEAR BAR .............................................136

CUTTING LENGTH SELECTION .......................................................................................................137

PROCEDURE FOR CHANGING THE CUTTING LENGTH ...............................................................138

PROCEDURE TO INCREASE THE FORAGE HARVESTER’S FEEDING SPEED BY 33% .............139

SMOOTH FEED ROLL CLEANER ADJUSTMENT.............................................................................140

MAINTENANCE PROCEDURE FOR THE CUTTER HEAD BOTTOM PLATE ASSEMBLY ..............141

MAINTENANCE PROCEDURE FOR THE FAN BOTTOM PLATE ASSEMBLY .................................142

CORN CRACKER SHEAVE ALIGNMENT .........................................................................................144

CORN CRACKER Q.D. BUSHINGS ..................................................................................................155

CORN CRACKER LOWER ROLL BEARINGS ...................................................................................145

CORN CRACKER UPPER ROLL BEARINGS ...................................................................................147

CORN CRACKER LOWER ROLL HALF BOTTOM PLATE ...............................................................149

CORN CRACKER ROLL SCRAPER .................................................................................................151

UPPER CORN CRACKER ROLL “ZERO” POSITION ADJUSTMENT .............................................152

UPPER CRACKER ROLL PRESSURE AND GAP ADJUSTMENT ....................................................153

CORN CRACKER INITIAL START UP ADJUSTMENT ......................................................................154

LIFTING THE ATTACHMENT .............................................................................................................154

LIFTING ARMS ..................................................................................................................................154

STONE CARRIAGE ADJUSTMENT ...................................................................................................155

STONE REPLACEMENT....................................................................................................................155

CUTTER HEAD SENSOR ADJUSTMENT..........................................................................................156

FEED ROLL SHAFT SENSOR ADJUSTMENT...................................................................................156

PTO FRICTION CLUTCH ADJUSTMENT (OPTION) .........................................................................157

VENTING THE CLUTCH.....................................................................................................................158

CLUTCH DISMANTLING PROCEDURE ............................................................................................159

CLUTCH ASSEMBLING PROCEDURE..............................................................................................160

CLUTCH TORQUE SETTING ............................................................................................................161

TRANSMISSION CLUTCH LEVER POSITION SENSOR .................................................................162

DISASSEMBLING AND ASSEMBLING THE RADIAL PIN CLUTCH (TORQUE LIMITER)................163

AT THE END OF THE SEASON, IT IS RECOENDED TO PROCEED AS FOLLOWS:......................167

METAL DETECTOR DIAGNOSTIC SHORT PROCEDURE..................................................... 168

«LED» DISPLAY ON METAL DETECTOR............................................................................... 169

JUMPER POSITION ................................................................................................................. 169

TROUBLESHOOTING.............................................................................................................. 170

TABLE OF CONTENTS

Manual No. F4117E987E V1.1

7

Specications and design are subject to change without notice

and without liability therefore.

WEIGHT (with 1100X16 tires)

with metal detector .................................................................................... 5280 lbs (2400 Kg)

without metal detector ............................................................................... 5230 lbs (2380 Kg)

DIMENSIONS

Overall width

With 31x13.50 - 15 Terra Rib tires. 142” (361cm) - Narrow tandem 130” (330 cm)

With 31x15.50 - 15 Terra Grip tires 150” (381cm) - Narrow tandem 138” (350 cm)

Length..........................................................................................................228” (579 cm)

Height ..........................................................................................................129” (328 cm)

Minimum height - F41 Stinger ....................................................................120” (305 cm)

Maximum height - F41 Stinger ....................................................................222” (565 cm)

Spout turning radius - F41 Stinger...............................................................200” (508 cm)

ANGLE DRIVE TRANSMISSION

540 or 1000 RPM (buyer’s choice)

MAIN TRANSMISSION

3 speed transmission with overload clutch

3 lengths of cut

OPERATING CAPACITY

540 RPM to 730 RPM - 90 to 135 HP

1000 RPM to 815 RPM - 90 to 180 HP

1000 RPM to 1033 RPM - 160 to 300 HP

ELECTRICAL CONTROLS

Transmission

Spout (230˚ rotation)

Deector

CUTTER HEAD

12 helicoidal knives (or 8 knives - buyer’s choice)

24” (61 cm) wide

22” (56 cm) diameter

speed: 815 or 1033 RPM

SINGLE TIRES AND WHEELS

1100 X 16 - 8 ply DYNA RIB

16.5 X 16.1 - 8 ply DYNA RIB

TANDEM TIRES AND WHEELS

31x13.50 - 15 Terra Rib

31x15.50 - 15 Hippo

29x10.5-15 - Trac Chief

SPECIFICATIONS

Manual No. F4117E987E V1.1

8

Specications and design are subject to change without notice

and without liability therefore.

STANDARD EQUIPMENT

Hydraulic lift control

Hydraulic tongue control

Cutting edges of the cylinder knives with tungsten carbide treatment

Built-in grinder

Transmission, spout and deector electrical controls

Double sprocket wheel for lengths of cut: 26 teeth for 3/8” (9.5 ) standard upon delivery

and 34 teeth for 1/2” (13 )

Shear bar adjustment on one side

F41: 240orotation spout

F41 Stinger: 310orotation spout

OPTIONAL EQUIPMENT

8 or 12 knife cutter head

Metal detector (standard on F41 Stinger model)

Spout extension (12” or 24”) (30 or 60 cm) (F41 model only)

Single wheels or tandem wheels

Double sprocket wheels for lengths of cut: 17 teeth for 1/4” (6.35 )

Deector light

Inspection light

Manual (cord) quick-disconnect hitch

Electrical heavy-duty quick-disconnect hitch (N/A on F41 Stinger model)

Liquid incorporation system

Extra tank for liquid incorporation system

Recuperation grain pan

Recuter bar (for corn only)

Corn Cracker

Draw Bar Hooker

Draw Bar Extension

Detection system for safety bolt breakage

System to increase Forage Harvester’s feeding speed by 33%

OIL CAPACITY

Angle drive transmission: 1.8 imperial gallons - 2.0 US gallons - 8 liters

Main transmission: 0.88 imperial gallon - 1.1 US gallons - 4 liters

SPECIFICATIONS

Manual No. F4117E987E V1.1

9

For your convenience, write down in full in this manual both the model and serial numbers of your ma-

chine, as shown on the name plate illustrated below. Always mention both the model and the serial num-

bers when ordering parts or regarding any other correspondence referring to your machine.

Write down your number here:

MODEL NO. SERIAL NUMBER

SERIAL NUMBER LOCATION

MADE IN CANADA

DION-AG INC.

BOISBRIAND QUE.

MODEL NO.

SERIAL NO.

Dion-Ag Inc.

DFE

MADEIN CANADA

D.F.E.INC.

BOISBRIANDQUE.

MODELNO.

SERIALNO.

PAR/BY

REAR

RIGHT

LEFT

FRONT

Manual No. F4117E987E V1.1

10

PRE-SEASON CHECKS

Check condition of knives and shearbar. Check that knives and shearbar are set at zero

clearance.

Check tension of belts and chains. Make sure sheaves and sprockets are correctly

aligned.

Check all adjustable components for correct setting. Make sure adjustments are

correctly done (fan, etc)

Check tire pressure. See specications.

Check wheel rim bolt torque. See Specications.

Perform complete lubrication and servicing of the machine. Make sure all grease ttings

are in place and taking grease properly. Check gearbox and transmission uid levels.

Look for loose or missing bolts and parts.

Run the machine in a stationary position at half-speed for a short period of time.

Shut off tractor engine. Make sure all moving parts have stopped, then inspect

bearings for over-heating, excessive wear, or loose anges and lock collars.

Check metal detection system for proper operation (if installed on machine). Always

service metal detector when tractor engine is switched off.

Make sure the proper operating adjustments have been made for current crop

conditions.

Make sure SMV emblem (Slow Moving Vehicle) is in good condition and visible.

Make sure all safety shields are installed. Review Safety Precautions.

Check parts for wear (paddles, fan bottom, spout liner, etc.).

CHECK LIST

Manual No. F4117E987E V1.1

11

DAILY CHECKS

Check metal detection system. Always check metal detector system after tractor

engine has been shut off.

Remove all crop residue and wipe off oil and dirt.

Lubricate and service the machine according to the Servicing section.

Check tension of belts and chains. Check all sheaves and sprockets for correct

alignment.

Check tire pressure. See Specications.

Make sure harvester is hooked to tractor correctly, and that the safety chain is

safely installed. Make sure all controls are operable.

Sharpen knives and adjust shearbar once or twice a day.

CHECK LIST

Manual No. F4117E987E V1.1

12

TO OUR CUSTOMER

The following pages and illustrations are printed to help

supply you with the knowledge to better operate and

service your Dion Forage Harvester.

Any piece of equipment needs, and must have a cer-

tain amount of service and maintenance to keep it in

top running condition. We have attempted to cover all

the adjustments required to t most conditions; however,

there may be times when special care must be taken to

t a condition.

Study this operator’s manual carefully and become ac-

quainted with all the adjustments and operating proce-

dures before attempting to operate your new equipment.

Remember, it is a machine and it has been designed and

tested to do an efcient job in most operating conditions

and will perform in relation to the service it receives.

If special attention is required for some conditions, ask

your Dion Dealer; its Parts and Service department will

be glad to help and answer any questions on the opera-

tion and service of your new machine.

THIS MANUAL SHOULD REMAIN WITH THE

MACHINE WHEN SOLD

This manual was prepared from the latest product in-

formation available at publication time. The Company

reserves the right to make changes at any time without

notice.

The Safety section of your Operator’s manual is intend-

ed to point out some of the basic safety situations which

may be encountered during the normal operation and

maintenance of your Forage Harvester, and to suggest

possible ways of dealing with these situations. This sec-

tion is NOT a replacement for other safety practices fea-

tured in other sections of this book.

WARRANTY INFORMATION

The warranty for this machine is located at the beginning

of this manual.

If the Forage Harvester is used with an attachment from

another manufacturer, the warranty is limited to the For-

age Harvester.

You, the equipment purchaser, shall assume charges for

service calls or transportation of equipment to and from

the location of servicing Dion dealer.

WARRANTY ON THE METAL DETECTOR

Because of its limitations, the metal detector cannot

and must not be expected to be a full proof device.

WARRANTY COVERAGE DOES NOT EXTEND TO

CONSEQUENTIAL DAMAGES.

SAFETY

The safety of the operator is one of the main concerns in

designing and developing a new Forage

Harvester. Designers build in as many safety features

as possible. However, every year accidents occur which

could have been avoided by a few seconds thought and

a more careful approach to handling farm machinery

and implements.

Read and implement the safety instructions detailed in

the safety section of this manual.

FOREWORD

Manual No. F4117E987E V1.1

13

SAFETY ALERT SYMBOL

The symbol above calls your attention to instructions concerning

your personal safety. It is found throughout the manual as well as

on the machine to point out specic hazards and ways to avoid

them. Always follow the instructions to minimize the risk of per-

sonal injury or death.

DANGER, WARNING AND CAUTION

Whenever you see the words and symbols shown below, used in

this manual and on decals, you MUST take note of their instruc-

tions as they relate to personal safety.

DANGER: This symbol together with the word

DANGER indicates an iinently hazardous situa-

tion that, if not avoided, will result in DEATH OR

VERY SERIOUS INJURY.

WARNING: This symbol together with the word

WARNING indicates a potentially hazardous situ-

ation that, if not avoided, could result in DEATH

OR SERIOUS INJURY.

CAUTION: This symbol together with the word

CAUTION is used to indicate a potentially hazard-

ous situation that, if not avoided, may result in

MINOR INJURY.

IMPORTANT: The word IMPORTANT is used to identify spe-

cial instructions or procedure which, if not strictly observed,

could result in damage to, or destruction of the machine, pro-

cess or its surroundings.

NOTE: The word NOTE is used to indicate points of particular

interest for a more efcient and convenient service and operation

of the machine.

DECALS:

WARNING: DO NOT remove or obscure Danger,

Warning, Caution or Instruction Decals that are

not readable or are missing. Replacement decals

are available from your Dealer in the event of loss

or damage. The actual location of these Safety

Decals is illustrated on page 17.

FOLLOW A SAFETY PROGRAM

For safe operation of a Forage Harvester, you must be a quali-

ed and authorized operator. To be qualied, you must read and

understand the written instructions supplied in this Operator’s

Manual, have training, and know the safety rules and regulations

for the job.

Some regulations specify that no one under the age of 16 years,

for example, may operate power machinery. This includes trac-

tors. It is your responsibility to know what these regulations are,

and obey them, in the operating area or situation.

These will include, but are not limited to, the following instructions

for proper operation:

WARNING: An operator should not use alcohol or

drugs which can change his alertness or coordi-

nation. An operator on prescription or “over the

counter” drugs needs medical advice on whether

or not he or she can operate machines

A WORD TO THE OPERATOR

It is YOUR responsibility to read and understand the safety sec-

tion in this manual before operating your tractor. You must follow

these safety instructions that take you step by step through your

working day.

In reading this section, you will note that illustrations have

been used to highlight certain situations. Each illustration

is numbered and the same number appears in the text in

parenthesis.

Remember that YOU are the key to safety. Good safety practices

not only protect you, but also the people around you. Study the

features in this manual and make them a working part of your

safety program.

Think SAFETY! Work SAFELY.

WARNING: In some of the illustrations used in

this Operator Instruction Book, panels or guards

may have been removed for clarity. Never oper-

ate the machine without these components in

position. If the removal of panels or guards is

necessary to make a repair, they MUST be re-

placed before operation.

SAFETY RULES

Manual No. F4117E987E V1.1

14

•

Disengage the PTO and shut off engine before leav-

ing the operator’s seat for refueling, lubricating or ad-

justing the machine.

•Always use a hitch pin large enough for the load to

be transported with a safety lock between the tractor

and the Forage Harvester and between the Forage

Harvester and the Forage Box, anytime the machine

is moved.

•The tractor engine ignition key must be removed

each time the operator leaves the tractor.

•Wear appropriate clothing, safety boots or shoes. Do

not operate the machine when visibility is bad, or dur-

ing night, in poor lighting.

•When driving on a public road, or on hilly land you

must remove the electrical box ignition key and put

the locking pin in the stop pawl of the quick-dis-

connect hitch to prevent unlocking. This locking pin

should also be used for the manual quick-disconnect

hitch.

•Attach a safety chain of at least 20,000 lbs (9071 Kg)

capacity for transportation.

•On F41 Stinger models, deactivate the spout hy-

draulic circuit and close the safety valve for road

transportation.

•Never hook a loaded trailer behind a Forage Harvest-

er when travelling on public roads.

•Keep children away from the machine at all times.

Maximum traveling speed of a forage harvester

should not exceed 20 mph (34 km/h).

•Carefully read all safety signs applied on the ma-

chine. If they are damaged, replace them iediately.

•If a feeding or throwing mechanism should become

jaed, never attempt to unblock it or remove any ma-

terial when the machine is in motion or the tractor

engine running.

• Never manually feed the Forage Harvester.

•When making a metal detection test, stop the PTO

and the tractor engine, then wait until all mobile parts

are stopped.

•Never operate a Forage Harvester without rst hav-

ing installed an attachment.

•Never remove guards or make adjustments while the

machine or tractor engine is running.

•Never attempt to check or adjust chains while the ma-

chine is running.

•Make sure all rotating parts are stopped and the trac-

tor engine is turned off before cleaning the machine

throat.

•Never park the Forage Harvester in its transport posi-

tion. Lower the attachment to the ground rst.

•Before starting the tractor engine, make sure all

guards, shields, and doors are in place and properly

secured and check the machine thoroughly for pos-

sible loose parts or bolts and tighten them.

•When knives are being readjusted, a piece of wood

should be used to iobilize the cutting head.

•Never stand underneath the forage harvester de-

ector or forage path when the machine is running.

Put the discharge toward the forage box.

•Always pick-up tools after performing any adjust-

ment.

• Never allow riders on any part of a machine.

•Block elevated components before servicing equip-

ment.

•Do not unhook a farm wagon when the land is slop-

ping down, or service the machine without rst

blocking wheels.

•Never lubricate or clean any part while the machine

or tractor engine is running.

•Keep hands and body out of hitch area when attach-

ing towing vehicle.

WARNING: Hydraulic uid under pressure can pen-

etrate the skin or eyes and cause serious personal

injury, blindness or death. Fluid leaks, under pres-

sure, may not be visible. Use a piece of cardboard

or wood to nd leaks. DO NOT use your bare hand.

Wear gloves and safety goggles for eye protection.

If any uid is injected into the skin, it MUST be sur-

gically removed within a few hours by a doctor fa-

miliar with this type of injury.

•Securely block the wheels from moving before work-

ing on or under the machine.

•Use a lift system with a minimum capacity of 2000 lbs

(900 kg) to install a Corn Attachment on the

Forage

Harvester.

•Make sure that all wheel rim bolts are properly torqued.

•Make sure to meet local regulations for excessive

width on public roads.

SAFETY RULES

Manual No. F4117E987E V1.1

15

SAFETY RULES

PTO OPERATION

•POWER-TAKE-OFF DRIVE - Before starting the

tractor engine, make sure that the PTO driveline

locking device is properly engaged onto both the

tractor and equipment drive shafts. Secure the safe-

ty chain to the tractor frame.

•Never wear loose clothing and keep people, espe-

cially children away from the driveline.

•Do not hook a tractor with a PTO speed of 1000

RPM on a machine equipped with a 540 RPM drive

or a tractor with a PTO speed of 540 RPM on a ma-

chine equipped with a 1000 RPM drive.

•Never proceed to the starting of the machine be-

fore making sure all driveline, machine and tractor

shields are well installed in place

•The PTO driveline shields should turn freely, be well

connected and kept in good condition.

• Never step across any PTO driveline.

• Never use the PTO driveline as a step.

•Keep a good distance away from a rotating driveline

(approximately the distance equal to your height).

MANDATORY STOPPING PROCEDURE

No matter what type of machine is being used, it is ex-

tremely hazardous to perform any kind of maintenance

work while the machine is running. It could lead to seri-

ous injuries or even death. Before cleaning, adjusting or

greasing the machine, the following procedure should

be followed to stop the Forage Harvester:

1. Place the transmission in neutral.

2. Disengage the tractor power-take-off (PTO).

3. Turn OFF the metal detector.

4. Switch off the tractor engine.

5. Engage the tractor parking brake.

6. Wait until all rotating parts have completely

stopped.

7. Remove the PTO from the tractor output shaft.

8. Block all equipment wheels.

WARNING: Rotating driveline contact may cause

serious injury or death.

Manual No. F4117E987E V1.1

16

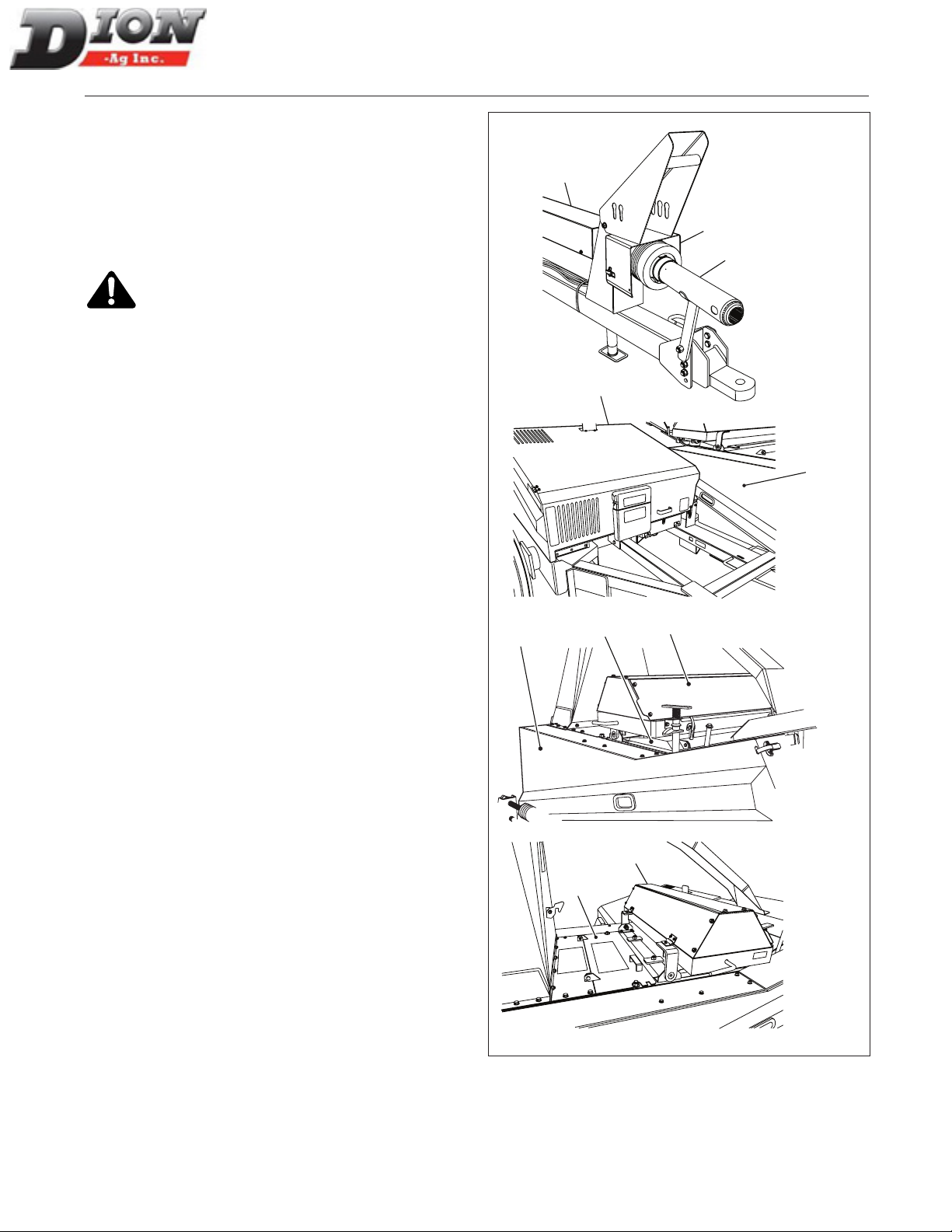

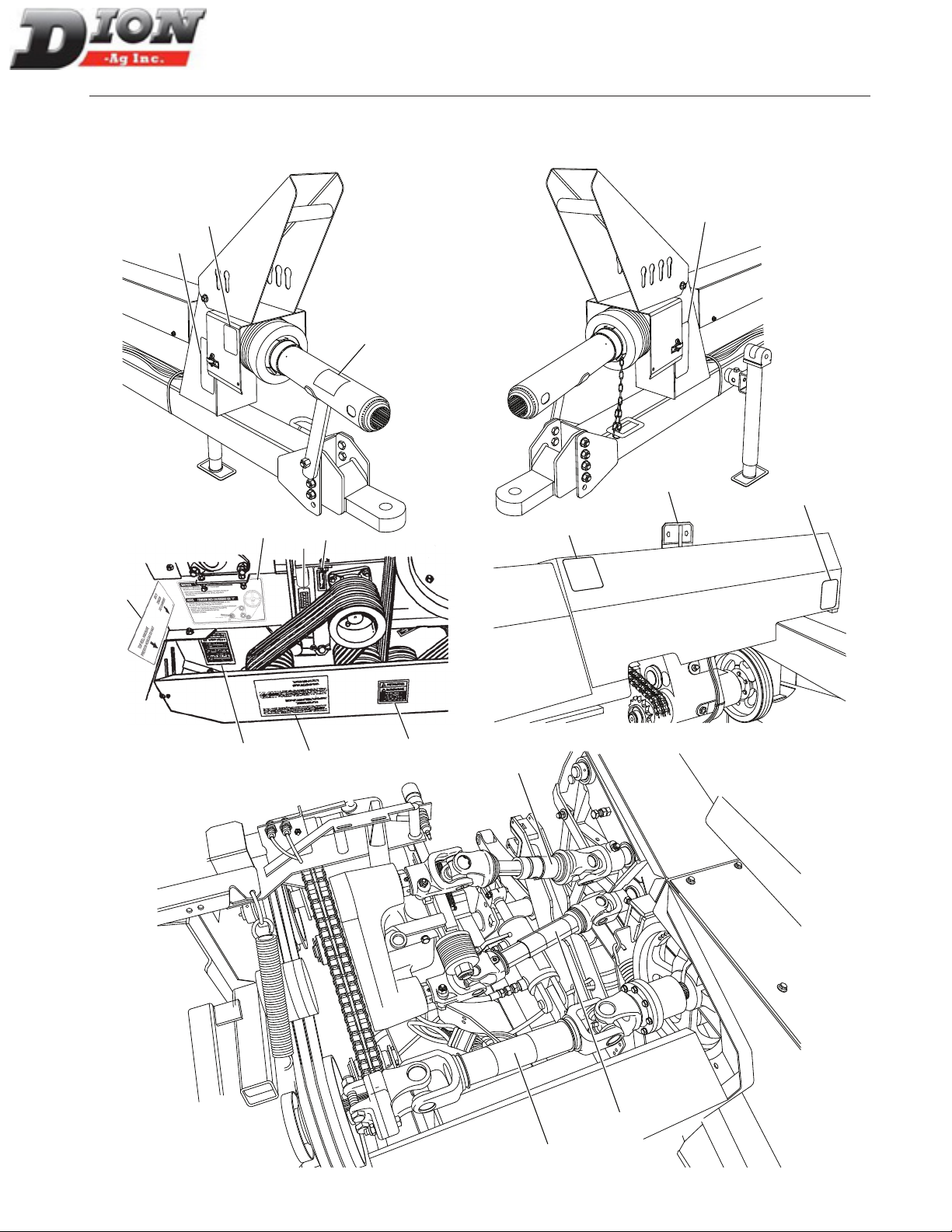

GUARDS AND SHIELDS - FIGURE 1

The Forage Harvester is equipped with guards and

shields wherever eventual accidents can occur. These

guards and shields do not keep the machine from oper-

ating properly. Observe various safety signs indicating

these hazardous locations that are properly applied to

the machine.

CAUTION: All guards and shields factory in-

stalled should be in place and maintained in good

condition.

Item 1 A bolted guard covers the transmission shaft (on

its full length) from the front bearing up to the an-

gle drive transmission.

Item 2 A hinged guard covers the universal joints.

Item 3 The telescopic driveline which attaches to the

tractor PTO is covered with a non-rotating shield.

Item 4 An hinged guard covers the tool box, the transmis-

sion shaft between the angle drive transmission

and the cutting head, the driving belts for the for-

ward-neutral-reverse transmission and the driving

system for the feeding rolls and the attachments.

Item 5 An hinged guard covers the 4 blowing fan riving

belts.

Item 6 An hinged guard covers the corn cracker roll belts

and the front feeding roll drive system belts.

Item 7 An hinged guard covers the sharpening system.

Item 8 An hinged guard covers the cutter head.

Item 9 An hinged guard covers the fan.

1

3

2

4

5

6

9

7

7

8

Figure 1 Guards and shields

SAFETY RULES

Manual No. F4117E987E V1.1

17

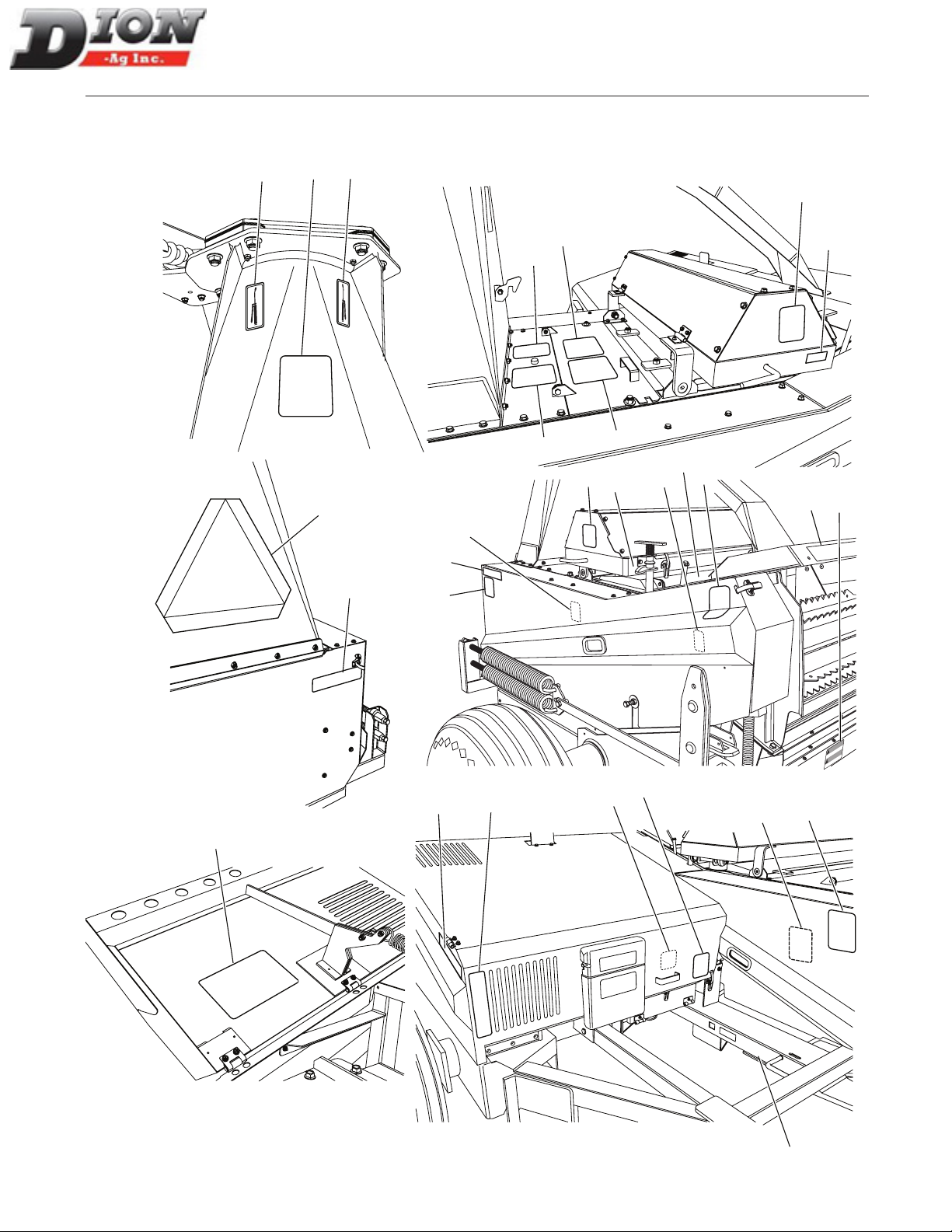

SAFETY SIGN LOCATION

IMPORTANT: Decals must be kept clean to allow easy reading at all times.

Manual No. F4117E987E V1.1

18

SAFETY SIGN LOCATION

IMPORTANT: Decals must be kept clean to allow easy reading at all times.

Manual No. F4117E987E V1.1

19

SAFETY SIGN LOCATION

IMPORTANT: Decals must be kept clean to allow easy reading at all times.

3A

3B

17

11 42

1

16

16

23

15 4

4

4

16

28 27 4

30-31

22

2

17

18

18

6

18

28

27

29

16

1000

CAUTION

AVERTISSEMENT

FOR CORN ONLY

POUR MAÏS SEULEMENT

F41-30751P

Manual No. F4117E987E V1.1

20

SAFETY SIGN LOCATION

14

7

15

24

35

16 26 4

32

8

4

20

12

12

12

12-13

4

IMPORTANT: Decals must be kept clean to allow easy reading at all times.

Manual No. F4117E987E V1.1

Other manuals for F41

1

This manual suits for next models

1

Table of contents

Other Dion-Ag Farm Equipment manuals

Popular Farm Equipment manuals by other brands

VENCE TUDO

VENCE TUDO PREMIUM 10000 manual

MacDon

MacDon M155 Unloading and assembly instructions

Swine Robotics

Swine Robotics Boar Bot owner's manual

Wiedenmann

Wiedenmann Terra Clean 100 Translation of original operating instructions

Birth Alarm

Birth Alarm Mobile Lite user manual

cormidi

cormidi C85 Series manual

Yetter

Yetter 2967-180B OPERATOR'S / INSTRUCTION MANUAL W/ PARTS IDENTIFICATION

ETB

ETB Pegasus user guide

Art's-Way Manufacturing

Art's-Way Manufacturing 6812A Operator's manual

Brinsea

Brinsea Chick Safe eco Installation and operating instructions

RITEWAY

RITEWAY HH-8200NT Operator's manual

Chapman

Chapman AH200 instructions