7.4 LUBRICATION .............................................................................................................................................................................. 39

7.5 ENGINE MAINTENANCE............................................................................................................................................................... 40

7.5.1 Engine Oil and Filter ................................................................................................................................................... 40

7.5.2 Fuel System.................................................................................................................................................................... 41

7.5.3 DEF Filters ...................................................................................................................................................................... 41

7.5.4 Cooling System ............................................................................................................................................................. 41

7.5.5 Engine Air Intake .......................................................................................................................................................... 41

7.6 TRANSMISSION MAINTENANCE .................................................................................................................................................. 42

7.6.1 Checking Transmission Fluid Level ....................................................................................................................... 42

7.6.1.1 Fluid Level Check Using Dipstick Method........................................................................................................ 42

7.6.1.2 Fluid Level Check Using the Electronic Shift Selector Method ................................................................ 44

7.7 TRANSFER CASE MAINTENANCE ................................................................................................................................................ 46

7.8 AXLES .......................................................................................................................................................................................... 46

7.8.1 King Pins ......................................................................................................................................................................... 46

7.8.2 Tie Rod............................................................................................................................................................................. 46

7.8.3 Planetary and Differential......................................................................................................................................... 46

7.9 SUSPENSION MAINTENANCE...................................................................................................................................................... 47

7.10 STEERING SYSTEM MAINTENANCE .......................................................................................................................................... 47

7.11 PNEUMATIC SYSTEM ................................................................................................................................................................ 47

7.12 TIRES......................................................................................................................................................................................... 47

7.12.1 Tire Replacement....................................................................................................................................................... 47

7.12.2 Wheel Torque Specifications ................................................................................................................................. 48

7.13 CAB MAINTENANCE.................................................................................................................................................................. 48

7.13.1 Cabin Air Filter............................................................................................................................................................ 48

7.13.2 Cabin Pressurizer Air Filter..................................................................................................................................... 48

7.13.3 Lights and Beacon ..................................................................................................................................................... 49

7.14 HVAC MAINTENANCE.............................................................................................................................................................. 49

7.15 BATTERY MAINTENANCE.......................................................................................................................................................... 49

7.16 HYDRAULIC SYSTEM MAINTENANCE....................................................................................................................................... 49

7.17 POWDERCOAT FINISH MAINTENANCE..................................................................................................................................... 50

8. TRANSPORTING ............................................................................................................................................................................ 50

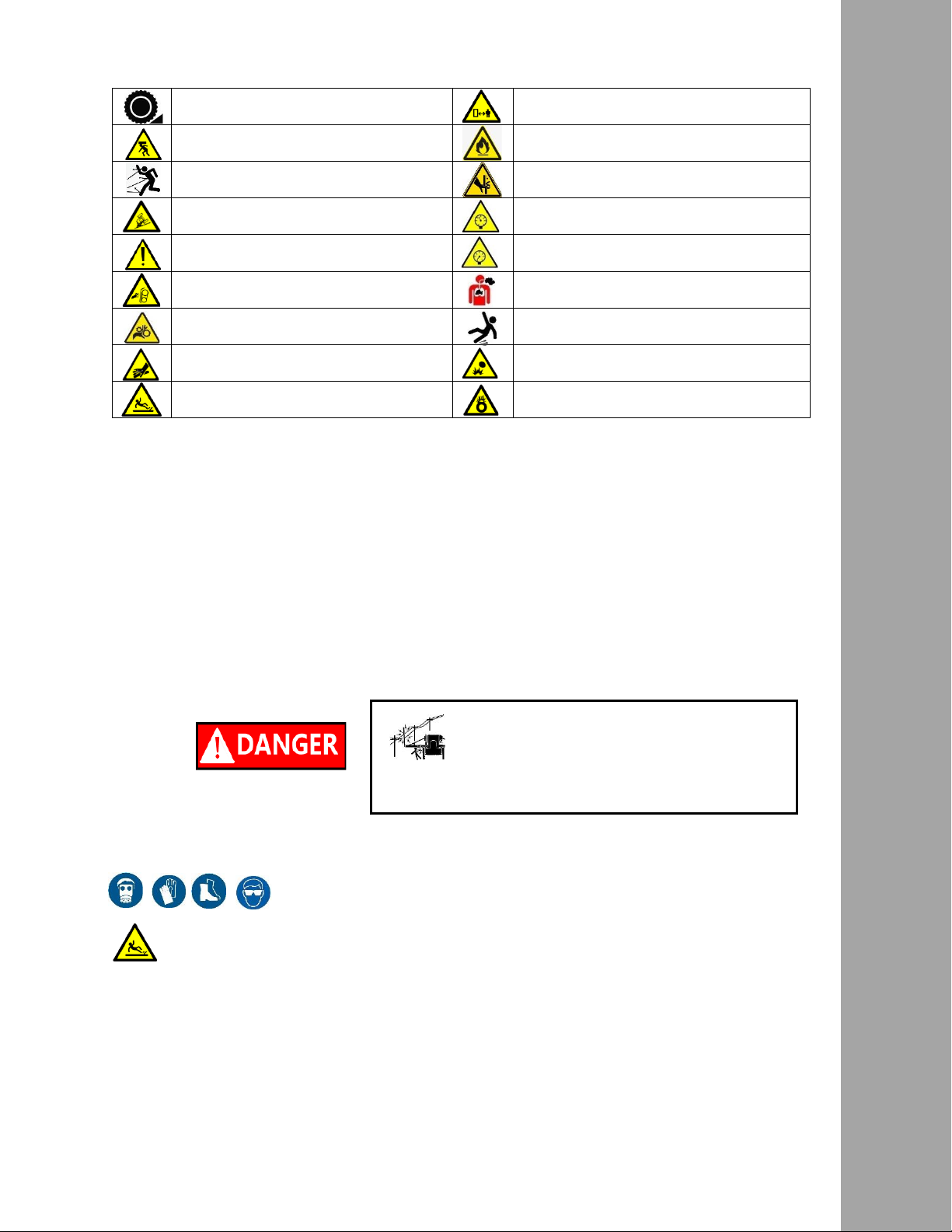

8.1TRANSPORTING SAFETY ............................................................................................................................................................. 51

8.2 BYSTANDERS………………………..…………………………………………………………………………………………………………..51

8.3 ROADWAY TRAVEL...................................................................................................................................................................... 51

8.4 TRAILER HAULING....................................................................................................................................................................... 52

9. LONG-TERM STORAGE ............................................................................................................................................................... 52

9.1 SAFETY......................................................................................................................................................................................... 52

9.2 PREPARING FOR STORAGE.......................................................................................................................................................... 53

10. COMPONENT IDENTIFICATION & REORDER INFORMATION ..................................................................................... 54

10.1 CHASSIS COMPONENTS DRAWINGS ........................................................................................................................................ 54

10.1.1 Engine & Transmission ........................................................................................................................................... 54

10.1.2 Engine & Transmission ........................................................................................................................................... 54

10.1.3 Engine Cooling & CAC Hoses................................................................................................................................ 55

10.1.4 Cooling Package......................................................................................................................................................... 55