Direct Connection RC Eclipse Manual

Page | 1

©Direct Connection RC

Eclipse Build Manual

Thank-you for your purchase of the new Eclipse kit, the following instructions are meant

to guide you in assembling your plane.

Advanced builders may find they need to make slight deviations in order to better suite

their abilities and desired plane outcome.

As always due to the type of wood used slight bends or warping to the wood may occur

but should not affect the overall structure.

**This manual contains instructions for both electric and glow type builds. **

Page | 2

©Direct Connection RC

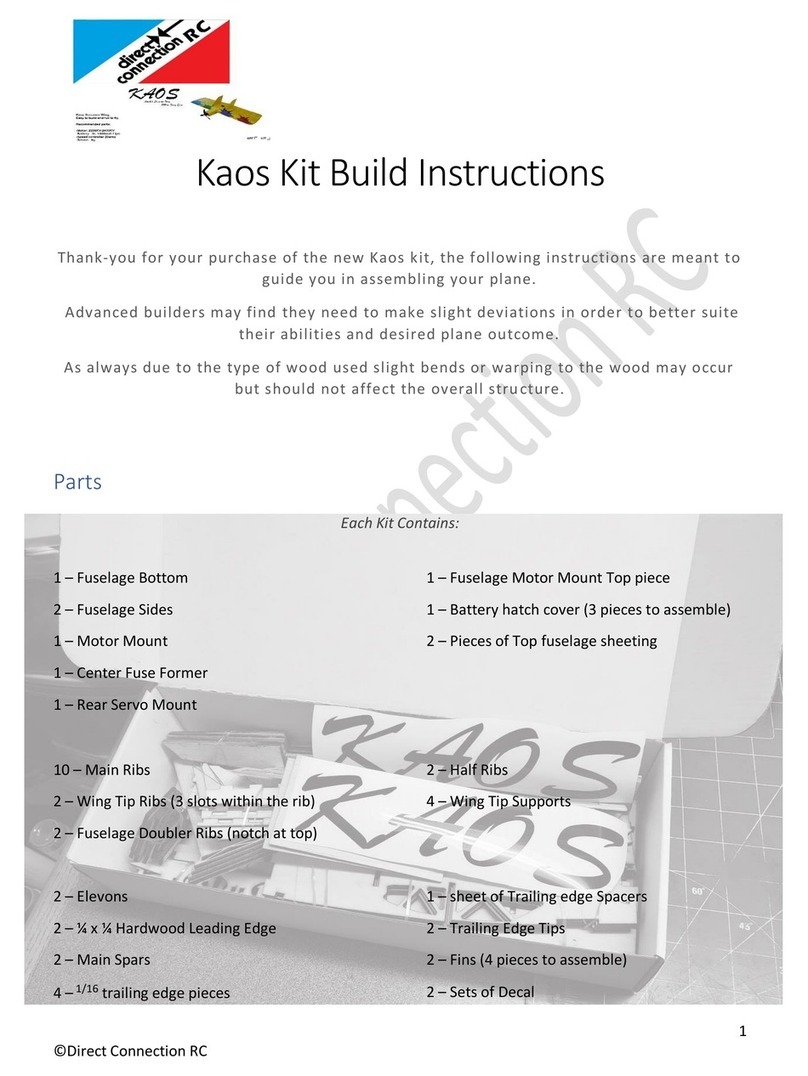

Parts

•Leading Edge (2pcs)

•Battery Cover (3pcs)

•Fuselage bottom, left and right sides

(3pcs)

•Fin Triangles (2pcs)

•Elevons (2pcs)

•Main Spar (2pcs)

•Main Spar Brace (1pc)

•Wing tips (2pcs)

•Trailing edge; top and bottom (4pcs)

•Rib Set; Numbered 1 –7 (14pcs)

•Motor Mount (4pc)

•Center fuse former (1pc)

•Servo Tray Mount (1pc)

•Throttle Servo Mount Box Top (1pc)

•Throttle Servo Standoffs (6pcs)

•Leading edge Wing sheeting (4pcs)

•Trailing Edge Spacers (12pcs)

•Trailing edge wing tips (2pcs)

•Top wing sheeting (2pcs)

•Decals (2pcs: Graphic and logo)

Additional Requirements

•CA or Wood Glue

•CA Glue Accelerator (recommended)

•Hobby Square

•Pins

•Sanding Plane/block

•Airplane covering & necessary items to adhere

•Epoxy

Recommended Parts

•3S 2200mah Battery

•Turnigy SK3546-1400 408 watts 1500kv motor

For Glow a .15 or .25 Glow Engine

•HS85mg or HS82mg Servos

•Speed controller; 40-50amp ESC 2-4S cell

•Dubro hinges

•8x8 APC electric prop or a 9x6 Glow rated prop

•Glow Use - 120CC tank; 3 ½” x 2” x 1 ½”

•256 push rods with steel clevises and fuel line to hold the clevises closed.

•Dubro control surface horns

Page | 3

©Direct Connection RC

Pre –Build

1. Align each set of the trailing edge pieces on a flat surface along a long straight edge. Glue

together each of the trailing edge sets at the zig-zag joint using your preferred glue (CA). Allow

to set. This will leave you with a top and bottom piece for the trailing edge. Set aside.

2. Lay the two main spar pieces flat, aligning along a straight edge. Recommended keeping the slot

end up and using small weights to keep the spar as flat as possible. Glue together the two main

spar pieces at the zig-zag joint using your preferred glue (CA); allow to set. Set aside.

Page | 4

©Direct Connection RC

3. Assemble the 3 pieces of the battery cover. Glue and allow to set. Set aside.

4. Ensure you have a complete rib set with 2 ribs numbered 1 through 7.

Page | 5

©Direct Connection RC

Build

1. Place the fuselage bottom on a flat surface. Identify the left (top circle; longer tab) and right

(bottom circle; shorter tab) sides of the fuselage; a thrust angle is built into the fuselage.

Page | 6

©Direct Connection RC

2. Identify the two fuse formers; F1 center fuse former (electric planes) and F2 fuse former (glow

planes). Note the top and bottom of the formers as shown.

3. Option 1 Electric Plane:

Set the left and right fuselage sides upright inserting the F1 center fuse former; the F2 fuse

former is NOT required, and may be discarded. All the F1 former tabs should fit snugly inside

the fuselage. Glue the front tabs of the fuselage and the F1 former at this time. Leaving the back

portion of the fuselage open at this time.

F1

F2

Page | 7

©Direct Connection RC

Option 2 Glow Plane:

For a Glow plane discard the F1 center fuse former. Set the left and right fuselage sides upright

and insert the F2 fuse former. The F2 fuse former is designed for a 4oz (120cc) 3 ½” x 2” x 1 ½”

fuel tank application. Ensure the F2 former is aligned appropriately before gluing along with the

front tabs of the fuselage. Leaving the back portion of the fuselage open at this time.

*Ensure the fuel tank is installed BEFORE the fuselage is glued to the wing.

You will want to build your throttle servo mount box. There are 3 sets of throttle servo mount

standoffs provided depending on the height option you desire for the servo. You can run the

throttle servo linkage through the center fuse former and drill your hole in the firewall as

required for your engine throttle linkage.

Page | 8

©Direct Connection RC

Once you have selected your appropriate height, glue the standoff pieces to the top piece and

insert into the fuselage gluing into place as shown. Ensure your fuel tank is secured prior to

installing the throttle servo mount box. We recommend using foam around the fuel tank and

some kind of strap epoxied to the fuselage to hold the fuel tank in place and all other necessary

items.

Page | 9

©Direct Connection RC

4. Identify the 2 motor mount pieces depending on your airplane type; glow or electric. The pre

drilled motor mounts are designed for electric and the solid motor mount pieces are designed

for glow application. In some instances, those with electric planes may wish to use the solid

motor mount pieces when using a custom motor. The extra motor mount pieces can be

discarded or saved for future use if desired.

5. Option 1 Electric Plane:

Insert the two pre-drilled motor mounts (or customed motor mounts) these will be stacked

against one another and should be epoxied and allowed to set before installing into the

fuselage.

Option 2 Glow Plane:

Using the undrilled motor mount set Epoxy the set together and allow to set before installing

into the fuselage. Once the mounts have set, we recommend you epoxy the mount into the

fuselage prior to drilling your required holes for the engine and throttle cable. You may wish to

take this time to install your blind nuts. You may also wish to brush coat a thin layer of epoxy on

the inside of the fuselage to protect the wood from fuel leaks.

Page | 10

©Direct Connection RC

6. Install the top motor box cover onto the fuselage. We recommend Epoxy.

7. Glue in the rear servo mount tray onto the rear back portion of the fuselage.

Page | 11

©Direct Connection RC

8. Curve the fuselage bottom to the sides, holding firmly and glue to the sides with CA using

accelerant as required. Fuselage should be sanded to allow for covering to adhere later on. Set

the fuselage aside.

9. Set the main spar up on edge with the slots facing up, ensuring the longest edge of the zig zag

joint is on the left-hand side as shown.

Page | 12

©Direct Connection RC

10. Set the main spar brace onto the front of the wing overlapping the zig zag joint before placing

the ribs into the main spar.

Page | 13

©Direct Connection RC

11. Loosely set the ribs (1 - 7) within the main spar. Working from the center at the first main spar

brace slot with ribs #1 out to the edge to ribs #7 on each side. (The 3rd rib is a half rib and is

tucked beside Rib 2 making the numeric non visible in the photo.)

Page | 14

©Direct Connection RC

12. Leave the main spar assembled without glue and push to the side to allow for working room for

the next step.

13. Pin one of the trailing edge sets to the mat or work surface (we’ve used such platforms as ½”

drywall, old ceiling tiles or thick foam board) to keep the pieces as flat as possible. To ensure the

best possible fit make sure the trailing edge piece has the 3 pieced zig zag joint aligning to the

left matching the main spar. Tips* Wax paper or Parchment paper before you pin the wing down

*

Page | 15

©Direct Connection RC

14. Align the main spar and the tail ends of the ribs to the designated spots within the trailing edge.

You may wish to remove the #3 half rib at this time as the proximity to rib #2 can make gluing

difficult. Square the bottom trailing edge to the ribs and pin as necessary.

15. Once everything has been squared and fitment is snug glue each rib (less the half rib at this

time) with CA. Pressing each rib firmly into place while gluing.

Page | 16

©Direct Connection RC

16. Replace both of the rib #3 (half rib) and glue the tail into place as best as possible. All ribs should

be glued to the bottom trailing edge while the center of the ribs remains unglued and loose in

the main spar.

17. This is the best time to insert the trailing edge spacers should be placed and glued flush as

shown. Each trailing edge spacer will have to be cut to size and sanded as required. Trailing edge

spacers provided are sent in a generic size to allow for size differences. There are 12 spacers

provided but only 11 should be required, the trailing spacers are imperative to being able to

ensure you have material to adhere your hinges to.

18. Locate your remaining trailing edge piece. Recheck the fitment for the top trailing edge piece

within the ribs as the zig zag should match the already glued trailing edge piece. Pieces may

require sanding for best fitment. Set the trailing edge aside and place glue (medium CA is

recommended without the use of an accelerator) on the top of each tail piece of the ribs and

the trailing edge spacers. Then insert the top trailing edge piece working from the center

outwards to adhere to the ribs and trailing spacers. You may require weights or additional pins

to hold the top trailing edge in place while the glue sets.

Page | 17

©Direct Connection RC

19. Unpin the plane from the building board.

20. Using CA, glue the main spar brace flush to the main spar. This can be obtained by tilting the

plane up and pushing the brace from the bottom to align with the main spar.

If building for a higher torqued plane than specified a piece of 1”fiberglass cloth may be

wrapped around the main spar joint to provide additional strength, in extreme circumstances.

21. Re-pin the plane to your building board.

Page | 18

©Direct Connection RC

22. Align the head of the ribs within the main spar and ensure each rib is sitting flush within the

spar. Some ribs may require more downward pressure than others to set appropriately. You

may wish to tack glue the ribs to start before adhering with CA or wood glue, using your

accelerator as needed to help the setting process. If the ribs are not sitting flush within the main

spar you will find your sheeting will be affected. Be careful not to add to much glue to rib #1 or

the fuselage may not fit on the inside portion of the ribs. Ribs #5 –7 (see 2nd photo) should be

aligned from the head of the rib to sit flush as the center portion of the main ribs after the spar

will sit slightly above to allow for the sheeting. Allow to set.

23. Unpin the plane from the building board. Turning the plane over glue the backside of the ribs to

the main spar using wood or white glue.

Note Ribs #5 - #7

Page | 19

©Direct Connection RC

24. Test fit the fuselage to the wing. The fuselage cutouts along the sides should align with the main

ribs. You may be required to sand the fuselage again.

25. Place the supplied wing tips into the main spar ends, ensure wing tips are sitting flush before

gluing into place.

Page | 20

©Direct Connection RC

26. With the fuselage Find the two leading edge pieces (¼” x ¼”x16⅝” hardwood) to the plane.

Leading edge pieces provided are slightly longer than required. Cut and sand the two leading

edge pieces to fit your plane accordingly.

27. Add a small amount of glue to the fuselage nose of the rib and the wing tip rib leaving the

center ribs open until fitted. Remove the fuselage.

28. Place the wing back on the building board. You may desire to re-pin the wing to the board. Using

your square to keep the nose of the ribs aligned with the leading edge as you glue each leading-

edge piece down into the ribs.

29. Repeat for both sides of the leading edge; top and bottom of the ribs.

30. Sand the inside pieces of the leading edge where the fuselage will sit.

Table of contents

Other Direct Connection RC Toy manuals

Popular Toy manuals by other brands

Holz-Hoerz

Holz-Hoerz pedalo Catapult user manual

marklin

marklin 37805 user manual

Fisher-Price

Fisher-Price PEEK A BLOCKS J5293 instruction sheet

Fisher-Price

Fisher-Price FPM23 Consumer information

babymoov

babymoov A035220 Instructions for use

Fisher-Price

Fisher-Price ColorMe Gemz Hat Set N1127 instruction sheet

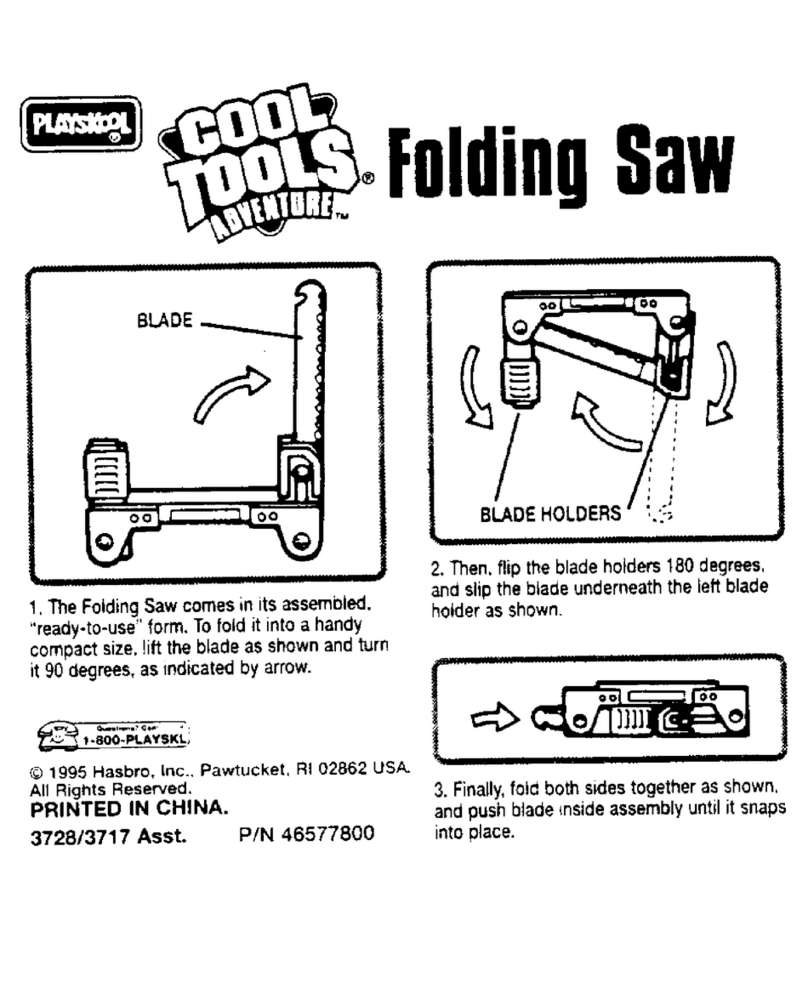

Playskool

Playskool Beddy Bright Ernie instructions

Seagull Models

Seagull Models STEEN SKYBOLT N250SB 15CC Assembly manual

MTHTrains

MTHTrains Premier SD45 Diesel Engine Operator's manual

Hobbico

Hobbico SUPERSTAR EP Assembly instructions

Eduard

Eduard ZOOM P-40E seatbelts STEEL manual

Harbor Freight Tools

Harbor Freight Tools 94737 operating instructions