1 x 5,5 kW for 2 operators Code B100ST – B125ST

Central vacuum cleaner consisting of:

- one silenced SIEMENS turbine with three-phase side

channel motor without transmission, secured on a

metal frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy

powder, secured on a metal frame, filter chamber

equipped with industrial-conceived star filter made of

special polyester cloth with high withholding proper-

ties, deflector for the mechanical-gravitational separa-

tion of dust, dirt receptacle on wheels with disposable

plastic bags and cushioned fasteners, safety and

compensation system in the dust bag, manual filter

shaker;

- electric control box with IP55 safety degree, realized in

accordance with CEI norms, with low-voltage (12 V)

outlet and equipped with electric chart for linkage;

- connections for correct linkage to the piping network

and all other parts and accessories for the profession-

al setting of the system;

- CE certificate.

1 x 2,2 kW for 1 operator Code A100 – A125

Central vacuum cleaner consisting of:

- one silenced SIEMENS turbine with three-phase side

channel motor without transmission, secured on a

metal frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy

powder, secured on a metal frame, filter chamber

equipped with industrial-conceived star filter made of

special polyester cloth with high withholding proper-

ties, deflector for the mechanical-gravitational separa-

tion of dust, dirt receptacle on wheels with disposable

plastic bags and cushioned fasteners, safety and

compensation system in the dust bag, manual filter

shaker;

- electric control box with IP56 safety degree, realized

in accordance with CEI norms, with low-voltage (12 V)

outlet and equipped with electric chart for linkage;

- connections for correct linkage to the piping network

and all other parts and accessories for the profession-

al setting of the system;

- CE certificate.

6

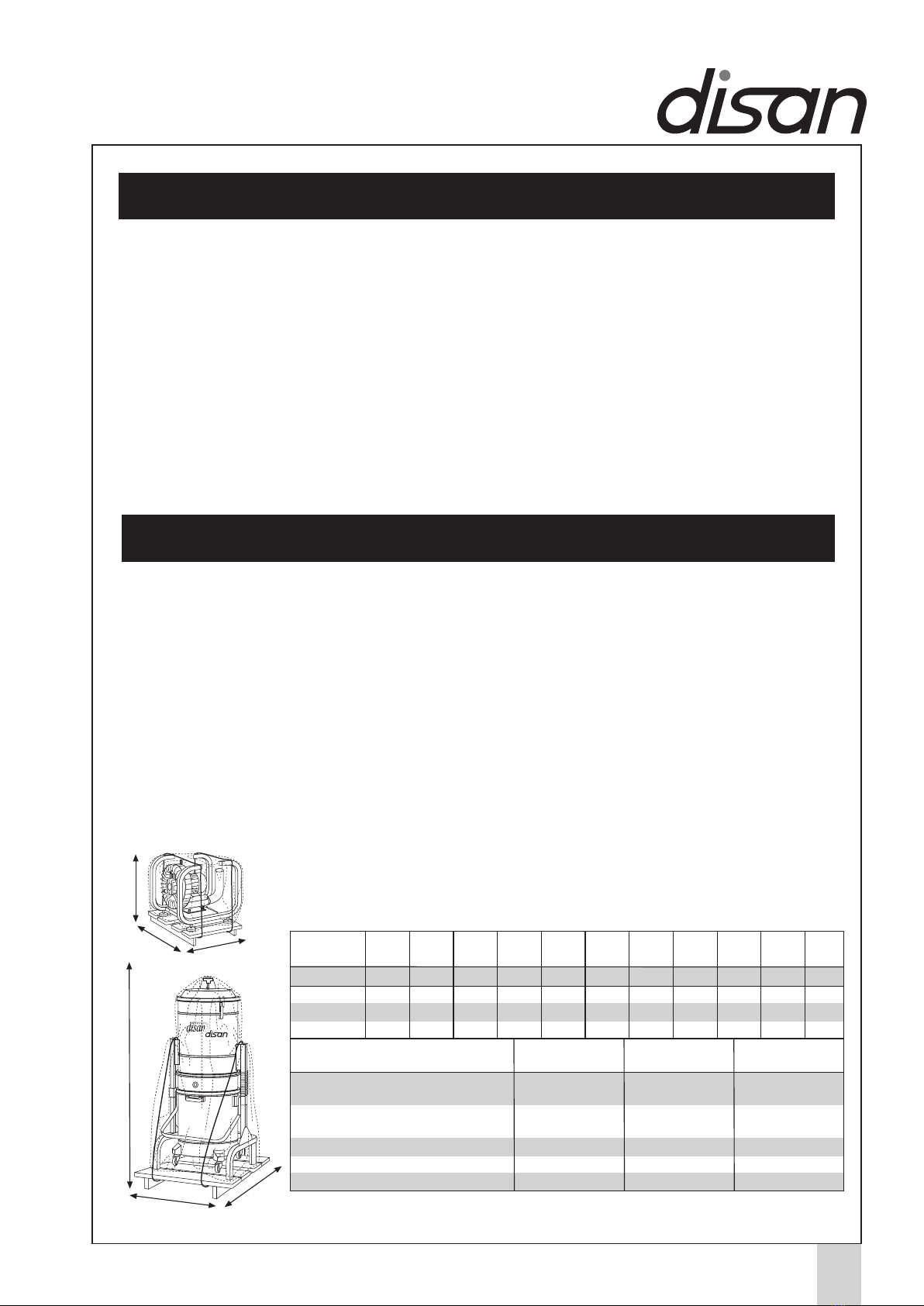

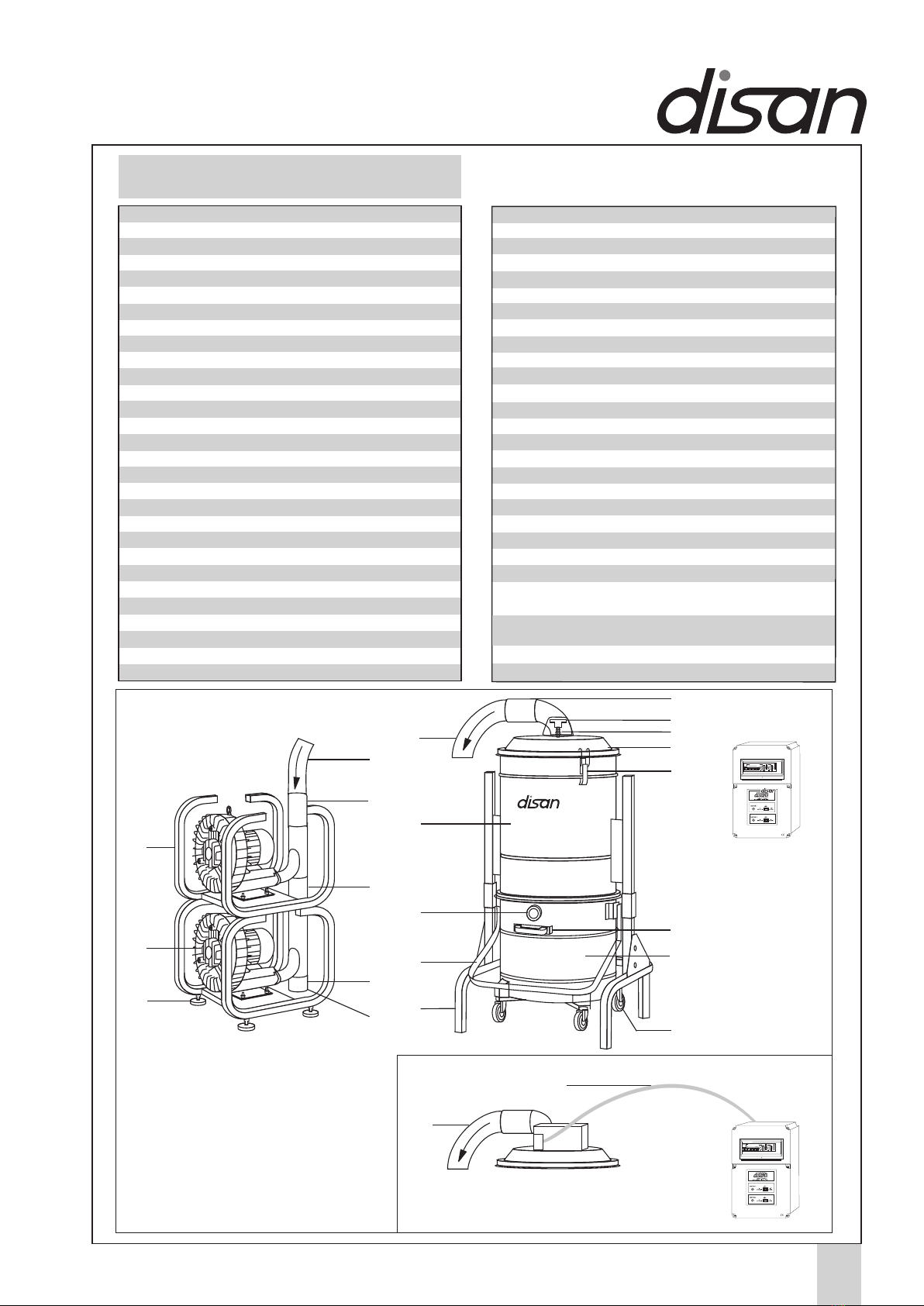

Central Vacuum Systems

CHARACTERISTICS OF THE CENTRAL VACUUM

CLEANER AND MAIN PARTS

Central vacuum cleaner

model DS A01 100l – 125l

Central vacuum cleaner

model DS B01 100 l – 125 l

Central vacuum cleaner

model DS B02 100 l - 125 l

2 x 2,2 kW for 2 operators Code B200 – B225

Central vacuum cleaner consisting of:

- Two silenced SIEMENS turbines with three-phase side

channel motor without transmission, secured on a metal

frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy

powder, secured on a metal frame, filter chamber

equipped with industrial-conceived star filter made of

special polyester cloth with high withholding proper-

ties, deflector for the mechanical-gravitational

separa-

tion of dust, dirt receptacle on wheels with disposable

Central vacuum cleaner

model DS BC 100i

1 x 4,5 kW for 2+1 operators Code BC100i

Central vacuum cleaner consisting of:

- one silenced SIEMENS turbine with three-phase side

channel motor without transmission, secured on a

metal frame;

- electronic inverter for continuous modulation of the

frequency and the other motor parameters with

electromagnetic shielding of type B (for applications

within the private and the industrial sector)

- cyclonic dust separator in steel, painted with epoxy

powder, secured on a metal frame, filter chamber

equipped with industrial-conceived star filter made of

special polyester cloth with high withholding proper-

ties, deflector for the mechanical-gravitational separa-

tion of dust, dirt receptacle on wheels with disposable

plastic bags and cushioned fasteners, safety and

compensation valves, arranged for pressure compen-

sation system in the dust bag;

- automatic self-cleaning filter device through program-

mable shaking device;

- electric control box with IP55 safety degree, realized

in accordance with CEI norms, with low-voltage (12 V)

outlet and equipped with electric chart for linkage;

- Ø70 metal muffler for low noise level;

- connections for correct linkage to the piping network

and all other parts and accessories for the profession-

al setting of the system;

- CE certificate.

+

Central vacuum cleaner

model DS C03 100 l – 125

3 x 2,2 kW for 3 operators Code C100 – C125

Central vacuum cleaner composed of:

- three silenced SIEMENS turbines with three-phase

side channel motor without transmission, secured on

a metal frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy

powder, secured on a metal frame, filter chamber

equipped with industrial-conceived star filter made of

special polyester cloth with high withholding proper-

ties, deflector for the mechanical-gravitational separa-

tion of dust, dirt receptacle on wheels with disposable

plastic bags and cushioned fasteners, safety and

compensation valves, arranged for pressure compen-

sation system in the dust bag, manual filter shaker;

- electric control box with IP55 safety degree, realized

in accordance with CEI norms, with low-voltage (12 V)

outlet and equipped with electric chart for linkage;

- connections for correct linkage to the piping network

and all other parts and accessories for the profession-

al setting of the system;

- CE certificate.

plastic bags and cushioned fasteners, safety and

compensation valves, arranged for pressure compen-

sation system in the dust bag, manual filter shaker;

- electric control box with IP55 safety degree, realized in

accordance with CEI norms, with low-voltage (12 V) outlet

and equipped with electric chart for linkage;

- connections for correct linkage to the piping network

and all other parts and accessories for the profession-

al setting of the system;

- CE certificate.

7

Central Vacuum Systems

Central vacuum cleaner

model DS CD 125i

1 x 5,5 kW for 3+1 operators Code CD125i

Central vacuum cleaner consisting of:

- one silenced SIEMENS turbine with three-phase side channel motor

without transmission, secured on a metal frame;

- electronic inverter for continuous modulation of the frequency from 34

to 84 Hertz with electromagnetic shielding of type B (for applications

within the private and the industrial sector);

- cyclonic dust separator in steel, painted with epoxy powder, secured

on a metal frame, filter chamber equipped with industrial-conceived

star filter made of special polyester cloth with high withholding

properties, deflector for the mechanical-gravitational separation of

dust, dirt receptacle on wheels with disposable plastic bags and

cushioned fasteners, safety and compensation valves, arranged for

pressure compensation system in the dust bag;

- automatic self-cleaning filter device through programmable shaking

device;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- Ø100 metal muffler for low noise level

- connections for correct linkage to the piping network and all other

parts and accessories for the professional setting of the system;

- CE certificate.

+

3 x 5,5 kW for 6 operators Code F125ST

Central vacuum cleaner consisting of:

- three silenced SIEMENS turbines with three-phase side channel

motor without transmission, star-triangle starting, secured on a metal

frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy powder, secured

on a metal frame, filter chamber equipped with industrial-conceived

star filter made of special polyester cloth with high withholding

properties, deflector for the mechanical-gravitational separation of

dust, dirt receptacle on wheels with disposable plastic bags and

cushioned fasteners, safety and compensation valves, arranged for

pressure compensation system in the dust bag, manual filter shaker

predisposed for self-cleaning filter device;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- connections for correct linkage to the piping network and all other

parts and accessories for the professional setting of the system;

- CE certificate.

Central vacuum cleaner

model DS F03 125 l

2 x 7,5 kW for 8 operators Code H175ST

Central vacuum cleaner consisting of:

- two silenced double-V shaped SIEMENS turbines with three-phase

side channel motor without transmission, star-triangle starting,

secured on a metal frame, IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy powder, secured

on a metal frame, filter chamber equipped with industrial-conceived

star filter made of special polyester cloth with high withholding

properties, deflector for the mechanical-gravitational separation of

dust, dirt receptacle on wheels with disposable plastic bags and

cushioned fasteners, safety and compensation valves, arranged for

pressure compensation system in the dust bag, manual filter shaker

predisposed for self-cleaning filter device;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- connections for correct linkage to the piping network and all other

parts and accessories for the professional setting of the system;

- CE certificate.

Central vacuum cleaner

model DS H02 175 l

Central vacuum cleaner

model DS D02 100 l - 125 l

2 x 5,5 kW for 4 operators Code D100 – D125

Central vacuum cleaner consisting of:

- two silenced SIEMENS turbines with three-phase side channel motor

without transmission, star-triangle starting, secured on a metal frame,

IP55 safety degree;

- cyclonic dust separator in steel, painted with epoxy powder, secured

on a metal frame, filter chamber equipped with industrial-conceived

star filter made of special polyester cloth with high withholding

properties, deflector for the mechanical-gravitational separation of

dust, dirt receptacle on wheels with disposable plastic bags and

cushioned fasteners, safety and compensation valves, arranged for

pressure compensation system in the dust bag, manual filter shaker;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- connections for correct linkage to the piping network and all other

parts and accessories for the professional setting of the system;

- CE certificate.

Central vacuum cleaner

model DS CD 125i

1 x 7,5 kW for 5+1 operators Code EF125i

Central vacuum cleaner consisting of:

- one silenced SIEMENS turbine with three-phase side channel motor

without transmission, secured on a metal frame;

- electronic inverter for continuous modulation of the frequency from 34

to 84 Hertz with electromagnetic shielding of type B (for applications

within the private and the industrial sector);

- cyclonic dust separator in steel, painted with epoxy powder, secured

on a metal frame, filter chamber equipped with industrial-conceived

star filter made of special polyester cloth with high withholding

properties, deflector for the mechanical-gravitational separation of

dust, dirt receptacle on wheels with disposable plastic bags and

cushioned fasteners, safety and compensation valves, arranged for

pressure compensation system in the dust bag;

- automatic self-cleaning filter device through programmable shaking

device;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- Ø100 metal muffler for low noise level

+

1x11kW for 8+1 operators Code HK175i

Central vacuum cleaner consisting of:

- one silenced double-V shaped SIEMENS turbine with three-phase

side channel motor without transmission, secured on a metal frame;

- electronic inverter for continuous modulation of the frequency from 34

to 84 Hz with electromagnetic shielding type B;

- cyclonic dust separator in steel, painted with epoxy powder, secured on

a metal frame, filter chamber equipped with industrial-conceived star

filter made of special polyester cloth with high withholding properties,

deflector for the mechanical-gravitational separation of dust, dirt

receptacle on wheels with disposable plastic bags and cushioned

fasteners, safety and compensation valves, arranged for pressure

compensation system in the dust bag;

- automatic self-cleaning filter device through programmable shaking

device;

- electric control box with IP55 safety degree, realized in accordance

with CEI norms, with low-voltage (12 V) outlet and equipped with

electric chart for linkage;

- double Ø'3f100 metal muffler for low noise level;

- connections for correct linkage to the piping network and all other parts

and accessories for the professional setting of the system.

Central vacuum cleaner

model DS HK175i

+

- connections for correct linkage to the piping network and all other

parts and accessories for the professional setting of the system;

- CE certificate.