Discount Equipment PP65 User manual

PP65

UU

UUSS

SS

CC

CCAA

AA

EE

EESS

SS

Operator’s manual

Manuel d’utilisation

Manual de instrucciones

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

To order go to Discount-Equipment.com

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto, Power

Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack, Lull,

Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic, Dynapac,

MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti, Morrison, Contec,

Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S. Curtis, Gehl Pavers, Heli,

Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin, Rice, CH&E, General Equip-

ment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, APT, Wylie, Ingersoll Rand /

Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith Surface Prep,Small Line,

Wanco, Yanmar

Discount-Equipment.com is your online resource for

commercial and industrial quality parts and equipment sales.

561-964-4949

visit us on line @ www.discount-equipment.com

TO PURCHASE THIS PRODUCT PLEASE CONTACT US

Select an option below to find your Equipment

Equipment Financing and

Extended Warranties Available

KEY

T

O SYMBOLS

2

–

English

Symbols on the mac

hine

W

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the

machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

En

vironmental marking.

Symbols on

the product or its packaging indicate that

this product cannot be handled as

domestic waste. It must instead be

submitted to an appropriate recycling

station for the recovery of electrical and

electronic equipment.

By ensuring that this product is taken care of correctly,

you can help to counteract the potential negative impact

on the environment and people that can otherwise result

through the incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac

hine refer to special

certification requirements for certain markets.

Explanation of warning le

vels

The w

arnings are graded in three levels.

W

ARNING!

CAUTION!

NOTICE!

!

W

ARNING! Used if there is a risk of

serious injury or death for the operator

or damage to the surroundings if the

instructions in the manual are not

followed.

!

CA

UTION! Used if there is a risk of injury

to the operator or damage to the

surroundings if the instructions in the

manual are not followed.

NO

TICE! Used if there is a risk of damage to materials

or the machine if the instructions in the manual are not

followed.

To order go to Discount-Equipment.com

CONTENTS

English

–

3

Contents

Note the f

ollowing before

starting:

KEY

TO SYMBOLS

Symbols on the machine

...................................... 2

Explanation of warning levels ............................... 2

CONTENTS

Contents

............................................................... 3

Note the following before starting: ........................ 3

PRESENT

ATION

Dear customer!

..................................................... 4

Design and features ............................................. 4

PP65 ..................................................................... 4

WHA

T IS WHAT?

What is what on the po

wer pack? ......................... 5

MA

CHINE´S SAFETY EQUIPMENT

Gener

al ................................................................. 6

ASSEMBLING AND ADJUSTMENTS

Install the po

wer unit ............................................ 7

Type of installation ................................................ 7

Connect a power source ...................................... 8

Software settings .................................................. 8

Before starting ...................................................... 8

OPERA

TING

Gener

al safety precautions ................................... 9

Protective equipment ............................................ 10

Power pack safety precautions ............................. 10

Work safety ........................................................... 11

Transport and storage .......................................... 11

MENU SYSTEM

Gener

al ................................................................. 12

First start-up ......................................................... 12

Menu overview ..................................................... 13

Menu system explanation ..................................... 14

MAINTENANCE

Gener

al ................................................................. 15

Daily maintenance ................................................ 15

Air filter ................................................................. 15

Service ................................................................. 15

Error messages .................................................... 16

TECHNICAL D

ATA

T

echnical data ...................................................... 17

Recommended cable dimensions ........................ 17

US

WARRANTY STATEMENT

W

ARRANTY POLICY ........................................... 18

EQUIPMENT ........................................................ 18

!

W

ARNING! Cutting, especially when DRY

cutting, generates dust that comes from

the material being cut, which frequently

contains silica. Silica is a basic

component of sand, quartz, brick clay,

granite and numerous other minerals

and rocks. Exposure to excessive

amount of such dust can cause:

Respiratory disease (affecting your

ability to breath), including chronic

bronchitis, silicosis and pulmonary

fibrosis from exposure to silica.These

diseases may be fatal;

Skin irritation and rash.

Cancer according to NTP* and IARC* */

National Toxicology Program,

International Agency for Research on

Cancer

Take precautionary steps:

Avoid inhalation of and skin contact with

dust, mist and fumes.

Wear and ensure that all bystanders wear

appropriate respiratory protection such

as dust masks designed to filter out

microscopic particles. (See OSHA 29

CFR Part 1910.1200)

Wet cut when feasible, to minimize dust.

To order go to Discount-Equipment.com

PRESENTATION

Dear customer!

Thank you for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorised

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (using, service, maintenance etc.) the life span

and the second-hand value of the machine can be

extended.If you ever lend or sell this machine, make sure

that the borrower or buyer gets the operator′s manual, so

they will also know how to properly maintain and use it.

More than 300 years of innovation

Husqvarna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Charles

XI ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

Owner responsibility

It is the owner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

Local regulations could restict the use of this machine.

Find out what regulations are applicable where you work

before you start using the machine.

The manufacturer’s reservation

Subsequent to publishing this manual Husqvarna may

issue additional information for safe operation of this

product. It is the owner’s obligation to keep up with the

safest methods of operation.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

4 – English

Design and features

This is a product included in a range of high frequency

powered equipment for cutting, drilling and wall sawing.

They are designed to cut hard materials like masonry and

reinforced concrete and should not be used for any

purpose not described in this manual.

Values such as high performance, reliability, innovative

technology, advanced technical solutions and

environmental considerations distinguish Husqvarna's

products. Safe operation of this product requires the

operator to read this manual carefully. Ask your dealer or

Husqvarna should you need more information.

Some of the unique features of your product are

described below.

PP65

The power unit is especially designed to drive High

Frequency tools.

• The unit gives high power output and can use both 1-

and 3-phase input, which makes it flexible and usable.

• The operator can easily make adjustments and

monitor system information via the digital display on

the unit.

• The design is lightweight, compact and ergonomic

which makes the unit easy to transport.

• The unit is air-cooled

To order go to Discount-Equipment.com

English

–

5

WHA

T IS

WHA

T?

What is what on the po

wer pack?

1

4

5

3

9

11

13

14

15

16 10

6

7

2

17

8

12

1

Handle

2 Place for cable holder

3 Adapter cable (Single-phase)

4 Cooling air intake

5 Power cord

6 Ground fault circuit interrupter

7 Cable holder

8 Connector

9 Emergency stop

10 Exhaust

11 Tool connection

12 Protective cover

13 Option keys

14 Display

15 Overvoltage indicator

16 USB connection

17 Operator’s manual

To order go to Discount-Equipment.com

MACHINE´S SAFETY EQUIPMENT

6 – English

General

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

This machine is used in combination with other products.

Please read the manual provided with the products

carefully and make sure you understand the instructions

before using the machine.

• Connect the power unit to a grounded outlet

• Connect the tool to be used.

Emergency stop

The emergency stop on the unit slows the connected tool

and disconnects it from the power supply.

Testing the emergency stop

•Check that the emergency stop button is not pressed

by turning it clockwise.

• Start the connected tool.

• Press the emergency stop and check that the

connected tool stops.

Ground fault circuit interrupter

A residual-current device is fitted to protect operators in

case an electrical fault should occur.

Check the ground fault circuit interrupter

Checking of the residual-current device must be done

with the power unit connected to an earthed or grounded

power outlet.

• Connect the power unit to an earthed or grounded

power outlet.

• Open the cover on the residual-current device to

access the switch (1) and test button (2).

• Set the control in the residual-current device in

position 1.

• Press the test button. The residual-current device

must trigger to disconnect the unit from the power

supply.

• Reset the residual-current device by first setting the

switch to 0 and then to 1.

•Refit and tighten the cover.

The residual-current device must be tested every two

weeks with the test button.

!

WARNING! Never use a machine that has

faulty safety equipment! If your machine

fails any checks contact Discount-

equipment to get it repaired.

To order go to Discount-Equipment.com

English – 7

ASSEMBLING AND ADJUSTMENTS

Install the power unit

Place the power unit on the workplace, making sure that it is standing on a stable surface and that it is protected from

water spray.

Type of installation

When the power unit is connected to an electrical installation protected by a Residual Current Circuit-Breaker this must

be of type B (fig.1), whereas an installation protected by a type A Residual Current Circuit-Breaker must support

connection to its primary side, i.e. upstream of the Residual Current Circuit-Breaker (fig. 2).

Local expertise may be able to recommend safe alternatives to the above connections. If you encounter a situation

where you are uncertain you should allways ask an expert. Contact Discount-equipment.

A - Power supply

B - Residual-current device type B

C - Residual-current device type A

D - Connector

E - Built in residual-current device type B

F - Other equipment

G - Power pack

H - Power tool

J - PP65

E

FJ

G

H

DD

BC

G

H

J

D

Fig. 1 Fig. 2

F

D

AA

E

To order go to Discount-Equipment.com

ASSEMBLING AND ADJUSTMENTS

8

–

English

Connect a po

wer source

F

or maximum performance, the power unit should be

connected to an earthed or grounded 3-phase socket

outlet. For more information, see the ”Technical data”

section.

In the lower region of the input voltage range there is a

reduction in available output power.

If a 3-phase electrical connection is not available, the

power unit can also be connected to a 1-phase socket

outlet. Use the supplied adapter cable for 1-phase

connection. The output at 1-phase operation is

substantially lower than at 3-phase operation. For more

information, see the ”Technical data” section.

• Before connecting a power tool to the power take-off

of the power unit, always check that the pins in the

power tool connector are not bended or damaged.

• During operation, fit together the covers for the cable

and the power unit to avoid dirt entering the covers

which could damage the connector.

A gasoline or diesel driven generator can be used as a

power source if sufficiently powerful. See typical

generator operation cases in Technical Data. The

generator must be earthed or grounded to safeguard the

function of the power unit.

Software settings

The f

ollowing settings should be made before the power

unit is commissioned. See instructions in the "Menu

system" section for additional information.

• Set time and date. (SETTINGS>TIME & DATE)

• Select the required display language.

(SETTINGS>SET LANGUAGE)

• Select the required units. (SETTINGS>SET UNITS)

Bef

ore starting

Perform daily maintenance.

See instructions in the section "Maintenance".

NOTICE! A generator which on some occasion

generates an input voltage outside the voltage range

specified in the technical data can damage the power

unit.

!

WARNING! Please read the operator’s

manual carefully and make sure you

understand the instructions before using

the machine.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury.

Check that the machine is assembled

correctly and do not show any signs of

damage.

NOTICE!

The generator must be earthed or grounded to

safeguard the function of the power unit.

To order go to Discount-Equipment.com

OPERATING

English – 9

General safety precautions

Work area safety

•Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

•Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

•Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

Electrical safety

•Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce the risk of electric shock.

•Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

•Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

•Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, charp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

•When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

•If operating a power tool in a damp location is

unaviodable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

• When operating the power tool in damp environments,

use an extension cord suitable for outdoor use.

Personal safety

•Stay alert, watch what you are doing and use

common sense when operaing a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

•Use personal protective equipment. Always wear

eye protection. Protetctive equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

•Prevent unintentional starting. Ensure the switch

is in the OFF-position before connecting to power

source and/or battery pack,picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

•Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

•Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

•Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

•Wear protective hair covering to contain long hair.

Loose clothes, jewellery or long hair can be caught in

moving parts.

•If devices are provided for the connection of dust

extraction and collection facilities, ensure that

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

Power tool use and care

•Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

•Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

•Disconnect the plug from the power source and/or

the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

•Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

•Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool´s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

•Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

•Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in

hazardous situations.

Service

•Have your power tool serviced by a qualified

repair person unsing only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

!

WARNING! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

IMPORTANT! Save all warnings and instructions for

future reference. The term ”power tool” in the warnings

refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

To order go to Discount-Equipment.com

OPERATING

10 – English

Always use common sense

It is not possible to cover every conceivable situation you

can face. Always exercise care and use your common

sense. If you get into a situation where you feel unsafe,

stop and seek expert advice. Contact Discount-

equipment. Do not attempt any task that you feel unsure

of!

Protective equipment

General

Do not use the machine unless you are able to call for

help in the event of an accident.

Personal protective equipment

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

Always wear:

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole

Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

Other protective equipment

• Fire fighting equipment

• Always have a first aid kit nearby.

Power pack safety precautions

This section describes basic safety directions for using

the machine. This information is never a substitute for

professional skills and experience.

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• Keep in mind that the operator is responsible for

accidents or hazards occuring to other people or their

property.

• All operators shall be trained in the use of the

machine. The owner is responsible for ensuring that

the operators receive training.

• The machine must be kept clean. Signs and stickers

must be fully legible.

!

WARNING! The use of products such as

cutters, grinders, drills, that sand or form

material can generate dust and vapors

which may contain hazardous chemicals.

Check the nature of the material you

intend to process and use an appropriate

breathing mask.

!

WARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection. Listen out for

warning signals or shouts when you are

wearing hearing protection. Always

remove your hearing protection as soon

as the engine stops.

!

WARNING! There is always a risk of

crush injuries when working with

products containing moving parts. Wear

protective gloves to avoid body injuries.

!

WARNING! Sparks may appear and start

a fire when you work with the machine.

Always keep fire fighting equipment

handy.

!

WARNING! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

!

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Never allow children or other persons

not trained in the use of the machine to

use or service it. Never allow anyone else

to use the machine without first ensuring

that they have read and understood the

contents of the operator’s manual.

Never use the machine if you are

fatigued, while under the influence of

alcohol or drugs, medication or anything

that could affect your vision, alertness,

coordination or judgement.

!

WARNING! Unauthorized modifications

and/or accessories may lead to serious

injury or death to the user or others.

Do not modify this product or use it if it

appears to have been modified by others.

Never use a machine that is faulty. Carry

out the safety checks, maintenance and

service instructions described in this

manual. Some maintenance and service

measures must be carried out by trained

and qualified specialists. See

instructions under the heading

Maintenance.

Always use genuine accessories.

To order go to Discount-Equipment.com

OPERATING

English – 11

Work safety

Work area safety

• Always check and mark out where gas pipes are

routed. Cutting close to gas pipes always entails

danger. Make sure that sparks are not caused when

cutting in view of the risk of explosion. Remain

concentrated and focused on the task. Carelessness

can result in serious personal injury or death.

• Make sure that no pipes or electrical wires are routed

in the work piece or in the working area.

• Make sure that electrical cables within the working

area are not live.

• Never start to work with the machine before the

working area is clear and you have a firm foothold.

• Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and can lead to

dangerous conditions, e.g. slippery surfaces.

Electrical safety

•Never use the tool without the residual-current device

delivered with the tool.

• The machine should be connected to an earthed or

grounded outlet socket.

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Check that the cord and extension cord are intact and

in good condition.

• Keep the connector dry and off the ground.

• Never use the machine if any cable or plug is

damaged, but hand it in to an authorized service

workshop for repair.

• To avoid overheating do not use the extension cord

while it is rolled up.

Personal safety

•Never leave the machine unsupervised with the motor

running.

• Always unplug the power supply to the power pack for

longer work breaks.

• Never work alone, always ensure there is another

person close at hand.Apart from being able to receive

help to assemble the machine, you can also get help

if an accident should occur.

• People and animals can distract you causing you to

lose control of the machine. For this reason, always

remain concentrated and focused on the task.

• People that need to be in close proximity of the

machine must wear hearing protection as the sound

level when cutting exceeds 85 dB(A).

• Always work in a manner that permits easy access to

the emergency stop.If an emergency situation should

arise anyway, push the red emergency stop button on

the power pack or the stop button on the remote

control.

Use and care

This machine is only intended for use together with the

intended Husqvarna products. All other use is forbidden.

• The machine is intended for use in industrial

applications by experienced operators.

• Inspection and/or maintenance should be carried out

with the motor switched off and the plug disconnected.

• Always switch off the machine before you move it.

• Observe care when lifting.You are handling heavy

parts, which imply the risk of pinch injuries or other

injuries.

• Never pull out the power cable without first switching

off the power pack and waiting for the engine to come

to a complete halt.

• Do not overload the machine. Overloading can

damage the machine.

• Check that all couplings, connections and cables are

intact and free from dirt.

Transport and storage

• Always switch of the power pack and pull out the

electric cable before moving the equipment.

• Secure the equipment during transportation in order

to avoid transport damage and accidents. If the power

unit was purchased together with wall saw equipment

WS220, it can easily be stored in the designated place

in the accompanying transport trolley.

• Store the equipment in a lockable area so that it is out

of reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and frost

proof place.

• Do not expose the unit to temperatures below -22 °F

or over 122 °F or to direct sunlight.

!

WARNING! There is always a risk of

shocks from electrically powered

machines. Avoid unfavourable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s manual to avoid damage.

!

WARNING! Do not wash the machine

with water, as water can enter the

electrical system or the engine and

cause damage to the machine or short

circuit.

To order go to Discount-Equipment.com

12 – English

MENU SYSTEM

General

Display texts are illustrated in English in the manual, but will appear in the chosen language on the product display.

When K6500 is running the display will turn off on the power pack.

Use the arrow keys (2) to scroll in the menus and the "OK" button (1) to confirm the selection. Use the ”back” button

(3) to go back in the menus.

First start-up

At the first start-up of the power pack the following settings must be made:

• LANGUAGE (1) Select the required display language.

• TIME FORMAT (2) Select the required time format.

• SET TIME (3) State the current time.

• DATE FORMAT (4) Select the required date format.

• SET DATE (5) State the current date.

When these settings have been made the main display is shown with information about the connected tool (6). Please

observe, the illustration shows an example.

OK

2

31

21 JUN 12:45

K6500

MENY

READY

OK

DATE FORMAT

DD.MM.YYYY

YYYY/DD/MM

YYYY-MM-DD

SET TIME

12:59PM

SET TIME WITH

STEP FORWARD WITH OK

OK

SET DATE

2010-04-22

SET DATE WITH

STEP FORWARD WITH OK

OK

OK

TIME FORMAT

12h

SET FORMAT WITH

STEP FORWARD WITH OK

OK

LANGUAGE

SVENSKA

FRANÇAIS

ENGLISH

DEUTSCH

OK

1

2

6

3

5

4

21 JUN 12:45

21 JUN 12:45 21 JUN 12:45

21 JUN 12:45 21 JUN 12:45

To order go to Discount-Equipment.com

English – 13

MENU SYSTEM

Menu overview

See following page for an explanation of each menu.

> MENU

SERVICE

SETTINGS

21 JUN 12:45

>> SERVICE

ERROR LOG

PRODUCT INFO

TOTAL RUNTIME

[12:24:42]

21 JUN 12:45

>>> RUNTIME

CURRENT RUNTIME

[2:35:42]

21 JUN 12:45

CLEAR RUNTIME

TIME COUNTER

[OFF]

TIME FORMAT

[24h]

SET DATE

[2010-21-06]

SET TIME

[12:45]

DATE FORMAT

[YYYY-MM-DD]

21 JUN 12:45>>> TIME & DATE

>>> ERROR LOG

ERROR 1

ERROR 2

21 JUN 12:45

OK

1

2

3

4

5

6

7

9

10

16

17

18

19

20

22

11

12

13

14

OK

>>> PRODUCT INFO

PP65

21 JUN 12:45

K6500

OK

LINE VOLTAGE

[ 230V/ 230V/ 230V]

8

21 JUN 12:45

CONNECT UNIT

NO CONNECTION

MENY

OK

21 JUN 12:45

K6500

MENY

READY

OK

>> SETTINGS

RUN TIME

TIME & DATE

[12:45 - 2010-21-06]

LANGUAGE

[ENGLISH]

21 JUN 12:45

SET UNITS

[METRIC]

FACTORY SETTINGS

15

DM 650

GEAR 1 2

RPM

Ø (mm)

21 JUN 12:45

246 532

500 225

23

24

25

21

To order go to Discount-Equipment.com

MENU SYSTEM

14 – English

Menu system explanation

CONNECT UNIT (1)

This image is shown if the power unit is not connected to

any tool. Connect the intended tool.

Electronic gear

When the intended tool is connected, the start screen (2)

is displayed. Press the menu button to start the settings

(3) and service (4) menus.

An illustration will be displayed when operating the

DM650 showing the selected electronic gear (23), current

rpm for mechanical gears 1 and 2, and recommended

bore diameter for these gears (24).The current feeder

load (25) of the drill will also be shown.

SETTINGS (3)

The ”Settings” menu consists of sub-menus, which in turn

consist of a number of part menus.

RUN TIME (11)

Run time

TIME COUNTER (16)

On activation, a stop-watch is started to count the time the

tool is active.

CLEAR RUNTIME (17)

Used to reset the stop-watch.

CURRENT RUN TIME (18)

Current running time

TIME AND DATE (12)

Set time and date.

SET TIME (19)

State the current time.

SET DATE (20)

State the current date.

TIME FORMAT (21)

Select the required time format. Choose from between

the following options:

• 12 h

• 24 h

DATE FORMAT (22)

Select the required date format. Choose from between

the following options:

• YYYY-MM-DD

• YYYY/DD/MM

• DD/MM/YYYY

LANGUAGE (13)

Select the required display language.

FACTORY SETTING (15)

Resetting to factory defaults:

• Display language (English standard)

• Time format (12h standard)

• Date format (YYYY-MM-DD standard)

SERVICE (4)

The ”Settings" menu consists of sub-menus, which in turn

consist of a number of part menus.

ERROR LOG (5)

List of errors (9)

TOTAL RUNTIME (6)

The machine’s total operating time is displayed.

VOLTAGE (7)

Connected input voltage of the machine.

PRODUCT INFO (8)

Information about the unit and the connected tool is

shown (10).

To order go to Discount-Equipment.com

MAINTENANCE

English – 15

General

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further

information please contact Discount-equipment.

Daily maintenance

• Check that the machine’s safety equipment is

undamaged. See instructions in the section

"Machine’s safety equipment".

• Check that the cables including any extension leads

are intact and in good condition.

• Always clean all the equipment at the end of the

working day. Use a heavy-duty hand-held brush or a

large paint brush.

• Make sure to keep the connectors and pins clean.

Clean with a rag or brush.

Air filter

Check the air filter and replace if necessary.

• Dismantle the air filter cover. Use torx key no. 27.

• Unsnap the metal frame to access the cover.

• Change the filter.

Service

!

WARNING! The user must only carry out

the maintenance and service work

described in this manual. More extensive

work must be carried out by an

authorized service workshop.

NOTICE! Do not use a high pressure washer to clean

the machine. The high pressure jet can damage seals

and lead to water and dirt permeating into the machine,

resulting in serious damage.

NOTICE! The air filter must not be cleaned or blown

clean with compressed air. This will damage the filter.

A blocked air filter can cause power unit overheating.

!

WARNING! All types of repairs may only

be carried out by authorised repairmen.

This is so that the operators are not

exposed to great risks.

To order go to Discount-Equipment.com

16 – English

MAINTENANCE

Error messages

In case of any faults, a fault message (1) and a fault code (2) appears on the display.

Measures for acknowledging fault messages:

• Press ”OK” on the display or activate the throttle control on the connected tool. No further action is required if the

fault message is deleted.

If the system freezes and an acknowledgment can not be made: Pull out the connector from the earthed socket outlet,

reconnect the power source. See instructions in the section "Assembling and adjustments".

If the fault persists, follow the instructions given in the troubleshooting guide or get in touch with an authorized dealer.

Please observe, the illustration shows an example.

The power unit software can be updated. Contact Discount-equipment for further information.

Troubleshooting schedule

Error messages are illustrated in the language you have chosen on the product alternatively in English.

* XX different numbers depending on the tool that is connected to the power unit.

Fault Code Error messages Cause Steps

F0101 Overcurrent detected Active tool current

too high

Contact Discount-equipmentif the

problem remains.

F0103 Fault detected in hardware Hardware fault Contact Discount-equipment if the

problem remains.

F0104 Error detected on the voltage bus Tool voltage error Check the power supply

F0105 High voltage detected on voltage bus.

Check the power supply connection.

Brakes applied too

hard

Contact Discount-equipment if the

problem remains.

F0106 Temperature in the IGBT module too

high

Power pack

overheated

Check the fan and filter and allow the

system to cool down.

F0107 Emergency stop switch pressed The emergency stop

is pressed in. Reset the emergency stop

FXX08* High motor temperature detected

Tool motor

temperature is too

high

Increase the flow of water coolant.

Refer to Technical Data in the

instruction manual for the connected

tool.

F0109 Low voltage detected on voltage bus.

Check the power supply connection.

Internal power pack

failure Check input power or contact Discount-

equipment

F0111 The clock has stopped, please

correct it if neccessary.Clock stopped Contact Discount-equipment for

a battery change.

F0112 Low input voltage detected Input voltage too low Check minimum input power in manual

F0113 High input voltage detected Input voltage too

high

Check maximum input power in

manual

FXX14* Tool temperature sensor error

detected

Interruption or short

circuit in the

temperature sensor.

Contact Discount-equipment

F0118 Fault detected in hardware Hardware fault Contact Discount-equipment if the

problem remains.

F0119 Temperature in the PP too high Power pack

overheated

Check the fan and filter and allow the

system to cool down.

2011-09-09 12:45

CODE: F0109 OK

Low voltage detected on voltage bus.

Check the power supply connection.

OK

1

2

To order go to Discount-Equipment.com

English – 17

TECHNICAL DATA

Technical data

Typical generator operation cases

Dimensions

Recommended cable dimensions

Engine PP65

Max. output, kW 6,5

Rated current 3-phase at 400V, A 12

Rated current 1-phase, A 15/16

3-phase voltage in, V 200-480, 50-60 Hz

1-phase voltage in, V 220-240, 50-60 Hz

Power supply

3 phase L1+L2+L3+N+PE/L1+L2+L3+PE

Single-phase L+N+PE

Weight, kg/lbs 9,5/20,9

PP65, output Generator output voltage (V) Minimum recommended

generator output (kVA)

3 phase Full power 3x400, 3x416, 3x440, 3x480 10

Decreased power 3x208, 3x220, 3x240

Single-phase Decreased power 220-240 5

NOTICE! Good motor performance depends on proper voltage.Extension cables that are too long and/or which have

a gage that is too small, reduce power to the motor under load, resulting in reduced output or malfunctions.

351 mm

184 mm

419 mm

To order go to Discount-Equipment.com

EXPLICATION DES SYMBOLES

French – 19

Symboles sur la machine

AVERTISSEMENT! La machine utilisée

de manière imprudente ou inadéquate

peut devenir un outil dangereux, pouvant

causer des blessures graves voire

mortelles à l’utilisateur et aux autres

personnes présentes.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d’utiliser la

machine.

Toujours utiliser:

• Casque de protection homologué

• Protecteurs d’oreilles homologués

• Lunettes protectrices ou visière

• Masque respiratoire

Les contrôles et/ou les entretiens

doivent être effectués avec le moteur à

l’arrêt et la prise électrique débranchée.

Marquage environnemental. Ce

symbole figurant sur le produit ou sur son

emballage indique que ce produit ne peut

pas être traité comme déchet ménager. Il

doit être collecté et amené à une

installation de récupération appropriée

de déchets d’équipements électriques et

électroniques.

En veillant à ce que ce produit soit correctement éliminé,

vous pouvez contribuer à prévenir les conséquences

négatives potentielles sur l’environnement et les

hommes, qui pourraient sinon être le résultat d’un

traitement incorrect des déchets de ce produit.

Pour des informations plus détaillées sur le recyclage de

ce produit, contactez votre commune ou le magasin où

vous avez acheté le produit.

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

Explication des niveaux

d'avertissement

Il existe trois niveaux d'avertissement.

AVERTISSEMENT!

REMARQUE !

ATTENTION !

!

AVERTISSEMENT! Symbole utilisé en

cas de risque de blessures très graves

ou de mort pour l'utilisateur ou de

dommages pour les environs si les

instructions du manuel ne sont pas

suivies.

!

REMARQUE ! Symbole utilisé en cas de

risque de blessures pour l'utilisateur ou

de dommages pour les environs si les

instructions du manuel ne sont pas

suivies.

ATTENTION ! Symbole utilisé en cas de risque de

dommages pour les matériaux ou la machine si les

instructions du manuel ne sont pas suivies.

To order go to Discount-Equipment.com

SOMMAIRE

20 – French

Sommaire Contrôler les points suivants

avant la mise en marche:

EXPLICATION DES SYMBOLES

Symboles sur la machine ...................................... 19

Explication des niveaux d'avertissement .............. 19

SOMMAIRE

Sommaire ............................................................. 20

Contrôler les points suivants avant la mise en

marche: ................................................................. 20

PRÉSENTATION

Cher client, ............................................................ 21

Conception et propriétés ....................................... 21

PP65 ..................................................................... 21

QUELS SONT LES COMPOSANTS?

Quoi est quoi dans le groupe moteur ? ................. 22

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités ........................................................... 23

MONTAGE ET RÉGLAGES

Installation de l’unité électrique ............................. 24

Type d’installation ................................................. 24

Branchez une source électrique ........................... 25

Paramètres de logiciel .......................................... 25

Avant le démarrage ............................................... 25

COMMANDE

Instructions générales de sécurité ........................ 26

Équipement de protection ..................................... 27

Consignes de sécurité relatives au bloc

d’alimentation ........................................................ 28

Sécurité du travail ................................................. 28

Transport et rangement ......................................... 29

SYSTÈME DE MENUS

Généralités ........................................................... 30

Première mise en marche ..................................... 30

Vue d'ensemble des menus .................................. 31

Présentation du système de menus ..................... 32

ENTRETIEN

Généralités ........................................................... 33

Entretien quotidien ................................................ 33

Filtre à air .............................................................. 33

Service .................................................................. 33

Messages d’erreur ................................................ 34

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques ................................. 35

Dimensions recommandées des câbles ............... 35

DECLARATION DE GARANTIE ETATS-UNIS

POLITIQUE DE GARANTIE ................................. 36

EQUIPEMENT ...................................................... 36

!

AVERTISSEMENT! La découpe,

particulièrement la découpe à SEC

soulève la poussière générée par le

matériau coupé qui contient souvent de

la silice. La silice est composée de sable,

de quarts d’argile, de granit et de

nombreuses autres substances

minérales et rocheuses. L’exposition à

une quantité excessive d’une telle

poussière peut causer:

Des maladies respiratoires (altérant les

facultés respiratoires), y compris

bronchites chroniques, silicose et

fibrose pulmonaire dues à une

exposition à la silice. Ces maladies

peuvent être fatales;

Irritation cutanée et démangeaisons.

Des cancers selon NTP* et IARC* */

National Toxicology Program,

International Agency for Research on

Cancer

Prendre des mesures préventives:

Éviter l’inhalation et le contact avec la

peau de la poussière, des vapeurs et des

fumées.

L’utilisateur et les personnes présentes

sur le site doivent porter des protections

respiratoires appropriées telles que des

masques spécialement prévus pour

filtrer les particules microscopiques.

(Voir OSHA 29 CFR Partie 1910.1200)

Couper si possible en utilisant le jet

d'eau afin de réduire la poussière

dispersée.

To order go to Discount-Equipment.com

Table of contents

Languages:

Other Discount Equipment Power Pack manuals

Popular Power Pack manuals by other brands

therm-ic

therm-ic Supermax Powerpack Instructions for use

Bluetti

Bluetti EP500-JP EP500-USA user manual

Chicago Pneumatic

Chicago Pneumatic PAC P18 Safety and operating instructions

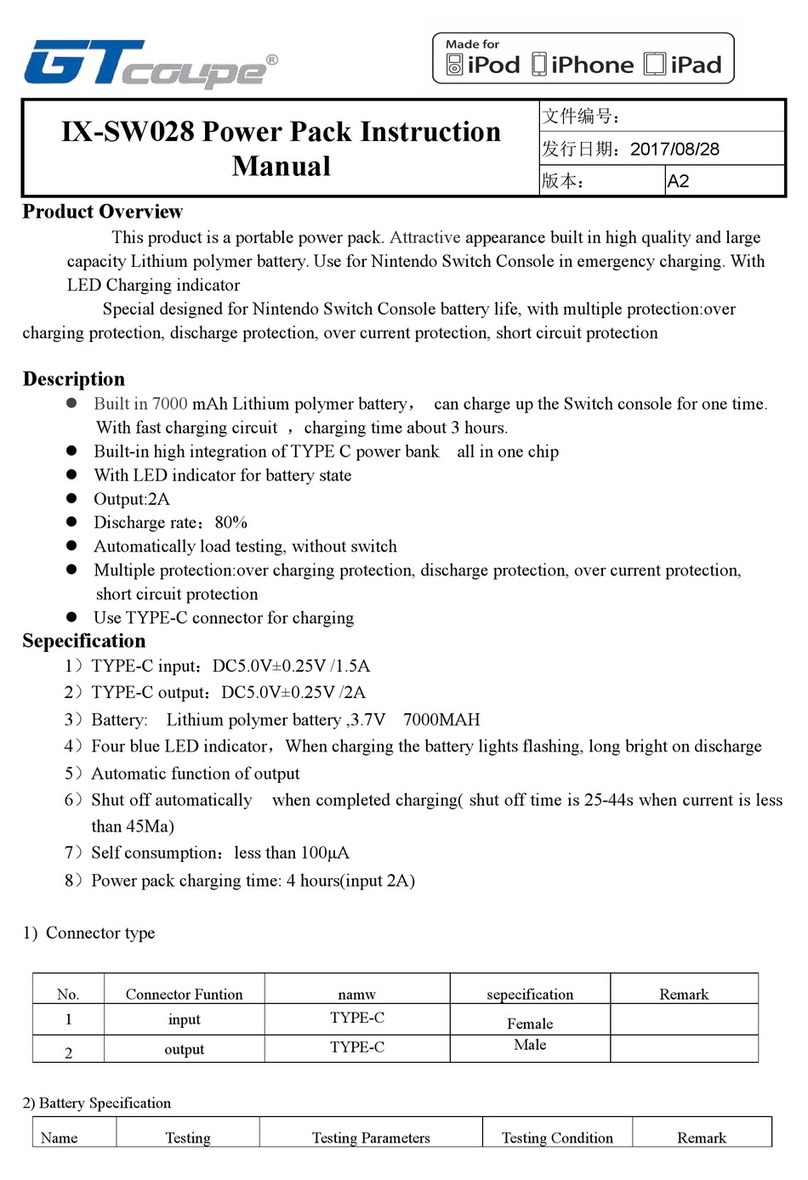

gt coupe

gt coupe IX-SW028 instruction manual

iTechworld

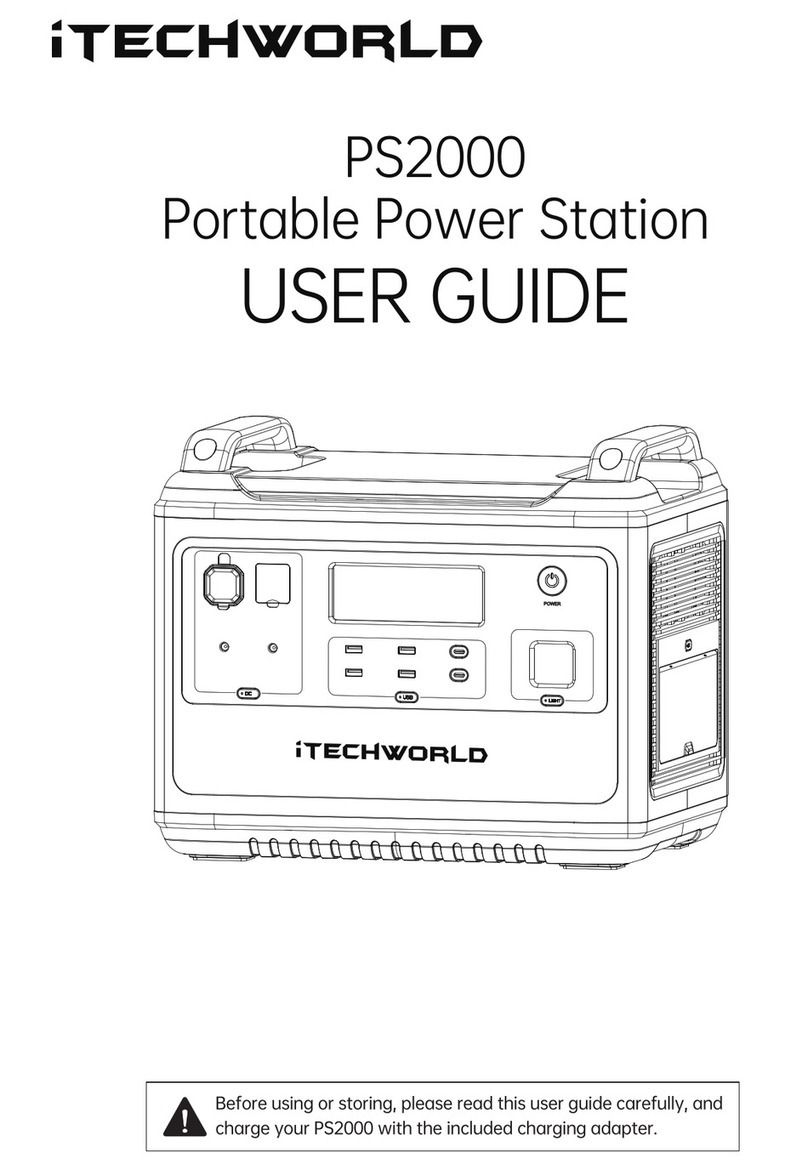

iTechworld PS2000 user guide

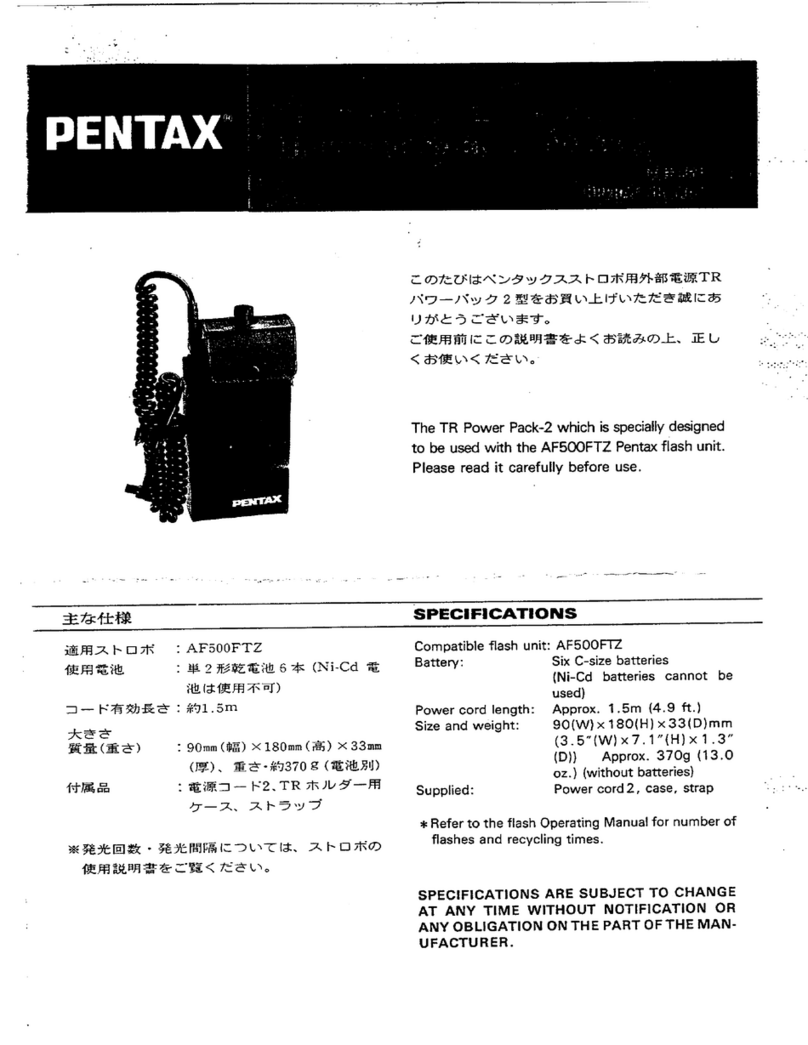

Pentax

Pentax TR Power Pack-2 (PW-222 operating manual