DiscreteHeat ThermaCurve User manual

05

05

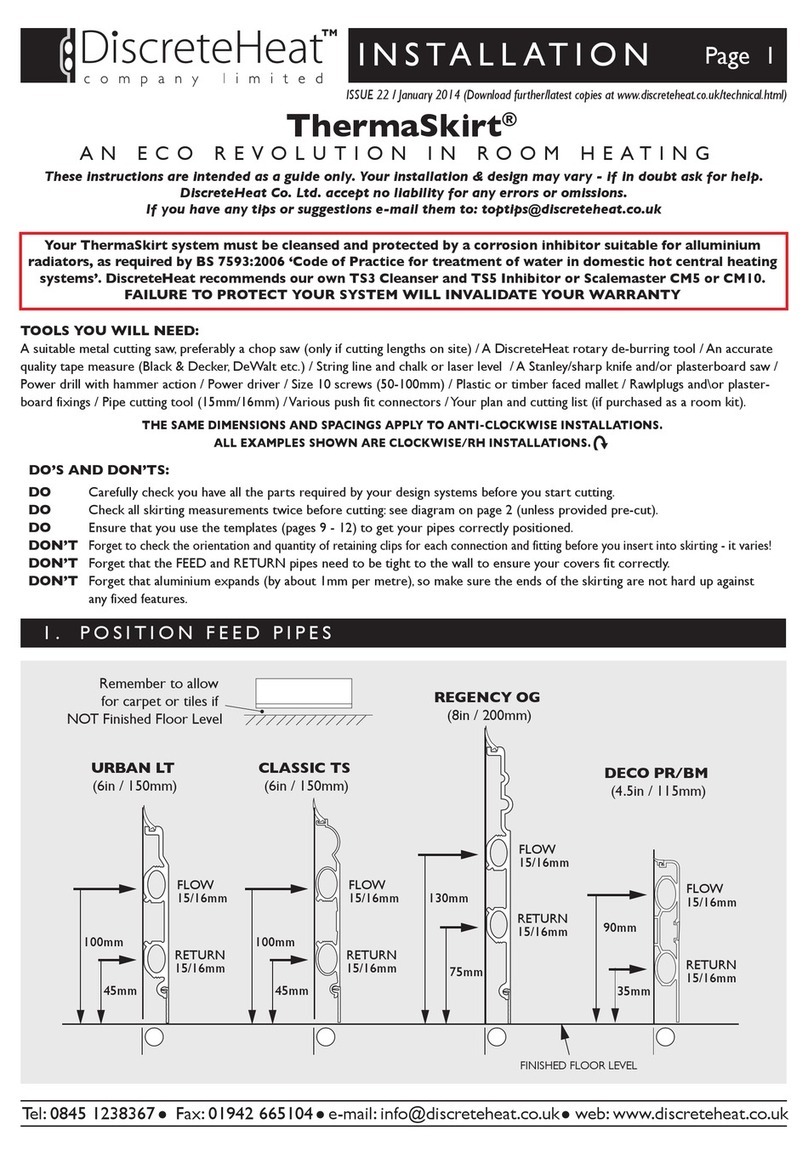

Installing the Power Connection PCB

Bracket

1. Mount the ‘Easy Bend’ PCB bracket

approx. 25mm (1”) from the corner

of the wall/start of run, and up to the

ceiling. Do not over-tighten the 2

mounting screws so the bracket can

still slide on the slots. For mid-wall

installation, see separate instructions

provided.

2. When secure. Bend the bottom edge

up at 45° to form the angled bracket.

3. Installing the 1st Wall & Ceiling

Brackets.

4. The Wall bracket is fixed using the

centre slot (with teeth) and the oval

washer. Check its secured.

5. The ceiling bracket is secured (but

slides) using the lower slot (no teeth)

and the round washer. Check bracket

still slides.

6. 2nd & 3rd Brackets.

The 2nd set of brackets is fitted in the

middle wall length. The 3rd set is fitted

~200mm from the end/ corner of the

wall.

Middle of wall

200 mm

250 mm

~225mm/9”

~200mm/8”

~250mm/10”

Bend here 90

~25mm/1”

Bed up to 45

Oval Washer

Wall Bracket

Fixed

Round Washer

Slides

06

Preparing the ThermaCurve Prole

When cutting the ThermaCurve profile, the following allowances should be made:

Power Connection

/ PCB Internal Corner External corner Special Angle End Termination

Wall length

MINUS

200mm/8’’

Wall length

MINUS

125mm/5’’

Wall length

MINUS

25mm/1’’

Wall length

MINUS

150mm/6’’

Wall length

MINUS

100mm/4’’

1. When cutting the ThermaCurve

profile, remove any back capping

to prevent swarf or chips becoming

trapped, which could damage the

heating cable when inserted.

2. Using a pair of long nose pliers or

similar, ‘splay out’ the cable channel at

the ends to create a wider, ‘bell mouth’

opening. This prevents the heating

cable from snagging.

3. De burr! Using the rotary de burring

tool (from the spares kit) chamfer the

cut ends. Note; failure to follow 8.2 & 8.3

may invalidate your warranty.

200mm

125mm

25mm

100mm

150mm

Wall

ThermaCurve Prole

Wall Length L

Wall Length CL

Prole Length PL

Clockwise System

1

2 3

4

5

6

Start Connection

Termination

End of Run

Cable Connectors

PCB/ Start

Prole

Cable Connectors

07

Preparing the cable lengths (if not

supplied factory cut)

Power Connection /

PCB Internal Corner External corner Special Angle End Termination

Wall length

MINUS

-100mm/4’’

Wall length

MINUS

-25mm/1’’

Wall length

PLUS

+25mm/1’’

Wall length

MINUS

-25mm/1’’

Wall length

MINUS

-50mm/’’

Or: Profile Length

PLUS

+100mm/4’’

Or: Profile Length

PLUS

+100mm/4’’

Or: Profile Length

PLUS

+50mm/2’’

Or: Profile Length

PLUS

+125mm/5’’

Or: Profile Length

PLUS

+50mm/2’’

Note: Heating cables are usually supplied pre-prepared. If not, prepare the cable ends before inserting into the

ThermaCurve profile; the cable is difficult to strip and mistakes are hard to correct once the cable is in the cable channels.

Preparing the Power Connection Cable

end

1. Remove the outer red silicone jacket

to reveal approximately 80mm (3 ¼”) of

black inner core.

2. Split the black inner core down the

middle and separate.

3. Using a Stanley knife (box cutter)

or similar at a shallow angle, slice

away the black core to reveal the inner

conductors; NOTE; safety gloves and

eye shields should be worn and always

cut away from yourself.

80mm

25mm

100mm

100mm

50mm

125mm

125mm

50mm

08

Preparing the Power Connection Cable

end

3. Apply some RTV silicone glue/sealant

and slide the silicone ‘trousers’ over the

conducting cores. Secure the trousers

to the outer silicone jacket.

4. Using an air heat gun, heat shrink

the trousers to the cable to create a

permanent joint.

25mm 30mm

100-120mm

09

Install the heating cables – First section

1. Lay the 1st ThermaCurve profile

face down (on a soft, clean surface to

prevent paint damage).

2. Insert the heating cables such that

the trouser PCB connection end is

protruding 100mm from the end. Secure

the cables into the cable channel using

the clear polycarbonate back capping.

3. Insert the heating cable into the

channel, and secure in place using the

clear back capping. The last section of

back capping can be cut to length.

Preparing the cable ends – Terminating

a single straight length (For onward

section see 12)

4. If the ThermaCurve is heating a single straight wall (no

corners or onward connections) then simply cut any excess

cable 50mm(2”) longer than the profile (50mm/2” shorter

than the wall).

5. Using the silicone ‘boots’, RTV/silicone sealant and the

heat shrink tubing, make safe the end of the cable.

100mm

Back Capping

50mm

Heat Shrink tubing

10

Preparing the cable ends – Making a

corner or onward connection

1. For an Internal Corner, the cable should be prepared as per

the Power connection 9.1 – 100mm longer than the cut prole

length (25mm/1” shorter than the wall length).

2. For an External corner, the cable should be prepared as per

the Power Connection 9.1, but 25mm/1” longer than the wall

(50mm longer than the cut prole).

Installing the Insulation panels

4. The insulation panels are supplied in

1500 x 100mm sections. They can be

cut to size using a Stanley knife or sharp

blade. The last piece should be cut to

within 50mm of the end of the section.

5. Once cut, they are secured in place

using the insulation clips as shown.

3. Protective gloves are recommended

when handling the insulation panels,

due to the nature of the material, which

can cause skin irritation.

50mm

100mm

50mm

Insulation Panel

11

Installing the 1st piece

2. At the power connection end, DON’T

forget to attach the EARTH lead into the

lower/wall earth way using the 6mm

self-tapping screw and serrated washer.

(Make sure the cable is facing towards

the wall to ensure the cover can be

fitted later).

3. Insert the security pins into the lower/

wall hinge point. There should be 3;

One for each of the end and middle wall

brackets. Note the security pins can

also be ‘squeezed’ into the wall side

hinge point groove.

4. In the ceiling/upper side hinge point

of the profile, insert the 8mm barrel nut

to a depth of approximately 50mm/2”

and loosely tighten the grub screw.

This forms the expansion stop against

the ceiling bracket and prevents cable

connection damage.

1. In the 2 wall brackets at either end

of the run, insert the 100mm/4” safety

cable line into the safety cable groove

and secure with the 2 x 5mm Roll pins.

5. Using a hop up platform or ladder if

required, raise the power connection

end to the wall brackets. Insert the

safety cable into the unused upper/

ceiling Earth way, and retain with 1 x

5mm roll pin.

6. Leaving the power connection end

hanging, move to the other end and

repeat.

Power Connection

End

Safety Cables

Earth Lead

Security Pins

Barrel Nut

12

12

Installing the 1st piece

1. With both ends suspended, move to the middle and raise the profile to the wall bracket. Locate onto hinge point. A firm

push may be required

2. With the bottom hinge point secure,

close up the profile to the ceiling

bracket. Ensure the top hinge feature

of the profile engages with the hinge

point of the bracket. Again, a firm push

may be required. If correctly installed,

the ceiling bracket will slide backwards

around 5mm, and the profile will lock

securely to the bracket. NOTE: Slide the

Security pins using a pick tool or prong

until it slides into the hinge groove of

both the wall and the ceiling bracket.

3. Move to the PCB connection end. The

profile should be close to the ceiling

bracket. Ensure there is good alignment

of the hinge point and profile and push

firmly home. Push home the Security

Pins into the wall and ceiling brackets.

4. Repeat for far end. Push home

the Security Pin. The 1st section is

now secure and ready for electrical

connection at the PCB end.

Power Connection

End

‘Click’

‘Click’

Security Pins

Security Pins

End Termination

13

Connecting the Heating Cables & Earth

1. If cut and secured correctly the Trouser ends of the cable

should be well located to reach the terminal blocks on the

PCB. Adjust if necessary, by sliding the Easy bend bracket or

alternatively carefully trim the trouser ends.

2. Connect the cables to the terminal. Do not over tighten to

prevent damage to the terminal blocks.

3. EARTH CONNECTION! For the safety of yourself and

others and the protection of the system, the earth lead must

be connected as shown.

4. DO NOT fit the PCB cover and end covers until after the

system has been connected and tested.

Terminal Block

Earth Lead

Adjust if necessary

14

Fitting the Next Section(s) (if a single

length only, skip to 16)

1. Using the same sequence as the first piece, install the

second section onto the wall and ceiling brackets, using the

clearances a shown in table 1.

2. EARTH CONTINUITY! Ensure that the earth leads are securely

connected using the saddle connectors and self tapping screws.

3. Connect the heating cables together using the clear 2 way

snap connectors

4. Repeat for additional walls and Sections.

Earth Continuity Testing

Using a test meter, ensure there is earth

continuity right back to the PCB earth

terminal. This is important for the safety of

yourself and others and for the protection of

the system.

First Piece Second Section

Earth Leads

Clear way snap connector

15

Testing & Energising the system 1st time

1. With all hands clear, power up the

system from the Thermostat or control

system. The red LED on the PCB will

indicate power ON.

2. After 1~2 minutes, the surfaces of

the ThermaCurve profile will feel warm.

Check all sections are getting warm.

3. After 5 minutes, using a test meter,

measure the voltage at each of

the Terminal blocks. It should read

220~240VAC (mains voltage). (For

the 1st 5 minutes the meter will read

100~120VAC as the system goes

through its soft-start phase)

4. If all ThermaCurve sections are not

warming after 5 minutes, power down

and check any connections between

profiles.

5. Note: on 1st energisation, there may

be a slight aroma from the heating

cables. This is normal and perfectly safe

and will dissipate after an hour or two of

operation.

16

Fitting the covers

1. Power down so it is safe to work on

the system.

2. Fit the PCB cover to the Easy Bend

PCB bracket, using the self tapping

screws provided.

3. Fit the Curved start end cover. This is

best achieved by hooking over the top

edge of the profile and pushing firmly

over the bottom edge. The cover should

fit snugly and securely.

4. Corner covers are best attached

by hooking over the longer edge first

and pushing the shorter edge over

afterwards (Internal corners: longer

edge to the top, External: longer edge

to the bottom).

5. It may be necessary to use a nail pry,

jemmy bar or similar behind the edge of

the profile to provide a firm leverage to

push against as the covers are a snug

fit.

6. The start and end covers should have

at least 20mm (3/4”) engagement on

the profile to be considered secure.

1

2

‘Click’

‘Click’

PCB Covers

Self Tapping

Screws

1

2

‘Click’

‘Click’

20mm

Pry bar

‘Push’

!

‘OFF’

17

Fitting the Sealing Gasket

1. The sealing gasket (standard or wide

option) are best inserted using a wet

wipe/baby wipe to provide a slippery

surface.

2. With the long leg to the wall/ceiling,

feed in the gasket, and smooth using

the wet wipe.

3. Trim ends to length. In the corners,

cut at 45°and glue using instant, super

glue or similar .

1. The sealing trim is inserted with the

long ‘leg’ to the wall/ceiling side.

2. The ‘soft’ front edge needs trimming

away to clear the covers. This is best

achieved with a Stanley knife/box cutter

at a shallow angle and slicing away from

the body. Use the ‘hard’ front leg as the

blade guide.

3. The sealing trim is then clicked

into the profile and butt jointed in any

corners.

Fitting the Sealing Trim

4. The system can then be sealed in

using a temperature resistant sealant

(>150°C/300F).

Wall or ceiling

Wall or ceiling

‘Click’

‘Click’

‘Click’ ‘Click’

18

Fitting the Capping.

1. The Capping mounting rail is cut to length and then clicked

into the ThermaCurve prole.

2. The mounting rail should be secured to the wall/ceiling

using appropriate fixings every 600~1000mm (2~3’)

4. The profile capping can be cut to the wall length. For

long straight lengths > 4m allow 5~10mm (1/4”~3/8”) for

expansion

5. Internal corners: Capping should be butt and scribed (like

skirting boards). For external corners, the capping should be

mitred

600~1000mm

4m

5~10mm

1‘Click’

Screws

Mitred

Butt and scribed

19

Trouble Shooting

If the cable has been damaged during or after installation, the system will trip out due to an earth fault. The damage to the

cable needs to be located and repaired. The normal sequence would be:

A) Isolate Power before removing any covers or skirting panels

B) Remove end connection sand termination covers first to check the cable ends for damage

C) Remove any intermediate stainless covers to check the cables for damage at any junctions

D) Starting from one end . remove the heating panels in sequence , checking the back for any signs of

Damage to the cable covers and cable

E) Remove the cable covers in sequence and check the heating cable for signs of damage

Usually, any damage to the front of the cable outer red sheath will cause an earth fault to the aluminium heating panel.

Damage to the back face of the cable cover side) will not ordinarily cause an earth fault as the cable covers are an insulator,

unless the cable cores have been cut and exposed or compressed together.

If the damage to the heating cable is slight (red outer sheath damage, black core exposed) then it can be repaired using the

red heat shrink tubing in the spares kit (see 13.1). If the heating cable is badly damaged (black core damaged, conductor

exposed) then that section must be replaced (see 13.2).

If the outer sheath has been damaged at a junction, double check the cable channels have been opened up and de burred

at each end.

13.1 Repair to Outer Sheath

Included in the spares kit are several lengths of toughened heat shrink sleeving which cab be slid over the cable to the

damaged section and heated into place. The cable will be able to squeezed back into the cable channel although it

will be tight fit. The cable cover may need to be modified locally in order to fit. Check the cable channel for any signs of

sharp edges or debris that may have caused the damage and rectify before replacing the cable.

13.2 Replacing a section of cable

If the damage to the cable has exposed the metal conductor cores then that section must be cut out and replaced.

If the damage is near to the end, it may be simpler to cut the cable short and insulate using the heat shrink sleeving

and termination boots. NB: The black heating core and conductors cannot be allowed to be in contact with the

aluminium or exposed to the touch as they are ‘live‘. If the damage is mid sections, and/or in more than one place it

is recommended to replace that section of cable with a complete new piece, joining and insulating the cables at the

corner junctions.

Maintenance

Routine maintenance if your ThermaCurve system is not required, except for perhaps a wipe down to

Remove any dust or marks that a traditional skirting board might accrue over time.

For further assistance please contact DiscreteHeat Co. Ltd on 01942 88 00 60 or email info@discreteheat.co.uk

Table of contents

Other DiscreteHeat Heater manuals