Dispens-a-Matic U-25 User manual

OPERATING INSTRUCTIONS

FOR MODELS

“U-25” “U-45” & “U-60”

Power advance dispenser for printed labels

in rolls, or one up fanfold label formats.

U-25 Designed for labels up to 2 ½” width.

U-45 Designed for labels up to 4 ½” width.

U-60 Designed for labels up to 6” width.

For rolls with 3” cores: Install one core insert

onto rod “A” with the ange facing the side

frame. Next, install the roll onto rod “A” with the

labels facing up. Then install the remaining core

insert onto the rod with the ange facing to the

right. Now, install the 1” collar “B” with thumb

screw so that it holds the core inserts against

the roll. (U-25 apply slight pressure to the roll

of labels by pressing against the outside core

insert and hold the Side-Guide against it while

tightening the thumb screw, referring to Diagram

2)

For rolls with cores smaller than 3”: Follow the

directions above, but instead of inserting the core

inserts into the roll, just let them rest against the side of the roll instead.

For Fan-Fold labels: Simply lay the stack behind the machine, and feed the labels over “A” and adjust the 1”

collar “H” within 1/8” of the web.

1.

Pull leading edge of carrier paper under rod “C” (U-25 does not

have a Rod “C”) through dispensing plate assembly (Rod “D” and

plate “E”) and around dispensing plate “E” down towards take-up

spool “F”. See diagram 1.

2.

About 5” of liner paper is needed for starting the dispensing

operation. Attach leader to take-up spool by pulling spring clip

“G” off of spool “F”, feeding the paper around the top of the

spool “F”, and then sliding the spring clip “G” back onto the spool

“F” pinching the paper between the spool and the clip.

Make sure to align the clip with one of the grooves

in the spool, and also make sure the paper is fairly

straight.

3.

Adjust Side-Guide “H” within 1/8” of web, but make

sure not to force the web against the side frame of the

machine, this will cause tearing.

4.

For all labels except for clear Labels: Point the sensor

towards the desired label stop position. Your can either

pivot the sensor on the shaft, or rotate the metal bracket,

or both. The sensor can see most labels at long distances

(1-3 Inches Away).

Clear Labels: (Refer to diagram 3 and 4) When using

clear labels it is important to keep the sensor perpen-

dicular to the label. The infrared beam must bounce off the label

back into the sensor as directly as possible. This is why the sen-

sor can be pivoted on the shaft AND the bracket. Usually sliding

the sensor all the way up the bracket puts the sensor at a good

distance for detecting clear labels. You can also rotate the rear of

the dispensing plate “E” down by slightly loosening screw “J”, as

shown in Diagram 3, giving a more perpendicular alignment to

the sensor. Diagram 4.

5.

Diagram 1

Diagram 2

Diagram 3

Diagram 4

PROBLEM LABELS: Very thin stock such as acetate, mylar, or vinyl may not release from the carrier paper,

but instead will continue down around the table and remain on the carrier. We can provide a special sharp edge

plate and tension kit which will usually work for dispensing these labels. (This is already included with the

U-25) If you supply us with a sample roll of your labels we can diagnose if the sharp table will work, or what

other modication can be made to dispense them.

MULTIPLE ROW LABELS: Some label printers will put more than one of the same label side-by-side on the

carrier. These labels are not a problem as long as the label length does not exceed 1 ½” in length, just peel the

labels from right to left, and once the left most label is peeled the machine will automatically advance the next

row.

6.

WASTE CARRIER PAPER REMOVAL: The more carrier paper waste permitted to wind on the take-up

spool, the faster the movement of the web thru the dispenser. This may or may not be benecial to the dispens-

ing operation. Waste should be removed periodically as necessary. It only takes a few moments when done

properly. To remove waste, rotate the roll of waste counter-clockwise, reversing its winding direction and loos-

ening the winding. When sufciently loose, pull the spring-clip straight out and then remove the waste easily

from the spool.

7.

CLEANING: MAKE SURE MACHINE IS UNPLUGGED! Cleaning adhesive from the machine is accom-

plished by using a safe for plastic solvent such as Naptha, or Lighter uid containing Naptha. MAKE SURE

ALL SOLVENT HAS EVAPORATED BEFORE PLUGGING IN MACHINE!

8.

WARRANTY: This unit is covered by a full 3 Year Warranty from date of purchase. If anything fails

on the label dispenser within the rst 3 years we will repair the unit, and return shipment within 2-days!

(This warranty does not cover abuse of the machine due to dropping, or bending the rods or side-frame.)

9.

Service: In the unlikely event your machine needs service after 3 years, just return the machine to us and we

will diagnose your machine the same day we receive it! If you approve the repair costs we will ship it out the

very next day! Please make sure to include a note with a description of the problem, and a phone number we

can use to contact you!

10.

Shipment to us is FOB, and return ground UPS shipping is covered under the warranty. After warranty expires

return shipping is FOB. Our address is:

Dispensa-Matic Label Dispensers

28220 Playmor Beach Rd

Rocky Mount, MO 65072

13.

Included with the machine:

2 Allen wrenches ( Large for dispensing plate adjustment, small for lateral sensor adjustment)

Operating Instructions

Warranty

This manual suits for next models

2

Table of contents

Popular Dispenser manuals by other brands

TUFFA TANKS

TUFFA TANKS 1350SLBFS Installation, operation and servicing manual

Star Manufacturing

Star Manufacturing Specialty Dispensers 1-12 Brochure & specs

Remcor

Remcor Spiral Ice Macker SID650A owner's manual

Hilti

Hilti HDM 500 user manual

U-Line

U-Line H-28 quick start guide

Cecilware

Cecilware GB1P Operation manual

Tork

Tork Image Design Matic 460001 manual

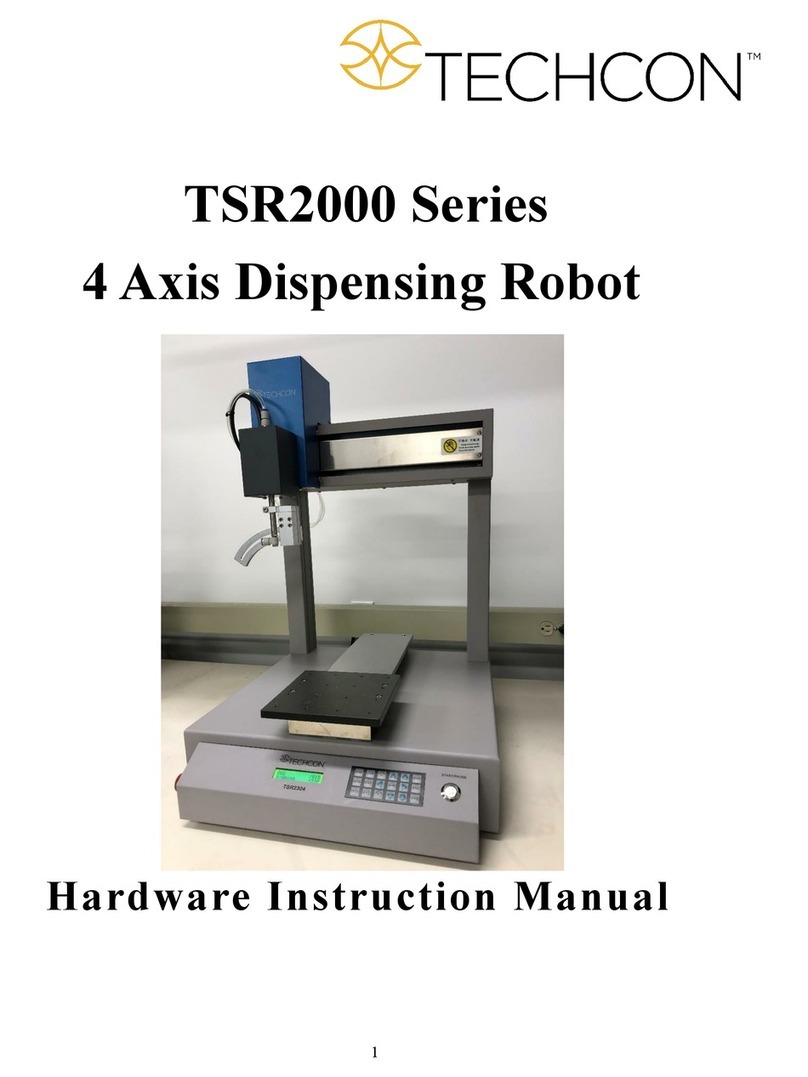

TECHCON SYSTEMS

TECHCON SYSTEMS TSR2000 Series Hardware instruction manual

Grindmaster

Grindmaster The Bubbler D-25 Specifications

CareCo

CareCo DL14036 quick start guide

Silvercrest

Silvercrest SSSES 1.5 B2 operating instructions

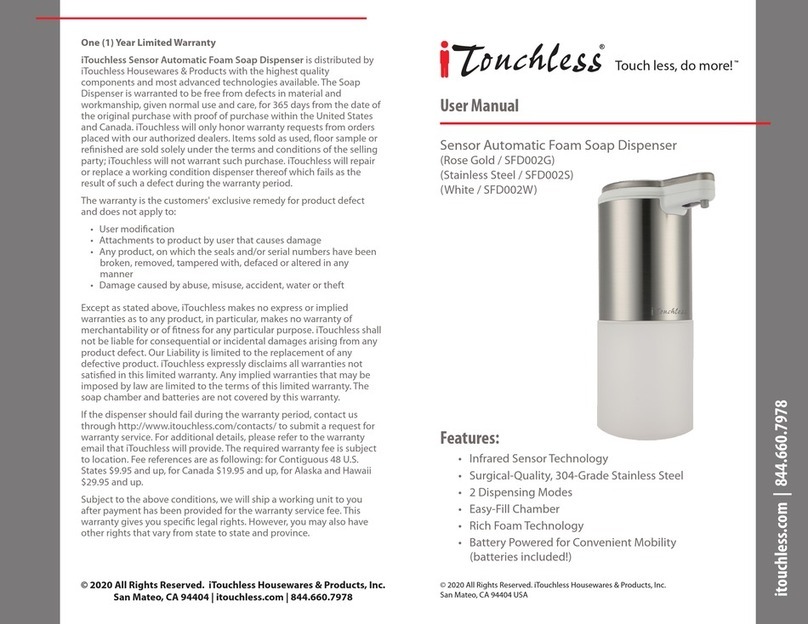

Itouchless

Itouchless SFD002G user manual