2 333587D

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

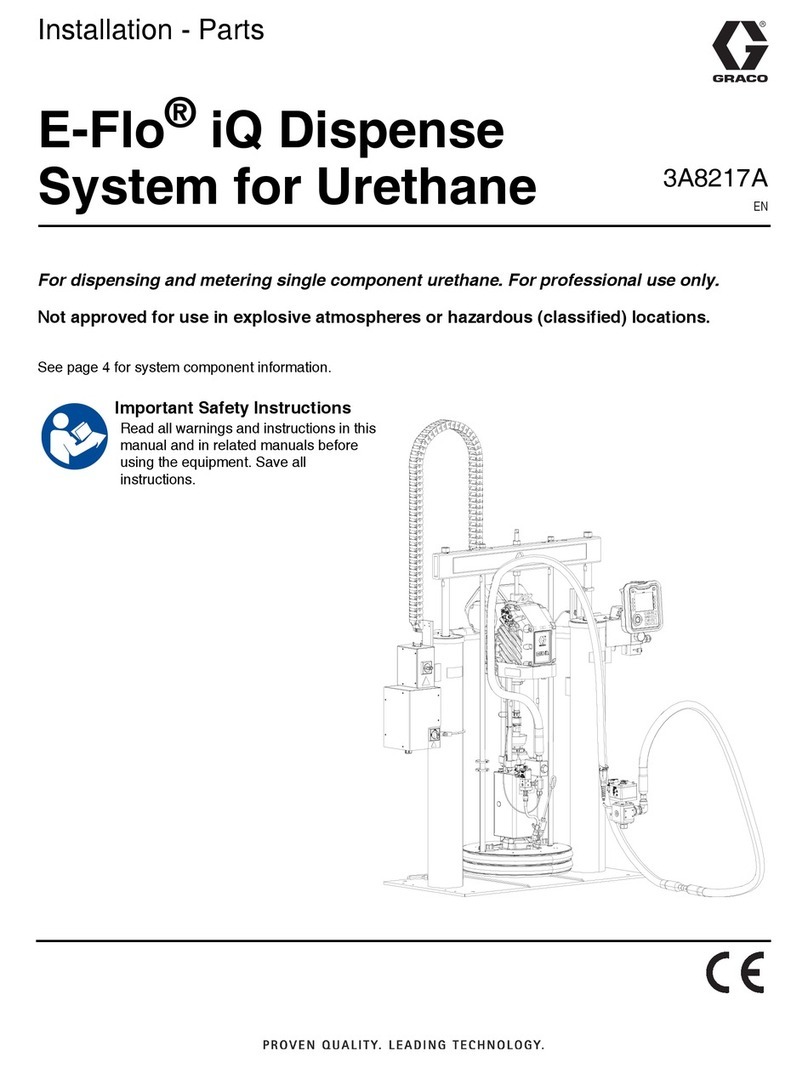

Dispense System Configurator . . . . . . . . . . . . . . . . 4

Dispense System Components. . . . . . . . . . . . . . . . 5

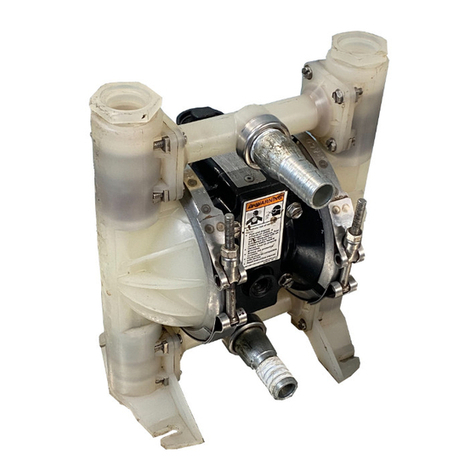

iQ Ram Supply Units . . . . . . . . . . . . . . . . . . . . . . 5

iQ Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . 6

Hose Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dispense System Pressure . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dispense System Component Identification . . . . 11

Tandem Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supply Unit Component Identification . . . . . . . . . 13

iQ Ram Supply Unit . . . . . . . . . . . . . . . . . . . . . . 13

Power Disconnect . . . . . . . . . . . . . . . . . . . . . . . 14

Integrated Air Controls (AG) . . . . . . . . . . . . . . . . 15

Integrated Air Line Accessories . . . . . . . . . . . . . 15

Advanced Display Module (ADM) . . . . . . . . . . . 16

ADM Display Details. . . . . . . . . . . . . . . . . . . . . . . . 17

ADM LED Status Descriptions . . . . . . . . . . . . . . 19

ADM Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADM Soft Keys. . . . . . . . . . . . . . . . . . . . . . . . . . 20

iQ Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Setup Screen . . . . . . . . . . . . . . . . . . . . 23

Style Definitions . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Heat Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Advanced Setup . . . . . . . . . . . . . . . . . . . . . . . . 32

Connect Light Tower Assembly . . . . . . . . . . . . . 34

Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 35

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Tandem Priming when Changing Drums . . . . . . 38

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ram Run Screen . . . . . . . . . . . . . . . . . . . . . . . . 39

Tandem Run Screen. . . . . . . . . . . . . . . . . . . . . . 40

Run Screen Editing Mode . . . . . . . . . . . . . . . . . 43

Heat Run Screen . . . . . . . . . . . . . . . . . . . . . . . . 44

Job Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Events and Errors. . . . . . . . . . . . . . . . . . . . . . . . 47

Pressure Relief Procedure. . . . . . . . . . . . . . . . . . . 48

Shutdown the System . . . . . . . . . . . . . . . . . . . . . . 49

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump Maintenance Screen 1. . . . . . . . . . . . . . . 50

Pump Maintenance Screen 2. . . . . . . . . . . . . . . 51

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pump Diagnostics Screen . . . . . . . . . . . . . . . . . 52

Heat Diagnostics Screen . . . . . . . . . . . . . . . . . . 52

Pressure Diagnostics Screen . . . . . . . . . . . . . . . 53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

View Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Troubleshoot Errors . . . . . . . . . . . . . . . . . . . . . . 55

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

USB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Download Procedure . . . . . . . . . . . . . . . . . . . . . 65

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Job Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Automation Log . . . . . . . . . . . . . . . . . . . . . . . . . 66

System Configuration Settings. . . . . . . . . . . . . . 66

Custom Language File . . . . . . . . . . . . . . . . . . . . 66

Create Custom Language Strings . . . . . . . . . . . 67

Upload Procedure . . . . . . . . . . . . . . . . . . . . . . . 67

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Discrete Inputs/Outputs . . . . . . . . . . . . . . . . . . . 68

Job Cycle Timing Diagram . . . . . . . . . . . . . . . . . 70

Discrete Timing Diagram . . . . . . . . . . . . . . . . . . 71

Communications Gateway Module (CGM). . . . . 72

Prime Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Depressurize Diagram . . . . . . . . . . . . . . . . . . . . 93

System Enable - Remote Start Diagram . . . . . . 94

Acknowledge - Clear Error Diagram. . . . . . . . . . 95

Manual Crossover Diagram . . . . . . . . . . . . . . . . 96

Data Exchange Diagram. . . . . . . . . . . . . . . . . . . 96

Power Reset Diagram. . . . . . . . . . . . . . . . . . . . . 97

Heat CGM Timing Diagram . . . . . . . . . . . . . . . . 97

Heat Module Acknowledge-Clear Error Diagram 98

Heat Zone Acknowledge-Clear Error Diagram . . 99

Heat CGM Data Exchange Diagram. . . . . . . . . 100

Connection Details . . . . . . . . . . . . . . . . . . . . . . 101

Gateway Setup Screens. . . . . . . . . . . . . . . . . . 104

Integration Feedback Screens . . . . . . . . . . . . . 107

Technical Specifications . . . . . . . . . . . . . . . . . . . 108

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . 109

End of Product Life. . . . . . . . . . . . . . . . . . . . . . 109

California Proposition 65 . . . . . . . . . . . . . . . . . . . 109

Graco Standard Warranty. . . . . . . . . . . . . . . . . . . 110