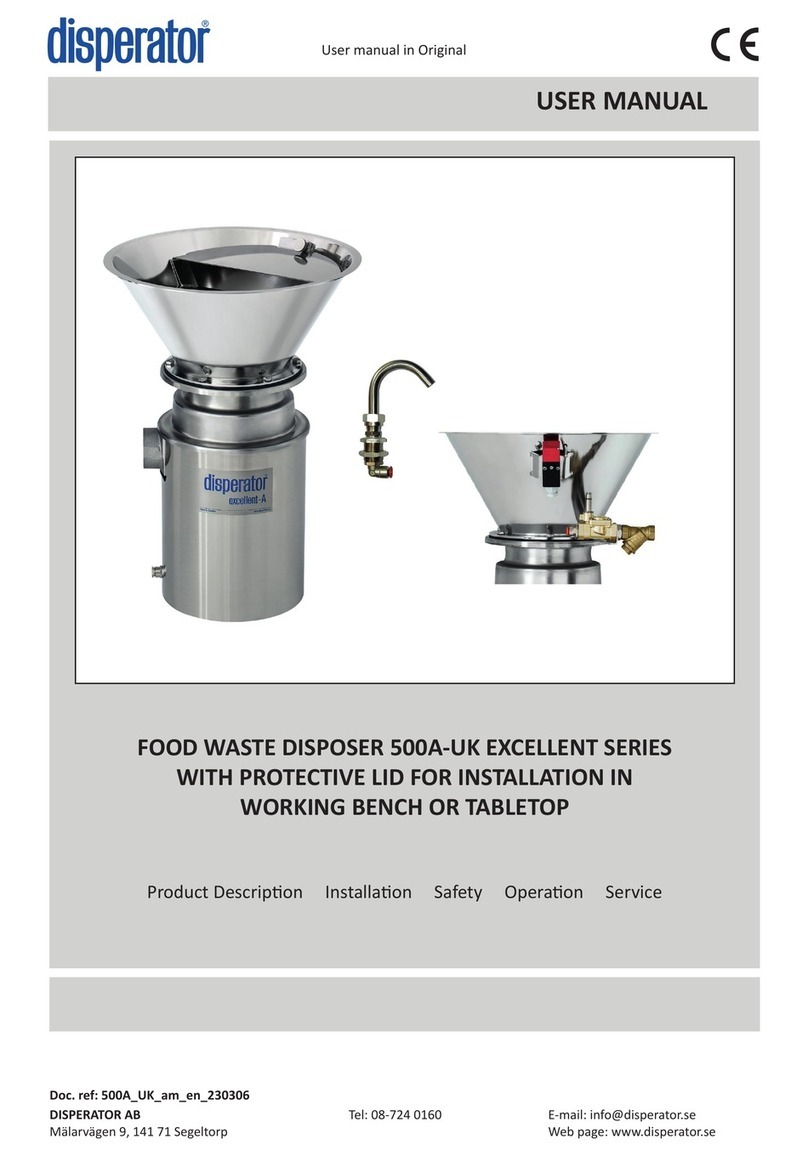

User manual in Original

Doc. ref: 500A_BAS_am_en_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

Table of Contents

1. Safety Precauons _______________________________________________________ 7

1.1. Safety Signs __________________________________________________________ 7

1.2. Personnel Qualicaons and Training______________________________________ 8

2. Company Prole _________________________________________________________ 9

3. Product Descripon and Technical Specicaon _______________________________ 10

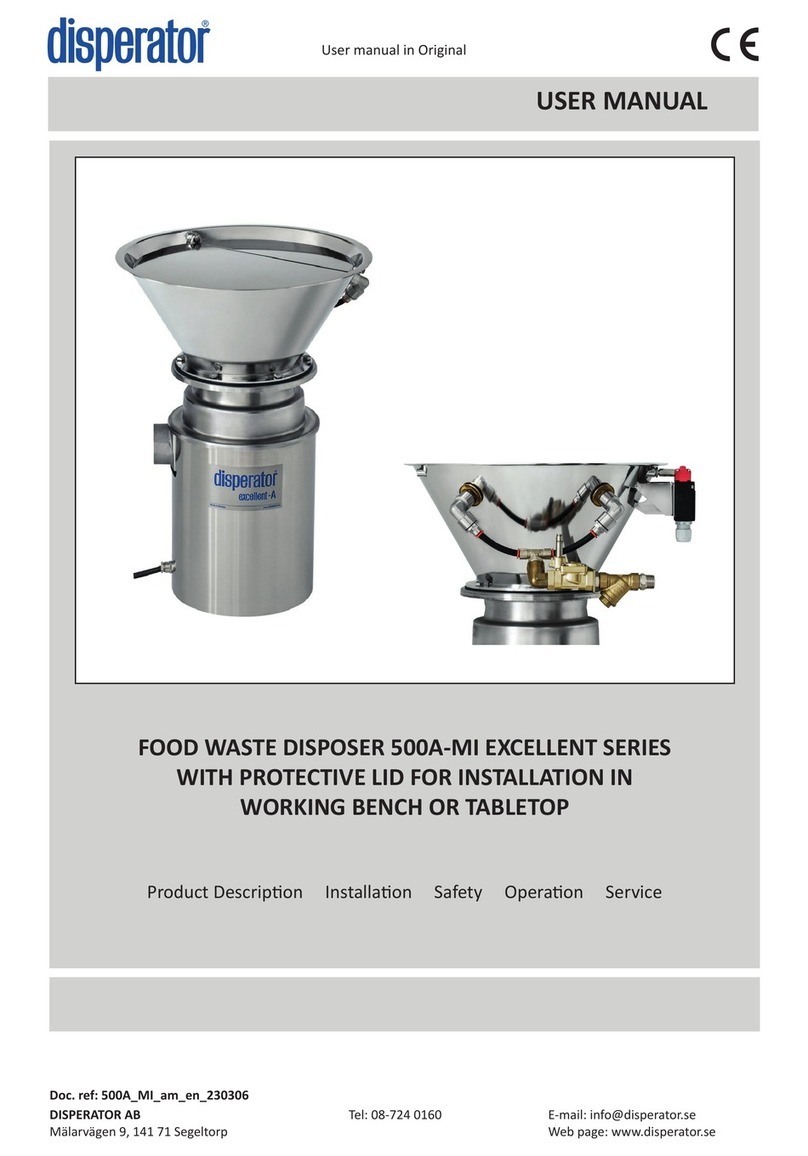

3.1. Food Waste Disposer 500A-BAS EXCELLENT-Series ___________________________ 10

3.2. Technical Specicaon _________________________________________________ 12

4. Storage and Displacement _________________________________________________ 13

4.1. Storage of the Machine_________________________________________________ 13

4.2. Displacement of the Machine____________________________________________ 13

5. Included in Delivery ______________________________________________________ 14

5.1. Documentaon _______________________________________________________ 14

5.2. Food Waste Disposer___________________________________________________ 14

6. Installaon Descripon for the Machine _____________________________________ 16

6.1. Assembly of the Machine _______________________________________________ 16

6.1.1. Mounng the disposer in an exisng assembly ___________________________ 16

6.1.2. Mounng and Support against Floor/Floor plate __________________________ 16

6.1.3. Fixaon of the Machine _____________________________________________ 18

6.1.4. Protecve lid connected to interlock switch______________________________ 18

6.2. Connecon of ushing water ____________________________________________ 19

6.2.1. Water pipe DN15___________________________________________________ 19

6.2.2. Line Strainer DN15 and Solenoid Valve DN15_____________________________ 19

6.2.3. Hose with Protecve Steel-Covered Stocking for Flushing Water, minimum

inner-Ø 9 mm _____________________________________________________ 19

6.2.4. Other orders / installaons for which standard EN 1717 does not apply _______ 20

6.3. Connecon of Machine Outlet to Water Trap and Sewer Pipe __________________ 21

6.3.1. Dimensions _______________________________________________________ 21

6.3.2. Depth and Threshold of Water Trap ____________________________________ 21

6.3.3. Curves and Bends __________________________________________________ 21

6.3.4. Level Dierence of Water Trap ________________________________________ 21

6.3.5. Slope of Sewer Pipe_________________________________________________ 21

6.3.6. Vacuum Evacuaon _________________________________________________ 21

6.4. Electrical Connecon___________________________________________________ 23

6.4.1. Supply Voltage_____________________________________________________ 23

6.4.2. Mains Fuses _______________________________________________________ 23

6.4.3. Wall/Bulkhead Mounted Electrical Security Breaker _______________________ 23

6.4.4. Cable Dimension ___________________________________________________ 23

6.4.5. Cable Protecon ___________________________________________________ 23

6.4.6. Earth Wire ________________________________________________________ 23

6.4.7. Direcon of Rotaon for the Disposer __________________________________ 23